Purpose of tape heaters

Heat consumers are interested in the heating system to be easily and quickly installed, to be cheap to maintain and operate. The same cannot be said for heating boilers with liquid heat transfer fluids, pipes and radiators. They require considerable funds and efforts to install and maintain the system in working order during operation. The more complex the system, the greater the likelihood of failure of its individual elements.

Manufacturers produce several types of tape heaters, which are installed depending on the location conditions and the functional purpose of the premises.

Band gas infrared heaters are used to heat large rooms with a large area:

- production workshops;

- warehouse hangars;

- greenhouse complexes and other commercial and industrial facilities.

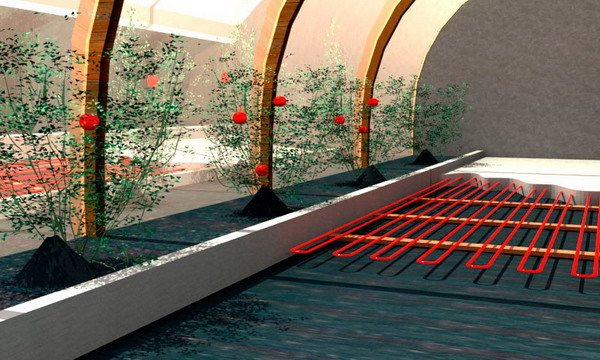

Example of tape installation in a greenhouse

Flexible band electric heater is widely used in various fields:

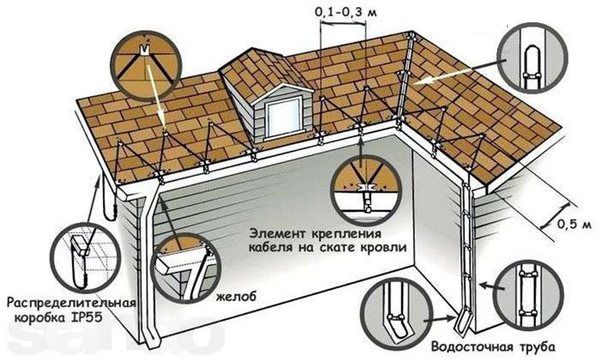

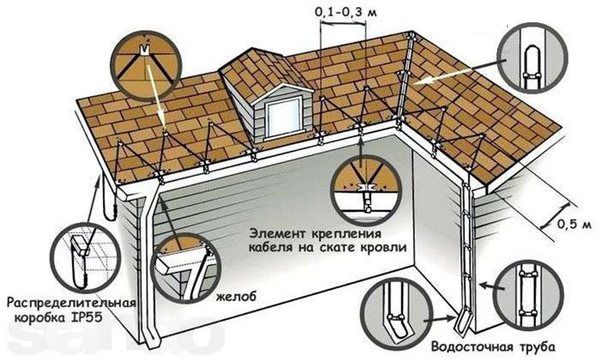

- Heating in order to prevent snow accumulation and freezing of icicles on the roofing of buildings;

Roof heating

- For heating pipes of drainage structures;

- Technological heating of individual elements of equipment on the line to ensure the production process;

- Protects the pipeline in certain areas from freezing;

- To maintain the set fluid temperature in the tanks.

Heating downpipes

The heating tape is used to heat the steps on the thresholds of buildings, paving slabs, protecting these places from icing in the cold season. Such measures reduce the risk of injury and labor costs for removing snow, ice and sanding. It is impossible to list all the options where tape heating elements are used, it depends on the engineering imagination of the personnel who solves certain technical problems.

Which wall mounted energy saving home heaters are better?

When making a choice and giving preference to one or another type or model of wall heaters, the following factors should be taken into account or the following questions should be answered:

- What thermal power should it have? The more power, the faster the room heats up. But, on the other hand, the more powerful the device, the more expensive it is and it requires an appropriate wiring cross-section. The thermal power of any electric heater is directly related to the electric one. Therefore, if you are promised that the heater consumes 1 kW of electricity, and its thermal power is 1.5 kW, then this, to put it mildly, cannot correspond to reality, the efficiency cannot be more than 100%, the law of conservation of energy has not yet been canceled. This is not a heat pump.

- How quickly should it heat up the room? For example, if you need to very quickly heat a room or some of its zone, then it is better to choose one of the infrared heaters. If the heating rate is not a big deal, other options can be considered.

- Should it heat the entire room or just create a separate comfort zone? To heat the entire room, it is better to use heaters with predominantly convector heating (convectors, radiators), and infrared to create a comfort zone.

- How safe should a heating device be and what is the permissible temperature of the case? The safest in terms of body temperature are convector heaters. If there are small children in the house, then it is better to give preference to this type of heating device.

- Will the heater be used as primary heating or as an additional (backup) heat source? If this is the main heating, then it is necessary to choose more powerful heaters with thermostats, sensors and all sorts of useful options. If this is an additional source of heat, then you can choose a less powerful and, accordingly, cheaper, without unnecessary options.

- Will it be used in a house where they live permanently or periodically, for example, in a country house?

- How much are you willing or able to allocate for such a purchase? The choice of the type of heater, manufacturer, and hence the quality and availability of various useful options in it also largely depends on this.

After you find the answers to these questions, it will already be clear to you which of the types of wall-mounted energy-saving heaters discussed above is most suitable for your home.

Types of tape heaters

Band heaters are divided into two main types according to the method of generating heat:

- gas band infrared heaters;

- electric tape heaters;

Gas infrared heaters

Infrared heaters were tested in the Soviet Union back in the fifties of the twentieth century. Due to the ideological concept, individual heating systems were not approved, preference was given to centralized heating systems. In the west, these technologies have been widely developed, several types of infrared heaters have been developed, one of them has a tape structure.

The design of a gas belt infrared heater can be divided into two components:

- Heat source - gas generator;

- Composite modules with tubes of a special coating structure, ensuring the maximum effect of infrared radiation.

Gas band heater design

The modules are assembled according to the principle of a children's Lego constructor, they can be installed indoors, giving any shape for pipes. The heating main is easily assembled, bending around obstacles, and is brought into a heated area.

The pipes form a closed loop through which the combustion products from the gas generator circulate. This ensures uniform heating around the entire perimeter. Depending on the functional purpose of the facility, the gas burner can be located outside or inside the building.

Advantages of a gas infrared heater:

- Versatility of application, for almost any premises

- Simple and fast installation technology;

- Complete autonomy of the heating complex;

- Low fuel consumption and long service life;

- No need for maintenance during operation;

- Short start-up time, exit and change to the required temperature regime, the system is not inertial.

The range of heating pipes during operation is 150-250 ̊С, there is no forced ventilation for uniform movement of hot air, a centrifugal fan is used.

Electric band heaters

Almost all band heaters have the same structure: the high resistance wire is covered in a heat-resistant, waterproof sheath. Electric current causes heating of wires, passing through a closed circuit with high resistance, heat is transferred through the insulator to the surrounding space, heating the air.

There may be structural differences in different brands of tape:

- by the number and diameter of wires in the tape;

- the structure of the metal and the value of the resistance of the wire;

- on the structure and material of the used outer insulating shell and other technical features.

Types of electric wall heaters

They are classified by three criteria.

Heating method: convector, infrared, flexible

The following types of devices are distinguished:

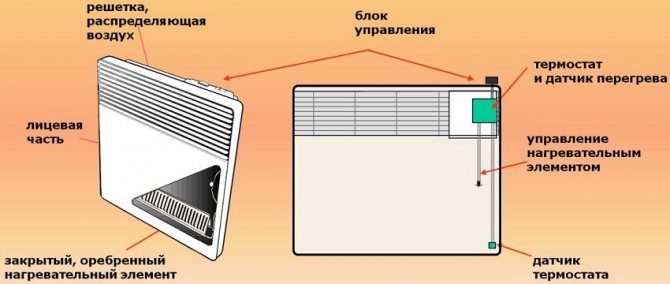

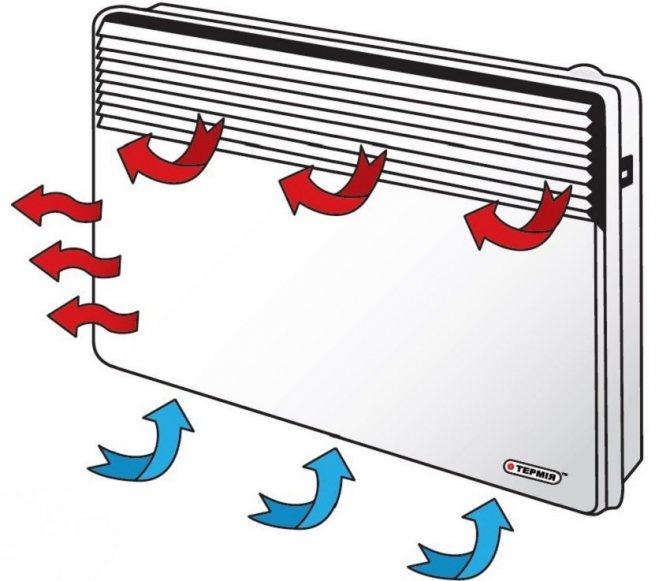

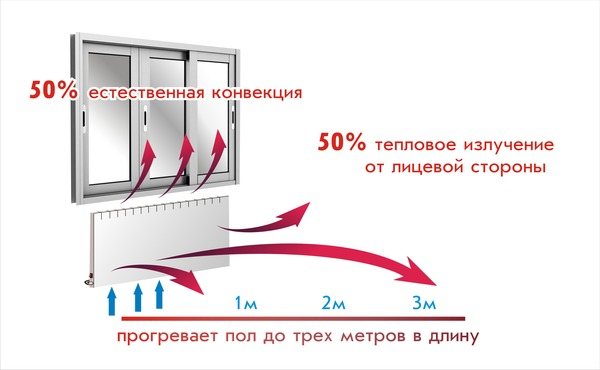

- Convection... They resemble an ordinary radiator with flat fins that set the direction of movement of heated air masses. The heat exchanger is located at the bottom of the entire installation.

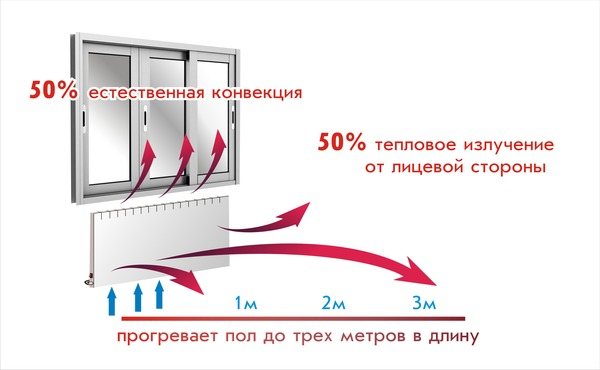

Photo 1. Operation of a wall-mounted convector-type heater: the movement of air masses provides heating.

- Infrared. Radiated heat is a consequence of the action of directional light radiation. Such units are able to cool down quickly after shutdown. The principle of their work is to heat the furniture to which the radiation is directed. The rest of the living space also receives heat from it.

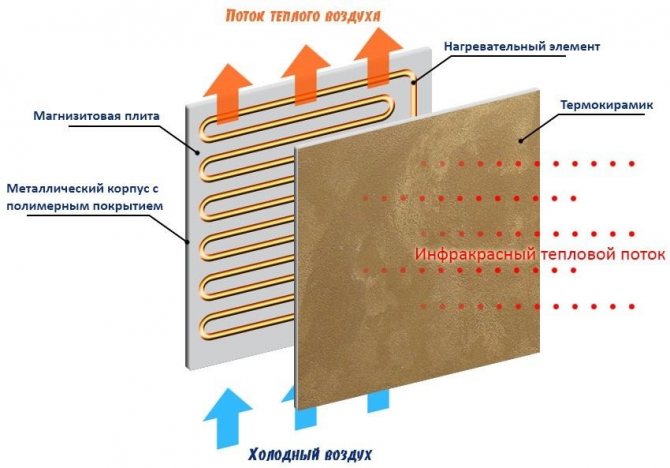

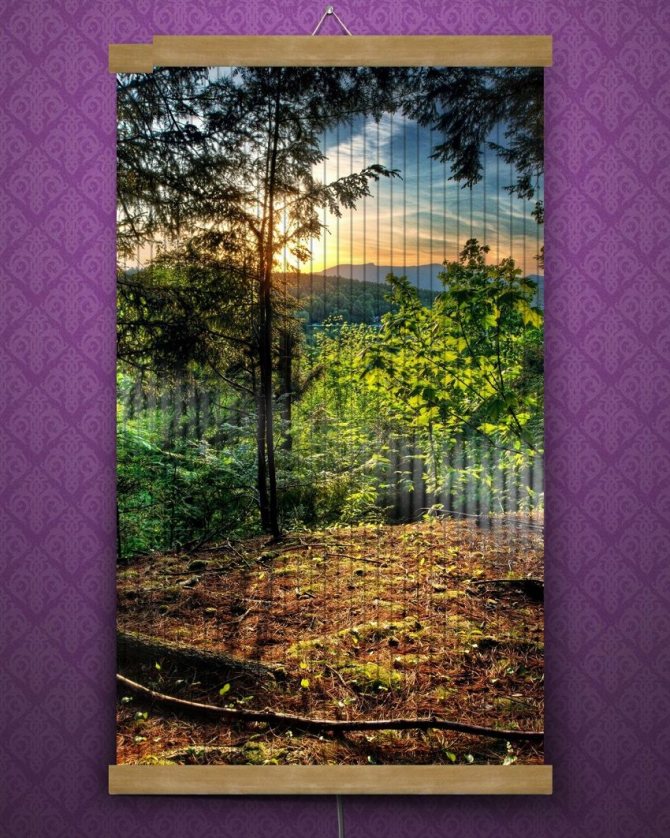

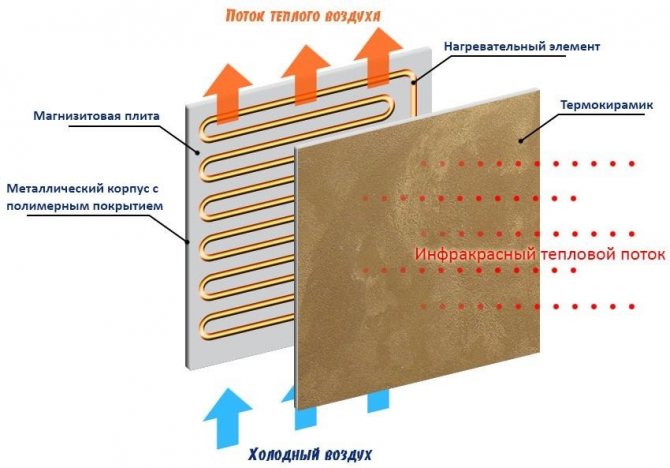

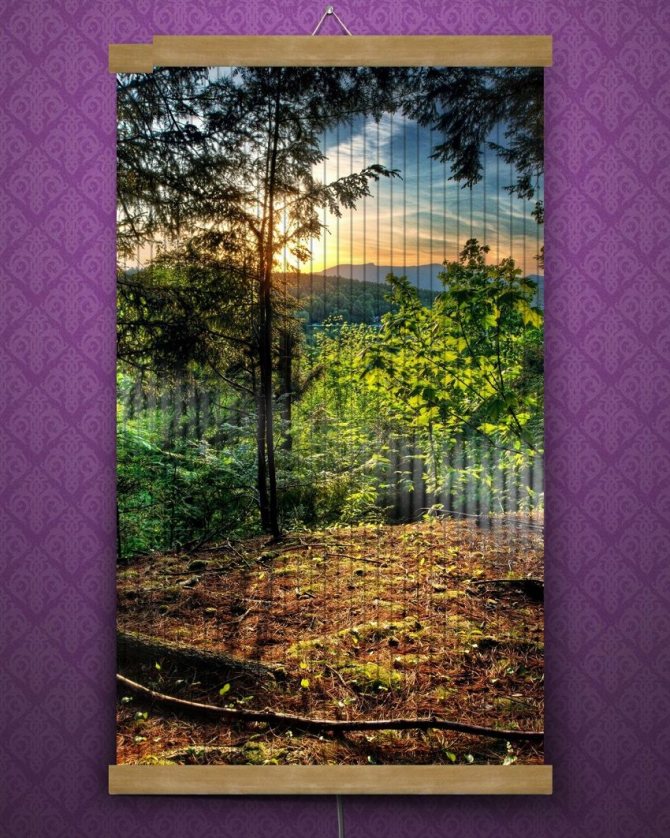

- Flexible... They are a great addition to the existing interior, as they are made in the form of paintings or panels. Heating element covered with foil, which is distinguished by high-quality electrical insulation and heat resistance. The principle of operation of the devices is as follows: after connecting the heat source to the outlet, after a few minutes, heat waves begin to radiate. Objects are heated, and then the air itself.

Photo 2. Flexible wall heater "Velvet Season" with a heat-emitting film, 200 watts.

Heating element configuration

There are the following varieties of heating lamps:

- Tubular. A wall-mounted energy-saving heater with such a heating lamp will look like a body consisting of a reflector, a flat lamp, and a heating element. The latter can be made from carbon fiber or contain tungsten filament.

Attention! When fixing such a device, it is important to understand that its location necessary define yourself.

- Panel.

- Film.

The last two types are energy-saving wall IR heaters... They can look like a panel with hydrocarbon fiber as a heating element, or as a flat picture that carries out heating. due to carbon... Both of these varieties complement the interior.

Temperature control

You can buy:

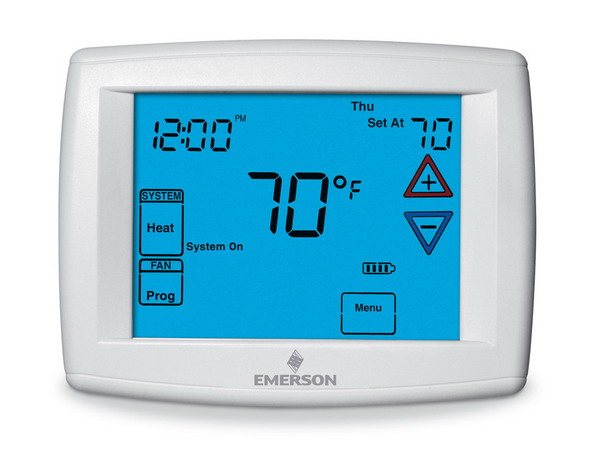

- wall heater with thermostat;

- appliance without regulation function.

With a thermostat the program will control the work itself wall heater, monitor temperature and power consumption. As the room cools automatic heating will start.

Thermostats have two varieties:

- thermostats mechanical type;

- thermostats electronic type.

First the option is relevant in the event that if there are frequent failurescaused by voltage surges. If there is no such problem, then it is preferable to use second option. This device is capable of working offline.

Composition and properties of high resistance wires

The following requirements are imposed on wires in tape heaters:

- High heat resistance and resistance to oxidation at high temperatures;

- Ability to withstand mechanical stress at high temperatures;

- Stability of electrical parameters (resistance) at high temperatures;

- Maintaining wire Ø dimensions to avoid changes in power consumption.

It might be interesting

Thermal insulation

Distinctive features and variety of ceiling tiles ...

Thermal insulation

How to insulate the ceiling in a wooden house?

Thermal insulation

What is a heating cable?

Thermal insulation

Warm "pie" for a metal chimney

To fulfill these requirements, a heating wire made of nichrome alloys is best suited, double or triple nichrome is often used. The alloy of double nichrome contains 20% nichrome, the remaining 80% is nickel, these are high-quality, but expensive wires. The ternary alloy contains 12-14% nichrome, 60% nickel, the rest is iron impurities.

Wires with increased heat resistance are made of iron-chromium-aluminum alloy: 12-13% chromium, 82-84% iron and 3-5% aluminum; if nickel is absent, such an alloy is called fechral. Chromium oxide is applied to the outer layer of the wire, as it has high heat resistance, protects the inner part of the wire from oxidation and destruction.

Depending on these characteristics, the functional purpose and operating conditions of the tape are determined.

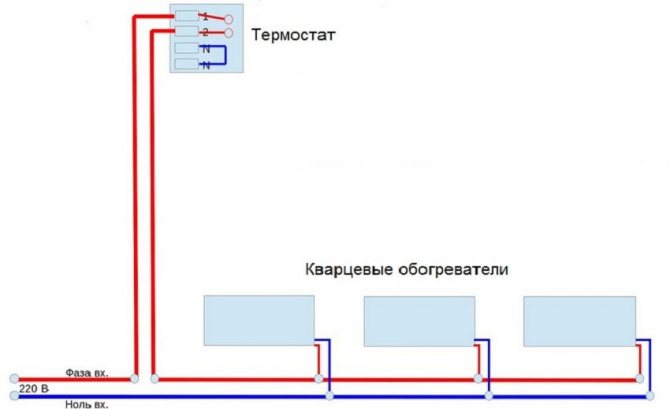

Quartz Wall Mounted Energy Saving Heaters for Home

Quartz Heating Wall Panel

This is another type of modern wall mounted energy saving heating panels. They represent a slab of quartz sand, in which heating elements in the form of metal spirals are located. Electric heating elements first heat the contents of the panel, which in turn accumulates this heat and releases it into the room. Due to this specific heating, such quartz panels have a fairly large thermal inertia. In order for such a stove to fully heat up, it takes from 15 to 25 minutes. Therefore, it will not be possible to heat the room instantly with such a heater. On the other hand, a heated panel can retain heat for a long time and heat up the room even when it is disconnected from the power supply. The maximum surface temperature of the slab is 95 ° C. If there are children in the house, then such heaters must be protected with special screens or suspended at such a height that the child cannot reach.

Heating of the room occurs mainly as a result of air convection, but infrared radiation from the panel is also present, like from any heated object. This is essentially the same "dry" electric convector, but with the difference that the heating element heats the air not using an aluminum heat exchanger, but through quartz sand. As a result, the temperature of contact of the heated surface with air decreases and dust is practically not burned, and the inertia of the device increases.Such wall-mounted energy-saving quartz heaters are best used for a house in which they live permanently and in which it is necessary to maintain a constant comfortable temperature.

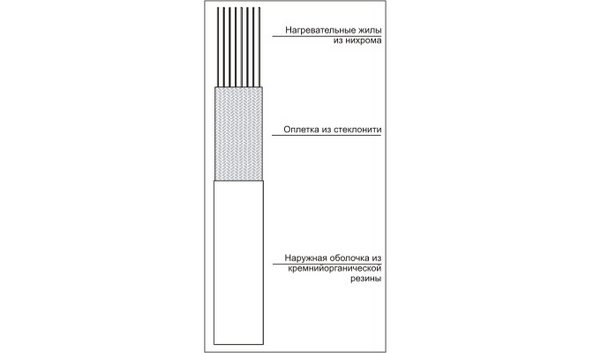

Flexible tape heater ENGL-1

At the heart of this tape are eight strands of nichrome wire, they are covered with silicone rubber, the outer shell is made of fiberglass for better thermal conductivity. Silicone rubber provides good flexibility and moisture insulation.

Belt heater ENGL-1

The heater has a calculated length and a sealed tip; it is forbidden to cut it into pieces. Manufacturers, at the request of the customer, produce tapes of various lengths and power consumption, but not more than 100 W per 1 m. It is very simple to install and connect, no special training is required.

Main technical characteristics:

- power supply from the 220V network;

- width - 24 mm;

- thickness - 3 mm;

- working temperature on the surface of the outer shell 180-250 ̊С.

It is recommended to use the tape for heating elements on production lines and heating roofing.

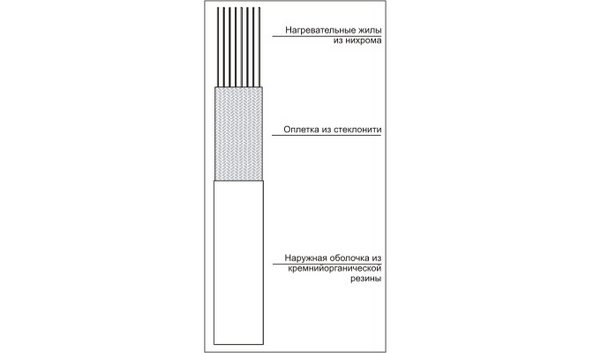

Band heater ENGLU-400

The heater contains eight strands of nichrome wire, the outer insulation contains three layers, the glass cloth of the first and second layers is impregnated in an organosilicate solution. Produced in certain sizes, not cut, the end is hermetically sealed with a cap.

Main technical characteristics:

- maximum operating temperature - 400 ̊С;

- power supply - 220, 24, 12 V, depending on the model;

- the length of the low-temperature leads for connection to the network is 70 cm.

Specification of some tape models ENGLU-400

| Ribbon brand | Supply voltage, V | Length | Power consumption, V | Working temperature, ° С |

| ENGLU-400 | 220 | 3 | 0,9 | 400 |

| Width - 21 mm, thickness - 1.9 mm, bending Rmin - 10 mm | 220 | 3,7 | 0,7 | 260 |

| 220 | 4,1 | 1,2 | 400 | |

| 220 | 5 | 1 | 260 | |

| 220 | 6 | 1,8 | 400 | |

| 220 | 7,4 | 1,5 | 260 | |

| 220 | 8,3 | 2,5 | 400 | |

| 220 | 10 | 0,5; 1; 2 | 70-260 | |

| 24 | 1 | 0,23 | 260 | |

| 24 | 1 | 0,12 | 200 | |

| 24 | 1,5 | 0,34 | 260 | |

| 24 | 1,5 | 0,15 | 170 | |

| 24 | 1,5 | 0,085 | 120 | |

| 24 | 2 | 0,46 | 260 | |

| 24 | 2 | 0,25 | 200 | |

| 24 | 2 | 0,11 | 100 | |

| 12 | 1 | 0,23 | 260 | |

| 12 | 1,5 | 0,15 | 170 | |

| 12 | 2 | 0,11 | 100 |

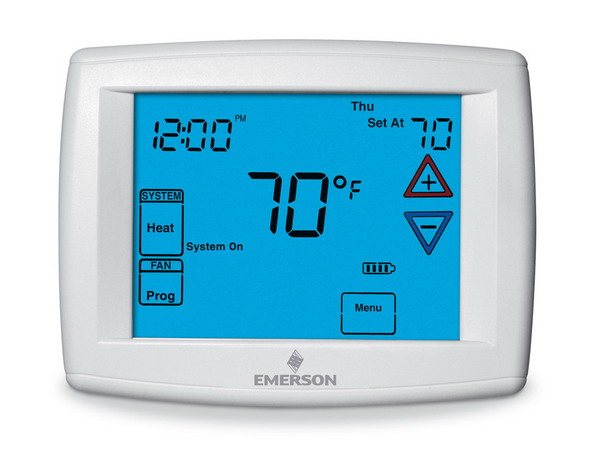

This tape is recommended to be used on industrial technological lines, for heating asphalt, bitumen, in order to keep tin and other low-melting metal alloys in a liquid state. They are successfully used for heating molds in injection molding machines. To set a given temperature in electric circuits with a tape of the ENGLU brand, thermostats of various types are used.

Thermostat appearance

Self-adjusting heating tape

The peculiarity of this tape is the use of a semiconductor film matrix between two copper conductors. The resistance of the semiconductor changes with the ambient temperature. With decreasing temperature, the resistance of the matrix decreases, the current and heating temperature increase. When the temperature rises, the opposite process occurs.

Technical characteristics of self-regulating heating tape HTM 10-15 W / m:

- working temperature - 65 ̊С;

- the maximum allowable temperature is 85 ̊С, but not more than 1000 hours;

- power supply from a 220V network, there are models designed for 110V.

A semiconductor film matrix with copper conductors is coated with a layer of modified polyopheline for tightness against moisture. For mechanical protection, a braid of tinned copper wire is put on the tape, which is grounded during installation. This measure eliminates electric shock in the event of a short circuit, the outer shell is made of ordinary PVC materials.

Self-regulating heating tape structure

It is recommended to use this tape for heating individual sections of water supply pipelines, roof coverings, sidewalks and steps at the entrance to buildings. Tapes are successfully used in "warm floors" technologies.

The advantages of self-adjusting tape are obvious:

- Automatic temperature control;

- Economical mode of consumption of electrical energy;

- Only those parts of the chain are heated where the temperature is too low;

- The ability to cut the tape into sections of the required length;

- Light weight, flexible, easy to operate and easy to lay during installation.

The properties of the film matrix make it possible to heat individual areas where the temperature is lower than the set one. This mode of operation significantly saves energy consumption.

One of the examples of practical application of HTM 10-15 W / m is for heating pipelines.

An example of attaching a heating tape to pipes

The tape is securely fixed along the pipes with plastic clamps, after which heat insulation and an external protective shell (plastic corrugated tube) are to be put on the pipes. The ends of the wires are connected to the network in the junction box, from where the line goes to the circuit breaker in the distribution board (switchboard).

The tape must not be attached to moving elements of structures; for safe operation, the tinned shielding sheath must be connected to the ground loop. In the tape circuit, it is connected to an RCD located on a din-rail in the distribution board, the leakage current of the protective shutdown is 30 mA.

The matrix begins to pass currents to heat the tape at a temperature of +5 ̊С, the maximum temperature is 85 ̊С. If there is no need for high temperatures, in order to save energy, it is allowed to install a thermostat in the circuit, limiting its maximum temperature to 50 ̊С.