Home / Electric boilers

Back to

Published: 06.01.

Reading time: 4 minutes

0

550

An important condition for the functioning of electric boilers in a private house is their safety. It should be borne in mind that even very reliable installations go out of service over time.

The period of operation of different units and parts have their own limitations. Malfunctions that occurred during the warranty period can be eliminated without payment to the service company. In all other situations, the owner will need to pay for the repair of electric boilers.

- 1 Causes of breakdowns of electric boilers

- 2 Basic malfunctions and repair methods 2.1 TEN

- 2.2 Safety automation

- 2.3 Heat exchanger

What is an electric boiler

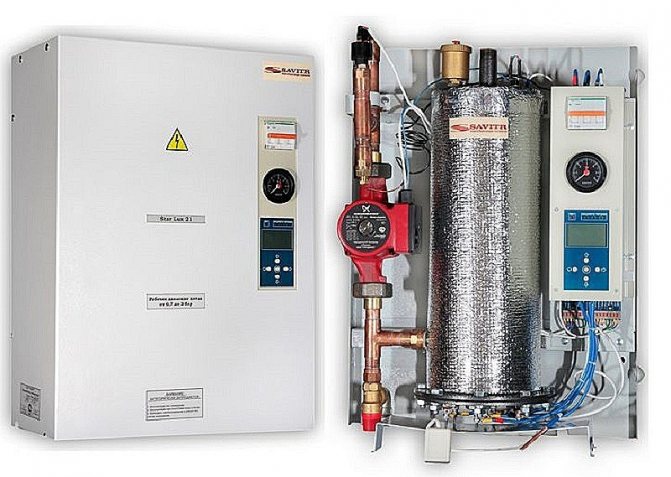

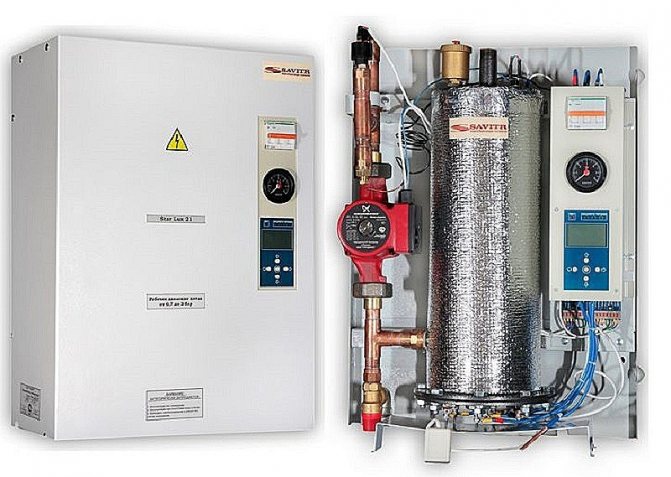

An electric boiler is a special high-tech equipment designed for heating various kinds of premises. A distinctive feature of such a unit is the use of a special type of fuel - electrical energy. In many respects, the boiler is superior to equipment operating on other types of fuel: liquid, solid, gas.

Electrical equipment is considered the safest to use. But in order for it to function well, it is necessary to strictly observe the rules of its operation and provide timely technological maintenance.

Watch a video describing the principle of operation and the device of the Protherm Skat electric boiler.

Device

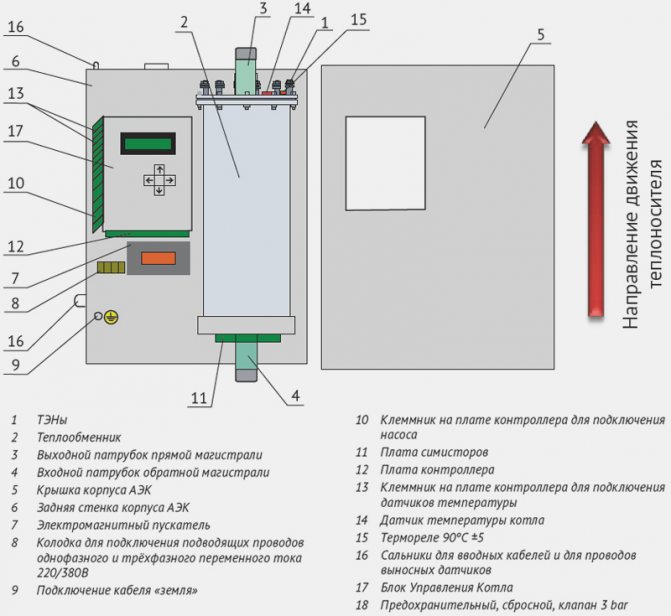

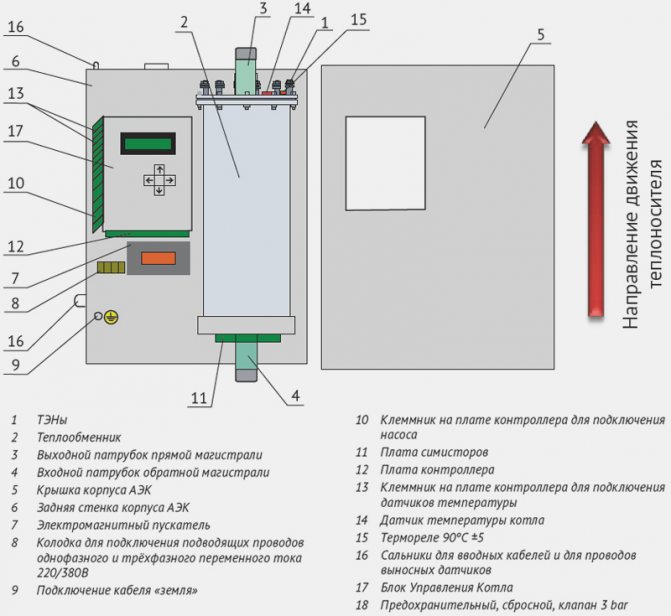

Despite the large variety of boilers with different operating principles, the device of all models is approximately the same. The main place in the structure is given to the heating element. Depending on the type of heater used and the principle of its operation, there are several types of boilers.

All heating elements are located in heat exchangers, which are considered the main structural elements of the boiler. In case of their malfunction, heating of the coolant is impossible.

Depending on the design and manufacturer, the equipment may have a different configuration.

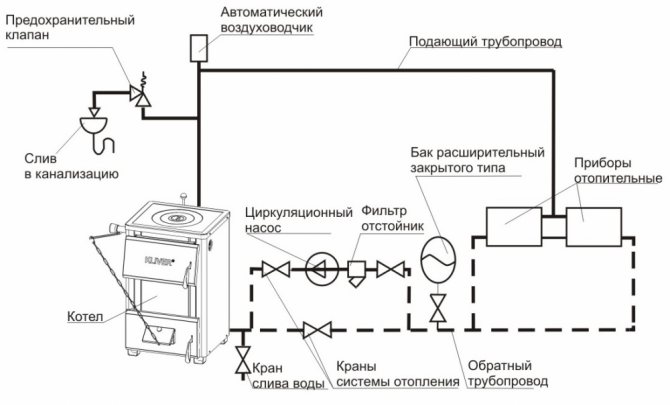

List of elements:

- Electronic control unit. Regulates the temperature, turning the equipment on and off at the right time.

- Circulation pump (heat pump). It is an indispensable component of the system, maintains a stable speed of movement of the coolant in the circuit. Produces forced circulation of liquid and creates the necessary pressure in the system, while ensuring the most efficient heat exchange and warming up the room.

- Expansion tank. Not all types of electric boilers with a pump are equipped with an expansion vessel. Therefore, if equipment is purchased without a tank, it will be necessary to purchase this part separately and install it by cutting into the heating pipe circuit.

- Filters. Various impurities are purified and removed from water.

- Safety valves. Protect the system from unwanted operational deviations.

- Safety valve. Connected to the return pipe. Performs emergency water discharge when the pressure rises above the set rate.

- Pressure gauge. This device determines the pressure of liquids, gases inside the boiler and pipes of heating systems, it is necessary for monitoring.

- Thermal switch ... It turns off the equipment when it overheats. Connected to the thermal sensor located at the top of the electric boiler.

- Automatic air valve. It is located above the heating tank and produces an emergency air release from the tank in case of overpressure.

Types of electric boilers

All electric boilers are divided into three types depending on the principle of operation of the heater.

Electric heating elements

The principle of operation is based on simple electrical heating of elements that give up their heat to the liquid. Heating element - heating element. Water or other permitted liquids are used as a heat carrier, in accordance with the instruction manual.

Induction

Their action is based on the principle of electromagnetic induction. The heating element is a coil, inside of which there is a pipeline filled with water. When an electric current passes through the coil under the influence of an electromagnetic field, the coolant is heated.

Ionic

The working element in such structures are electrodes placed in a special aqueous medium, where the process of heating the coolant occurs when an alternating current passes through it.

A feature of the use of this type of boilers is the mandatory control of the electrical conductivity of the liquid and the adoption of measures to regulate it. The phenomena of electrolysis and breakdown must not be allowed. Failure to do so could result in equipment damage.

The liquid used must not be used for domestic purposes. The heat carrier that circulates through the pipes and enters the working tank of the boiler is in direct contact with the electric current. It is not recommended to carry out repair and commissioning work without the involvement of an experienced foreman.

Features of electric boilers

Domestic heating electric boilers are devices consisting of a powerful heater (usually up to 24 kW) and a circulation pump. There are also household electric boilers for heating with a capacity of up to 240 kW. Sometimes water circulation is provided due to natural convection - hot water, which has a lower density, rises up.

Using heating equipment that converts electricity into heat is an expensive way to heat your home. Economical electric heating boilers do not exist. The efficiency of each such device is 100%, so all consumed electricity is converted into heat energy. Therefore, when choosing an electric boiler for a heating system, you must immediately be ready to pay huge amounts for electricity.

At the same time, this equipment has its own advantages that other types of heating devices lack. For example, this is a simple connection of an electric heating boiler, the absence of combustion products, compact dimensions, the ability to adjust the operation of devices.

Causes of breakdowns

The causes of breakdowns can be laid down even before the start of boiler operation. These are: errors in design and calculations for the choice of additional devices (not included in the boiler configuration), switching elements, determination of the type and section of the required installation wires.

The causes of breakdowns in the future may be:

- Poor quality, incorrect installation and connection of the device with deviations from the installation requirements.

- Violation of the basic rules for using the equipment specified in the instructions.

- Failure to comply with the requirements for routine, as well as preventive and periodic work and inspections.

- The presence of a factory defect, which is found both during the warranty period and after its completion.

- All units and assemblies have a certain service life, and the reason for their failure is natural wear and tear.

- In TEN boilers, the failure of the heating elements themselves is possible due to the low quality of water and the formation of salts and scale on their surface.

- Failure of most components and assemblies due to large voltage surges exceeding all permissible standards. These tolerances are specified in the operational documentation.

For ionic boilers, it is of great importance that the water meets the required standards.

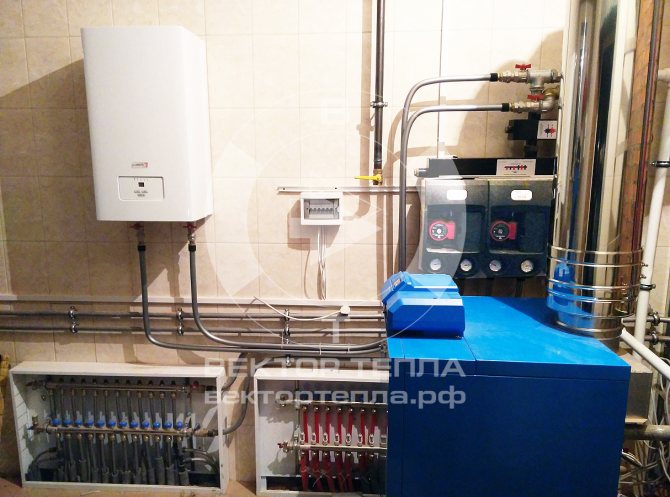

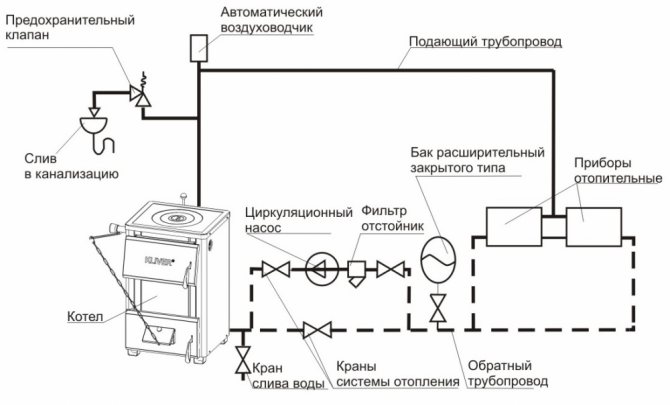

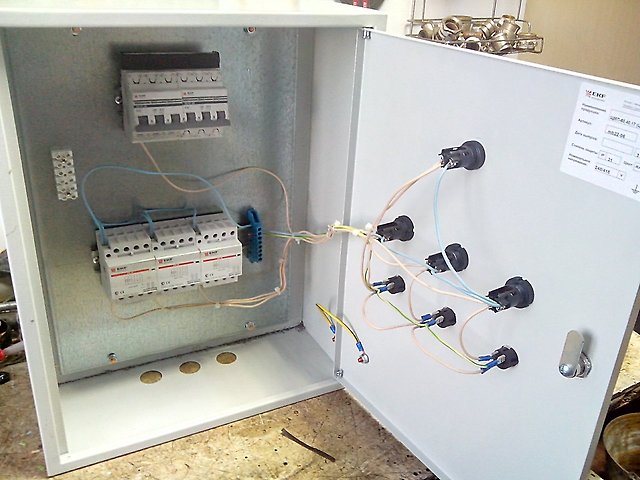

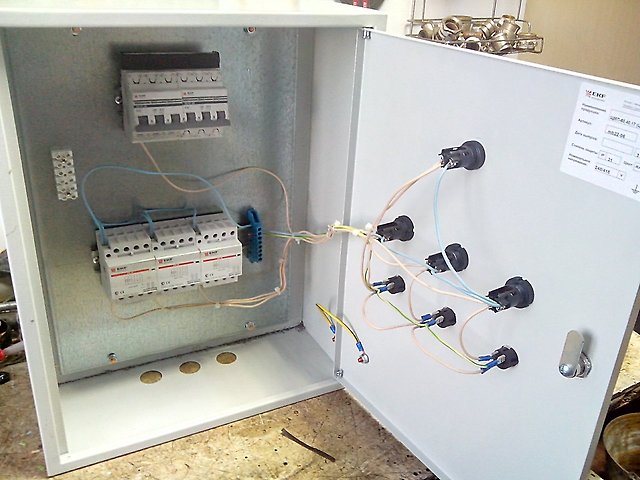

Connecting the electric boiler to the heating system

There is nothing complicated in how to connect an electric heating boiler. The main thing is to comply with all manufacturer's recommendations and safety regulations. Only in this case the heating system will work efficiently, and the operation of the boiler will become completely safe.

To reduce the amount of electricity consumed, it is advisable to resort to the following scheme:

- equip a floor heating system that evenly distributes heat throughout the room;

- install a heat accumulator - a heat-insulated storage tank. In it, the water will be heated at night, when a lower electricity tariff is in effect, and during the day it will slowly cool down, giving off heat to the room (for more details: "The correct heating scheme with a heat accumulator").

Electric boilers are very easy to install; to create a heating system with them, no special permission is required, as, for example, in the case of gas equipment (read: "Connecting an electric boiler to the heating system: instructions"). The main disadvantage of electric boilers is a significant electricity consumption and a relatively short service life, which is associated with the likelihood of overheating of the heating elements.

Types of malfunctions

During the operation of electric boilers, various kinds of malfunctions arise - from coolant leaks in pipelines and structural elements to malfunctioning of automation. If the electronics fail, it is recommended to entrust the repair to specialists in this field.

Typical malfunctions include:

- violation of the tightness of the system, the presence of leaks and smudges in the fuel lines, elements and assemblies;

- heating of electrical wires and smell due to a violation of electrical insulation;

- various kinds of noises in highways and system elements;

- there is no or slight heating of the coolant;

- when turned on, the boiler does not start;

- after heating the coolant, the electric boiler does not turn off.

DIY repair

To carry out work on the repair of an electric heating boiler with your own hands, you must have a minimum amount of knowledge on the design and installation of electrical equipment, as well as the heating system as a whole.

It is recommended to study the information on operation, installation and follow all the requirements specified in the instructions. To find faults in the operation of the electric boiler, it is necessary to use the diagrams.

For all types of malfunctions, you must first de-energize the equipment, and then conduct a thorough visual inspection. Attention should be paid to burning, the integrity of various kinds of connections, insulation damage and other deviations.

Doesn't start

To determine the reasons for the impossibility of starting the boiler unit, it is advisable to use the electrical diagram of the equipment. Check the integrity of the cable and all fuses, and ensure that the circuit breakers are working properly using a multimeter and other appropriate items on the control panel. All work should be performed with de-energized equipment.

To fully turn on the boiler, it is necessary to operate the starting circuit, which includes, depending on the type of boiler, its own set of elements.

Components:

- emergency thermal switch;

- pressure meter;

- flow switch;

- thermostat sensor.

It is necessary to check their serviceability, if a breakdown is found, make repair or replacement. Otherwise, starting the boiler will be problematic.

The emergency thermal switch is a bimetallic contact that opens when too hot. It is designed to shutdown the boiler in the event of a temperature overload and failure of the main circuit of the thermostat. When a critical indicator is reached, the thermal switch opens its contacts and removes the voltage from the electrical appliance.

When it cools down, the contacts close again and prepare the circuit for the next start. It is worth noting that the reason for the inoperability of the electrical appliance can be just the thermal switch itself, the contacts of which remain open. Then the boiler will not be able to start.

Simple thermal switches are checked by a “dial-up” method using a tester. In the normal “cold” state, the contacts are closed. To check the operation of this element, it is necessary to heat it above the shutdown temperature by the usual action of an open fire or a soldering iron, and then measure the resistance of the contacts.

Turning off and turning on the heating elements to maintain the required temperature of the coolant is carried out when the thermostat and the temperature sensor in the boiler are in good working order. If they break down, the boiler cannot be started.

A level sensor is installed in the upper part of the unit body (the presence of a coolant), it provides a power cut-off to the electric boiler in the absence of liquid in the tank. In this case, the "dry" type electrode must be in the water. In this case, the corresponding relay is activated, and a circuit is prepared for starting the boiler. The flow switch is designed to turn off the equipment in the absence of circulation of the coolant in the system, which makes it possible to exclude overheating of the liquid.

Doesn't turn off

If the boiler does not turn off when overheating, then the emergency thermal switch does not work, if, in the absence of water in the boiler, the level sensor is faulty, and so on.

To turn off the boiler, it is necessary to break the starting circuit, which includes the corresponding automation elements. It is necessary to check the serviceability of all components that are present in this type of boiler and determine why this or that device does not turn off. The same search methods are used with a multimeter. Do not forget about de-energizing and completely shutting down the boiler if necessary.

Makes noises

During the operation of any electric boiler, there is always a certain background and noise. This is a typical and natural phenomenon. But the nature of the noises can be different, and some sounds can be used to judge the technical condition of the boiler. In the course of operation, the types and nature of the noises change somewhat over time. It all depends on the quality of equipment installation, installation, setup, physical wear and tear of components and assemblies, as well as operating conditions.

The low noise figure in the system indicates the high quality of the electric boiler used. A uniform, monotonous sound of operation indicates normal functioning, and the source of the noise is, like in a kettle, heated water. The volume of sounds depends on the degree of oxygen saturation of the liquid. This process does not have any negative effect on the condition of the boiler and the system.

If you hear an uneven noise, accompanied by a crackling, then this is due to the formation of lime deposits on the walls of the heat exchanger. Over time, their number increases, gradually they begin to exfoliate and enter the system.

Depending on the amount of deposits, sounds of different volume and timbre are heard, with a significant increase - crackling. To eliminate this phenomenon, it is recommended to flush the heat exchanger elements. In addition, the temperature of the inner walls of this device also increases, and this affects the wear resistance and durability of the equipment.

Doesn't heat water

The lack of water heating, provided that the rest of the equipment circuit is working and working, can be due to two reasons: insufficient voltage at the terminals of the heating elements or malfunctions in the elements themselves and their connections.

The integrity of the heating elements can be determined by checking the resistance with a tester or similar device. Each component of the device must be tested separately. To do this, you must disconnect them to ensure access. If a malfunction is found, the heating elements should be replaced.

Replacing the heating element

Depending on the type of boilers, appropriate heating elements are installed in them. These can be heating elements or electrodes. If it is impossible to repair them, they must be replaced.

Procedure:

- Shut off the water supply to the unit.

- Drain the system.

- Disconnect the equipment from the mains.

- Make sure there is no voltage.

- To access the heating elements, dismantle the necessary equipment and its elements.

- Disconnect the wires from the heating elements. To facilitate installation, it is advisable to first sketch or photograph the connection diagram.

- After unscrewing the fasteners and removing them, dismantle the faulty element.

- Install a new heating element corresponding to this boiler.

- Install a new waterproofing gasket and fix the heating component.

- Connect the appropriate wires to the pins of the element and compare the result with the previously sketched diagram.

- Check the correctness of installation.

- Fill the system with water and start up the boiler in accordance with the operating instructions.

Prices for heating elements for boilers

Heating element boiler spare part

Restoration of performance of electrode and induction boilers

Unlike heating boilers, in electrode-type heaters, faulty electrodes are replaced. The same approach is applied here as in the case of the repair of heating elements. Requirements for the replacement of heaters in electrode boilers are higher.

Typical problems

Among the most common malfunctions that are typical for electric heating boilers, one should highlight the breakdown of heating elements, equipment for monitoring and controlling the operation of the system.

In case of failure of the heating elements, the restoration of the boiler's operability involves the replacement of heating elements or electrodes, depending on the type of equipment.

To prepare for the planned activities, you must visit a specialized parts store. Here you can easily find the required electric heating element. You can find out the model of a spare part that will help to carry out repairs from the technical passport of a specific heating unit.

If the problem concerns the control and monitoring systems, you must first take measures to identify the faulty units.

In cases where it is impossible to repair heating boilers by repairing a non-working element, it should be replaced.

Breakdown reasons

Common reasons for the insufficient efficiency of the operation of electrical equipment and its complete failure are as follows:

- untimely maintenance of boilers and unfair operation;

- poor-quality installation and connection of the heating unit;

- incorrect design;

- the presence of a factory defect;

- natural wear and tear of functional elements.

Replacement of heating elements

Elimination of malfunctions in the operation of an electric boiler by replacing the heating elements requires the following sequence of actions.

To begin with, the boiler is disconnected from the mains, which is a basic safety requirement and avoids electric shock. All working fluid is drained from the heating system.

If the heating element fastening is in a hard-to-reach place, the electric boiler is dismantled. Further, the wires are disconnected from the heating elements.Each wire is pre-marked with convenient designations. The initial attachment order (zero and phase) is recorded.

Then the fasteners of the electric heating elements are unscrewed. The heating element is dismantled directly. A special waterproofing gasket is being replaced.

Using an old gasket can lead to early leaks when a new heating element is in operation.

A serviceable heating element is installed and fixed. In the reverse order, proceed as described above in the description of the disassembly process. The electric boiler is connected to the network. The functionality of the boiler and the reliability of the functioning of the entire heating system are checked.

Restoration of performance of electrode and induction boilers

Repair of electrode-type boilers occurs by replacing the electrodes. The same approach is applied here as in the case of the repair of heating elements. However, electrode boilers are more demanding in terms of assembly accuracy.

As for the restoration of the operation of induction boilers, such heating devices do not have heating elements. Therefore, in the event of a malfunction, self-repair is not possible here.

It is worth noting that the most likely breakdowns of electric heating boilers, as well as the reasons and methods for their elimination, are given in the operating instructions for specific models.

Prevention and recommendations for use

Compliance with the operating rules, together with the implementation of timely preventive measures, prolongs the period of trouble-free operation of the unit. It is preferable to carry out preventive maintenance during the lowest boiler load, in summer.

During the current heating season, it is advisable to pay attention to malfunctions and deviations that occur during operation. In the warm season, it is recommended to replace all unstable elements and troubleshoot. Then make a preliminary start and check the performance of boiler equipment and systems.

Preventive measures include: cosmetic repairs, cleaning of various kinds of systems and equipment. Particular attention must be paid to fasteners and connecting elements that can significantly affect the functionality of the equipment.

Timely, regular implementation of preventive measures along with high-quality installation and proper operation will allow heating equipment to operate reliably for decades.

To extend the service life of the heating unit, it is necessary to descale the heating elements. However, you can prevent the problem by pouring distilled or soft water into the heating system. If before that ordinary water was used, then the heating elements are cleaned with the help of special powders that are sold in household or car dealerships.

The powder is diluted in water, the resulting mixture is poured into the heating system, which turns on at full capacity. After 30-40 minutes, the entire solution (it will be rusty) is drained into the sewer system. Now you can be sure that the whole system will get its nominal 100% power again. A less efficient option is to install devices for filtering the working fluid.

The reliability of the home electrician is of particular importance. Outdated wiring is one of the most common causes of electrical failure. It is advisable to change the aluminum wire to copper with a cross-sectional margin.

A feature of the use of this type of equipment is the mandatory control of the electrical conductivity of the liquid and the adoption of measures to regulate it. The phenomena of electrolysis and breakdown must not be allowed. You can find out how to cook in a Pompeian oven here.

Boiler characteristics

Usually, when buying, people pay attention to such characteristics of electric boilers as their power, dimensions, thread diameter at the inlet-outlet. The very principle of operation of the equipment of consumers is often not interested, but absolutely in vain

When choosing a device, you need to pay attention to all its characteristics.

The wiring diagram for an electric heating boiler depends on its power. If the device consumes no more than 3.5 kW, then it can be connected to a regular outlet. Boilers with a capacity of 3.5-7 kW are connected to the panel using a dedicated cable. For them, a voltage of 220 V is sufficient. The use of a separate cable is mandatory - for safety reasons, the maximum current at the outlet is limited to 16 amperes. For the operation of boilers with a capacity of more than 7 kW, a voltage of 380 V is required. In any case, grounding is mandatory.

When choosing this parameter, the device must be taken into account:

- the height of the ceilings - the higher they are, the greater the volume of the room;

- the thickness and material of the walls - for example, if they are made of 20 cm sip panels, they let less heat pass than from 10 cm reinforced concrete;

- the number and total area of windows, the material from which the frames are made (metal-plastic and wood have different thermal conductivity), the number of chambers in a double-glazed window (two-chamber with special energy-saving glass passes twice less heat than single-chamber);

- type of roof, the presence of an attic or attic.

When choosing a boiler, you should give preference to a model with a higher power - in reserve. To calculate the approximate power of the device, you need to divide the area of the house by 10. For example, with an area of 80 "squares", an 8 kW unit will suffice. If the building is poorly insulated (the walls are thin, the frames are old), it is better to buy a boiler with a capacity of 10-12 kW.

In the northern regions, for effective heating of a house of a similar area, equipment with a capacity of 12-16 kW will be required, in the southern regions of the country - only 6-7 kW. Thus, when choosing the power of an electric boiler, you need to focus on the area and degree of insulation of the building, as well as on the features of the climate.