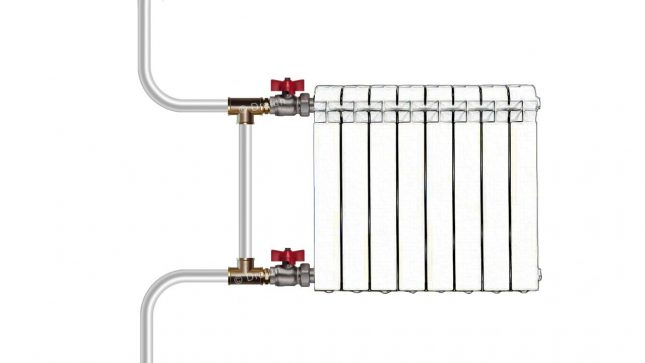

A bypass (jumper on the radiator) is a pipe that connects the inlet and outlet pipes of the radiator. Next, we will consider what a bypass is needed for heating.

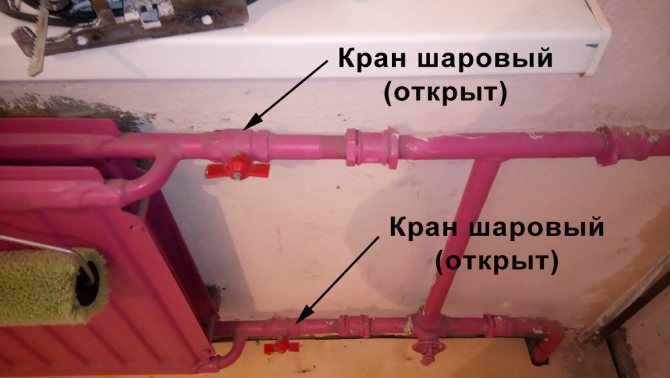

Typically, apartment buildings use a one-pipe heating system. Typically, hot water goes up the riser, and then down, passing through the heating batteries. That is, first, the coolant enters the radiators of the upper floors, and then to the lower floors. There are houses where the coolant moves in the opposite direction (from bottom to top) - but the essence of the system does not change. The main feature of a one-pipe system is that the battery in your apartment is directly connected to the battery in the apartment from the bottom and from the top. The question arises: what will happen if someone turns off the battery - all the neighbors in the riser will be left without heat? This will be the case if the bypass (jumper) is not installed on the heating battery. If there is a bypass, the coolant will go further along it, bypassing the blocked battery.

When is a jumper not needed?

If there is no tap on the battery with which it can be shut off, then the bypass on the heating radiator is not needed. After all, there is still no way to shut off the battery without disconnecting the riser.

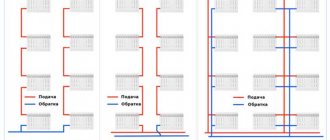

In cottages and some new buildings there is a two-pipe heating system. In this case, each radiator is independently connected to two pipes - supply and return. The jumper is not used with this scheme, since the batteries are independent of each other. The temperature in two-pipe systems is usually automatically controlled.

Why do you need a jumper on radiators

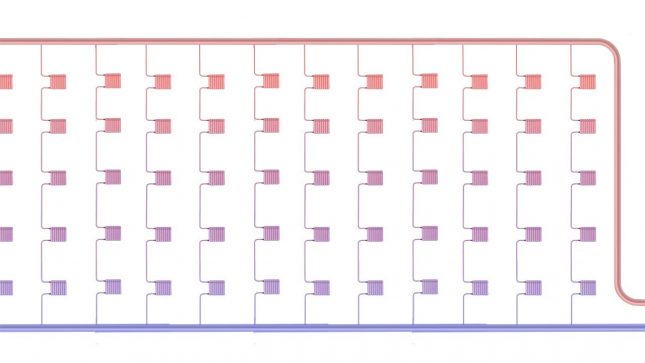

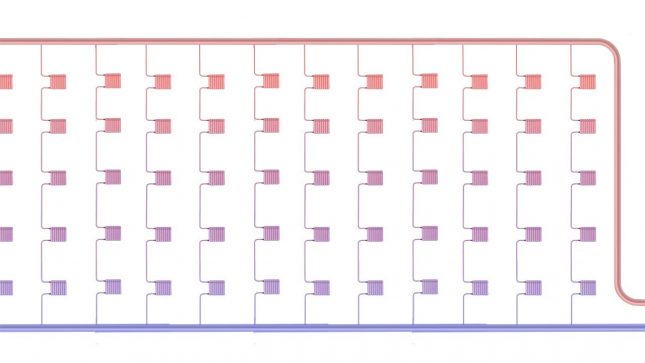

A jumper on the radiator, or bypass, is a special pipe that allows you to isolate the battery from the heating riser. In a one-pipe system, water moves along the riser from top to bottom or vice versa, heating the apartment after the apartment on each floor. From the pipe, hot water enters the battery and, after passing through it, returns to the common pipe.

A single-pipe heating system is a multi-level structure of dependent flow-through radiators subordinate to one heater

The bypass connects the common pipes of the riser to each other, which makes it possible to adjust the radiators in the apartment without shutting off the heating throughout the house.

The bypass allows the heater to pass through the riser bypassing the radiator, which makes it possible to control the temperature of each battery using a regulator

By and large, the jumper allows you to:

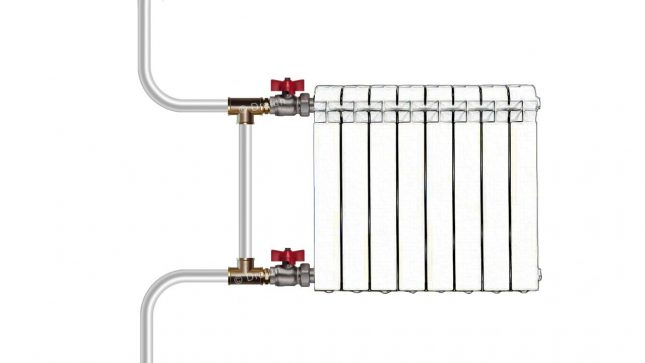

Bypass is legally permitted and can be incorporated into the heating system in any apartment, without exception. According to the norms, the jumper should have a smaller diameter than the main heating pipe of the riser; water valves or regulators cannot be installed on it. Fittings, gauges and filters can only be legally installed if they are located downstream of the bypass and will not interfere with heating the entire riser.

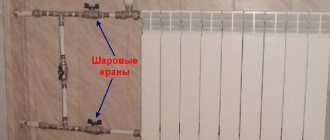

In the presence of a bypass, heating controllers, as well as flow and gate valves are installed after the riser jumper

Rules for installing a bypass in the heating system

It is advisable that specialists take care of the installation of the bypass on the heating battery.They will mount all equipment according to the established rules and standards, carry out pressure testing of the system, and check for defects. But if a situation arises when you need to put the jumper yourself, use a number of rules that will help you do this.

- The decisive role in the installation of the jumper is played by the correctness of the calculations. The bypass diameter must be one size less than the pipe diameter. You can take a ready-made jumper, or make it yourself.

- If you have not previously mounted such elements, it is better to take a ready-made jumper. This will keep the chance of errors to a minimum.

- The bypass must not be placed directly on the riser. Move it closer to the radiator. However, it must not be installed end-to-end, as this can lead to improper operation of the heating system and overheating of the return current. As a result, the effect of installing the jumper becomes minimal.

- After installing the bypass, it is necessary to carry out a pressure test with a pressure 1.5 times higher than the calculated one and check the system for leaks.

Bypass installation

Jumper installation

Jumper installation requires compliance with certain rules:

- in terms of its diameter, the bypass pipe must be smaller in diameter than the supply and return pipes. This is due to the law of hydraulics, when water will go bypassing the radiator along the path of least resistance;

- installation should be carried out as far as possible from the riser and in close proximity from the heating device;

- if automatic regulation is planned, then instead of ball valves, it is necessary to install thermostats.

For clarity, you can give an example of installing a bypass in a one-pipe heating system of a country house, the advantages and disadvantages of such an installation, the rules for installation work, and what kind of pipeline fittings are required.

Installation of a circulation pump

In country houses where the heating system works autonomously, without fail installation of a circulation pump is required. This allows not only to evenly distribute the coolant throughout the entire heating system, but also to save significantly, since heating the whole house will take much less time than with natural circulation.

The problem is that the circulation pump requires availability of electricity, and given that in remote suburban areas, its shutdowns can be constantly observed, then certain problems arise with the circulation of the coolant. They can be solved by simple installation of a bypass. The main thing for the system to work efficiently both with and without a working circulation pump is to install a bypass in compliance with all technological requirements.

Effective operation of the circulation pump is only possible if it directly integrated into the heating system. At the same time, it is desirable to install it in the return line and this requirement is explained quite simply: to enable the circulation pump to work out the warranty period. The pumping device consists of:

- different rings

- seals

- rubber cuffs

If the pump is installed on the supply pipe, then under the influence of high temperatures, it is very will fail quickly, and on the "return" the coolant temperature is an order of magnitude lower, which allows it to work for a longer period.

It is well known that the fewer curved sections in the heating system, the more it works more efficiently. Therefore, they try to install the circulation pump on a straight section. But this is if there is no bypass. If it is, then in this case, the coolant will have to overcome three obstacles at once: shut-off valves and two branches. it will greatly reduce the circulation of the coolantTherefore, in a one-pipe heating system with a bypass, the pump must be installed directly on the pipe with a jumper. What shut-off valves and consumables in this case may you need?

Please note that the coolant should, if possible, pass in straight sections. The more various fittings in the heating system, the less efficiently it works. This is the law.

Now let's turn to such a situation when the pump is installed in a straight section, and the coolant must pass naturally through bypass... In this case, he will have to overcome two branches and a valve (gate valve), which cuts off the bypass from the main. For hot water, 3 obstacles at once in a small area are too much. The circulation will be slow, which means that the efficiency of the system will drop sharply.

So, it is decided - the circulation pump is always must be installed in the bypass section... What is needed for this from consumables and valves? First of all, the valve. They are of two types:

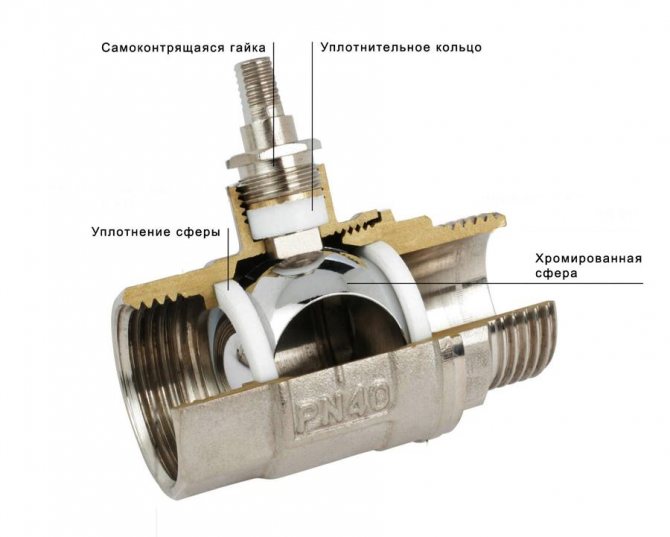

- with ball locking device

- with movable stem

The sliding stem valve has one significant drawback... Its valve seat diameter is almost half the diameter of the heating pipe. This serves as an obstacle for the coolant and due to this there is a sharp decrease in the efficiency of its circulation through the heating pipeline. Therefore, it is not practicable to install them in a bypass system.

Ball valves in their diameter exactly coincide with the heating pipe, but if they are not used for a long time, they can get stuck and it will be very difficult to open them, if at all there is such an opportunity. There are two ways out of this situation. In the first case, install double diameter bellows valve... In the second case, do not forget to regularly open and close the ball valves. This is when we talk about the bypass system. It is much more difficult with the central line, in parallel with which the bypass is located. It will require the installation of several types of valves, with the help of which it will be regulate the head and the quality of hot water.

Installing the locking device

First of all, you will need to install a shut-off device - a check valve or a tap. If the central line of your heating system is not blocked, then the coolant supplied to the system by the pressurized circulation pump will move in a closed small circle. The traffic pattern in this case will look like this: bypass-main line-bypass... To prevent this from happening, when the circulation pump is running, the main line must be closed. If you install a ball valve, it will need to be closed manually. When installing a check valve, the line will be cut off automatically.

It would be useful to install in the bypass immediately before the circulation pump

replaceable mechanical filter, which well retains foreign impurities in the coolant. This will extend the life of the pump, especially if hard water is used as the heat carrier. It is recommended to install the filter on a horizontal section of the pipeline.

As can be seen from the above, in an autonomous heating system, a bypass is one of the most important elements of the network... Therefore, when installing heating, installing a bypass should be given special attention and try not to violate the technological scheme.

Is it possible to put a tap on the bypass?

Some apartment dwellers use a faucet on the lintel to increase their temperature control capabilities. However, in the case of an apartment building, this is a serious violation. The valve can interfere with the flow of liquid and prevent proper circulation throughout the riser.

Even with a valve, the battery will not get hotter.And instead of improving the microclimate in the apartment, you can turn off the bypass tap and forget about it. As a result, you will have to deal with neighbors from frozen apartments.

Use cases

Bypasses have several purposes.

Temperature control in the radiator

For temperature control in a system with a bypass to the heater (after a shut-off valve) install elements:

- Control valve for manual temperature change. Turning the knob changes the area of the through hole in the valve. Accordingly, the amount of heat pump entering the heating device and its temperature also change.

- Thermal head valve for automatic temperature change. The regulator sets the position corresponding to the desired temperature. To increase the temperature, the valve is moved to the "open" position, and passes the HT to heat the heater. Otherwise, the valve is moved to the "closed" position so that the heater cools down.

Both elements regulate the flow of the coolant through the heater, directing its excess bypassing the radiator through the shunt jumper.

Operation without power supply

If the gravitational heating system is equipped with a central heating system with a bypass, then in the event of a power outage the circulation of the heat pump continues through the bypass... With a check valve on the bypass, this happens automatically, the ball valve must be opened manually.

Attention! If the ball valve is not opened in time when the pump is stopped (while the solid fuel boiler is running), this can lead to to disruption of circulation and damage to boiler equipment.

Therefore, for the central pump, an uninterruptible power supply is installed with an autonomous operation time of 5-10 minutes... This is enough to have time to open the tap after a power outage.

Improvement of the one-pipe system

For the complex modernization of a one-pipe system apply technical solutions:

- Equip every radiator in the House shunt bridge and valve with thermal head for uniform heating of all heating devices.

- Each riser after the last battery equip special thermostatic regulator with an external thermal sensor. When the riser battery regulators are closed, the return temperature is higher than the design temperature. In order not to waste the heated HP, the thermostatic regulator closes the riser. This allows you to balance all the risers in the house in terms of the heat pump flow rate depending on the temperature.

As a result of comprehensive modernization, the real HP consumption may decrease from 500 liters per hour to 100 liters per hour while maintaining a comfortable temperature.