- the main

- Service

- Preparing the heating system for the heating season

/

/

In winter, the safe operation of the equipment depends on the quality of the measures taken to prepare heating systems. Careless preparatory work increases the risk of accidents. Various objects are being prepared for the heating season: residential buildings, industrial enterprises, administrative buildings, cottage settlements. Maintenance of heating units is carried out in a timely manner by qualified specialists.

offers to use services for preparing systems for safe operation in the winter. We will carry out high-quality pressure testing of the heating system with the preparation of the relevant documents.

How much does it cost to prepare the heating system for the heating season?

We will make a calculation according to your size in 5 minutes!

Preparation for the heating season

11.1. In preparation for the heating season, in order to ensure the reliability of heat supply to consumers, it is necessary to carry out a set of measures in a timely manner, the main of which are:

11.2. In preparation for the upcoming heating period, defects in the operation of equipment and deviations from the hydraulic and thermal regimes are identified, work plans are drawn up, the necessary technical documentation and material and technical resources are prepared. Schedules of preparation for the upcoming heating period of heat sources, heating networks and heat consumption systems are developed before the end of the current heating period, but no later than May of the current year. 11.3. To ensure reliable and safe operation of heat supply systems, timely elimination of accidents and prevent their development, organizations conduct training on interaction of personnel in the elimination of emergency situations, organizational and technical measures (instructions) have been developed. 11.4. Prior to the beginning of the heating season, heat supply organizations develop and approve in local governments the schedules for limiting the supply of heat energy and heat carrier in case of urgent measures to prevent or eliminate accidents in the heat supply system. 11.5. To check the readiness for the heating period, when accepting heat points, it is checked and drawn up by acts:

11.6. To check the readiness of heating systems and the heat supply system as a whole for operation in the heating season, test furnaces are carried out before it starts. Test furnaces are carried out after the completion of the preparation of the heat supply system for the autumn-winter period. The beginning and duration of the test furnaces are determined by the schedule of the heat supply organization, which should be agreed with the local government body and brought to the attention of consumers no later than three days before the start of the test furnace. 11.7. The heating period begins if, within five days, the average daily outdoor temperature is +8 degrees. C and below, and ends if, within five days, the average daily temperature of the outside air is +8 degrees. C and above. Turning on and off of heat consumption systems is carried out according to the schedule agreed with the power supply organization. 11.8. At the end of the heating season or at shutdown, the boilers and auxiliary equipment of the boiler house are preserved.Preservation methods are selected by a specialized commissioning organization, based on local conditions, based on the recommendations of the current guidelines for the preservation of heat and power equipment and are included in the preservation instructions approved by the technical director of the organization. When hot water boilers are put into operation, as well as before the start of the heating season, heating networks and internal heat consumption systems are pre-flushed. 11.9. Power supply organizations with heat sources ensure the creation of standard fuel reserves in a timely manner.

__________________________________________

What work is carried out in preparation for the heating season

Repair measures in the heating networks of consumers are linked to the plan for repairing the heating power systems of heat sources. Acts and the entry of information on the volume of repairs performed and the results of pre-start checks are drawn up by the responsible persons.

Boiler equipment check

When preparing the boiler room for the heating season, the following main activities must be performed:

- repair of boiler heating surfaces according to PPR, replacement of defective sections of pipes, economizers, air heaters, boiler fittings, fittings, smoke ventilation systems and lining of boilers;

- refurbishment of pumps, smoke exhausters and fans;

- restoration of fittings and primary instrumentation sensors;

- repair and commissioning of instrumentation and automation;

- repair and commissioning of electric power equipment;

- repair and commissioning of chemical water treatment facilities;

- repair and adjustment work of the fuel supply system;

- preparation of stoves for the heating season;

- state verification of heat metering devices.

After the completion of the repair and restoration work, the thermal diagrams of the boiler plants are assembled and the hydrotesting of the boiler units is performed with a pressure equal to 1.25 of the working pressure of saturated steam in the boiler.

Renovation work

Renovation work is required. Photo source: ao-ustek.ru

In heating networks, based on the results of the spring inspection and PPR, it is required to carry out the following main types of repairs:

- replacement of defective pipe sections;

- restoration of thermal insulation and anti-corrosion coating;

- repair and revision of stop valves, drain valves, air vents, check and safety valves;

- revision and repair of network and feed pumps;

- replacement and repair of electromagnetic and hydraulic actuators of control valves and starting devices;

- replacement and repair of instrumentation;

- cleaning mud collectors and accumulator tanks;

- repair and adjustment of safety automation, control instruments recorders.

Upon completion of all planned work, a thermal circuit is assembled and hydraulic tests of heating networks are performed with a pressure of 1.25 working pressure, but not less than 1.6 MPa and a network water temperature not higher than 40 C.

Checking devices

According to the Heat Energy Metering Rules, each heat source and receiver must be equipped with commercial metering devices, in addition, boiler rooms and consumer ITPs are equipped with security system devices.

To ensure the reliable operation of the above devices in the OZP, the following devices are repaired and verified:

- regulation of heat consumption;

- regulation of the temperature in the DHW system;

- maintaining static pressure in heating systems;

- by pressure in the supply / return network pipeline;

- to protect heat supply systems from over / under pressure;

- to protect heat supply systems from excess temperature in the supply network;

- to automatically turn on the backup pump;

- for automatic protection of the accumulator tank from overflow;

- automatic on / off of drainage pumps.

Commissioning and preparation of performance maps

After flushing and hydraulic testing of heating networks, commissioning works are performed on heat power plants, both at heat supply organizations, and at consumers.Based on the results of commissioning, the operating maps of the heat-power equipment are established.

Basic data of regime cards:

- Estimated volumes of the coolant for the operational sections of the heating network.

- Operating parameters for pressure in network pipelines: direct and return line.

- Operating temperature graph of direct and return network water, depending on the ambient temperature.

- Heat carrier consumption by consumers.

- Calculation of the thermal expansion of the heating network.

- Analysis of the hydraulic and thermal modes of operation of the heating network.

- Calculation of the diameters of the limiting washers and nozzles of the elevator assemblies at the consumer.

Cleaning the heating system before the heating season

The first thing to do is flush the inside of the heating system. This stage of preparation for the heating season is very important. Scale and other impurities settle on pipes and radiators inside. As a result, the wall thickness increases and the thermal conductivity decreases. Accordingly, the heating circuit starts to work worse, energy costs rise.

Professional booster.

There are many flushing options, but chemical cleaning is the most popular among owners of autonomous heating systems. The method does not imply the use of special expensive equipment. You only need one that you can easily do with your own hands. The principle of flushing is that an acidic solution is circulated along the circuit for several hours.

The acid corrodes not only scale, but also rust, sometimes it can damage the paranite or rubber gaskets. It happens that leaks appear after cleaning with a chemical method. This is good, since the weak points were identified even before the start of the heating season and there is enough time for repairs.

You may have seen how the contours of steel pipes and cast-iron radiators are painted over the old layer. Over time, the metal becomes overgrown with such a layer of paint, which significantly reduces thermal conductivity.

Replacing the coolant before the heating season

The next stage in preparing the heating system for the heating season is replacing the coolant. If, after flushing the heating system, no leaks and faulty elements were detected, then the circuit can be filled with coolant and it is already ready for operation. It is necessary to change the liquid in the heating system, even if cleaning has not been carried out. Experts recommend pouring distilled water or non-freezing liquid into the circuit.

If you have a double-circuit boiler, do not use antifreeze.

Antifreeze has its own service life, after which the liquid begins to disintegrate into components. The most dangerous component is hydrochloric acid. It turns out that if you do not change the anti-freeze, then acid will circulate along the circuit, which will quickly destroy all elements of the system. The resource of the anti-freeze liquid is indicated on the package.

You can fill the heating system:

- using a crimping pump;

- by making up from the water supply;

- you can even fill in the coolant with a bucket.

If the coolant contains the minimum iron content, and the PH is close to optimal, then the equipment (boiler, pump, radiators) will last much longer. The requirements for the quality of the coolant are indicated in the product passport.

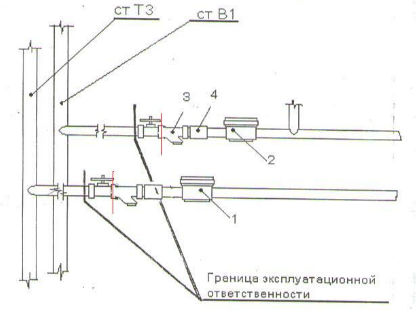

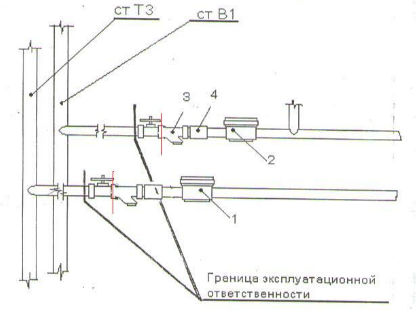

Liability boundary

First, let's figure out what we are going to press. There are several options for connecting the building to the heating network. The first, the most common option, is when the gate valves are installed next to the wall at the entrance from the city. With this option, the boundary of the delimitation of responsibility is considered to be the flange of the inlet valve, for everything that follows (including the inlet valve) is the responsibility of the owner of the building. Accordingly, the heating unit and the building heating system are pressurized.

The second option is when the heating unit is located inside the building, and an internal heating main runs to it from the input valves through the building. With this connection option, it is necessary to clarify where the demarcation boundary lies. In this we will be helped by the "Heat supply agreement", which is concluded between the owner and the heat supply company. This agreement has an appendix, which indicates where the border of delimitation passes.

If the entry gate valves are considered the boundary of the demarcation, we press three elements of the system: an internal heating main, a heating unit and a heating system. If the line of separation of responsibility passes through the valves at the heating unit, naturally, we pressurize only the elevator (heating) unit and the heating system.

Beginning of work

The Russian Federation includes many subjects located in a variety of climatic conditions. Depending on the specific region, the heating period for 2017-2018 will be launched at different times. In addition, experts take into account seasonal characteristics, since weather conditions even in one region can vary greatly from year to year.

The same applies to preparatory work, since their timing is in direct proportion to the start of heating systems. Nevertheless, there are certain time frames established by law, in which all work must fit:

- 10th of March. Prior to this date, test work on hydraulic testing of heat exchange systems should be started;

- March 12. On this date, the start of testing of heating mains and heating stations is scheduled;

- May 25. By this date, all repair and other preparatory work must be completed;

- October 15th. The last day when it is allowed to start heating houses and buildings of social infrastructure. In exceptional cases, for certain premises, this period may be extended by two weeks.

However, the heating season can be opened earlier than the established date, if weather conditions require it. The following rule is legally established: if the average daily temperature for 5 days is kept at +8 degrees Celsius and below, then the heating should be started immediately, regardless of the date. This measure is due not only to the issue of ensuring a comfortable temperature in homes and other premises, but also to material and technical needs. If the heat supply systems are not put into operation at such a temperature, then they may be damaged in the future under the influence of cold weather, which entails significant financial costs.

However, the deadline for launching the operation of heating mains remains unchanged - this is October 15, 2020. The heating season will last until spring 2020. The exact date when the heating is turned off also depends on the weather conditions. Scheduled work to turn off heating systems will begin in April and may last the entire month.

Preparation of individual systems for heating

The decisions of local authorities regarding the beginning of the heating season do not apply to owners of autonomous heating systems for industrial and residential facilities. They have the right to independently decide when to start heating, based on the temperature indicators outside the window and the climatic characteristics of the region. Usually, owners of private households start heating residential premises earlier than heat appears in buildings that are serviced by housing and communal services and management companies.

A similar situation is developing with the termination of the heating season. With individual heat supply, each owner of an apartment or house has the right to decide when to stop supplying heat and thereby save on energy costs.

According to generally accepted rules, heating systems are turned off when the average daily temperature outside exceeds 8 degrees Celsius for 7 days in a row. When this parameter is lowered, the heat supply must be resumed.

Beginning of work

The Russian Federation includes many subjects located in a variety of climatic conditions. Depending on the specific region, the heating period for 2017-2018 will be launched at different times. In addition, experts take into account seasonal characteristics, since weather conditions even in one region can vary greatly from year to year.

The same applies to preparatory work, since their timing is in direct proportion to the start of heating systems. Nevertheless, there are certain time frames established by law, in which all work must fit:

- 10th of March. Prior to this date, test work on hydraulic testing of heat exchange systems should be started;

- March 12. On this date, the start of testing of heating mains and heating stations is scheduled;

- May 25. By this date, all repair and other preparatory work must be completed;

- October 15th. The last day when it is allowed to start heating houses and buildings of social infrastructure. In exceptional cases, for certain premises, this period may be extended by two weeks.

However, the heating season can be opened earlier than the established date, if weather conditions require it. The following rule is legally established: if the average daily temperature for 5 days is kept at +8 degrees Celsius and below, then the heating should be started immediately, regardless of the date. This measure is due not only to the issue of ensuring a comfortable temperature in homes and other premises, but also to material and technical needs. If the heat supply systems are not put into operation at such a temperature, then they may be damaged in the future under the influence of cold weather, which entails significant financial costs.

However, the deadline for launching the operation of heating mains remains unchanged - this is October 15, 2020. The heating season will last until spring 2020. The exact date when the heating is turned off also depends on the weather conditions. Scheduled work to turn off heating systems will begin in April and may last the entire month.

Preparing the heating system for winter step by step

There is no life without heating. It is very unpleasant to stay in winter without heating or on the eve of frost to understand that the house is warming up in parts or the radiators are "slightly warm". Preparing the heating system for the winter, which must be done strictly step by step, will help to avoid the problem.

Heating system preparation steps

The first step is to check the tightness of the heating circuit. For this, we fill the heating system with water. Filling is done through the drain valve, it is the lowest in the system. Bottom water filling allows air to be forced out of the system.

The system is completely filled, and the air release is controlled using air vents.

We leave the filled system for 1-2 hours. This time is enough to bypass the entire heating system and check the absence or presence of leaks in the system.

We pay special attention to the connection points of heating devices, pipe connections and all kinds of threaded connections

We pay special attention to the readings of the manometer. If you do not see leaks, but the pressure of the manometer drops, then we continue to look for leaks.

We mark the found leaks for elimination.

If possible, we fix the leaks immediately. If the leak is serious, then we eliminate it after draining the water and re-check the system for leaks.

After eliminating the leaks, if any, of course, we proceed to the next step of the check - pressure testing. Pressure testing is the same test of the heating system, but under pressure, 1.5 atm.We complete the pressure testing with a control start-up of the heating boiler.

Important! Depending on the type of boiler, starting up the boiler also requires some checks. The boiler check is done according to the boiler operating instructions.

So for a gas boiler, you need to carefully check the gas pipeline and the inlet, gas fitting.

After starting the heating boiler, go to the next step, check the heating radiators. We go through all the radiators and feel each section of the radiator. If we find that the radiator section has not warmed up, then we reduce the temperature in the system, poison the air to eliminate air congestion and check the system again. If we find that the sections of individual radiators do not warm up well, then these radiators need to be noted and washed after draining the water.

When all checks are certified, it remains to flush the entire system under pressure with clean water.

The preparation of the heating system for winter is completed by filling the proven system with a heat carrier (water or antifreeze).

Obotoplenii.ru

Other articles in the section: Heating installation

- Heating system pumps: types and methods of installation of heating circulation pumps

- About the heating system: the components of the heating system

- Heating installation tools

- About home heating: professionals about the installation of heating systems

- 10 answers to the practical use of antifreeze in heating systems

Washing is carried out using the following methods:

- Hydraulic flushing, which is the most simple. It is carried out during a period of heavy rain, ensuring the supply of high pressure water in the system.

- Hydropneumatic flushing. A mixture of coolant and compressed air is launched into the system under high pressure. Thanks to this, the heating system is cleaned of such hazards as lime deposits.

- Chemical washing. It is carried out using special formulations that effectively dissolve contaminants and remove them from the system.

Pressure testing is the method of complex hydraulic testing carried out to prepare premises for operation during the heating season, as well as:

- after installing heating equipment;

- before the pipeline is put into operation;

- upon completion of overhaul;

- after work related to the reconstruction of the ITP;

- in the process of replacing valves or gates.

When preparing heating systems, it is necessary to carry out the following operations:

- prepare safety and non-return valves;

- check their serviceability;

- check the performance of the temperature regulator, thermometers and manometers;

- check the serviceability of the shut-off valves;

- check the stuffing box;

- check and eliminate malfunctions in threaded connections;

- rinse mud collectors and filters.

Certificate of readiness of heating systems and heating networks sample

The act of readiness of the heating systems and heating networks of the consumer for operation in the heating period of 2014 - 2020.

Settlement "____" _____________ 20___ We, the undersigned, the Perm department of EDMTO represented by (position, full name) made the acceptance of the heating networks of the building and heating networks

The test and inspection results are as follows:

1. During the hydraulic test, the pressure was raised to the required gks / cm2 according to the instructions. In this case: a) after 15 minutes. After turning off the press, the arrow dropped to ____ gks / cm2. b) the specific point of water per 1 m3 of volume did not exceed __________ t / h, m3.

2. When inspecting the system, the following defects: a) for building insulation b) for insulation c) for devices d) for cranes

3. Condition of hatches on the external networks of the consumer

4. Flushing the network and system

The consumer is obliged to eliminate the defects established by this act of readiness of heating systems and heating networks by

Subject to the elimination of the above defects, the system can be allowed to be connected to the heating network of the heat supply organization

Defects have been eliminated, the subscriber's system is full and is considered accepted from "______" ________________ 20 _____.

Representative of the heat supply organization ________________ Representative of the consumer ________________ "______" _______________ 20 ____

Incoming search terms:

- act on the technical readiness of heating networks and power receivers of installations (24)

- flushing of heating networks before the start of the heating season, form of act (1)

- certificate of preparation for the heating season form (1)

- heating season preparation certificate (1)

- certificate of readiness for the heating season sample (1)

- certificate of readiness for the heating season form (1)

- certificate of readiness of the heating system for the heating season sample (1)

- act of readiness of the heating system and heating networks of the consumer for operation in the heating period 2017-2018 (1)

- certificate of readiness of the object for the heating season sample (1)

- certificate of readiness of the object for the heating season (1)

A selection of the most important documents on demand Heating season

(regulations, forms, articles, expert advice and much more).

Regulations: Heating season

Decree of the Government of the Russian Federation of 05/06/2011 N 354 (as amended on 06/27/2017) "On the provision of utilities to owners and users of premises in apartment buildings and residential buildings" (together with the "Rules for the provision of utilities to owners and users of premises in apartment buildings and residential houses ") 5. If heat energy for the needs of heating premises is supplied to in-house engineering systems through centralized networks of engineering and technical support, then the contractor begins and ends the heating period within the time limits established by the authorized body. The heating period must begin no later than and end no earlier than the day following the day of the end of the 5-day period, during which, respectively, the average daily outdoor temperature is below 8 degrees Celsius or the average daily outdoor temperature is above 8 degrees Celsius.

Articles, comments, answers to questions: Heating season

Circumstances of the case: An accident occurred on the heating main during the heating season. It was possible to turn off the heat supply for no more than three hours. In this regard, the customer entered into a contract for the elimination of the consequences of this accident with a single contractor. There was no competitive procurement procedure. The antimonopoly authority found the customer's actions unlawful.

The conclusion is based on the fact that in an emergency situation associated with the supply of heat to the house during the heating season, the employee was obliged to provide access to her apartment for repair work. Her absence from the workplace was due to good reasons.

The document is available: in the commercial version ConsultantPlus

Forms of documents: Heating season

Form: Act of checking the readiness for the heating period of municipalities (heat supply and heating network organizations, heat consumers, heat-consuming installations of which are connected to the heat supply system) (recommended sample)

The document is available: in the commercial version ConsultantPlus

Form: Passport of readiness for the heating period of the municipality, heat supply organization, heating network organization, heat energy consumer, in respect of which the readiness for the heating period was checked (recommended sample) (Order of the Ministry of Energy of Russia dated 12.03.2013 N 103)

The document is available: in the commercial version ConsultantPlus

The article was written based on materials from the sites: pandia.ru, dogovor-obrazets.ru, domvpavlino.ru.

Main menu

Hello dear readers! In order for the internal heating systems to work reliably in winter, it is necessary to carry out preventive maintenance in the summer. The preparation of heat consumption systems for the heating season includes such work as: inspection and revision of the elevator, inspection and cleaning of mud collectors in the ITP, revision and repair of valves (valves).Since far from everywhere ITPs have been modernized (the elevator circuit with admixture was replaced by a circuit with a pump and a variable valve, parallel valves were replaced by ball valves), we will consider the work on preparation for winter in a standard "Soviet" heating unit.

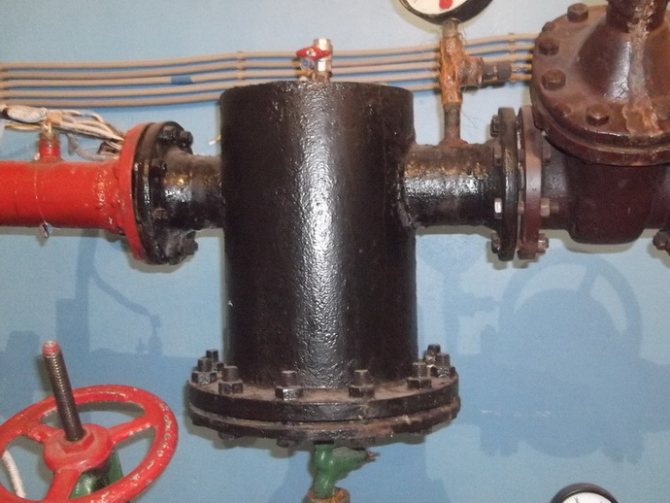

After the end of the heating season, it is necessary to carry out a routine inspection of the mechanical elevator. If the elevator malfunctions during the heating season, it is necessary to disassemble the elevator and check if everything is in order with the nozzle.

If the elevator has generally worked smoothly, this is good, but you can carry out preventive cleaning of the nozzle (cone) as follows. We close the input valves in the ITP, close the house valve on the return, open the house on the supply, and through the drain valve under the influence of static pressure we carry out preventive cleaning and flushing of the elevator. Inlet valves are the very first valves at the inlet to the heating unit at the supply and return. House valves are valves in the ITP, after which the coolant goes directly into the house. The house valve on the supply is always after the elevator in the direction of movement of the coolant.

The mud sump in the heating point must be cleaned during the inter-heating period.

The sump is disassembled to clean the grate. Cleaning the sump grate is done with a metal brush, individual holes are cleaned with a metal wire. Here you can also carry out preventive flushing and cleaning of the sump. The holes in the sump grate are cleaned by the return flow of water by opening the appropriate valves and opening the relief valve.

When carrying out work on the preparation of heating systems for the heating season, the main attention should be paid to the repair and revision of valves, mainly valves.

After all, faulty valves do not make it possible to reliably disconnect a section of internal heat supply networks, and do not allow repair work. And in general, a lot of problems can be created by a faulty shut-off valve at a heating point during the heating season, if a non-standard situation occurs. Therefore, the revision and repair of shut-off valves are strictly obligatory and in the interests of the heat consumer himself.

In parallel valves, the valve consists of two parallel discs and a wedge placed between them, which, when the valve is closed, tightly expands the discs. A parallel valve differs from a wedge valve in that the sealing surface of the valve is parallel, in the wedge it is at an angle. Parallel valves used for heating and hot water usually have bronze O-rings to better seal the valve bore. Bronze rings are inserted into the body by pressing. The same rings (plug-in) are mounted on the disc, so that when the flywheel rotates, the disc rings slide over the body rings. By closing the valve in this way, the required tightness is achieved.

However, during operation, sand, scale gets into the valve. When the valve is closed, coarse sand or scale gets stuck between the O-rings and grooves are cut in the rings. The valve, thus, loses its tightness, or, as they say, “does not hold”. What can be done here? It is necessary to disassemble the valve and grind the disc o-rings to ensure that the disc o-rings fit exactly to the body rings.

Lapping is carried out with grinding powder on the oiled surfaces of the rings. After the required lapping is achieved, the valve is assembled. When assembling the valve, a new gasket lubricated with graphite oil is placed under the cover. Then the gland is stuffed with asbestos packing, the last ring is better made of heat-resistant rubber.After all this, the valve must be subjected to a hydraulic test, that is, pressurized and checked for leaks. After crimping and checking for tightness, the job can be considered done.

Then, during the heating season, you need to periodically inspect the shut-off valves, if necessary, tighten the gland. But there will already be confidence that the shut-off valves are working, reliably opens and closes the coolant passage.

On the topic of preparing for the heating season, I wrote a book with the same name, you can view it at the link below:

Preparing for the heating season

This book was written by me on the basis of my 15-year experience as a thermal power engineering practitioner. I also attached additional materials to the book, namely: an action plan for preparing for the heating season in Exel format, working programs for flushing and pressure testing of the building's internal heating system, forms of flushing and pressure testing acts in Word format, ITP (heat point) passport with a diagram, passport of the heating network (heating mains), instruction manual for ITP in Word format, answers when passing the exam for the person responsible for the safe operation of thermal power plants in Rostekhnadzor using the OLIMPOX system (testing on a computer).

And here is the content of the book:

1. Introduction

2. What does the preparation for the heating season consist of?

3. Preparations for the heating season (appointment of a person responsible by order for the operation of heat and power plants, passing exams at Rostekhnadzor.)

4. Revision and repair of valves and other technical measures

5. Flushing and pressure testing of internal heat supply systems

6. Conclusion

Preparing the heating system for the winter season

When creating any type of individual heating, first of all, it is necessary to comply with fire safety rules. This is especially true for houses with stove heating. Your actions:

- Check chimney and stove for damage. If necessary, fix the masonry, replace the grates and cover the cracks with clay mortar.

- Be sure to clean the chimney from accumulated soot.

- Check the contact of the chimney with the elements of the roofing system. The wooden structure should not fit snugly against the chimney.

- Whitewash the repaired structure and heat the oven. If not all cracks are repaired, you will immediately see.

- Move furniture away from the stove at a distance of at least one meter.

- Cover the floor covering near the firebox and ash pan with a sheet of iron or lay out with tiles.

- Check the operation of the chimney damper and the integrity of the hob, if any.

- Move the electrical system wires, sockets and switches located near the stove to another place.

- Set aside a separate dry room to store firewood and coal. Calculate the fuel supply in advance so that it will last for the season.

- Protect your family from possible carbon monoxide poisoning by installing a simple gas detector.

The rules for preparing and conducting the heating season in a private house using electric heating also need to be known and followed:

- First of all, carefully inspect the cables and, if necessary, replace them. Do not use wires with broken insulation - this is a direct path to spontaneous combustion.

- Call a technician to service the electric heaters in your home.

- In order not to be left without heat during natural disasters and possible damage to the power line, take care of an alternative way to heat your home. This can be a gas boiler, a wood-burning stove or a fireplace that is independent of the energy carrier.

If you are using a gas boiler for your home, preparation for the heating season will also be needed. Your actions:

- Call a specialist from the gas service for a technical inspection of the equipment.

- Check the operation of the ventilation ducts in the room where the equipment is located.

- Check the heating system for water filling. Top up with water if necessary so that all batteries and pipes warm up evenly.

- Check the operation of the shut-off devices on the heating system.

- Paint pipes outside and inside the house.

Maintenance of autonomous systems

With the arrival of heat and after the completion of the operation of the heating structure, it will be necessary to take measures related to the conservation of equipment for heat supply for the summer period. The fact is that in this way it is possible to minimize the negative impact of the coolant (water) on the elements of the heating system.

The sequence of actions is as follows:

- a thorough examination of the elements of the heat supply system, especially the boiler, radiators, pumps, pipelines, valves, is carried out for leaks and other damage;

- identified malfunctions are eliminated, but first the coolant is drained from the network;

- check the functioning of the automatic control systems of the electric or gas heating boiler, as well as the circulation pump and other components of the system;

- if individual mechanisms and elements are inoperative, they are repaired or replaced;

- when the repair work is completed, the system is filled with a coolant.

Thanks to these activities, the house is being prepared for the heating season at the same time. To remove air pockets from the system, shut-off valves are provided at certain points. Performing a whole range of works on your own allows you to qualitatively prepare for the future period of heat supply with minimal costs, especially since the procedure for preparing for the heating season is standard and is reflected in the corresponding instructions.

Get started now

- Check all windows. Put plastic structures in the winter mode. Replace worn seals.

- The entrance doors also need to be insulated. Metal structures do not retain heat in the house if there is no insulation.

- Apply Styrofoam sheets to the plastered exterior walls and apply a new layer of plaster.

- The attic space is insulated in a variety of ways. The easiest way is to smear the base of the attic with a mixture of clay and straw. If the premises are not inhabited, install mineral wool. For the attic room, use Penoizol. There are many ways. Choose the one that suits you best.

- Install foil screens behind the batteries to help keep your home warm.

Now your home is winter-prepared and your financial energy costs will be significantly reduced. You will find not only coziness and warmth in cold weather, but also saving the family budget if, after reading the article, follow all our recommendations.

Russia is one of the most difficult climatic countries. Many regions of the country experience long frosty winters every year.

That is why, since Soviet times, special attention has been paid to preparatory work. Preparations for the heating season 2017-2018 of heat supply facilities began in the spring of this year

Its efficiency will determine when and to what extent Russian cities will receive heat in autumn.

It is difficult to overestimate the role of preparing energy supply facilities for winter, given that most houses, schools, hospitals and buildings of other social authorities in the country are heated by the district heating system. The same goes for industrial enterprises. To control the process of preparation for the heating season, a department of fuel and energy facilities was formed. It is he who sets the program of preparatory measures on which the heating season 2017-2018 in Moscow and the regions of the country depends.

The larger the subject (city, settlement), the more extensive work is needed to prepare it for the autumn-winter period. This is due to the total number of houses and buildings.

The existing program of preparation of settlements for the heating season includes a clearly defined sequence of measures that are ordered to be carried out by the executive authorities.

The main points of this program are:

- Formation within the relevant executive state bodies of commissions for the preparation for the heating season. The main task of such commissions is to monitor the timing and scope of all preparatory activities;

- Formation of a schedule of upcoming works, including procedures for test start-up of heating systems. Such launches make it possible to identify all existing problems in heat supply systems, identify emergency areas;

- Based on the results of test runs, a general estimate is formed, which includes the costs of all future work.

In other words, preparation for the 2017-2018 heating season consists of checking existing systems and heat supply lines in order to identify emergency areas. Carrying out timely repairs and replacing outdated equipment guarantees a stable supply of heat in the autumn-winter period to all houses and buildings of social infrastructure.

We minimize heat loss before the heating season

You can check the house for heat loss using a thermal imager - this is a device that shows a picture in the infrared spectrum. Ideally, the check should be done in winter, and heat loss should be eliminated before the heating season begins.

A snapshot of a house in the infrared spectrum.

Ideally, on the screen of a thermal imager, the house should be blue - this means that it is cold outside, therefore, the heat does not leave the room. All places where heat escapes will be indicated in red or yellow. The brighter and more saturated the color, the higher the heat loss. The main places for heat leakage are windows and doors. Therefore, the replacement or at least sealing of windows and doors is performed first.

After all the gaps have been eliminated, the windows are replaced and you can proceed to the thermal insulation of the enclosing structures:

- walls;

- ceiling;

- foundation.

When the heating season ends, the insulation continues to work. Only now he does not let heat from the street into the room, so in summer it is cooler in such a house. Energy efficient houses are very popular today.

The beginning of preparing the house for the heating season

Heat supply organizations and management companies begin preparations for the heating season immediately after its end. They wash and pressurize the nets. Tests are carried out. Check and, if necessary, change valves, manometers, pipes and metering devices.

It is necessary to rinse and pressurize the nets to clean them from salts and rust. Without this, a lot of resources are spent on heating, but there is little benefit. Hydraulic tests check the strength of the network and reveal leaks. The management company and the owners eliminate them in the summer.

A complete list of requirements is contained in the Order on preparation for the heating season of the Ministry of Energy of the Russian Federation No. 103 dated March 12, 2013. It specifies the requirements for heat supply organizations and consumers.

The list of works to prepare the house for winter

Preparation housing and communal services facilities for the heating season is necessary in order to ensure timely and high-quality performance of repair and maintenance of buildings and equipment that meets the legislative standards for people living in winter.

By order of the Ministry of Energy dated March 12, 2013 No. 103 (hereinafter referred to as Rules No. 103), the Rules for assessing readiness for the heating season were approved, in accordance with which heat consumers must complete the necessary preliminary work before the next cold season no later than September 15 of this year.

Preparing for the heating season. List of activities:

- elimination of faults in walls, roofs, ceilings, fillings of windows and doors;

- correction of malfunctions in the operation of heating furnaces, gas and chimneys, heat, electricity and water supply systems;

- ensuring proper waterproofing of foundations, staircases, walls, checking the health of fire hydrants;

- bringing the territory of households to a technically sound state, removing obstacles to the drainage of melt and atmospheric waters.

The start date of the heating season is also set by local governments. They, taking into account the proposals of the organization that maintains this housing stock, determine the timing of the beginning and completion of preparations for the winter of each residential building and infrastructure facilities. End dates of events, including test fireboxes in central heating systems and stoves, depend on the location of the territory and are:

- in the central regions - by September 15;

- in the north and east - by September 1;

- in the south - by October 1.

The owner of the housing stock or the organization carrying out activities for its maintenance draws up a schedule for preparing the house and its engineering equipment for winter. This document is approved by local governments based on the results of the spring inspection of the shortcomings that were identified over the past period.

The function of monitoring the progress of work on preparing the house for winter is assigned to:

- local government bodies;

- owners of the housing stock and their authorized representatives;

- housing supervision authorities.

During the preparation of the house for the heating season, testing, calibration, repair and adjustment of all systems and devices that are involved in the process of uninterrupted heat supply to apartments are carried out. Among them:

- boiler rooms;

- local and group heating points in houses;

- intra-house networks;

- ventilation and heating systems.

We have made a convenient service with which you can draw up a schedule of preventive maintenance for the summer period. First, we will tell you how to inspect common property and draw up an act, and then using the service you can select only those works that you need and get a schedule for your MKD.

For improper preparation of MKD for the heating period, the UO faces administrative liability under Part 2 of Article 14.1.3 of the Administrative Code. The fines are big. The fines are large - up to 300 thousand rubles. for organizations and up to 100 thousand rubles. for officials. It also provides for disqualification for up to three years.

At heating units and points, as well as boiler houses, during preparation for the heating season, it is necessary to provide:

- automation equipment;

- instrumentation;

- shut-off and control equipment;

- wiring diagrams of heating systems, cold water supply, hot water supply, supply and exhaust ventilation;

- designs indicating how the equipment should be operated in various modes (filling, draining water from heating systems, make-up, etc.);

- technical data sheets of equipment;

- regime cards;

- parameter recording logs;

- equipment defect logs.

When preparing gas facilities for winter, it is necessary to adjust pressure regulators and shut-off and safety valves. Pumping stations, fire-fighting equipment systems must be equipped with basic and backup kits. In addition, it is necessary to adjust and check the serviceability of automatic switching on of backup pumps in case of failure of the main ones.

Preparing for the heating season. The following activities are carried out:

- training and retraining of personnel of workers of heating points, boiler houses, emergency services, janitors;

- preparation or restoration of diagrams of such in-house systems as gas and water supply, sewerage, etc. At the same time, for locksmiths and electricians who, in the event of malfunctions and accidents of in-house engineering systems, will participate in their elimination, the location of switches and valves must be indicated;

- preparation of emergency services (equipment, transport, communications, materials, tools), as well as briefing of personnel;

- as for unheated premises, it is important to repair the insulation of water supply and sewer pipes.

If there is water in the basements, during the preparation of the house for winter it must be pumped out, the irrigation water pipe must be disassembled after shutdown, the water meter unit must be insulated. It is equally important to do everything necessary to ensure that the inspection wells of the courtyard network, as well as sewer and general outlets at the ends of the house from the collection pipeline, which is laid in the technical underground (basement), work smoothly.

In the cold period, the air vents in the technical undergrounds and basements of the house are allowed to be closed only during severe frosts.

During the production of all these works in rooms that are not heated, they insulate the fire-fighting water supply system, check the condition and repair the insulation of sewer pipes and cold water supply, hot water supply and central heating.

Preparing for the heating season. List of actions:

- insulate the openings of windows and balconies, as well as the entrance doors to apartments;

- replace, if necessary, glass in doors and windows on balconies and in auxiliary rooms;

- insulate attic floors;

- check the serviceability of blinds and dormers;

- repair and strengthen the parapet fences of the house;

- insulate pipelines in attics and basements;

- renovate existing or produce new walkways and running boards in the attics of the house;

- repair, test and adjust central heating systems;

- repairing kitchen hearths and stoves;

- insulate boilers and smoke ventilation ducts, clean them;

- canning watering systems;

- strengthen the flag holders on the house;

- equip entrance doors with door closers;

- check the air vents in the basement rooms;

- strengthen and, if necessary, repair the entrance doors;

- insulate and restore external water columns and taps.

The schedule, which is made up for a week, a month and a year, reflects the timing of work to prepare for the heating season and their list.

Heating quality

The main criterion for the quality of heating is the air temperature in the apartment. It depends on the air temperature outside and the temperature of the water in the heating networks. According to the Decree No. 354 on preparation for the heating season, the temperature must be above 18 ° C.

To save resources and maintain a comfortable temperature in the apartment, heat supply organizations regulate the temperature of the water in the networks. If this is not done, it will be cold at home in the cold, and hot in the thaw.

The backbone networks of the heat supply organization lose heat due to slagged pipes, leaks, worn-out thermal insulation and outdated regulators. At the same time, the water temperature and pressure drop, and the heating fee is calculated according to the amount of the resource sent. The situation is similar with in-house networks. A common house heat meter helps to identify losses and reduce heating costs.

Shut-off valves

Shut-off valves must perform their main function - to shut off the flow of the coolant. If there are valves on the heating unit that “do not hold”, they must be replaced. Different sections of the system are pressurized under different pressures, and if there is an inoperative valve in the circuit, it will certainly show itself.

Valve marking

Ideally, everything should look like this: the heating point should have a diagram showing numbered and marked inlet and outlet pipelines, shut-off and control valves, drainage and drainage devices. The diagram should correspond to the state of the system at the moment, that is, if changes have been made to the system, they should be displayed on the diagram.

All of the above devices must have labels with designations corresponding to the designations in the diagram (1,2 - shut-off valves on the supply and discharge pipelines, t1 and t2 - thermometers, P1 and P2 - pressure gauges, etc.).

In practice, in small heating points, inspectors do not always focus on this. The main thing is to make it clear what is going where, for example: "supply to the left wing", "return from the right wing", "supply to ventilation", etc. But if everything is "according to Feng Shui" - this is an additional plus.

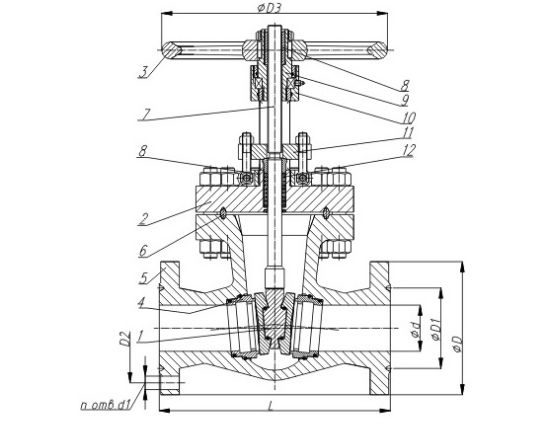

Wedge gate valves revision

Old-style gate valves require extra attention during operation.

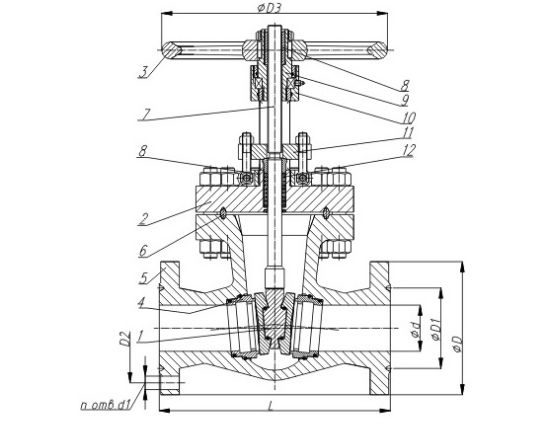

Wedge gate valve device: 1 - wedge, 2 - cover, 3 - flywheel, 4 - seat, 5 - body, 6 - sealing ring, 7 - spindle, 8 - threaded bushing, 9 - bushing, 10 - post, 11 - gland flange , 12 - stuffing box packing made of thermally expanded graphite.

In such valves, it is imperative to stuff the stuffing box every year. And within a year, if a leak occurs from the stuffing box, it is necessary to tighten the flange. If this is not done, the valve will become unusable.

To replace the stuffing box packing, loosen the nuts on the union bolts, raise the flange, remove the old packing box and fill in a new one. The seal is wound with rings around the spindle and pressed against the flange.

When tightening the flange, you need to be careful: if you overdo it, the cast iron flange can burst, and its replacement is very problematic, in practice it is easier to change the valve completely.

There should be no signs of rust on the valve. The body should be painted black, the flywheel red, and the rising stem should be greased with grease.