Styrofoam

Polyfoam is a porous and lightweight insulation. It is made of polystyrene by foaming. It is considered one of the best (at a low cost) in relation to other thermal insulation materials. It is produced in the form of slabs of different sizes, density and thickness. It has good thermal insulation characteristics, as it consists of tightly connected sealed balls filled with air or gas.

Advantages of expanded polystyrene:

- low coefficient of thermal conductivity - 0.035 W / m · K;

- ecologicaly clean;

- does not allow humid air to pass through;

- able to serve for decades;

- not subject to decay;

- windproof.

The foam is easy to install by one person, as it is lightweight. It is used both inside the living space - walls, ceiling, floor, and outside. They finish different surfaces with it: wood, brick, concrete and others.

It is not used as sound insulation, since it has weak soundproofing properties.

Extruded polystyrene foam

Externally, extruded polystyrene foam is similar to conventional foam, but has a higher density and less thickness. An extruder is used in its production. Due to this, the extruded expanded polystyrene has closed cells of the same size.

Due to its high density, extrusion is used in the construction of railways and highways, as well as runways. This material has excellent strength, so it can be used not only as thermal insulation, but also as an auxiliary or supporting structure.

Positive qualities of extruded polystyrene foam:

- does not absorb liquids;

- does not sit down;

- not afraid of chemicals;

- does not rot and does not overgrow with mold and fungi;

- service life - about 50 years;

- has one of the lowest thermal conductivity coefficients.

It is used for insulation of walls, ceilings, floors, foundations in private houses, apartments and industrial facilities. Also, like polystyrene, it is used only as thermal insulation.

Polyurethane foam

Consists of two components: polyul and isocyanate. By mixing these substances on special equipment, you can get polyurethane foam of different states - from elastic to hard. Polyurethane foam has one of the best thermal conductivity coefficients, therefore it is used for heat and sound insulation of residential buildings and other objects. The consistency is similar to foam.

Related article: Modern materials and methods of noise insulation for a private house

It is applied to any structure by spraying. In just a few seconds, a durable and seamless layer of thermal insulation material is obtained. It is important that all the rules for the application technology are followed. Only qualified specialists should work with this thermal insulation, using the appropriate equipment.

Positive characteristics of polyurethane foam:

- operating temperature - from −150 ° С to + 200 ° С;

- thermal conductivity coefficient 0.022-0.028 W / m · K;

- sprayed onto any surface;

- a solid and monolithic layer is formed;

- has anti-corrosion properties;

- long service life;

- environmentally friendly;

- excellent soundproofing material;

- does not require additional transportation costs, since all the components are brought by the service company.

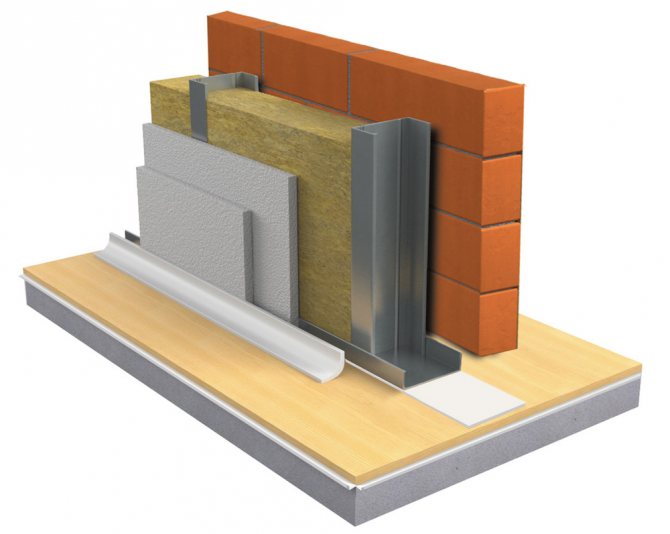

External heat and noise insulation of walls

The advice of the masters is practically the same - you need to choose this particular type for insulation (if this is the main task), since it is easier to prevent the cold from penetrating the wall of the room than to deal with the consequences of its freezing.There is a certain algorithm of actions that is applicable to heat and noise insulation outside the house.

- The walls must first be prepared. The substrate must be dry, clean and sound. If we are talking about the performance of work for which a frame or crate is needed, before they are constructed, it is necessary to take care of a vapor barrier so that the materials are not exposed to moisture. This is especially true for working with wadded heat and noise insulators, since one of the disadvantages of the latter is, just, the fear of moisture. Under its influence, cotton wool loses its properties, and the work will not bring the desired effect. If you want to work with adhesives, dry the wall thoroughly. It is not recommended to carry out such outdoor work in the autumn - spring period, when the humidity is high, it is better to choose a summer day on a sunny week, then your walls will dry on their own, naturally without your help.

- Placement of heat and noise insulator. It is worth fixing the material in the way indicated in the technology above - either by gluing (attaching with a stapler), or placing it under the frame (formwork). It is customary to close the insulator with special materials for facade work. It can be slabs, siding, or more.

If you do not have the opportunity to carry out thermal and noise insulation of the walls in the apartment from the outside, you can resort to internal installation. The technologies of insulation and sound insulation have already been given by us in this article.

Basalt wool

During the production process, from the molten basalt rock processed according to a special technology, mineral wool is obtained. Additives and binders are also added. Basalt slabs are used to insulate residential premises and other buildings. They are very convenient for installation, as they are easily cut with a knife. They can be given any desired shape and installed close to the structures of the house. Basalt slabs are often used as sound insulation on exterior or interior walls.

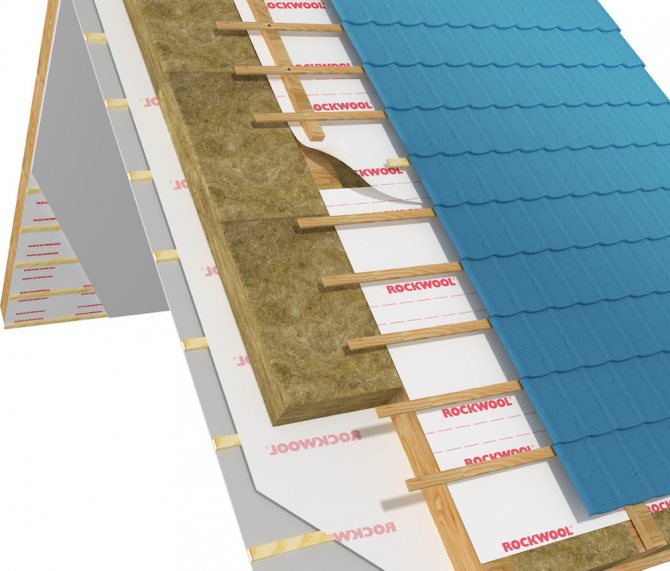

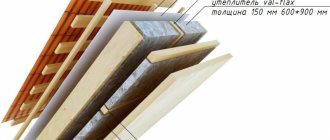

It is convenient to insulate inclined surfaces in attic buildings with mineral wool of the required thickness. Basalt wool is well suited as a device for fire protection of parts of roofs and roofs in houses with stove heating and baths.

Basalt wool properties:

- low hygroscopicity;

- high sound insulating ability;

- easy to process;

- has low deformation;

- is non-flammable material;

- has high thermal insulation qualities.

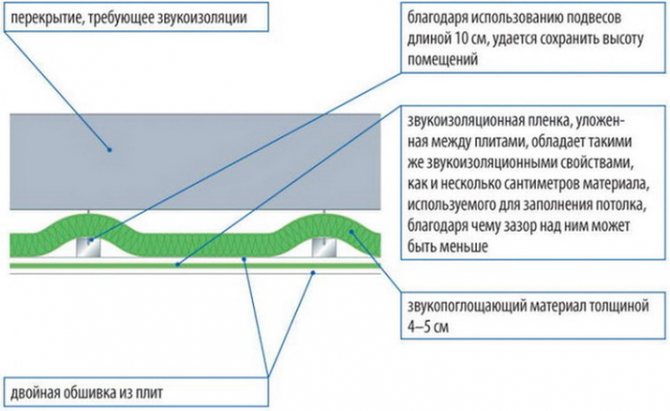

Effective sound insulation with mineral wool

Stone wool is widely used for soundproofing floors, suspended ceilings, internal partitions and attics, since it has a high sound absorption coefficient. It comes in several forms:

- stitched mats;

- soft and hard plates.

Soundproof mineral wool excellently withstands high-temperature heating, does not emit harmful substances into the environment, does not contribute to the development of rodents, moldy fungi and microorganisms. In addition, it is easy to cut with simple tools, extremely easy to install and lay. That is why sound insulation with mineral wool is actively used in construction, agriculture, refrigeration and aircraft production.

Bung

Environmentally friendly wood material made from oak bark and having a porous structure. All cells are filled with inert gas. Differs in positive qualities in sound and heat insulation when used in residential premises. Not used outside.

Technical cork materials provide excellent sound insulation. It can be classified into three application groups:

- Agglomerate panels are made from crushed cork oak bark, followed by steam treatment and then pressed. Since the bark contains the suberin adhesive, unnatural additives are not required.Two types of panels are made: white - from the bark taken from tree branches, and black - from the trunk bark.

- Natural cork - used for decorating rooms. The panels are additionally coated with wax, after which they will not be able to absorb moisture and odors.

- Cork granules - used to insulate frame structures.

Related article: Soundproofing Maxforte: types, specifications, prices, installation

Technical cork is produced in three forms: sheet, roll, in the form of mats.

Roll insulation is most often used as a backing for wallpaper. It can be with or without antibacterial and refractory impregnation. It is produced in lengths of 10 m and a width of 30 cm to 100 cm. For fixing on the surface of the walls, special glue is used.

Cork in the form of mats and sheets is used to insulate floors, walls and ceilings indoors. Also well suited for sound insulation from the inside of the roof, the covering of which is made of metal or profiled sheet.

Plugs of cork:

- low thermal conductivity - 0.042 W / mK,

- it is resistant to deformation;

- good sound insulating performance - reduces noise by 17 dB;

- excellent antistatic properties;

- environmentally friendly;

- durable;

- natural material.

Working with a cork sheet does not require additional physical effort, since it is easily cut to the size of the shape and is easy to install.

In rooms with high humidity, the cork coating must be protected with waterproofing materials.

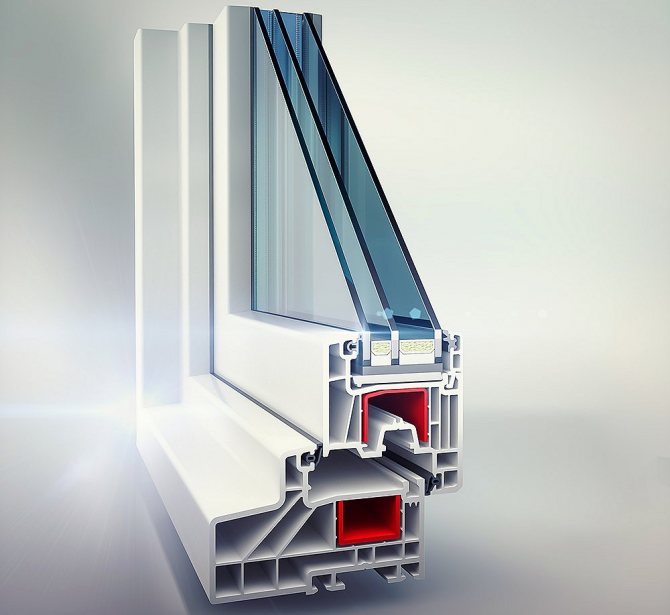

Membrane

The main task of insulating building membranes is to protect a home or non-residential premises from wind, moisture and condensation. They are a special semi-permeable film, divided according to technical characteristics and purpose. They can have a multi-layer or single-layer structure, they are supplemented with an aluminum coating or a reinforcing mesh.

Warm floor. Anti-icing systems. Types and purpose >>>

Modern membranes are environmentally friendly, made from high-tech materials, do not enter into chemical reactions with alkalis and acids, are not affected by fungi and mold, and do not emit odor. With their minimal thickness, the membranes are characterized by a sufficiently high strength and long service life.

Mineral wool (mineral wool)

Fibrous, environmentally friendly material used in construction for sound and heat insulation. It is obtained by melting basalt rocks and adding various binders and water-repellent substances. It is used for insulating houses and other premises from almost all sides: outside, inside, for insulating loggias, attics, attics. It is also used for sound insulation.

On the construction market, you can buy many different options for mineral wool - rolls, panels, cords, etc. Modern mineral wool is much more convenient to install, more wear-resistant and has a longer service life. It is distinguished from other heaters by resistance to temperature extremes, incombustibility, high sound and heat insulating ability, inertness to the effects of biological and chemical substances, low, practically zero hygroscopicity.

Styrofoam

A building material that is obtained by foaming a special plastic mass. The advantages include ease of installation, the ability to use in different climatic conditions, non-susceptibility to the effects of fungi and microorganisms. With the help of foam, you can insulate floors, walls from the inside, outside, and even place the foam in the middle of the walls at the time of their construction. Polyfoam has also proven itself as a soundproofing material.

Expanded polystyrene

You can often hear the opinion that expanded polystyrene and polystyrene are one and the same material. Undoubtedly, they have a lot in common, and both materials are excellent for heat and sound insulation of premises.But there is also a rather tangible difference.

First, the technologies for the production of these materials are different: unlike foam, polystyrene foam is obtained by melting and subsequent pressing of polystyrene granules. In the foam, the granules are adhered to each other, and the expanded polystyrene is a single structure. Secondly, the physical properties of these materials differ. Expanded polystyrene is superior in characteristics to polystyrene. Its advantages include strength, plasticity, environmental friendliness, minimum moisture and sound permeability, much higher density than foam, and at the same time low weight.

This material can serve as a heater for up to 50 years, retaining its physical properties after multiple temperature drops. If you choose the right polystyrene foam, you can forget about the problems with heat and sound insulation for many years, and also significantly reduce heating costs.

Extruded polystyrene foam

An innovative heat-insulating material, one of the varieties of expanded polystyrene. It has unique technical characteristics and a wide range of applications. The peculiarity of the material is a uniform, dense structure, consisting of small, completely closed cells. It can be used for processing and insulating surfaces under high compression loads.

Polyethylene foam

It is used as a substrate for laminate and parquet boards, pipes are insulated with it, premises are insulated, etc. This material is rightfully considered one of the most versatile, since it copes with the same efficiency not only with the tasks of insulation, but also protects buildings from moisture, steam, wind and strong noise.

The structure of the material is a cellular mass. It is produced in rolls, in the form of hollow cylindrical shells for pipes of different diameters, in the form of cylindrical bundles.

Its main characteristics include durability, flexibility, resistance to aggressive building materials (lime, concrete, cement and others), ease of installation, moisture resistance and a low level of thermal conductivity. Excellent quality indicators allow using polyethylene foam not only as insulation for walls, floors and ceilings, but also as an insulating material for pipelines and air ducts, as well as as thermal insulation for refrigerators.

Its service life can be up to 25 years, and in some cases even more. This is an absolutely environmentally friendly and harmless material for humans, which can be used in any room without harm to health. The more durable and versatile types of material include exrusive polyethylene foam.

Synthetic rubber

It is used not only in construction, but also in many other areas. This became possible thanks to the appearance of artificial rubber, because natural material is expensive. Synthetic rubbers, from which rubber is obtained after special processing, are characterized by elasticity, strength, water resistance and excellent electrical insulating properties. They are often used as an excellent thermal insulation material capable of retaining their properties for up to 20-25 years.

Advantages of rubber: incombustibility, environmental friendliness, low cost, ease and availability of installation. Synthetic rubber is used to ensure the tightness of various systems, to prevent condensation, and to create sound insulation.

Heat and sound insulation panel manufacturers

On the market of heat and sound insulating materials, cork insulation is represented by the Portuguese company Amorim Group.

The most popular brands of basalt wool are:

- TechnoNicol;

- Paroc;

- Isover;

- Linerock;

- Rockwool.

Well-known trade brands of expanded polystyrene are Penoplex, URSA and TechnoNicol.Knauf is the most popular foam manufacturer.

Examples of materials and their comparison

For example, the largest insulation manufacturer, K-FLEX, divides its products for noise insulation in the following way depending on the type of material

| SOUND ABSORBING MATERIALSTo absorb and dissipate sound energy by reducing its amount K-FONIK 160-240, K-FONIK P, K-FONIK PU, K-FONIK FIBER P, K-FONIK B |

| SOUND INSULATING MATERIALSFor isolation of airborne noise, preventing its propagation and reflected back to the source K-FONIK GK, K-FONIK ST GK, K-FONIK GV |

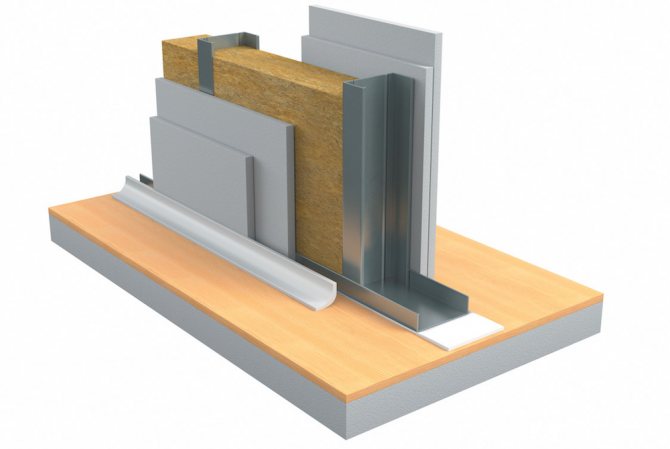

Installation of mineral wool on the walls

The procedure for soundproofing walls with basalt wool:

- A frame is made of wooden beams on the wall. The distance between the vertical posts is made 2 cm less than the width of the insulation.

- Basalt wool slabs are laid.

- Planks are attached to the wooden frame in a horizontal position - for mounting the gypsum board.

- Plasterboard sheets are installed. Screwed to horizontal crossbars with self-tapping screws.

Expanded polystyrene plates are installed in a different way - they are attached to the walls or ceiling with glue and special plastic dowels-nails.

Features of thermal insulation in the apartment and tips for choosing

Only environmentally friendly heat-insulating materials should be used in houses and apartments. Cheap basalt wool will contain hazardous phenol formaldehydes. During the heating of the insulation, they begin to turn into volatile compounds that are harmful to human health.

Insulation made of expanded polystyrene is best used for insulating floors (filling with a screed), balconies, loggias, since it is highly flammable. When the foam burns, it emits toxic fumes that cause poisoning. Also, expanded polystyrene does not allow moisture to pass through, therefore, in houses or apartments with poor ventilation, the microclimate will worsen.