Here you will find out:

- Disadvantages of other devices

- Infrared heaters - principle of operation

- Advantages and disadvantages

- Varieties of infrared industrial heaters

- Scope of application

- Popular models of IR heaters

Heating industrial and industrial premises is a problem - not every heating device will be able to efficiently heat large volumes, including those with high ceilings. The way out of the situation is industrial infrared heaters, which are optimal for use in large rooms. Let's see what these heaters are, how they work and what are their advantages.

Disadvantages of other devices

Heating in industrial buildings is often based on classic radiators and bulky registers made of large-diameter pipes. But if the room has a large area, then heating it will be somewhat difficult - high ceilings and too large a distance between the walls affect. Let's see in what other ways we can heat industrial premises:

The use of diesel heat guns requires a lot of space, and the high noise level and the need for ventilation make this method rather inconvenient in many rooms.

- Using gas heat guns is an excellent way out of the situation, allowing you to pump heat into large rooms. The downside is that these devices require a source of liquefied gas;

- With the help of diesel heat guns - these devices are often used for industrial premises, but they require good ventilation, which is necessary to remove combustion products;

- Using convectors is not the best option, it is only suitable for small workshops. The thing is that the height of the ceilings in this case should not exceed 3-3.5 meters. A different type of heater should be used in taller buildings.

Therefore, the best industrial space heater is an infrared device that works by means of infrared radiation.

Another disadvantage of the cannons is the increased noise level - they buzz perceptibly. Also, they are not environmentally friendly.

Varieties of industrial gas infrared emitters

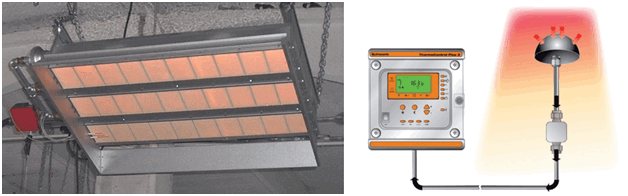

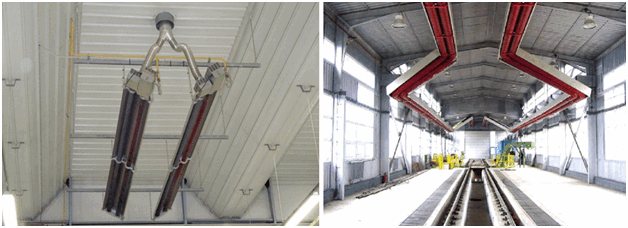

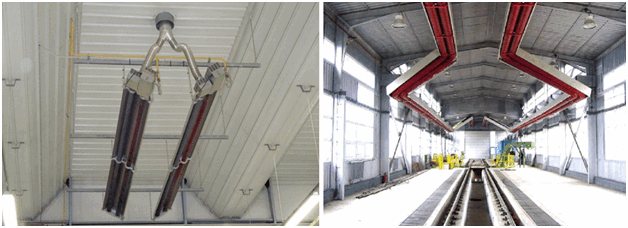

Heaters on a real site

The sun warms up the Earth with infrared rays. A natural heat source is the most efficient and versatile heating system available. The only drawback of the sun is that it cannot shine around the clock and cannot be regulated. The rays heat the earth's surface, water and solid objects, from which heat enters the surrounding air. Infrared gas heaters also work according to this principle, in contrast to traditional counterparts that directly heat the air.

Gas emitters are divided into:

- light, equipped with an open burner;

- dark, with a gas burner block.

In the first case, the heaters are not provided with an organized removal of combustion products, and the temperature of their radiating surface is more than +600 degrees. In the second case, the exhaust gases are orderly removed outside the premises, and the radiating surface during operation is heated to a temperature of less than +600 degrees.

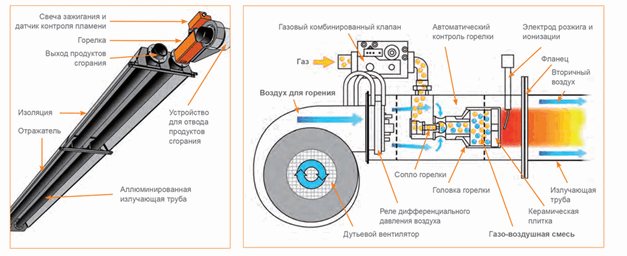

The design of the IR gas emitter intended for industrial facilities includes:

- gas burner block;

- heat-reflecting layer;

- emitting screen;

- control system.

The principle of operation of the device is quite simple. The emitting surface heats up from the action of the gas combustion products on it, after which the transfer of heat in the form of radiation to objects located in the zone of action of infrared rays begins.

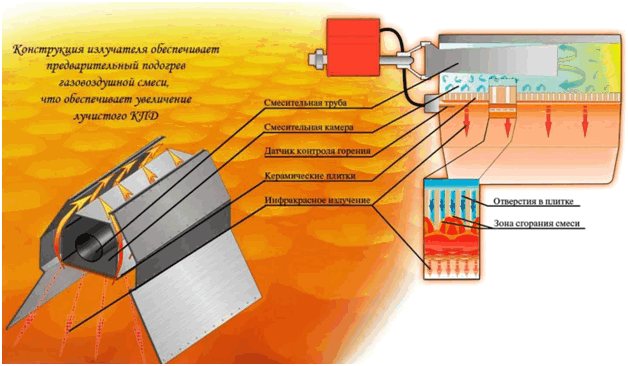

Light emitters

Manufacturer Schwank

The equipment belongs to highly efficient and high temperature heating systems. Light gas heaters are intended for installation in rooms with a ceiling height of at least four meters. Their calculation is based on the condition that for every 20 cubic meters of volume, one kW of the radiator's thermal power is required.

The principle of operation of such heaters is the combustion of the gas-air mixture on the surface and inside the burner at a heating temperature of about 800-1000 degrees. The gas jet exiting the nozzle sucks air from the room into an annular air intake. The resulting gas-air mixture enters the pressure equalization chamber, and then through the through holes into the combustion chamber.

In the design of light emitters, there is no organized exhaust gas removal system. To remove combustion products, either a gas outlet or artificial exhaust ventilation, but more often supply and exhaust ventilation, is provided.

Light gas infrared heaters are the best option for high mechanical, foundry and blacksmith shops. They are allowed to be used in rooms with high humidity and dustiness. The devices insignificantly increase the load on building structures, therefore, they do not need to be installed on additional support frames. Often, light emitters can be found, for example, as panel heating systems on tennis courts, or in camp pavilions.

Infrared heaters - principle of operation

Our natural luminary called the Sun does not warm the air at all, as it might seem at first glance - it warms up for completely different reasons. It delivers infrared radiation to the Earth's surface. This radiation, reaching the surface of the planet, landscape elements and artificial buildings, is absorbed by them and turns into heat.... In principle, we can call infrared rays thermal, although this is a bit different.

We go further - objects located on the surface of the planet (including the surface of the earth with landscape elements) begin to give off heat. It is this heat that heats the air and the objects around us, buildings and much more. With an increase in altitude, air cooling is observed, since it simply has nowhere to take heat from. Therefore, at the heights where the planes fly, a terrible cold reigns, reaching marks of -50-60 degrees and even lower.

Industrial heaters, which are based on sources of infrared radiation, work in a similar way. Here's how they work step by step:

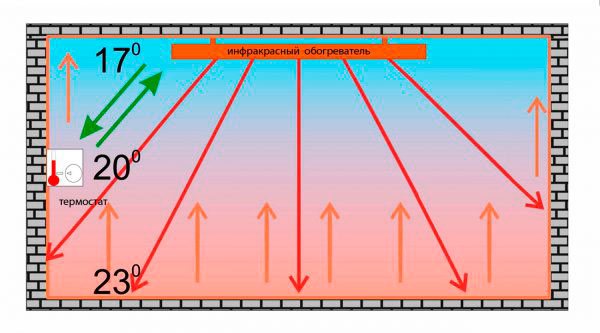

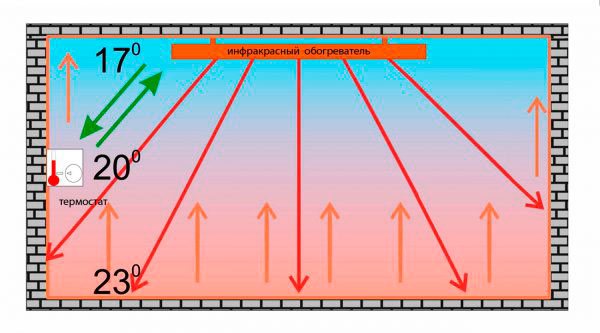

IR heaters concentrate heat in the floor area, which allows people to be in the most comfortable environment.

- Infrared emitters are connected to the power grid and begin to generate infrared radiation (or generate it due to the combustion of natural or liquefied gas), and in very large quantities - you need to remember about the volume of industrial premises;

- Infrared rays penetrate the surrounding objects (ceilings, walls, floors, machines, furniture, etc.), as a result of which they begin to give off heat. In other words, they become noticeably warm;

- Heat is removed from heated objects into the air - as a result, the industrial premises become warm and comfortable.

While standard batteries heat the air near the walls, industrial heaters based on IR emitters actively heat almost all surfaces and objects. Even if the distance between the walls is 50 meters, the rooms will be heated practically throughout the entire volume.

What is an infrared heater for industrial premises

An infrared industrial heater uses gas, electricity or another type of fuel to create an initial energy source and then convert it to infrared radiation.

The device has a simple, but at the same time reliable design, the constituent elements of which are:

- metal body, on the surface of which heat-resistant paint is applied;

- sealed flask with a heating element inside;

- aluminum reflector.

By heating workplaces in industrial premises with an infrared heater, you will save money. Traditional heating by means of radiators will cost more.

Warmth in the room begins to feel a few minutes after turning on the device. Infrared radiation acts on the surface of objects through heating. Excess heat energy is transferred to the air by natural circulation.

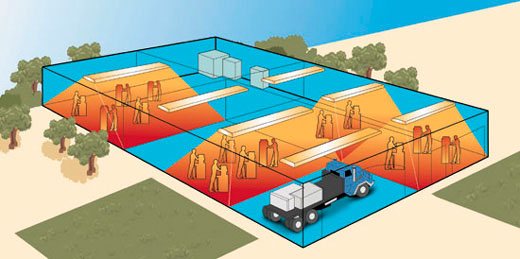

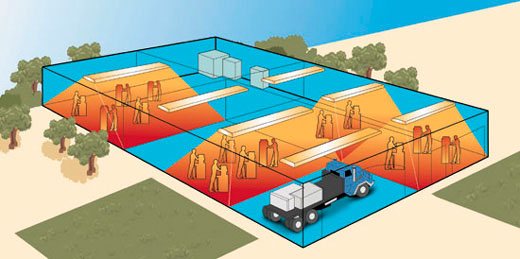

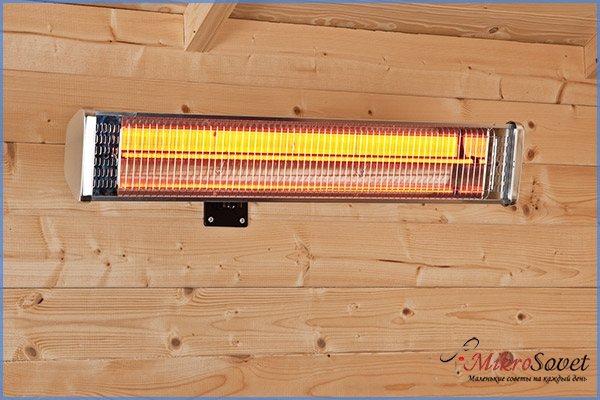

IR heaters in production

Advantages and disadvantages

Industrial air heaters are ideal for large spaces. They warm them up throughout the entire volume and do not interfere with anyone, since in most cases they hang from the ceiling or are located on tripods (on stands). Infrared radiation spreads over fairly long distances, so it easily reaches surrounding objects, floors and even partially reflects towards ceilings. Let's see why infrared industrial heaters are so good. First of all, we note the fact that they are absolutely harmless to human health - provided they are correctly installed. Some experts point out that they are even useful. In any case, they do not harm at all and give a pleasant sensation of warmth - standing under them, you begin to feel how life-giving warmth penetrates literally into every cell of the skin and into its inner layers.

Absolutely silent operation is a very important advantage. It is one thing when it is noticeably loud in industrial premises (machines, pumps, various technological equipment are working). And it's another matter when the production is quiet - in this case, industrial heaters with fans will add a few extra decibels. Therefore, the noiselessness of infrared devices is a solid plus.

Other advantages:

When using infrared heaters, it is not at all necessary to cover the entire area of the heated room. It will be enough to concentrate them directly on the jobs of people.

- High efficiency - heating industrial premises with infrared heaters allows you to deliver heat directly to consumers. They are located above equipment and workstations, creating a comfortable environment. Their high speed of work is also noted - if the room has not been completely frozen before, then it will warm up rather quickly;

- The ability to work in rooms with high ceilings - industrial infrared heaters heat from top to bottom. Suspended from the ceiling or by cables, they send infrared radiation down to the consumers;

- Maintenance-free - industrial electric heaters don't require any attention. We hang them at the required height and use them;

- Economical - the use of industrial infrared heaters can reduce heating and energy costs by 10-15%;

- Even distribution of heat - only infrared devices can boast of this.

There are also some disadvantages:

- If the industrial infrared heaters are located incorrectly, people may have headaches - be sure to observe the correct installation height of the equipment;

- Electric models are quite voracious - but there is no getting around it.Gas infrared heaters for industrial premises are becoming an alternative to them;

- Potential Burns - The emitting plates of infrared industrial heaters are heated to a high temperature, so accidental contact (for example, when placed on a wall) can cause burns.

Some of the disadvantages are quite serious.

Gas infrared industrial heaters still need periodic maintenance - they need to be cleaned and checked for leaks. In addition, gas equipment is more dangerous than electrical equipment.

How to use the infrared heater correctly

Ceiling mount models require little maintenance. They are just sometimes cleaned of dust. Floor and wall options are also cleanable as well as overhead options. They should not be covered with anything. The front of the device should not be located near a power outlet or furniture.

Infrared rays are not harmful to the human body. If you stay under them for a long time, you can get heatstroke, as in direct sunlight. For home, it is better to choose models of low power, for example, 60-100 W per 1 square meter.

Experts recommend models with long rather than short radiation. The latter can harm health. It is safer to have several small, low wattage devices than a large, high wattage infrared heater.

Varieties of infrared industrial heaters

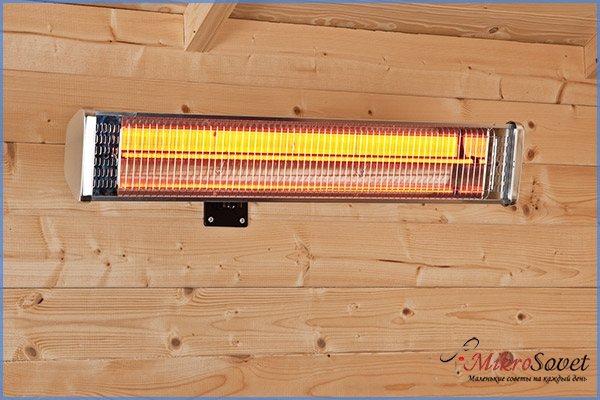

Let's take a look at what infrared industrial heaters are for industrial premises. To begin with, they are divided by the type of fasteners - there are wall, ceiling and floor. Wall mounted models are designed for small spaces. They are mounted on walls at a height of 2.5-3 meters and are most suitable for buildings of limited volume and small area.

For uniform heating, infrared heaters should be placed at an equal distance from each other.

Ceiling industrial air heaters are designed for large areas. They are distinguished by their high power, therefore they are mounted at high heights, on suspensions or cables. Such devices are quite popular and the most convenient - they have great power, do not interfere with anyone, and the risk of burns is excluded.

Floor standing industrial infrared heater is the rarest type of heating equipment. A device of this type is a tripod or a single stand with emitters attached to them. Scope of destination - spot heating.

The next division of industrial infrared heaters is by the type of power supply. Industrial gas heaters run on liquefied or natural gas. They are equipped with miniature burners with automatic ignition. They heat metal or ceramic emitters, causing them to generate infrared radiation that is sent to rooms.

Gas industrial infrared heaters are divided into dark and light. In the dark, the combustion process is hidden; it takes place in a sealed pipe through which air is supplied. Infrared radiation is emitted using finned emitters. The combustion temperature in the system does not exceed +400 degrees.

Light infrared industrial heaters operate at higher temperatures - high-temperature burners are installed in them, giving a flame with a temperature of up to +1000 degrees. Compared to dark appliances, they are lighter, so they can be used in prefabricated buildings where various restrictions apply.

Types of infrared heaters for industrial use

So, infrared heaters are recognized as the most effective and appropriate for production conditions, since they do not use air as a transit medium (drafts are common in workshops) and therefore are suitable for work in open areas, have a high heat transfer rate and are effective for heating moving objects (conveyors , drying chambers, kilns).

But infrared radiation can be obtained by using various energy carriers that determine the design of heaters. Consider the most common types of infrared heaters produced for industrial needs.

Electric infrared heaters for industry

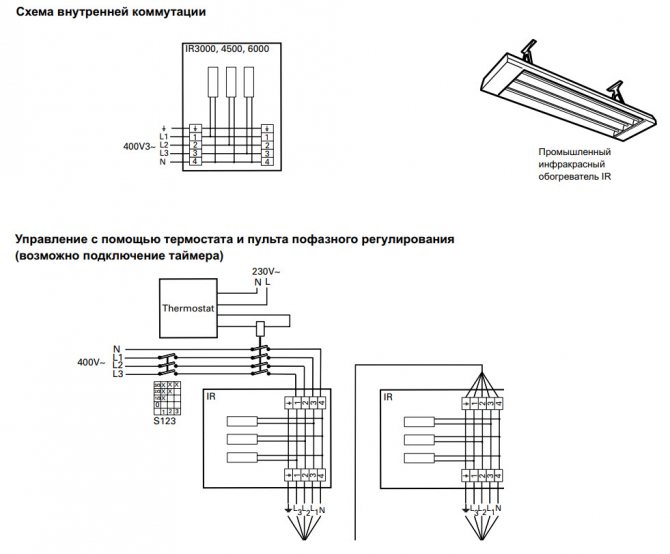

Installation of such units is carried out on ceilings or walls, control is carried out mainly from wired wall-mounted devices, but for ease of use, some models provide remote wireless control and, in addition, the ability to connect to a thermostat.

The power of electrical units is in the range of 2-7.5 kW, which determines the consumed voltage - 220 or 380 V.

Manual remote control of the heater and the location of the signal switch.

Structurally, industrial infrared electric heaters consist of a metal body, a reflector-reflector and an infrared emitter.

The body is covered with a heat-resistant protective paint and varnish composition, made, as a rule, by the method of spraying. The reflector is made corrugated in order to increase the reflecting area.

As an emitter in industrial electric infrared heaters, quartz or halogen lamps with a special sputtering on the bulb (carbon ones are not used due to their low power) or heating elements (tubular electric heaters) are used.

Mounting methods for infrared industrial heaters - outboard brackets and suspension devices.

Heating elements, in turn, can be open or closed.

With an open layout, the heater in the housing is visible and, although the unit is equipped with a protective grill, the heater is less safe, since its temperature after heating reaches 800 degrees. Heaters with a heating element of an open layout are mounted in places inaccessible to personnel and are used in industrial premises with a significant ceiling height (10 m or more), in the absence of external thermal insulation, with the presence of drafts or the need for regular ventilation.

Infrared electric heaters with open heating elements.

When the heating element is closed, it is located behind a corrugated metal plate that does not come into direct contact with it and therefore only heats up to 200 degrees, which increases the safety of the electric heater, but reduces the heating efficiency. Units with indoor heating elements are used in non-ventilated rooms with external wall insulation.

To calculate the efficiency of an industrial heater in a particular room, a value is used called the power density and is measured in watts per square meter (W / m2) - the amount of power to provide the required temperature regime on an area of 1 square meter. The calculated values are summarized in a table, taking into account the region, the degree of thermal protection of the enclosing structures and the recommended temperature threshold for this production. For example, to maintain a room temperature of 19 degrees, it is necessary to spend up to 100 W per 1 sq. square meter.

Installation of wall and ceiling infrared heaters for industrial use is carried out in accordance with the standards of GOST and the manufacturer's recommendations, including the location, orientation and height of the installation.

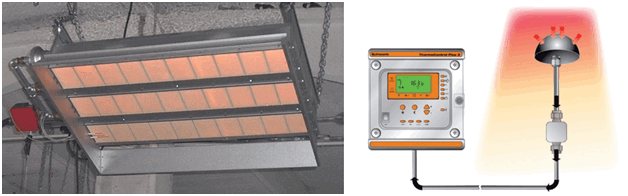

Gas industrial infrared heaters

The high power of industrial heaters leads to increased energy consumption, therefore gas heaters are mainly designed for mains, natural gas, but there are also models that consume propane (butane).

Gas infrared heater in action. It is possible to connect a remotely controlled thermostat.

Industrial infrared gas emitters are classified according to the temperature of the heat transfer plane - into devices of “light” (800–1000 ° С) and “dark” (300–600 ° С) types.

Gas infrared heaters of light type are designed to heat large premises with high ceilings - production workshops, warehouses, agricultural and zootechnical premises equipped with canopies of open areas, etc.

Important! IR heaters of "light" type belong to gas equipment of group A1 - combustion products are not removed anywhere and remain in a heated room, which must be equipped with a forced exhaust ventilation system.

Diagram of the device of a gas infrared heater of the "light" type - the absence of removal of gas combustion products is indicated.

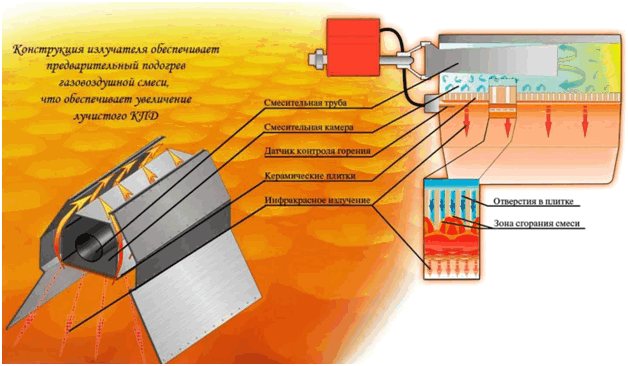

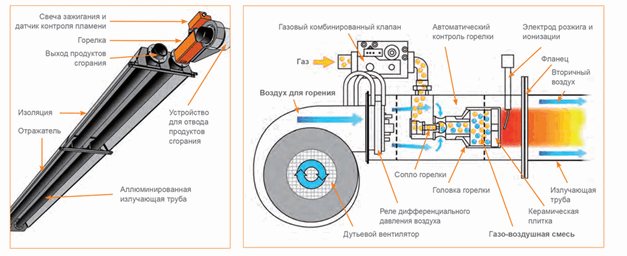

Gas infrared heaters of the "dark" type structurally represent a pipe with a diameter of 75 to 120 mm, in one end of which a burner is mounted, and in the other - a fan.

Diagrams of the device and the principle of operation of industrial gas infrared heaters of the "dark" type.

The pipe is made of a special heat-emitting alloy or covered with a heat-resistant coating with identical properties and placed on a steel sheet with a mirror surface.

Gas (natural or liquefied) is supplied to the burner, which, when burned, heats the pipe from the inside and initiates infrared radiation by it.

Most - 50-75% of the thermal energy is transferred to the surface of the pipe and in the form of infrared radiation is directed downward - towards the floor, the middle and lower zones of the walls of the room, as well as equipment, which is facilitated by the mirror reflector located behind the pipe.

25-40% of the heat energy from gas combustion goes to compensate for heat loss by the room through the roof, the upper belt of the walls, and only 5-10% of the heat goes into the atmosphere along with the gas combustion products, which are removed to the outside.

Real image of one of the models of a gas infrared heater of the "dark" type and its section.

Industrial gas heaters of "dark" type are subdivided into the following types:

- modular - for local heating of limited areas or workplaces;

- tape (block) - designed for the assembly of heating systems of complex configuration, repeating the geometry of the room.

Modular on the left and tape type of "dark" gas infrared heaters on the right

Gas infrared heaters are attracted by the cheapness of the energy carrier used, but it should be remembered that gas is a fuel of increased danger of use, and the operation of such equipment requires more attention than the use of heaters on electricity.

Liquid fuel infrared industrial heaters

The energy carrier consumed by these units is diesel fuel or aviation kerosene.

The principle of operation of the device is based on heating the emitter with fuel burning in the nozzle, followed by radiation of the infrared spectrum of waves. Therefore, unlike a liquid fuel heat gun, these units do not create directional air flows that raise dust.

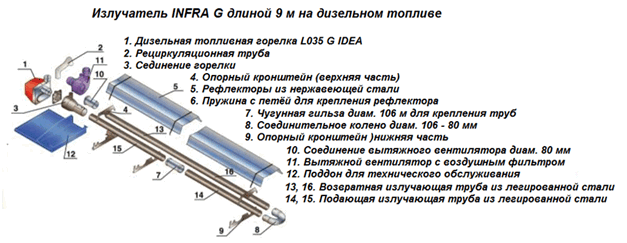

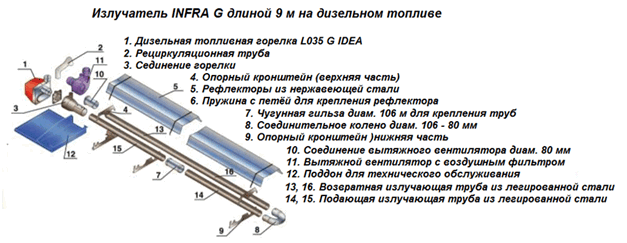

Liquid-fuel infrared heaters are manufactured for stationary (modular) and portable use. The device of stationary diesel infrared heaters for industrial use resembles gas infrared units, but only at first glance - the difference in the energy carrier causes a different design of the components.The similarity of the systems can be seen on the example of the INFRA heater, which has proven itself in the Russian market.

Diagram of the device of an industrial infrared emitter on diesel fuel for stationary placement

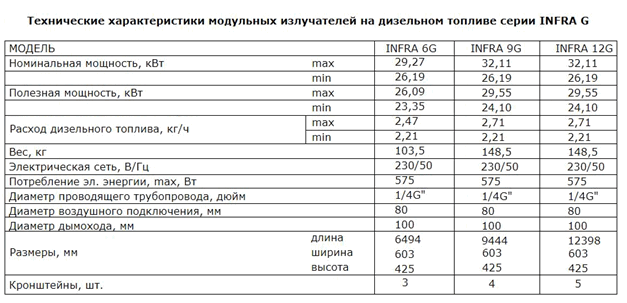

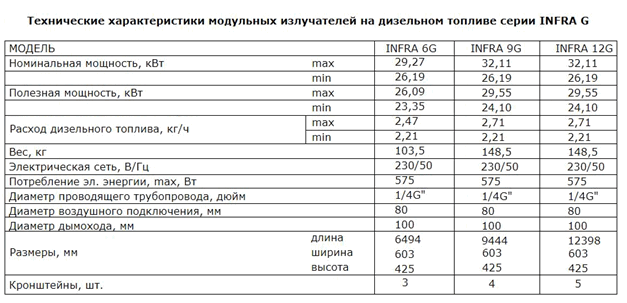

Modular diesel infrared emitters are used to heat medium and large areas of industrial premises, closed agricultural facilities (poultry factories, farms, greenhouses), storage areas and sports facilities. When choosing a heater of the required power, it is convenient to use the following table of the line of models of these units:

Portable diesel infrared heaters, which are not distinguished by their compactness, are no less effective than modular ones. Their design, thanks to a carriage with wheels, with unit dimensions of more than a meter in length, allows one worker to move the equipment to the desired place. The heat transfer power of such devices can reach 40 kW or more with a fuel consumption of 2-3 kg / h, which allows heating rooms with an area of 300-400 square meters. But efficiency also determines the price - the cost of top models can exceed one hundred thousand rubles.

Important! The use in liquid fuel infrared heaters of energy sources not specified in the user's manual is prohibited.

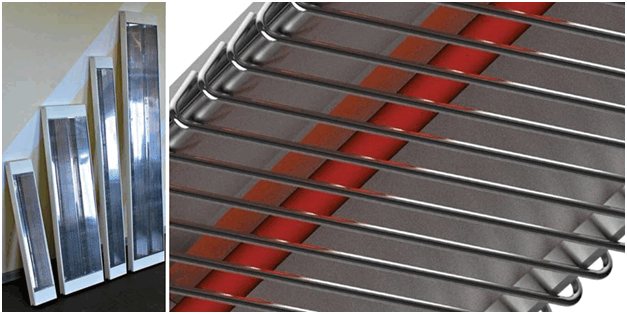

Water thermal panels

This infrared emitting device for industrial use is a system assembled from separate sections, which represent a profiled steel or aluminum reflector sheet, in which a system of pipes for the movement of a heat carrier - hot water - is mounted. The sections are connected using fittings.

Types of heating sections with hot water supply and their connection

Such devices, with their simple design, are distinguished by their reliability, durability, high efficiency and efficiency of use. Of no small importance is the absence of a combustible energy carrier in the system, which makes the device absolutely environmentally friendly and highly safe.

Infrared heaters with hot water supply are mounted on the ceiling or walls and are ideal for industrial, agricultural, warehouse and other premises. The base, planned for the placement of the heating system, is pre-equipped with thermal insulation - to reduce heat loss through the supporting structure. The insignificant weight of the sections in most cases does not impose additional requirements on the bearing characteristics of the base, and compliance with the installation rules recommended by the manufacturer ensures the reliability of the device installation.

Scope of application

Industrial gas heaters and their electrical counterparts can be used in various premises. First of all, these are factories, factories, furniture shops, technological buildings and much more. They are also in demand in warehouses. An infrared warehouse heater will create excellent conditions for storing any goods, including food.

Industrial infrared heaters are also used in agriculture. Here they are needed to heat large greenhouses. For greater savings, gas models are used in greenhouses - they are economical and emit carbon dioxide consumed by plants and converted into oxygen through photosynthesis. And the infrared radiation itself has a beneficial effect on crops.

Operation of heaters and industrial scale

Industrial scale will require bulk purchases of equipment to support the entire enterprise. After receiving the goods, you will make sure of its integrity, make an inventory and you can safely start installation. The heater turns on and off with one click. The settings are set automatically or you yourself can set the values convenient for you.The heater can serve you for decades if you handle it with care, not neglecting the elementary rules of operation.

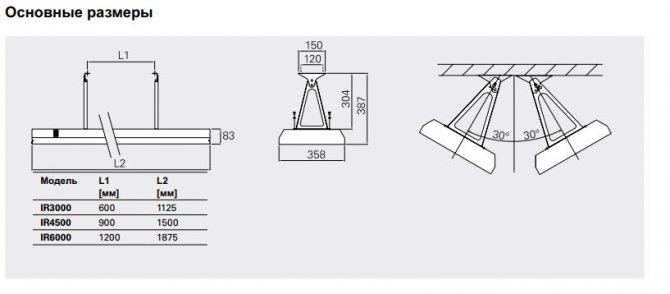

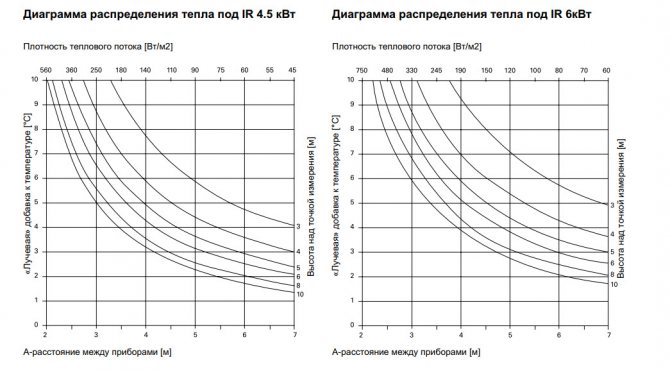

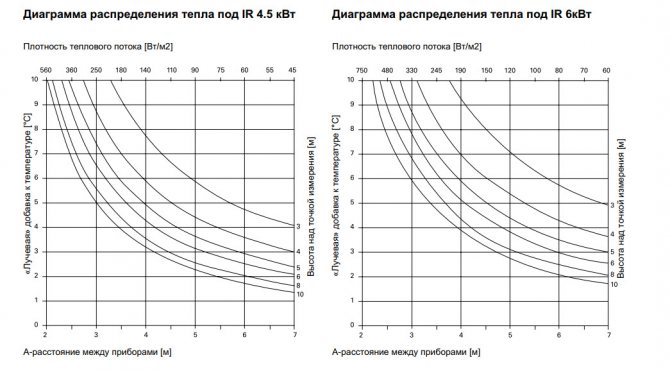

Heat distribution diagram for IR 4.5 kW

Popular models of IR heaters

If there is a need to buy infrared industrial heaters, pay attention to the following models:

Ballu BIH-T-6.0

This is an excellent device from a trusted manufacturer. Its power is 6 kW, which allows it to heat an area of up to 60 sq. m. and even a little more (depending on the ambient temperature).

MO-EL Hathor 793

Wall mounted shortwave infrared industrial heaters with three heating elements. Suitable for small spaces and open areas.

Neoclima UK-05

Gas appliance for small rooms. Endowed with a ceramic emitter.

Heater selection

What to consider when choosing

An infrared heater can be used both as the main and as an additional heat source. It is on this basis that a specific model should be selected.

Installed heater

The main factor when choosing a particular heater is its power. As a rule, to use a heater as the main heat source, its power should be about 100 W / m2 (for a ceiling height of no more than 3-3.5 m).

Before choosing a heater, you should also consider:

- The type and thickness of the walls.

- Features of the ceiling (on top of the roof of a house or another apartment).

- Features and quality of glazing (old wooden windows or modern structures with energy-saving double-glazed windows are installed).

Taking these factors into account makes it possible to clearly determine whether the power of the heater is sufficient, or it is necessary to install a more efficient model.

Infrared film heaters

These micathermic panels are very easy to use. Thin graphite fibers are fixed on one thermostatic film. It is a flexible device that can be attached anywhere - on the floor or ceiling, any wall size.

Such devices disguise themselves as decorative rugs, operate silently and economically.

You can buy Gas infrared emitters (heaters, burners) ceiling industrial with selection, calculation, design, installation, installation, commissioning and commissioning in the following cities of Russia: Moscow, St. Petersburg, Novosibirsk, Yekaterinburg, Nizhny Novgorod, Kazan, Chelyabinsk, Omsk, Samara, Rostov-on-Don, Ufa, Krasnoyarsk, Perm, Voronezh, Volgograd, Krasnodar, Saratov, Tyumen, Togliatti, Izhevsk, Barnaul, Irkutsk, Ulyanovsk, Khabarovsk, Yaroslavl, Vladivostok, Makhachkala, Tomsk, Orenburg, Kemerovo, Novokuznetsk, Ryazan, Astrakhan, Naberezhnye Chelny, Penza, Lipetsk, Kirov, Tula, Cheboksary, Kaliningrad, Kursk, Ulan - Ude, Stavropol, Balashikha, Magnitogorsk, Tver, Sevastopol, Ivanovo, Bryansk, Nizhny Tagil, Vladimir, Arkhangelsk, Surgut, Chita, Kaluga, Simferopol, Smolensk, Volzhsky, Kurgan, Oryol, Cherepovets, Vologda, Saransk, Vladikavkaz, Vladikavkaz, Yakutsk, Murmansk, Podolsk, Tambov, Grozny, Sterlitamak, Petrozavodsk, Kostroma k, Novorossiysk, Yoshkar-Ola, Komsomolsk-on-Amur, Taganrog, Syktyvkar, Khimki, Nalchik, Mines, Nizhnekamsk, Bratsk, Dzerzhinsk, Orsk, Angarsk, Blagoveshchensk, Engels, Stary Oskol, Veliky Novgorod, Korolevsk, Pskov, B Mytishchi, Prokopyevsk, Yuzhno-Sakhalinsk, Balakovo, Rybinsk, Armavir, Lyubertsy, Severodvinsk, Petropavlovsk-Kamchatsky, Abakan, Norilsk, Syzran, Volgodonsk, Novocherkassk, Kamensk - Uralsky, Mt. Kerch, Berezniki, Rubtsovsk, Kopeysk, Pyatigorsk, Krasnogorsk, Maykop, Kolomna, Odintsovo, Carpets, Khasavyurt, Kislovodsk, Serpukhov,Novomoskovsk, Neftekamsk, Novocheboksarsk, Nefteyugansk, Pervouralsk, Shchelkovo, Cherkessk, Derbent, Bataysk, Orekhovo-Zuevo, Nevinnomyssk, Domodedovo, Dimitrovgrad, Kyzyl, Oktyabrsky, Nazran, Kamyshin, Ugninsk , Seversk, Pushkino, Noyabrsk, Evpatoria, Essentuki, Yelets, Achinsk, Artem, Sergiev Posad, Arzamas, Elista, Novokuibyshevsk, Berdsk, Noginsk, Dolgoprudny. Russia. Kazakhstan. Atyrau, Alma-Ata, Astana, Shymkent, Karaganda, Aktyubinsk, Taraz, Pavlodar, Ust-Kamenogorsk, Semey, Uralsk, Kostanay, Kyzylorda, Petropavlovsk, Aktau, Temirtau, Turkestan, Kokshetau, Taldykazgan, Rudykazen, Zhudny Baikonur, Balkhash, Kaskelen, Satpayev, Kulsary, Ridder, Talgar, Stepnogorsk, Shuchinsk, Kapchagai, Saran, Zharkent, Aksu, Arys, Saryagash, Shakhtinsk, Esik, Zyryanovsk, Ayaguz, Lisakovsk, Shu, Zhitikara, Aksai

The principle of operation of the IR heater and design features

From convectors and standard batteries, infrared heaters do not warm the air, but household items, as well as wall surfaces and floors. It is a sun-like glow that passes through the air masses, but does not warm them. Only objects in the path of infrared rays begin to heat up. Drafts and winds do not interfere with such infrared waves.

Convectors heat up the room gradually, and people have to freeze and feel discomfort for some time. Air flows move up and down. As for the infrared unit, the principle of operation is different. Households feel warmth immediately after turning on the device.

The steel body is painted with durable paint and an aluminum reflective screen. There is a heating element on it. It can be tubular (tenon), made of durable ceramics, carbon or halogen.

To regulate the temperature regime, each infrared heater is equipped with a thermostat, and there is also a sensor that is necessary to turn off the device if overheating occurs. The floor-standing models are equipped with a mandatory rollover alarm to prevent a fire.

How to clean and humidify the air in the room to improve the microclimate, read the article: washing the air for home

Electric infrared heating systems

There is also a type of heaters that do not run on gas, but on electricity. They are suitable both for heating a large area of the room and for local use. There are several types of such devices and each of them has its own special approach and individual design characteristics.

Types of electrical infrared systems

To begin with, let's say that they can be classified according to the following characteristics:

- Fixation type. There is a possibility of installation on the ceiling, walls, and there are also universal models. There are also options for installing a stationary or mobile installation. Such options for heaters are very popular with teams of workers.

- By type of work. There are different purposes of industrial infrared heaters, one of them is wood drying. For this purpose, systems are specially bought with short wavelengths of radiation. But here's the minus, for a person, these waves are quite dangerous. For this reason, if the device is switched on in the room, work near it must not be performed! But emitters with long waves, on the contrary, are useful for humans. Therefore, they are often bought on construction sites. They are often used as the main source of heating.

Pros and cons of electric emitters

A fairly large number of buyers want to purchase this particular option for a number of the following reasons, or rather advantages:

- Ideal for dusty environments. In general, they easily transfer any location with difficult conditions.

- They are used as the main source of heating, as well as an additional one. It happens that they heat a part of the desired zone.

- There is an option to heat up pointwise, very locally. Usually used to heat the material before work.

- It can often be found in circulation in medical schools.

Of the negative sides, only one, consumes a large amount of electricity, which means, accordingly, a rather expensive device.