Is it possible to hide heating in the walls?

Is it possible to hide heating pipes in the wall, many are interested. The described method has a lot of supporters and people with opposite opinions. Some argue that you cannot do this, others say that you can hide the heating in the wall.

So, is it still possible or not? Which opinion is correct, and what are the pros and cons of such decisions? And, in order not to keep the intrigue for a long time, you need to answer that this method can be used. And they use it very often.

This is an effective way to hide unsightly pipes in your home. There is no technical need for such actions, and in terms of functioning it is quite possible to do without it.

Consensus on this issue, as well as in the only correct option for laying, has not yet been found. Therefore, decision options, after weighing carefully all the pros and cons, everyone will take independently.

Hidden broach

Laying heating pipes in the wall is a fairly popular practice. This is justified by the fact that heating communications spoil the interior space very much. This is their big disadvantage. They stretch along the walls, catch the eye, and do not add attractiveness to the overall design. For these reasons, many want to hide them.

Heating can be installed in different ways, but the most common of them is wall mounting. At first glance, this is a very good solution, the pipe is completely hidden, the overall appearance of the room has improved a lot, but is it really that simple, and what are the advantages of this solution?

Often, when laying a heating network in the walls, the joints lose their sealing. As a result, leaks are formed. It is impossible to see such places on a hidden pipeline, and defects can only be detected by a water pressure sensor.

All modern heating devices are equipped with such a device. When determining the leak, you need to establish the location of the accident, and make repairs.

If, after weighing all the pros and cons, and it is decided to lay the heating main in the wall, then the surface coating must be designed in such a way that access to possible emergency zones is free.

For these reasons, the cladding is made of plastic panels, lining, drywall, etc. The disadvantages of various decorative plastering are that in the event of an accident, the wall will have to be dismantled, and this is not only physical, but also financial costs.

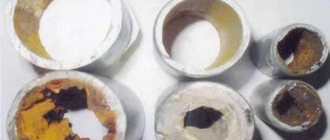

Advice! When laying a polypropylene system with a hidden method, it is necessary to first test for strength. In this case, the test load must exceed the normal operating mode by at least 1.5 times. For metal systems, it is not recommended to use this method of laying, because of their significant disadvantage - poor resistance to corrosive formations.

You should also take into account one more nuance. The disadvantage of the plastic system is the linear increase during heating. When installing, this minus must be taken into account.

Problem

The main problem that my relatives told me about was absolutely cold radiators in two adjacent rooms, while in other rooms the radiators got noticeably warmer with the beginning of the heating season.

- In rooms with warm batteries, the average daily temperature was + 17C;

- In rooms with inoperative heating + 13C.

As they say, feel the difference ...

For several days, calls from neighbors and relatives in the heating network ended in approximately the same way - nothing, becausethe house is cooperative, and its maintenance is not within their competence, except in emergencies.

And it was expensive for a cooperative of 60 apartments (4 entrances), where more than half of the residents are people of deep retirement age, to support their permanent plumbing from their own pockets. The part-time specialist only made sure that there were no leaks during system startup, and nothing more.

Searching of decisions

Arriving at the place, the first thing I do is check the taps on the radiators and bypasses - everything is open in both rooms. I open Mayevsky's taps on each radiator - a thin stream of water informs that there is pressure in the system, and the radiator is not air-conditioned. But you need to find out if there is a coolant in the system at all.

To this end, I go to the basement of the house. From the elevator unit I determine the direction and find "my" supply and return pipes.

This is our highway.

Having reached the location of the apartments in our entrance, I see two pipes - supply and return. To the touch, both pipes differ quite noticeably, so it was not difficult to determine that the colder one is the return pipe.

In the foreground is the return line.

Again I use my hands - both risers are cold, although literally a meter before this area the temperature was more than comfortable. The reason is the airing of the system on the upper fifth floor, which is why the coolant does not circulate.

I leave the basement and go to get acquainted with the neighbors of the upper floor, along the way asking other residents about the presence of stopcocks and their condition. As you'd expect, everyone has cast iron radiators installed 30 years ago.

The fifth floor is a lintel between rooms.

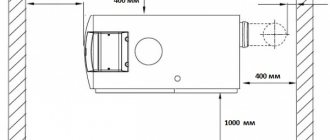

In Khrushchev houses there is no technical floor, so the coolant is supplied from below from the basement. For clarity of the operation of the heating system, I propose to consider the diagram below.

Red arrows show the direction of movement from the feed, blue - the return.

We return to the apartment on the fifth floor. Cast iron radiators with 12 and 7 sections were installed in two rooms of the family of pensioners. It was them who were to be airy.

The reason for the lack of heat is in the accumulated air inside the radiator.

The only method available for this is with the help of a nipple (a prototype of the Mayevsky crane) embedded in the radiator cap.

Upcoming place of work.

- Old galvanized bucket for 12 liters;

- Pliers;

- Two flat-blade screwdrivers;

- A few doormats - splashes are inevitable.

Here it is our simple tool.

I install a bucket under the radiator.

Since a lot of splashing is expected, I provide a place for work around the radiator - I remove the flower pots and move the furniture away

Then I take a screwdriver and carefully, so as not to lick off the edges, unscrew the screw counterclockwise

Excessive efforts have to be made.

- The old system did not give in on the first try, I had to use the pliers - with their help I turned the screwdriver until the screw moved off the stuck place;

- A hiss of air marked the beginning of an airlock. Within 3-4 minutes the air left the radiator, after which cold water flowed in a thin stream;

- By adjusting the screw so that water flowed into the bucket that was placed, I gave time - in about half an hour, when the bucket was half full, the temperature of the water changed from ice to warm, after which I screwed the screw back.

How not to remember the classics: "Oh, lukewarm went ...."

I did the same operation with a cast-iron battery in another room. A few hours later, it became noticeably warmer in the apartments - the thermometer showed a rise of a couple of degrees. Of course, there is no need to talk about a complete solution to the problem of cold in the apartment, becausethe temperature of the coolant is far from 75C, but outside the window is not yet a fierce winter.

I hope that my experience will be useful to some of you. If the symptoms are similar, negotiate with the neighbors of the upper floor and air the riser before winter sets in. Good luck comrades!

How to hide a heating network in an apartment - consider ways

Heating pipes can be hidden in panel walls in several ways. And there are not so many of them for this room. The first option in panel houses is the use of strobes, and the second way is the construction of false walls. Each of the options has pros and cons, and a decision for yourself must be made after a detailed study of these methods.

In the wall of a panel house, the heating pipe can be hidden when a new circuit is being assembled, or repair work is being carried out in an already functioning structure. As a rule, the wall of a panel house and the heating main are placed in different planes.

And when you need to bring them into one plane, recesses are cut in the panel walls and the heating main is placed there. With such actions, you need to focus on the following points:

- Before starting work in a panel house, the riser is blocked. You should not rush to perform these actions. And you should definitely make sure that the work is planned on the right riser.

- If the depth of the channel exceeds half of the partition thickness, then the best option would be to abandon the intended actions. So, for example, a bathroom in a panel house is a separate concrete block system. And the thickness of such panel walls for this task will be small.

- The dimensions of the grooves in the panel walls should not be close to each other, and they should not infringe on the contour. Deepening must be done with the calculation of the fasteners of the system, its volume and the insulating layer.

- Before covering the system in the wall of a panel house, it should be covered with insulation, otherwise condensation will form on the surface of the pipe.

- Before fastening the structure to the wall of a panel house, you need to determine its main places. These include joints and zones of change in the direction of the heat carrier.

To facilitate the action of chipping the wall in a panel house, it is recommended to use a grinder. First, markings should be made, and then, along the corresponding lines, the grooves are made to a certain depth level.

TIP! When working with a grinder, there is not only a lot of noise, but also dust. Modern tools have a big plus - the function of connecting to a construction vacuum cleaner, and this prevents the appearance of dust.

According to existing rules, the communication network in the wall of a panel house should be located in an unobstructed access zone. Only those zones are left directly closed where the probability of an accident is zero.

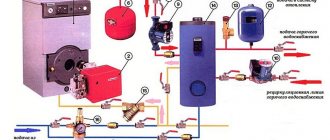

Elevator unit for centralized heating system

Of course, few people have heard the term "elevator unit" before. It can be safely called an injector, which includes a heating scheme for a nine-story panel house or a house with fewer floors. After all, it is into it through a special nozzle that the coolant heated almost to the limit enters. Here, the return water is injected, after which the liquid begins to actively circulate in the heating system. As a matter of fact, after the coolant and return have entered the system through the elevator unit, they receive the temperature that we feel when we touch the battery.

Calculation of heating a private house

Elevator unit for centralized heating system

Often, depending on the plan, which implies a project for heating an apartment building, valves of various types can be installed on the heating unit. In many ways, their appearance depends on how many rooms should be heated, whether this unit is involved in heating one riser (entrance) or the whole house.In addition, sometimes, in addition to the gate valves, an additional manifold is installed, on which, in turn, the shut-off elements are fixed. Often, a separate section of the input system is used to install meters. Most often, one metering device is used for one entrance.

Heating pipes under a false wall

Watch the video

If a decision is made to hide the heating pipes in a false wall, then in this case there are no special difficulties. First, a base is erected from guides, and at the end, it is decorated with any of the selected materials: clapboard, drywall, blockhouse.

There is an opinion that if you hide the heating in a false wall, then the useful space of the housing is significantly reduced. Fortunately, this minus is only a myth. For example, if you need to hide the heating pipeline under the window, in reality this space is practically not used.

The only thing that is lost in this situation is incomplete fifteen centimeters under the windowsill, but it itself becomes wider by the same distance. This addition is much more useful than the unused area under the window.

If you need to hide unaesthetic designs of the heating system, then experts recommend a false wall. They call it just the perfect solution. A very important advantage of this building is that it can be designed without the participation of professional craftsmen. And this is a great advantage of this building.

In many situations, when it is necessary to hide the intersection of a horizontal and a vertical line, or to mount an overall system unit, the box may not always help out. But false - the wall in such situations to cope perfectly.

Another great advantage of this method is the excellent combination of construction with the overall design. When deciding to hide the heating pipes under a false wall, you can also reconsider the placement of other systems, for their decoration this method can also be effective.

Box

Performing modern high-quality repairs, we hide the heating pipes in the wall. This installation option requires careful calculation and drawing up a detailed diagram. If they hide the heating network at the stage of building a house, then the task is not difficult to complete.

But, with an already operating pipeline stretched along the walls, they do this. In addition to false - the walls can be sewn up with a box. At the same time, a frame is assembled from wooden boards or from a profile, which is subsequently sheathed with various materials suitable for design. Neither the construction nor the cladding of the frame presents any particular difficulties.

If we hide pipes in a box, and not in a wall, then the advantages of this option speak for themselves. The structure is not difficult to build, with a small financial investment. Also, a clear advantage of such a building is the ability to quickly get to the nodes for repair work.

Watch the video

If they hide the highway under a box without openings, then this also does not constitute big problems, so this building is easily dismantled, and then it also returns to its original place. And one more important nuance cannot be ignored. When they hide the heating main under the box, then such a building acts as a decor detail that can be decorated to your liking.

Isolation is or may not be done

The transfer of heating pipes to the wall involves the use of insulation. Many people pose a completely justified question: "Why is this insulation needed when transferring pipes under plaster?" The answer is simple, otherwise the heat will go into the walls for warming up.

Most of the heat is lost in the walls that are in contact with the street. In the inner walls, the problem of heat loss is not big, since heat will still go into the room, but its amount will be slightly less.

Carrying out the transfer of the heating pipeline to the wall, they carry out not only thermal insulation.This creates an obstacle to the formation of condensation. After all, any moisture is a fertile soil for the development of a fungus.

It is also important to note that insulation during the transfer of heating pipes has another important function. It protects the line from mechanical stress.

Watch the video

When choosing an insulation option when transferring a pipeline, it is important to take into account that each of the proposed materials has its own pros and cons. For example, polyurethane foam should be taken with the lowest thermal increase, in the case of polyurethane foam, a material should be taken that exactly matches the size of the system, etc.

How to fix the pipeline

Heating pipes are laid in the wall with various devices. Let's consider several options:

- sliding;

- hard.

The immovable support for the pipeline holds the structure "tightly". With this arrangement, the contour cannot be displaced. And when laid with sliding fasteners, it can move a little. When broaching the line, it is recommended to alternate these two types of fasteners.

Types of fasteners that are used when laying the network under plaster:

- Metal clamps. These are fairly simple devices in which fixation is made by tightening the bolt.

- Clip. These devices are also simple in design. The advantage of such a device is that the fixation is performed with one click.

- Retractable plastic clamps. Unlike their metal counterparts, such pipeline laying devices are equipped with only one fixing point.

- Dowel - hook. These options are recommended for laying the system on a flat surface. Such a screw is tightened or carefully hammered into the prepared place.

- Crab - systems. These mechanisms are used when fixing the pipeline to the walls, and for fastening the highways to each other.

Pros and cons of this type of gasket

Professionals are inclined to believe that installing heating pipes into the wall is not an easy and expensive procedure.

It is difficult to name the objective advantages of such actions, apart from the aesthetic design. But, the disadvantages in this situation are obvious.

- The most important thing is the complexity of the installation. Before starting work, it is important to consider that it is difficult to dock the parts. It is especially difficult to perform high-quality welding in grooves.

- High probability of leakage. With this installation, in the event of an accident, you will have to break the wall.

- The whole range of installation work in this case is associated with high physical and financial costs. And this is a very significant disadvantage of this installation option.

Watch the video

System - panel heating

Surface heating systems can be widely used in residential and public buildings.

Surface heating systems are usually tested with hydraulic pressure. Pneumatic pressure is allowed at subzero outside temperatures. MPa (01 kgf / cm) If there are heaters in the panel heating system, the test pressure should not exceed the pressure set for them.

Surface heating systems must be tested before the installation windows are sealed. Pneumatic testing of surface heating systems at negative outside temperatures is allowed. For combined panel-radiator or convector heating systems, the test pressure is determined based on the requirements for heating systems with the above devices.

It is recommended to use panel heating systems in schools, childcare facilities, hospitals, sanatoriums, residential buildings in order to provide a hygienically high-grade microclimate in these buildings.

Surface heating systems can be connected to house boiler houses and to heating networks from CHP and district boiler houses. Due to the use of heating elements made of steel pipes in panel heating systems, a hydrostatic pressure of up to 8 atm is allowed.

| Permissible temperatures on the surface of the ceiling pas. |

Surface heating systems have a high heat capacity, so their household regulation is not very effective and requires a significant investment of time. However, adjusting valves must be provided on each device in order to ensure installation adjustment.

For surface heating systems combined with heating devices, the test pressure should not exceed the maximum test pressure for the heating devices installed in the system.

Installation of panel heating systems and sanitary cabins is carried out simultaneously with construction work according to the combined work schedule. A team of plumbers-installers begins installation after the builders have installed the two upper floors in compliance with the requirements of SNiP III-A. Installation work is carried out from bottom to top in the following sequence: laying of highways and installation of inputs (zero cycle); connection of risers to highways and heating elements of the first floor to risers; connection of risers of heating systems with vertical and horizontal inserts - brackets; blowing compressed air with a pressure of 0 2 - 0 3 MPa of each riser separately and filling the system with water for testing.

The test of panel heating systems is carried out before closing the mounting holes in the panels, while the welding places of the interfloor inserts should be especially carefully inspected.

Installation of panel heating systems and sanitary cabins is carried out simultaneously with construction work according to the combined work schedule. A team of plumbers-installers begins installation after the builders have installed the two upper floors in compliance with the requirements of SNiP III-A. Installation work is carried out from bottom to top in the following sequence: laying of highways and installation of inputs (zero cycle); connection of risers to highways and heating elements of the first floor to risers; connection of risers of heating systems with vertical and horizontal inserts - brackets; blowing compressed air with a pressure of 0 2 - 0 3 MPa of each riser separately and filling the system with water for testing.

The test of panel heating systems is carried out before closing the mounting holes in the panels, while the welding places of the interfloor inserts should be especially carefully inspected.

For surface heating systems combined with heating devices, the test pressure should not exceed the maximum test pressure for the heating devices installed in the system.

The design of a building underfloor heating system begins with the choice of the type of heating panels and their location in the premises. Having established the thermal loads and the temperature of the panels, their preliminary area is calculated. They check the fulfillment of the thermal comfort conditions and clarify the heat loss through the enclosing structures of characteristic rooms.

The design of a building underfloor heating system begins with the choice of the type of heating panels and their location in the premises. When placing heating panels in rooms with an increased glazing area, it is advisable to place panels under light openings or in a narrow floor strip adjacent to external fences to reduce radiation cooling of people and localize cold air flows.