Today we will talk with you about induction heating. Many are trying to present induction boilers as something innovative, which supposedly will save our money and ensure the existence of our heating system. And what is it really?

In fact, induction boilers are very expensive units, large-sized, inconvenient to use and not endowed with a sufficient number of properties and qualities that are necessary for the normal operation of a modern electric heating boiler.

Those people who invent these boilers and try to sell them to you do not tell the consumer anything about these aspects of their products, but expose only positive qualities to the light. Here we will display all the pros and cons of induction heating at home.

What do induction heating manufacturers say?

Most often, manufacturers of induction heating boilers are compared with traditional ones, and traditional ones are 99% of all electric boilers on the market.

Boilers are always compared according to the following scheme: the imaginary flaws of the heating boilers and the positive qualities of induction heating of the house are highlighted.

For example, such indicators:

- There are a lot of heating elements;

- That supposedly one or even several heating elements can fail;

- It is said that the boiler may lose its working capacity;

- They pay special attention to scale, which can appear as a deposit right on the very surface of the heating elements;

- The complexity and bulkiness of the design is due to a sufficiently large number of electrical contacts;

- The creators of induction boilers claim that their boilers last longer due to the fact that they can soften the water;

- Absolutely unfounded and unfounded assertion that periodic replacement of gaskets, heating elements and risers is required.

Advantages and disadvantages

First, let's talk about their advantages.

- One of the most important advantages of using such a heating system is its durability and high quality of work. The quality of heating does not decrease, although other types of heating systems can decrease efficiency by 30 percent over the years.

- There is practically no scale formation during boiler operation. This is due to the fact that these devices are inherent in microvibrations, which, in this matter, effectively play a preventive role.

- Various types of fluids can be used as a heat transfer fluid. This allows you to choose the ones that suit you the most.

- A very significant service life of such heating boilers. In fact, it depends on the strength of the welds that are present in this design or on the quality of the induction coil. Usually it is 30 - 40 years old.

- There are practically no detachable connections in the boiler body. This factor reduces the likelihood of leakage during operation.

- Another important circumstance is that the heating system actually works in a completely autonomous mode and does not require regular inspection or repair. It can be simply purchased and installed. After that, it will work flawlessly for many years.

- If we take into account the complete quiet operation of such heating boilers, this makes it possible to install them in almost any desired place.

- Fast heating of the coolant creates a feeling of comfort when using them. It usually takes only five minutes to fully warm up.

- To conclude the list, we note that the efficiency of this heating system is relatively high.When compared with similar (heating elements) systems, the gain is up to thirty percent.

As you know, there is always a reverse side of the coin. Induction boilers, along with their advantages, have their own disadvantages.

- As you know, the circulation of the coolant can be one of two main types: forced or natural (there are also systems with a mixed type of circulation). The system under consideration has a forced circulation type. Why is that bad? For her, a constantly running pump is required, which increases the power consumption for her operation. In addition, a safety system must be provided to ensure that the boiler is shut down if the pump stops working. This is necessary in order to reduce the likelihood of an emergency.

- This structure is relatively heavy. It can be up to forty kilograms.

- Induction boilers have a higher price compared to similar heating systems.

Criticism of the wrong heating boilers

It is indicated that there are no heating elements in a high-quality induction heating boiler. Of course, this is not the case, because without a heating element we would have nothing to heat the water with, that is, it is always there in any boiler!

In the overwhelming majority of installed electric boilers, the heating element does not fail almost the entire service life of the boiler.

If the heating element still fails, then we can easily change it, since it is under the flange or on the thread. If suddenly, for no reason at all, the unit breaks down during induction heating, then it is almost impossible to replace it.

Now about the scale... It exists in a kettle, but in home heating systems it does not exist, because there water does not boil at all, deposits are present always and everywhere, in any systems: on gas, diesel, wood-burning, electric, heating, electronic, induction boilers. It doesn't matter which boiler. Sediments will always be present as these are deposits that are always present in the water. This is not a disadvantage or an advantage, but a reality.

About electrical contacts. Manufacturers write that there are no electrical contacts in an induction heating boiler. But in fact, electrical contacts are always and everywhere. And if we talk about heating boilers, then electrical contacts, terminal blocks. absent there for many years. There are electrical contacts under the screw connections that do not require tightening, and there are spring clips that are not worth servicing either.

Regarding the service life of the heating element and the numbers arguing this period. It is not clear where these figures are taken from and how they are confirmed. In addition, here the authors confuse water supply and heating systems. The heating system does not have as many impurities as there are in the water supply system. Water softening in the carrier of the heating system is not required.

It should be noted that in an induction heating boiler, the replacement of units is practically not possible at all, because everything is in a sealed flask and it must be cut in order to pull something out of there.

Pros and cons of induction boilers

Factory-assembled induction boiler

Is this type of heating really as efficient as advertised by manufacturers? Reading reviews about induction heating, it is impossible to draw an unambiguous conclusion. Many consumers complain about the high consumption of electricity, some home-made models of boilers are clearly dangerous to operate.

Before making an induction heating boiler with your own hands, select components and accessories for it - it is recommended to familiarize yourself in detail with the pros and cons of this type of heat supply.

- Rapid increase in the temperature of the coolant to the required level. Unlike the operation of heating elements, induction heating of water for heating does not require additional insulating materials. Those.thermal energy from the rod is transferred directly to the coolant;

- Long service life. This is due to the absence of moving parts and the high reliability of materials of manufacture;

- Small dimensions of the structure;

- Scale does not form on the inner walls. This is due to the slight vibration of the rod during its operation. However, if you read reviews about induction heating boilers, then no one complains about the high noise level.

But along with this, it is necessary to take into account the negative aspects of the operation of heating boilers of this type:

- High cost of factory models. Truly high-quality electric induction heating boilers are made using modern materials, the cost of which, to a greater extent, determines the high price. Therefore, home-made models are significantly inferior in quality and technical parameters to the factory ones;

- To install boilers with a capacity of more than 7 kW, it will be necessary to equip a 380 V power grid. Otherwise, the load will not allow the equipment to work in normal mode;

- In the absence of water during the operation of the induction heating furnace, overheating and failure will occur. Therefore, the design must include pressure sensors that are connected to the circuit breaker. If the pressure drops, the device will automatically shut off.

Having decided that it is still necessary to do induction heating on your own, you can start choosing the optimal boiler scheme and calculating its parameters.

The induction heating principle has been used for decades in the steel industry to heat metal. It is from this industry that induction heating boilers came from.

We reveal the main myth of induction heating

Recently, they have already stopped saying that the efficiency at induction heating higher than the efficiency of a heating boiler 2-3 times. But the supporters of the induction boiler argue that the heating boiler quickly loses its properties and goes out of service, because scale builds up on it!

It is said that the power of the heating boiler decreases by 15-20% during the year. Is it really?

Yes, deposits are not really present, but the heating system and the water supply system should never be confused. For example, scale actually forms in the water supply system, just like it forms in the kettle that we see in the kitchen every morning. This never interferes with our work, we know, and there is no doubt that water boils in a kettle anyway.

On the contrary, in the heating system known to us, impurities rarely enter the water. The deposition layer is very thin and does not pose any significant obstacle to heat transfer.

If the energy has gone somewhere from the network, it does not completely disappear anywhere. It turns into absolute heat and the heat carrier is heated, which, in turn, heats up with exactly the same efficiency as it was heated before and as it will always be heated. If it were not so, the ten would have burst with surplus energy.

As soon as scale appears, heat exchange takes place at a higher temperature. There can be no talk of any decrease in efficiency, no matter what temperature is in the heating element.

Induction water heater

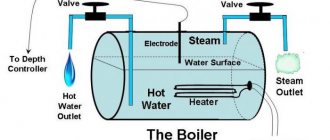

Induction water heaters have a housing and an original electric inductor (transformer) inside it, and its secondary winding is the metal pipe with water itself, in the form of a short-circuited loop.

As a result of the flow of significant electric currents in it, from the inductively induced electric voltage in it, this pipe heats up intensively and heats up the water in it with its heat.

In a nutshell, how does an induction heater work-

this is a step-down transformer installed in a pipe

At first I decided that if the name contains the word "induction" then heating occurs by high-frequency currents like in a microwave oven, it turned out that it does not.

There is no high frequency at all, power supply from a network of 220/380 volts at an industrial frequency of 50 Hertz.

The technology is actually very simple - there is an ordinary coil in a shielded pipe - it is, as it were, the primary winding of a transformer, if we draw an analogy with a transformer.

The role of the secondary winding, and at the same time the magnetic circuit, is performed by the metal heating pipe!

The cost and maintenance of induction heating boilers

Induction heating boilers are 2 times more expensive than heating boilers. Despite the fact that they are qualitatively lower, as we saw from a critical analysis of their so-called "advantages".

They also weigh 2 times more than heating boilers, have large bulky dimensions, and all the electronic filling is outside. While in heating boilers, it is hidden in the boiler itself. And here there is an additional box, which sometimes there is nowhere to place, especially when it comes to a very small room for a boiler room.

In induction boilers there is no automatic power selection, that is, only a heating element boiler can choose itself at what power it needs to work at the moment.

With induction heating at home, there will be constant voltage surges and overloads, and in heating boilers, the relay works very quietly. And you can only notice it as quiet clicks, being next to a working boiler.

Even in induction boilers, thermal protection for overheating and freezing is completely absent, which is available in heating boilers.

There are no low water pressure sensors in induction heating boilers. There is no error indication that allows you to accurately establish the malfunction due to which it got up (the corresponding indicator will blink on the display of the heating boiler).

But the most important thing that induction boilers do not have is the ability to connect a boiler!

Another option for an induction boiler

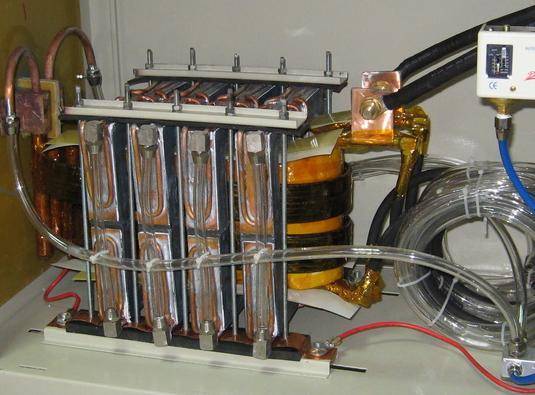

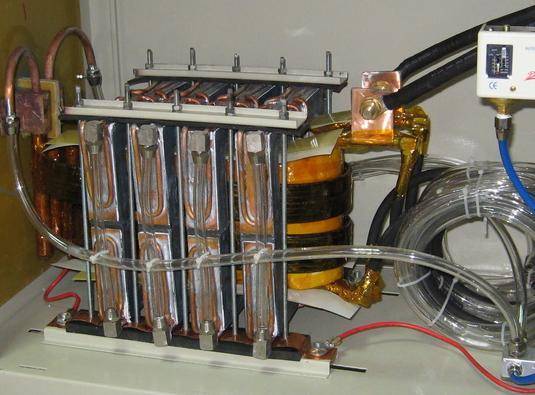

There is another option for creating an induction boiler with your own hands. Such inductive heating boilers, of course, will cost a little more, but their efficiency will be higher.

It will be a little more difficult to make such a boiler than the previous version. You will need skills in working with a welding machine, the presence of a three-phase inverter, which would preferably be fixed permanently, as well as some tools.

Homemade induction boiler

Note that the design of this version of the induction boiler will consist of two pipes that will be welded into each other. If you look from the side of the end, then this design will remind you of a donut. At the same time, the device will be both the core, which will create an electromagnetic field, and the heating element.

The copper coil is wound directly onto the boiler drum. Thanks to this, increased productivity will be achieved, while the relatively small size and weight of the device will be preserved. To supply and remove the heat carrier, special pipes are welded into the inductor.

When you assemble such induction boilers for heating a house, several recommendations and installation requirements should be considered:

- A device such as an induction boiler can only be installed in closed heating systems that are equipped with a circulation pump.

- The device can also be installed in systems that use plastic pipes.

- There should be at least 30 centimeters of free space between the induction heating system and walls (or pieces of furniture, household appliances). And from the ceiling and floor, such devices are placed at a distance of 80 centimeters.

Of course, you will have to work a little more and more difficult on this version of the boiler, but the effect that will be achieved in the future will delight you.Such an induction boiler, as the reviews show, is a truly productive device that can not only provide you with high-quality heating of your home, but will also serve you for at least 25 years without maintenance.

Homemade induction boiler connected to the heating system

The use of induction heating boilers provides users with many advantages. Among them, several should be noted:

- First of all, it is the ability to work with alternating and direct current.

- Such a device simply does not have such heating elements that will wear out.

- The design of the device is extremely simple.

- It is not required to take a separate room for installation. All induction boilers belong to the 2nd class, according to fire safety.

- The efficiency of both home-made and factory induction boilers is almost 100% (usually 98-99%). Compared to traditional heating systems, this is just an excellent result.

- Several types of heat carriers can be used, and the induction boiler will not suffer any harm. So, you can use not only water, but also work with oil and antifreeze.

- Making an induction boiler yourself will not be difficult for you, and at a cost it will turn out to be very cheap.

Thus, modern induction boilers are devices that belong to the technology of a new generation. These are not only practical devices, but also powerful and economical ones. They are able to heat not only an ordinary country house, but also a large industrial premises. With all this, you do not spend money on complex installation and maintenance of such devices.

To buy or not to buy an induction heating boiler?

Of course, you yourself must make a decision for yourself which boiler you should buy: a high-quality heating element or still a more bulky, less efficient and expensive induction boiler.

But you must consider the following: an induction boiler is not a unit for heating systems, especially if they are individual and do not require large capacities. Of course, it is impossible to do without induction heating in some industrial areas of technical production, but this applies to production tasks.

Still, there is nothing to drag a complex, heavy and expensive unit into your house. You can get by with a more elegant solution - a heating boiler.

Manufacturers of induction heating boilers deliberately give incomplete information about their products, which misleads those who make a choice in the direction of one or another boiler. It is important here to tell the truth and show your product from all angles so that people know what they are buying.

Overview of manufacturers and models of induction boilers

For you, we have prepared an overview of manufacturers of induction heating boilers, as well as some of its models.

VIN

It has many models and thus provides a huge choice for the consumer. The power of VIN heating boilers is from 3 kW, the heating area is from 30 m², the starting price is from 32,000 rubles.

VIN models are called vortex models. Their difference in power supply: the first winding, which is already converted and high-frequency, the strength of the electromagnetic field is amplified due to Foucault currents. The specifics of the manufacture of the boiler body and heat exchanger are also taken into account. Ferromagnetic alloys are used for their manufacture.

Consider the features of the models of boilers of this manufacturer in the table.

| Model | Heating area, m2 | Mains voltage, V | Average cost, rub |

| VIN-3 | 30-40m2 | 220 | 32000 |

| VIN-5 | 50-60 | 220 | 33000 |

| VIN-7 | 70-90 | 220 | 37000 |

| VIN-7 | 70-90 | 380 | 46000 |

| VIN-10 | 100-120 | 380 | 50000 |

| VIN-15 | 150-170 | 380 | 46000 |

| VIN-20 | 200-230 | 380 | 60000 |

SAV

The characteristics of the SAV heating boiler are ease of use and installation, environmental friendliness, automatic operation, durability. There is practically no possibility of scale formation, and there are no parts that move and are subject to wear.

Models of the SAV company have their own peculiarities of work. The first winding of the induction heater from the boiler power supply is supplied with prom / voltage, 220/50. The second winding takes place in a closed loop. Liquid moves along it. It is part of the heat exchanger in which the heating medium of the heating system is heated. In addition to water, antifreeze may also work.

Since the current rapidly increases the temperature of the circuit, the efficiency of all boilers is very high.

| Model | Power, W | Mains voltage, V | Average cost, rub |

| 2,5 | 2100 | 220 | 32 950 |

| 3,5 | 2950 | 220 | 35 100 |

| 5 | 4235 | 220 | 37 000 |

| 5/2 | 4235 | 220 | 42 500 |

| 7/2 | 5970 | 220 | 45 000 |

| 7/3 | 5970 | 220/380 | 52 000 |

| 10 | 8750 | 220/380 | 55 000 |

| 15 | 12670 | 220/380 | 65 000 |

The disadvantages of the induction boiler "SAV" include the high cost. The price of models of such a boiler ranges from 32,950 to 65,000 rubles. Two more disadvantages are dependence on electricity and the difficult process of adjusting power.

Geyser

There are many models from this manufacturer. They are distinguished by their high performance. The power range is from 4.5 to 250 kW, and the efficiency reaches 98%.

The Geyser-5 model requires a mains voltage of 220 V, the rest of the main models (10, 15, 20, 25, 50, 100, 250) - 380 V.

The uniqueness of this model is in its reliability, as evidenced by the reviews. These boilers are stable and have a second class for electrical safety. They do not require special maintenance, and due to the absence of combustion products, there is no possibility of getting harm to health. Geyser boilers are small in size, so the unit can be installed in a small space. The model works quite quietly, so the owners do not have to use materials for sound insulation.

As a minus, the complex installation and connection of the Geyser boiler can be noted. All models of an induction heating boiler need 380 / 3ph. Only boilers with a low power of 220/50 can work from the network.

Edison

This brand is used for heating residential premises, as well as industrial, administrative buildings, etc. Its models are different (4.7; 13; 22; 50; 100; 250; 500). Such an induction boiler is used in closed heat supply systems. As a rule, water acts as a heat carrier. The heater operates “automatically”, but if desired, you can change the operation of the heater either by the temperature of the coolant or by the temperature of the air in the building.

Cauldron Edison

The Edison boiler has more positive characteristics than negative ones. Its advantages include a long service life, high electrical and fire safety, as well as a constant efficiency factor during operation. In addition, when buying this boiler, you do not need to constantly monitor it and constantly maintain it.

Some more characteristics of the Edison heating boiler:

- current frequency 50 Hz;

- the maximum temperature of the coolant in degrees - 115;

- the weight of the equipment ranges from 40 kg ("Edison - 4.7") to 1500 kg ("Edison - 500").

- use (with the consent of the manufacturer) of various heat transfer fluids, such as oil, water, antifreeze.

Miratron

The range of these boilers has a power ranging from 6 to 30 kW and is also suitable for heating industrial and residential premises (up to 350 m2).

Cauldron Miratron

Here are some more characteristics:

- efficiency factor of the heating boiler "Miratron" 90%;

- excellent protection against limescale;

- correct energy consumption and saving the user's budget;

- connection to any type of electrical network;

- works very quietly and does not require constant supervision;

- work only with closed heating systems;

- the use of an inverter starter in control and, as a result, the high cost of equipment;

- large weight and dimensions of the boiler.

The cost of the heating boiler "Miratron" is different. For example, the model "Miratron A006" with a power of 6 kW, a heated area of 70 m² and weighing 50 kg has a price of 45,000 rubles. "Miratron A006" with a power of 15 kW, a heating area of 170 m² and a weight of 80 kg - 65,000 rubles.

Comparison of popular models

Let's compare some models of different manufacturers of induction heating boilers with similar characteristics.

| Name | Power, W | Cost, rub. | Country of Origin | Heating area, m2 |

| VIN-5 | 4250 | 27 000 | Russia | 60 — 150 |

| Edison 5 | 5000 | 35 000 | Russia | 100 — 120 |

| INERA SAV | 4500 | 30 000 | Russia | 50 — 80 |

There are also heating elements and electrode electric boilers on the market.

Expert review of an induction heating boiler

One of the leading Russian experts in the field of boiler installation and maintenance in Russia Vladimir Sukhorukov in one of his YouTube programs "Induction boiler - a big misunderstanding", released on December 12, 2020, he proved in detail and in detail that induction heating boilers are inferior to traditional heating boilers.

Vladimir Sukhorukov found no reason to use an induction boiler in a boiler room. Moreover, he strongly advises not to buy induction boilers under any circumstances when there are high-quality heating boilers that work stably and smoothly.

Perhaps you need to heed the advice of an expert.