A heating system is a complex of technical elements for generating heat, transferring it and transferring it to all heated rooms. Heating can be local or central. In the first case, the heating equipment and the pipeline are structurally combined into one device and installed in a heated room. Local heating is not quite suitable for warehouses due to the specifics of the terminals themselves.

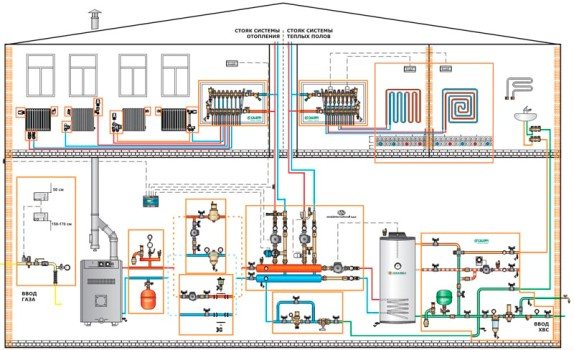

Here, the central system will be optimal, in which the boiler or heat generator is placed in a separate room. When drawing up a warehouse heating project, special attention is paid to the calculation of the fire hazard category and the location of the main equipment. All instruments must be accessible for maintenance and repair.

Types of heating systems with different heat carriers

By the type of coolant, steam, air and water are distinguished. warehouse heating... In some cases, the systems are combined, arranging steam-air, steam-water or water-air heating. Everything in order.

Steam systems

The heat carrier is dry saturated steam with a temperature not exceeding 130 ° С. The system can be open-loop, when the condensate is transferred to the heat exchanger by a pump, or closed, when the condensate moves by gravity. Main advantages:

- minimal heat loss in heat exchangers;

- fast heating of radiators and other heating devices;

- low inertia;

- the possibility of heating multi-storey buildings;

- compactness of equipment;

- low hydrostatic pressure in the system.

Disadvantages:

- high heat losses in steam lines, as a result - a decrease in efficiency;

- noisiness;

- you cannot make the temperature of the coolant below 100 ° C;

- intensive corrosion of the metal elements of the circuit.

Steam heating is permitted for terminals with non-flammable and non-toxic dust, non-flammable and non-flammable vapors and gases. Steam lines are installed separately from the ventilation and air conditioning system.

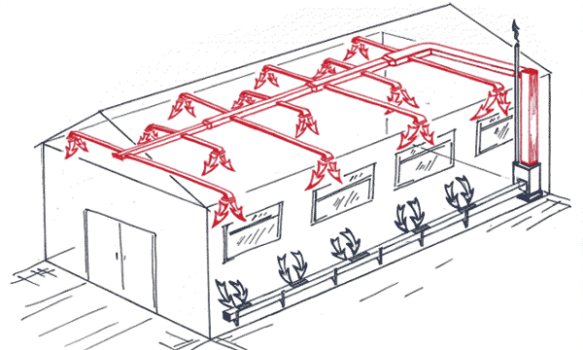

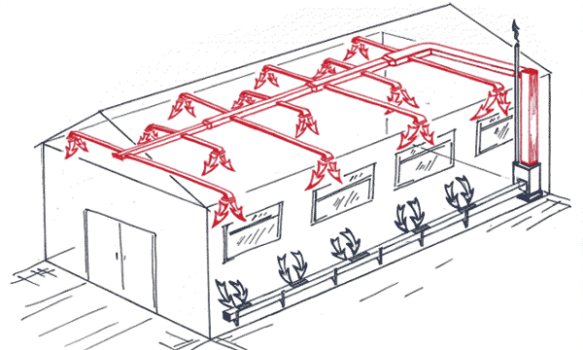

Air systems

Air heating systems for warehouses are the most common today. The heat carrier is air that heats up when passing through the generating set. The heated air is distributed evenly throughout the warehouse volume through the air duct system. The units are mounted on the roof and along the walls. The system is well suited for heating large high-rise buildings.

Main advantages:

- the possibility of combining the heating circuit with ventilation for the flow of fresh air into the room;

- high efficiency up to 95%;

- rapid heating of the air due to the absence of an intermediate heat carrier;

- the ability to automate the heating system, adjust the exact parameters.

Warm air outlets are designed so that there are no massive building structures in the path of the air flow. At a warehouse height of less than 8 meters, the release is carried out with covering jets, at a height of more than 8 meters - with non-covering jets. The air jet, when the air is discharged, is applied to the ceiling at a height equal to 0.85 times the height of the terminal (H). Non-overlapping jets are formed at a height of 0.35-0.65 N from the floor. The distance between the diffusers when installed in a row is no more than three room heights.

Air heating of a warehouse is economical in operation, pays off quickly, can be installed with or without air ducts. The system works effectively in terminals with high ceilings, it allows you to evenly heat the entire volume of air. Combining heating with ventilation and air conditioning reduces the financial costs of the project.

If there is no need for constant heating of warehouses, but a strong drop in temperature cannot be allowed, heat guns are used as more compact devices. The equipment is placed around the perimeter of the terminal and connected to the thermostat sensors. When the temperature drops to the set value, the equipment turns on and starts generating heat. The device of such heating does not require drawing up a project, it allows you to quickly warm up the room. But after turning off the heat gun, the air cools down just as quickly.

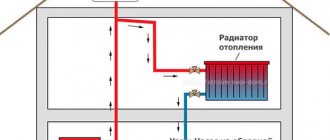

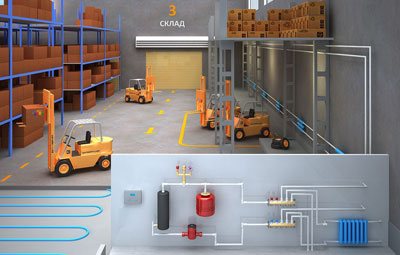

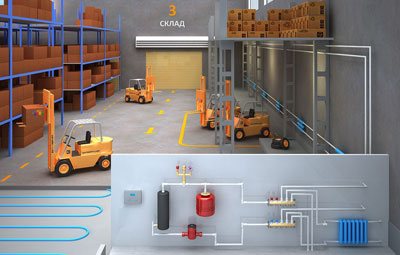

Water systems

The heating medium in the water heating system can be water or water-based antifreeze. For small rooms, arrange a circuit with natural circulation. The pipes are angled so that the water moves by gravity. For warehouses of a large area, such a solution will not be effective; installation of pumps is required. Forced circulation systems are highly efficient but require electricity.

Water heating is often chosen by warehouse owners as the most optimal option. In places where there is a possibility of connecting to the central network, the task is simplified. In the absence of such a possibility, the calculation of the heating of the warehouse should include the choice of a boiler and the device of a separate room for the boiler room. As a disadvantage of such a system, the aesthetic component is indicated - the pipes along the walls do not decorate the warehouse.

The advantage of water systems over steam systems is uniform heating of heating devices, the air does not dry out, and optimal conditions for goods are maintained. But such heating is not recommended for storage terminals higher than five floors. This is because warm air rises and collects at the top, increasing heat leakage through the roof and leaving the ground floor areas cold. In warehouses with high tops and hot water heating, specialists install ceiling fans to increase efficiency. The rotation of the propellers in winter allows warm air to circulate throughout the warehouse, while in summer it provides some coolness.

Air-thermal curtains

Air curtains are required to separate zones with different temperature conditions. The equipment is mounted in the aperture of doors, windows, gates. The curtain is formed by the movement of a high-speed air flow. It is a kind of invisible barrier that does not allow warm air to escape and does not let cold air in from outside. In addition, the air curtain isolates the warehouse from exhaust gases, dust and other negative phenomena without interfering with the movement of special vehicles.

The curtain width is 0.6-2.5 meters. In wider openings, several devices are mounted close to each other. When calculating the heat curtain, the following factors are taken into account:

- maximum temperature of the supplied air 50 ° С at the entrance

- temperature of air entering from outside 5-14 ° С;

- air speed no more than 8 m / s at the entrance and no more than 25 m / s at technological openings and gates;

- installation of thermal curtains is justified for entrance doors without vestibules that are opened five or more times a day or for 40 minutes per shift.

Installation of industrial heat pumps

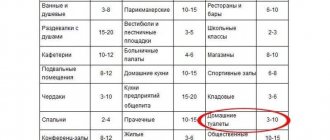

When arranging engineering highways, it is necessary to observe a number of rules and GOST standards, which are defined as binding. Additional requirements should be taken into account at the design stage of the structure. They relate to the specifics of the premises - warehouse, commercial, industrial. Dimensions of the area, product features, nuances of temperature regimes, sanitary and hygienic standards.

Other factors that we take into account are the "wind rose", the thickness of the walls and roof, the material from which the building was constructed. Therefore, the process of project approval and its implementation is a responsible process.The height of premises in warehouse and industrial facilities can be up to 10 meters or more. Therefore, the coordination, design and construction of a heat supply system can take several months, since each stage is associated with special difficulties and the need to solve a number of intermediate tasks.

The potential capabilities of the supplied equipment are not limited to the above - the cost of the pump is offset by its huge functionality. What is the best way to use the pump in your production, how profitable will it be, and how much does the installation cost? - we already have preliminary answers to all these questions - call us right now and our experts will advise you free of charge.

Cooperation with us is a guarantee that all work at the facility will be carried out by specialists with a high level of qualifications, in compliance with all the norms prescribed in the cooperation agreement.

Types of heating systems by energy source

The energy source can be gas, electricity or solid / liquid fuels.

Gas heating of the warehouse

In gas heating systems, gas air heaters or boilers are used as a heat source. This is a fairly simple and economical way of heating, especially if there is a central gas main. Special equipment is also inexpensive, but the device of such heating requires approval from the supervisory authorities and the preparation of a competent wiring project. Each gas boiler must have its own supply pipe and a separate chimney.

Heating the warehouse with electricity

Here we will not talk about the use of electric boilers. Due to the high cost of electricity, the installation of such equipment is not always economically viable. The operation of electric boilers will be very expensive for owners of large storage areas.

A relatively new method of creating comfortable conditions for warehouse employees is the installation of infrared heat emitters. Special panels are mounted on the ceiling, directly above the workplace. There is a local heating of people, floors, furnishings. At the same time, the air does not heat up and does not circulate. The main advantages of infrared emitters:

- compact placement on the ceiling;

- light weight;

- simple installation.

This heating method is suitable for warehouses of any purpose and area. Infrared panels consume a lot of electricity with constant use, but this is almost half the amount of electric boilers.

Installation of radiators is justified in cases where it is not possible to arrange water, steam or air heating, for example, in the absence of fuel. The choice of infrared equipment depends on the fire hazard group of the room

Technical standards

Various SNiP, PPB and PUE regulate the rules for the installation of heating systems in warehouses, but only a specialist can understand the jungle of technical terminology. Here are some excerpts from the regulations:

- SNiP 2.11.01-85, clause 5.3 says that it is allowed to install air heating or combine air heating with local heating devices in warehouses.

- PUE clause 7.4.25: if in a fire hazardous zone of any class (which includes warehouses) heating is possible only with the help of electric heating devices, then the heating surfaces must be protected from contact with flammable substances. A stand made of non-combustible material should be arranged under the appliances. For protection, fireproof screens are used that do not allow thermal radiation to pass through. It is prohibited to use electric heating devices in fire hazardous areas of warehouses, museums, archives, libraries, etc. An exception is specially designed rooms, for example, a dining room.

- SNiP 41-01-2003 clause 7.9.1. It is not allowed to place heating equipment in serviced warehouses of categories A, B, B1-B4.In terminals of category B2, B3, B4, it is possible to place heating equipment if several conditions are met:

- heating devices must have a degree of protection not lower than IP-54;

- the warehouse premises must be equipped with an automatic fire alarm that can turn off the equipment in the event of a fire.

- SNiP 41-01-2003 clause 12.2. Electrical receivers for heating systems must be of the same category as electrical receivers of engineering and technological equipment of the warehouse.

- SNiP 41-01-2003 clause 12.18. When using air heaters for heating a warehouse, it is necessary to provide protection against overheating.

- SP 31-110-2003 clause 15.7. It is forbidden to use heating devices with direct conversion of electrical energy into heat in warehouses with combustible materials. Such equipment can be installed in utility rooms and rooms for service personnel, which are separated from the warehouse terminal by a wall.

- SNiP 2.04.05-91. In rooms of category A, B, C, without the release of aerosols and dust, you can arrange water and steam heating with a maximum steam temperature of 130 ° C, water - 150 ° C. If dust or aerosol is emitted in a warehouse of category A or B, then the maximum temperature is taken to be 110 ° С, in rooms of category B - 130 ° С. If the warehouse stores substances that, when interacting with water and steam, form flammable, spontaneously igniting or explosive substances, then steam and water heating is prohibited.

- For heating auxiliary and utility rooms, you can use oil radiators powered by an independent electrical network and having thermostats.

In general, all the standards speak about the device of gas heating for warehouses, but the use of electrical equipment is also allowed. The electric boiler must be installed in a separate room or in an annex with walls made of non-combustible materials.

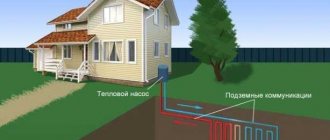

Economical heating of warehouses and production facilities with heat pumps

performs the whole range of works on the installation and commissioning of thermal equipment for industry, including the use of modern heat pumps, we carry out our activities in Moscow and throughout Russia. Heat from air and earth. Without gas. Heating savings up to 4 times... On the 1 kWh consumed electricity 3-4 kWh useful heat. Payback period of equipment 3-4 years.

Industrial heat pumps supplied by our company will help to save energy resources for heating, air conditioning and water treatment in production workshops, warehouses, auto repair shops and other technical premises.

If you want to buy a high power heat pump, then you have certainly come to the right place.

The main features of industrial heating are large areas of premises, significant ceiling heights and large heat losses, which require increased power and reliability of the system as a whole.

We supply, install and service the following types of industrial systems:

- geothermal thermal water-water for heat supply, cooling and use in technological processes;

- air heat pumps, including recuperation systems.

We help you save up to 3/4 of your heating costs in winter and cooling in summer using heat pumps.

- Heat energy processing. Production technologies imply the removal of waste gases and effluents, chimney, etc. All these media carry a huge amount of heat, which is better directed to the benefit of the business - for example, for heating workshops or in the technological process.

- Heating and air conditioning. One industrial unit equipped with a heat pump can solve several problems at the same time. Heat redistribution is one of them: the heat pump cools the air from the warehouse and heats up office and industrial buildings.

- Preparation of raw materials. Production often involves heating and cooling the raw materials. The heat pump will bring the parameters of raw materials to the required ones and, as a result, will significantly reduce the consumption of energy resources.

Features of industrial heating

Heat pumps have long been used in Europe and many are beginning to implement such systems in our country. The use of heat pumps will help to more efficiently and economically heat both small production facilities and warehouses, as well as large hangars, factories, and large production facilities. Additional use of weather-dependent automation will save even more. Features of industrial heating in energy-intensive facilities, large length of communications, harsh conditions for temperature, humidity and dust, as well as in non-standard engineering solutions at each specific facility. It should be borne in mind that in addition to the equipment, there are always people at the facility - employees of the enterprise. Therefore, when designing a heating system, it is necessary to ensure an even distribution of heat along the entire perimeter of the object, taking into account the zones with a specific temperature regime.

Economic efficiency of heat pumps

It is in vain to believe that the cost of the heat pump and installation will return in a couple of months. At the same time, the equipment really pays for itself: gradually the costs will be fully compensated by reducing energy costs. Thus, industrial heat pumps should be treated as an investment that, over time, will give visible results to both production and nature. In the course of cooperation with you will be provided with a package of documentation with which you can calculate the investment schedule.

The specialists of our company have gained vast experience in installing pumps in production. In practice, we have made sure that in industry, the efficiency of pumps (COP) varies from 2 to 7 and depends on the season, operating mode, installation method, etc. To clarify the efficiency of the system for your production, invite our engineers to get acquainted with the specifics of the facility ... You can agree on the date and time of the visit right here, through the feedback form, or by calling +7.

Detailed turnkey documentation

An important criterion in industrial heating is the quality of the accompanying documentation. For each completed project, we provide all technical documentation, permits, licenses, approvals and certificates, equipment passports.