Any living space, be it a private house or apartment, is equipped with heating systems. Without this, it is impossible to live in our harsh climatic conditions.

House heating

A heating system is installed in each apartment or country house. But without filters that ensure the purity of the coolant, the system will quickly fail. Filtration of water extends the life of the heating system.

Features of filters for home heating systems

Another name for this filter is "sump". It consists of a unit where the direction of flow of the coolant through the filter changes.

Filter

The device is equipped with a mesh that prevents the spread of debris through the pipes. Dirt settles on the filter element. It is necessary that there is an unobstructed approach to the device for its maintenance.

Where does the dirt in the system come from?

The water contains many metals and lime compounds, which form deposits in the form of scale on the pipe walls. And if the pipeline has been used for a long time and at the same time has never undergone maintenance, then the layers increase, narrowing the channel for the passage of the coolant.

But this is not the only reason for the lack of movement in the pipes. Clogging can be caused by other debris. These can be pieces of thread, metal particles or grains that have come off the inside of the pipeline.

The most unpleasant surprise can occur if metal pipes have been installed in a private house for a long time and are still in use. Iron corrodes even after periodic cleaning.

Small particles come off along with the coolant flow, are directed to the outlet of the system and enter the boiler filter of the heating system, where they settle.

Recommendation! In case of deterioration in the operation of the heating system, as well as in case of insufficient liquid circulation, the boiler filter must be inspected.

Installation ↑

Different types of filters are installed in different ways. But there are several rules that apply to almost all models:

- one simple, but not very pleasant operation will have to be carried out regularly - cleaning the filter. Therefore, it is imperative to wind the seal on the cover thread. It will prevent the system from leaking in this place. A seal must also be required at the junction of the filter with the pipe. The sump should be cleaned when the fluid pressure decreases in all taps and consumers;

Photo: be sure to wind the seal on the cover thread

- The main cleaning element should be at the bottom. But if there are no other options, then vertical installation is allowed. In this case, it is better to use an oblique filter. In this case, it is easy to install the mesh in the lower level;

Photo: the main cleaning element should be at the bottom Photo: oblique filter

- it is important to additionally strengthen the connection between the filter and the pipe. This is especially true for plastic and metal-plastic pipes;

- before starting to cut the filter, be sure to turn off the cold and hot water supply. It is also important to check the general condition and reliability of the entire communication system as a whole;

- the filter itself (if necessary) can be fixed to the wall with special clamps.

You can try to make a coarse water filter with your own hands, but it is better to entrust this important point to professional equipment. In addition, some models are not that expensive.

Filter types

Filters differ in the type of cleaning.

Sump filter

The device has an angular shape with a filter mesh inside. The design provides for a side outlet where debris settles. With the help of such a device, the coolant is purified from particles of large and medium fractions.

Rough cleaning

Device design

Filters for gas boilers installed on water are divided by design type:

- The connection to the heating pipe is made using a flange, threaded, or welded to the pipe.

- There are two types of device placement: vertical and horizontal.

Vertical arrangement

The heating device can be manufactured:

- Brass. Capable of withstanding high temperatures.

- Of steel. Short-lived, wears out quickly.

- Made of plastic. Adapted for low temperature indicators within +90 ⁰С.

There is a more advanced filter design for the heating system. It has a flask with a sump located in the lower part of the device, and a grid is fixed above the flask. When the flows of the coolant bring debris, it settles on the mesh, and it falls down under the influence of gravity. The main accumulation of dirt is held in the lower part of the filter - the flask.

Also, the device is equipped with a separating element. Its main task is to get rid of accumulated air in the system. When this happens, the drain valve on the device (at the top) opens. This is how the system gets rid of air congestion.

Operating principle

The device is equipped with a mesh element, which is placed in the inner part. The mesh blocks the free passage of the coolant flow. Due to this, all large and medium-sized particles settle on the mesh element, cleaning the coolant. Liquid comes into radiators without impurities.

The installation cleans the coolant from dirt, increasing the service life of the heating devices.

Benefits

Advantages of the improved designs:

- The device is equipped with a flask, so the device cannot be disassembled for cleaning from debris.

- There is a drain valve at the bottom of the device for removing water with dirt particles.

- Air plugs are removed through the valve. In this case, the water circulates normally, and the system does not become overgrown with foreign particles.

Place and features of installation

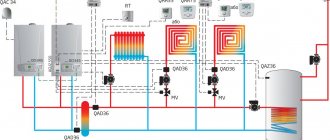

Depending on the type of heating system, the place of installation of the device is determined. Installation in autonomous circuits is carried out in front of a gas boiler, on a bypass or at branch points.

A high-quality installation guarantees the correct operation of the device. Before installation, it is necessary to clean the coolant from debris.

In the event of installation errors, the device quickly fails, and the heating system wears out.

Improper placement of the filter or complete refusal to use it can provoke a breakdown of the pump that pumps water in the heating system. Debris will settle on the blades, damaging the entire device.

Fine filter

The filter element for the circulation pump is mounted as an additional element that cleans the coolant from debris with a smaller fraction.

Fine cleaning

Device structure

Filter types:

- A metal mesh is inserted inside the device. Cell size up to 5 microns.

- A cartridge made of fabric that has been folded several times.

- The cassette contains a polymeric porous filler.

- Mineral sorbent filling.

Operating principle

Installation is carried out after a large debris sump. The element that filters small debris cannot be installed as the main link in the cleaning system, since it very quickly clogs up from particles of a large fraction.

The cassette filters small debris particles, and the coolant circulates through the pipes in a cleaned state.

Benefits

By removing dirt from the liquid, the service life of the entire heating system is extended. Reduces the risk of corrosion deposits on the inner walls of pipes and radiators. This is the main advantage of the fine cleaning device.

Where is mounted

The fine filter is designed in such a way that its location can only be horizontal. During installation, it is necessary to install a faucet behind and in front of the device, one at a time, so that in the event of a device breakdown, it can be dismantled without draining the water from the entire system.

If the pipeline is filled with antifreeze, then the installation of a fine filter is not necessary, since antifreeze does not pass through it.

The installation of a mud collector is carried out along the flow of the coolant flow, reducing damage to the heating system.

Magnetic models of mud collectors

What is a magnetic filter? This is a device consisting of two magnets in parallel with different polarities. Its main task is to clean the coolant from metallic impurities.

Magnetic

Types of devices

The filter can be of the following types:

- Detachable design. The device has two plates that are installed opposite each other. The fixation is done on the pipe. Among the advantages is the quick replacement of the entire device.

- Non-removable device. In shape, it is a pipe made from ferromagnetic alloys.

Operating principle

The plates of the device are positioned in such a way that metal particles in the coolant are attracted to one of the sides. This prevents the heating system from clogging and prevents premature rusting.

Benefits

Positive sides:

- Particles of metal are contained in small quantities, so the device is very rarely cleaned.

- Metal cleaning of the system reduces the formation of scale and rust build-up on the inside of the pipes.

- A clean coolant increases the service life of heating devices by several years.

Installation rules

The device is installed strictly in front of the entrance to the circulation pump. For installation, it is desirable to find a place where the cross-sections of the pipe and the filtering device will be identical. If the dimensions differ, you can use adapters.

When installed, the device is placed vertically and secured with brackets.

General Provisions

Tap water in an apartment or from a well in a country house is not poisonous, which is used by skeptics as an argument that there is no need for additional forced filtration. But let's touch on this issue more closely.

Urban water supply

Two particularly negative circumstances can be distinguished here:

- The deplorable state of the city water supply system, many elements of which have not changed for decades... The accumulated debris, rust, scale and other insoluble substances again contaminate the liquid purified at the cleaning station. And this poses a danger not only to the human body, but also to all household plumbing, including a washing machine, shower cabin and faucets.

- Chlorine... Chlorination as a means of neutralizing drinking water has not been used for a long time in most civilized countries, since chlorine itself is a poison, and nothing good can be expected from its frequent use. Sometimes, with an increased content of this element, even when visiting a bath, unpleasant sensations are experienced in the form of overdried, tight skin.

Autonomous water supply

Here you yourself monitor the condition of the pipes and do not use harmful chlorine, but particles of sand, clay, organics and heavy metals may come across.If you have drilled an artesian well, then a large number of natural filters in the form of sand and clay layers minimize possible pollution, but a sandy or ordinary well cannot guarantee the absence of the mentioned impurities in dangerous quantities.

Tip: When arranging sand wells and wells, try to place them at a distance of at least twenty meters from street toilets, cesspools and compost heaps. Otherwise, the produced water will get even more pollution.

Places of installation of filter elements

A dirt filter removes large debris from the coolant. The device is placed at the entrance to the system or in front of the pump. In a large house, it is necessary to install several "mud traps" in the heating system.

The task of the fine cleaning device is to sift out smaller debris, therefore it is installed after a sump that catches large particles.

The function of the magnetic filter is more modest in comparison with previous examples: it filters out metal particles from the water. Installation of such a device is carried out before entering the system in front of the heater.

Maintenance of mud filters

Any type of filter requires periodic maintenance, as debris constantly accumulates inside the device.

TO mud collectors

How the device is cleaned:

- The taps located on the sides of the device overlap, in this case it is not necessary to drain the coolant from the system.

- Before disassembling, a container must be installed to drain the remaining water.

- There is a plug on the filter that needs to be removed.

- The mesh is washed and reinstalled.

- A muffler is mounted.

- Couplings are twisted.

- The taps are opening.

Periodic filter cleaning extends the operating life of the entire system.

Cleaning the straight or corner filter

To work, you need to prepare the following tools:

- Gas key.

- Adjustable wrench or box spanner 17 (19).

- A container filled with water for rinsing.

- Rust remover.

- FUM tape (it can be replaced with tow).

Important! The filtration device is not often cleaned, so in most cases the plug sticks to the body tightly (especially if a paronite gasket is used). Therefore, preliminary preparation cannot be dispensed with.

Cleaning the coarse water filter in front of the meter is carried out in the following order:

- Close the valve located at the hot or cold water supply.

- Be sure to check that there is no water in the tap, and that the valve itself is working.

- Apply WD-40 Rust Remover around the circumference of the plug. This partially solves the problem with lime deposits and limescale.

Important! If there is no special tool at hand, it can be replaced with kerosene. Saturate the fabric with kerosene and wrap a rag over the joint. You will have to wait about 5 minutes.

- Unscrew the plug with a wrench. Make the first movements sharper to get rid of the caked joint.

- Remove the cylindrical mesh and rinse it well in a container. A metal brush helps to get rid of silt deposits. Then put the mesh back in its original place.

- Screw on the plug, securing it with FUM tape.

- After opening the valve on the inlet, make sure that the plug does not leak.

Important! If a paronite gasket was used, heating the plug with a burner or boiling water helps a lot. To prevent water from boiling inside the pipe, you need to make sure that the filter is free of water and open the tap in the mixer.