A few years ago, the question of choosing the type of battery was not at all, the range of this equipment was very small, and all had the same radiators. During the Soviet Union, bulky cast-iron options were massively installed, which differed from each other only in size and color. Now the situation has changed dramatically, buyers can choose batteries made of aluminum, steel, composite materials and modern cast iron options. Each type has its positive and negative sides. You should dwell in more detail on the study of aluminum batteries, to determine their scope and criteria for the correct choice.

It so happened that most apartment buildings in Russia, Ukraine, Belarus and other neighboring countries have a central heating system. In Western Europe, you can often find steam systems, but they have not found application in our country. At the same time, all kinds of electrical equipment are perceived by people only as additional devices that allow maintaining the required temperature in the house.

This situation with the maintenance of warmth and comfort in the home does not suit everyone. Outdated central systems sometimes show poor performance. And the old, cast-iron batteries, which are still installed in many homes, are long overdue to throw away and install modern efficient options.

Among these, bimetallic and aluminum batteries are distinguished, they can qualitatively replace old samples. The new equipment not only looks more pleasant, but also has good performance characteristics.

What is the effect of the dimensions of aluminum heating radiators

One of the most important parameters is the gap between the axes of the radiators. Most often, you can find aluminum devices on sale, in which the distance between two collectors - the lower and the upper one - is 350 or 500 millimeters. True, there are products with an indicator equal to 200, 400, 600, 700 and even 800 millimeters.

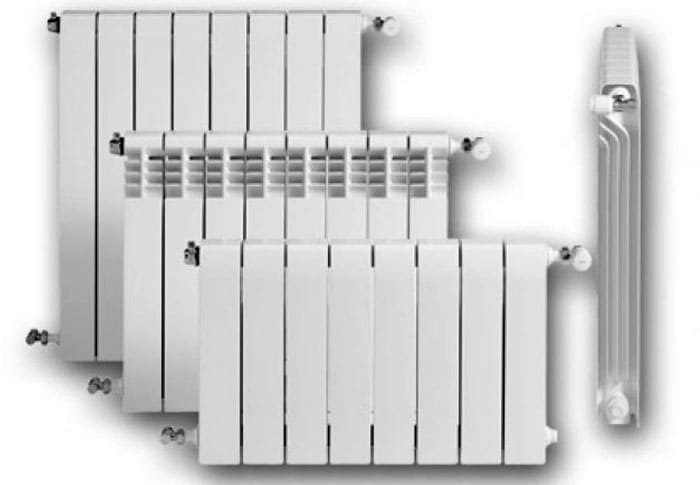

The dimensions of aluminum radiators are practically unlimited in length. The longer the battery, the higher its capacity. To reach the required power level, it is necessary to purchase a certain number of heating sections.

The total length of the device depends on the power required to heat the room, on the dimensions of the heating batteries, sections and heat transfer.

To dock individual elements of an aluminum radiator with pipelines of a heating structure, use a mounting kit for installation, which includes:

- special brackets for hanging the battery on the wall in the amount of 2-4 pieces;

- Mayevsky crane - a device for bleeding air that has entered the system;

- key for the crane;

- straight through radiator plugs with a diameter of 3/4 or ½ of the right or left type;

- plugs for the heater, they are also called blind plugs;

- sometimes dowels are also provided to secure the brackets.

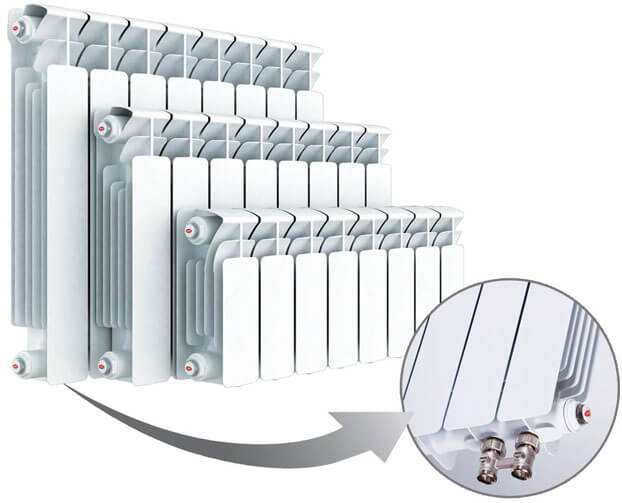

Depending on the type of manufacture of an aluminum alloy radiator, the heater can be cast or extrusion:

- thanks to the molding, the battery becomes durable and reliable. In this case, the sections are made up of separate parts, cast as a whole and then assembled into a single heater. Its lower part is welded very last;

- in the process of using extrusion equipment, the heated aluminum alloy is pushed through a special metal plate with holes. This method allows you to make a long aluminum profile of the required shape. When it cools down, it is divided into segments that correspond to the dimensions of the device.Only then the top and bottom of the battery are welded. In this case, it is impossible to adjust the length of the radiator, and sections cannot be added or subtracted to it. Extrusion devices are rarely found on the market.

Varieties of aluminum batteries

There are three options for aluminum radiators on the market today:

- Injection molded;

- Extrusion;

- Combined.

Injection models

This type of aluminum battery is more expensive than others. During production, all sections are injection molded separately. The main material is an aluminum alloy - silumin. It contains about 12% silicon, which makes the structure more durable. Various structural parts are connected by welding in an inert gas atmosphere. The manufacturability of the entire process allows for the production of reliable batteries. Already from the finished sections, radiators with the required power indicators are formed.

The advantages of this type:

- Details are connected securely and tightly;

- By delivering or uncoupling sections, the size and power of the equipment is controlled.

Disadvantages:

- Higher price compared to other types.

Extrusion models

In order to make the process of making radiators cheaper, the central part of the battery began to be produced by the extrusion method. This means that the middle piece is not made by casting, but is simply squeezed out by an extruder with high pressure. At the next stage of work, the part is pressed with collectors. To connect all parts of the radiator together, use composite glue. This solution also makes the battery production process cheaper. True, it will no longer be possible to disassemble a structure of this type.

Advantages of extrusion radiators:

- For products, they take secondary aluminum, which has good heat transfer;

- The volume of the middle of the sections is 50% less than that of cast models;

- Narrow ribs make the construction lighter;

- Such batteries are much cheaper.

Disadvantages:

- Disassembly is impossible, which excludes the process of alteration or internal repair;

- The vulnerable part of the battery is the connection of the sections and the collector. Leaks often form in these places. Moreover, wear can touch both the rubber seals and the adhesive base;

- Cracking is possible with temperature drops.

Experts say lithium models will be a more durable and functional option. It is these radiators that are advised to buy for apartments or private houses. Extrusion ones are equipped with very thin walls, this, of course, makes the structure lighter, but reduces its performance at high pressures. When the most important selection criteria are low cost, good heat dissipation and light weight, it will be better to purchase extrusion radiators.

Combined models

There is also a third version of aluminum batteries, which combines the two previous ones. As a result, the batteries consist of vertical extruded parts and cast manifolds. This variety is hard to confuse with something; it is sold in the form of blocks or special sections that have certain functionality.

Regardless of which models you need to make a choice in, the manufacturer's factor is also taken into account when buying. Here it is better to trust companies with a name.

Parameters and dimensions of ROVALL aluminum radiators

The company producing aluminum radiators TM ROVALL is one of the divisions of the Italian concern Sira Group. This company manufactures aluminum alloy batteries with a distance between the two collectors equal to 200, 350 and 500 millimeters. The kit for their attachment, which is purchased separately, includes the following products: plugs, adapters, for connecting sections - nipples with gaskets and for wall mounting - brackets, as well as a Mayevsky crane. Main parameters of ROVALL aluminum radiators:

- the permissible operating pressure is 20 bar, and when tested - 37.5 bar;

- maximum temperature - no more than 110 ° С.

All Rovall Alux 200 models, according to the official sources of the manufacturer, with a distance of 200 millimeters between the axes, have a height of 245 and a depth of 100 millimeters. In this case, the minimum length is 80, and the maximum is 1280 millimeters. In turn, heat transfer can be at a minimum of 92, and at a maximum - 1472 watts. The number of sections varies from one to 16.

The Rovall Alux 350 radiator models, with a distance of 350 millimeters between the collectors, have a height of 395 and a depth of 100 millimeters. At the same time, the minimum length of the devices is 80, and the maximum is 1280 millimeters. In turn, heat transfer can be from 138 to 2208 watts. The number of sections is from one to 16.

Rovall Alux 500 instrument models, with a center distance of 500 mm, have a height of 545 mm and a depth of 100 mm. At the same time, the length of the devices is minimum - 80, and maximum - 1280 millimeters. In turn, the power can be at - a minimum of 179, and at a maximum - 2840 watts. The number of sections is from one to 16.

Installation

As a tool for installation, it is enough to purchase a universal installation kit: special wall brackets, plugs, gaskets and air vents.

The main rule for installing aluminum radiators is not to connect them to copper pipes, since when these metals come into contact with each other, they can cause air to accumulate. The service life of heating devices varies from 5 to 15 years, and some manufacturers have increased it to 20-25 years.

Radiator volume parameters from Climatic Control Corporation LLP

This company from the UK produces BiLUX AL aluminum heating devices, which have an excellent degree of heat transfer, and are manufactured taking into account the peculiarities of autonomous heating systems. The surface area of these batteries is significant, and the cross-section of a vertically located pipe, when the calculation of aluminum heating radiators was made, was determined optimally.

The plant that manufactures the BiLUX AL M 300 and BiLUX AL M 500 radiators is located in China. Between both axes of the collectors, the distance is 300 or 500 millimeters. During the manufacturing process, the die-cast heads of the devices are connected to the bottom, which is manufactured using a specially developed welding technology.

When the products are ready, they are subjected to chemical and mechanical processing after assembly. Only then are the aluminum devices tested and checked for strength and tightness. Their painting is carried out in several stages. In addition, they are exposed to an electrostatic field and at the same time they are sprayed with enamel produced on the basis of epoxy resins. Then, when heated to a high temperature, the surfaces of the radiators are polymerized.

The peculiarity of BiLUX AL devices is that their ends have a special design solution, which allows using a special ring for laying. The material of its manufacture completely seals the joints. Nipples for them use cadmium plated, as a result, the probability of coolant leakage is reduced to zero.

Main dimensions of BiLUX AL aluminum radiators:

- the permissible operating pressure is 16 bar, and when testing the device - 24 bar;

- the pressure that can break the device is 48 bar.

Single-cell batteries BiLUX AL M 500 with a distance of 500 millimeters between axles and 180 watts have the following parameters (in millimeters):

- height - 570;

- depth - 75-80;

- length - 75.

One-section BiLUX AL M 300 with a distance of 300 millimeters between axles at a power of 128 watts have the following dimensions of an aluminum radiator section (in millimeters):

- height - 370;

- depth - 75-80;

- length - 75.

disadvantages

Aluminum heating radiators also have negative characteristics:

- the risk of leakage between sections in case of malfunctions in the heating system;

- concentration of heat on the ribs;

- susceptibility to corrosion;

- low convective capacity and high probability of gassing.

The last minus is especially dangerous - even a small volume of air can lead to a complete failure of the heating system. Therefore, it is imperative to install an automatic drainer!

The use of an oxide, chemically inactive film, as well as additional anti-corrosion preparation, helps to prevent corrosion, which is associated with the activity of the metal.

Dimensions of aluminum radiators from Fondital

The Fondital company (Italy) produces Calidor Super aluminum batteries adapted for the climatic conditions of Russia and the CIS countries (see photo). In their manufacture, European standards are taken into account, such as EN 442 and Russian, according to GOST R RU.9001.5.1.9009.

The method of their manufacture is high pressure casting. Painting is carried out in two stages: initially, one layer of enamel is applied using anaphoresis as a protection, and then, using powder enamel, the product is given a decent appearance. You will have to buy a mounting kit for the radiator separately. It includes: adapters; brackets; blind plugs and Mayevsky's tap.

The distance between the axles is:

- 350 millimeters for the S4 model, which has 4 side ribs and a section depth of 97 millimeters;

- 500 mm for models S4 and S3 (3 ribs and 96 mm depth).

Main parameters of Calidor S aluminum radiators:

- allowable working pressure - 16 bar, and when testing the device - 24 bar, maximum breaking limit - 60 bar;

- limiting temperature - no more than 120 ° С.

Radiator models Calidor Super 350 S4, with a gap of 350 millimeters between the two axles, according to the manufacturer's official sources, have a height of 428 millimeters and a depth of 96 millimeters. At the same time, the length of the devices is minimum - 80, and maximum - 1120 millimeters. In turn, heat transfer can be at a minimum of 145, and at a maximum - 2036 watts. The number of sections is from one to 14.

The dimensions of aluminum heating radiators Calidor Super 500 S4 with a center-to-center distance of 500 millimeters are as follows: height 578 millimeters, section depth - 96 millimeters. At the same time, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the power can be at the minimum 192, and at the maximum - 2694 watts. The number of sections varies from one to 14.

All models of Calidor Super 500 S3 devices with a distance of 500 millimeters between the axes have a height of 578 and a depth of 100 millimeters. At the same time, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the minimum power can be 178, and the maximum - 2478 watts. The number of sections varies from one to 14.

Application features

As already mentioned, aluminum and its alloys used in the manufacture of radiators are highly sensitive to the quality of the coolant. Namely, its acidity. The normal acidity of the coolant should be in the range of PH = 7-8. In case of a deviation from the norm, the protective oxide film is washed out, and as a result of the formation of a new one, hydrogen is released (the effect of champagne). This causes a lot of troubles, ranging from the formation of air locks and ending with the failure of the battery due to accelerated corrosion. This is especially well traced in the summer months, when the coolant is drained from the common system, and the pipelines are clogged. The large amount of hydrogen released simply breaks the housing from the inside.

Using a radiator with an insufficient strength indicator in a city apartment

When choosing aluminum radiators, it is also necessary to take into account the operating pressure in the system. For centralized networks, the standard is 10-15 atmospheres. However, this is the working pressure. When starting up and checking heating systems for leaks, the pressure test is increased up to 1.5-2 times.Thus, for apartments with a centralized system, only anodized aluminum radiators can be used.

Aluminum radiators are available in the widest range of sizes. In addition, you can add and remove sections yourself, optimizing the heat dissipation of the battery.

In individual heating systems, the operating pressure rarely exceeds 1.5-2 atm. Therefore, any type of aluminum radiators can be used there.

Galvanic couple effect. There is a fairly well-founded opinion among engineers and thermal installers that aluminum radiators cannot be used in conjunction with boilers that are equipped with copper heat exchangers. The reason is the formation of an aluminum-copper galvanic pair, which leads to electrochemical corrosion. In the case of its formation, copper attracts aluminum ions, and, literally for several years of operation, aluminum on the radiator turns into foil.

Galvanic couple effect. The intense release of hydrogen can not only destroy batteries, but also cause a fire.

However, this effect can only be achieved in the case of direct contact between copper and aluminum. If PVC pipes are used to transfer the coolant or special cadmium, chrome-plated or nickel-plated adapters are used during installation, then the galvanic pair is ruptured.

Features of aluminum radiators from Faral S.p.A.

This company, exclusively for the Russian market of heating equipment, produces durable radiators FARAL Green HP (Italy), capable of withstanding a working pressure of 16 atmospheres. In their manufacture, the injection method is used. The outer and inner surfaces are covered with a zirconium protective layer that penetrates deeply and is not washed off during operation. As a result, no gas evolution occurs when the device comes into contact with water. The possibility of electrochemical corrosion is excluded.

The Green HP batteries are 80 millimeters deep, while the Trio HP batteries are 95 millimeters deep. The distance between the axes is 350 or 500 millimeters. The separately sold instrument mounting kit contains: a bleeder valve; brackets; adapters with plugs; self-tapping screws with plugs and silicone gaskets.

The main parameters of FARAL aluminum radiators:

- operating pressure up to 16 bar is allowed, and when testing devices - 24 bar;

- limiting temperature - no more than 110 ° С.

All models of FARAL Green HP 350 devices, according to information from the manufacturer's official data, with a distance of 350 millimeters between two collectors, have a height of 430 and a depth of 80 millimeters. Moreover, the length is from 80 to a maximum of 1120 millimeters. The power can be at least 134 watts, and at the maximum - 1904 watts. The number of sections is from 1 to 14.

The radiator models FARAL Green HP 500, with a distance of 500 millimeters between the axles, have a height of 580 millimeters and a depth of 80 millimeters. In this case, the length of the devices is from 80 (minimum) to 1120 millimeters (mausimum). In turn, heat transfer can be at a minimum of 180, and at a maximum of 2520 watts. The number of sections is from one to 14.

FARAL radiators of the Trio HP 500 model range have a center-to-center distance of 500 millimeters, the height of the devices is 580 millimeters, and the depth is 95 millimeters.

At the same time, the minimum length of the devices is 80, and the maximum is 1120 millimeters. With regard to heat transfer, its minimum value is 212 watts, and the maximum is 2968 watts.

The number of sections, depending on the capacity, can be from 1 to 14.

FARAL radiators of the Trio HP 350 model range have a center-to-center distance of 350 millimeters, the height of the devices is 430 millimeters, and the depth is 95 millimeters.

At the same time, the length of the devices is from 80 to a maximum of 1120 millimeters. With regard to heat transfer, its minimum value is 151 watts, and the maximum is 2114 watts. The number of sections can be, depending on the power, from one to 14.

Benefits of aluminum options

The main characteristics of aluminum are lightness, fusibility, the possibility of various processing and good heat transfer. These features forced the craftsmen to use aluminum products in heating systems. In particular, radiators have proven themselves well, they have such positive aspects:

- With a small size, the system provides good heat transfer;

- Compared to cast iron batteries, aluminum ones are not so heavy, and this greatly facilitates the process of transportation and installation;

- Low inertia of heating. This characteristic means that in a short period of time the radiator will react to changes in the temperature of the coolant;

- Good price / heat ratio;

- High quality and stylish design;

- Powder coating protects equipment from rust. Also, non-batteries do not need regular painting;

- Convection heating eliminates large dust balls between sections.

In principle, aluminum batteries can be painted with a special paint of the desired shade, but in most cases, consumers install white radiators at home, they fit perfectly into any room design. If you need an individual solution, you can purchase custom-made colored batteries or additionally buy a decorative grille. If the painting is done in a production environment, then its service life is comparable to that of the battery itself. There are also special photographic images, but their material must tolerate high temperatures well.

Calculation of aluminum radiators from Global

Global radiators from the company of the same name (Italy) can be installed in apartments of multi-storey buildings, and in their own houses. Their distinctive characteristics are elegant and original appearance. The most popular are the ISEO and VOX models with a center distance of 350 or 500 millimeters. A mounting kit is standard and sold separately.

Main parameters of Global aluminum radiators:

- the maximum working pressure is 16 bar, and when testing the device - 24 bar; the limiting temperature of the heated water is no more than 110 ° С.

For Global VOX 350 models, according to the manufacturer's official sources, with a distance of 350 millimeters between the axes, the height is 440 and the depth is 95 millimeters. At the same time, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the power can be at a minimum of 145, and at a maximum - 2030 watts. The number of sections varies from one to 14.

Global radiators of the VOX 500 series have a center-to-center distance of 500 millimeters, the height of the devices is 590 millimeters, and the depth is 95 millimeters.

At the same time, the minimum length of the devices is 80, and the maximum is 1120 millimeters. With regard to heat transfer, its minimum value is 193 watts, and the maximum is 2702 watts. The number of sections can be, depending on the power, from one to 14.

For Global ISEO instrument models, according to the manufacturer's official sources, with a distance of 350 millimeters between the axes, the height is 432 and the depth is 80 millimeters. At the same time, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the power can be at a minimum of 134, and at a maximum - 1976 watts. The number of sections varies from one to 14.

The Global radiators of the ISEO model range, which have a center-to-center distance of 500 mm, have a height of 582 mm and a depth of 80 mm.

At the same time, the minimum length of the devices is 80, and the maximum is 1120 millimeters. With regard to heat transfer, its minimum value is 181 watts, and the maximum is 2534 watts. The number of sections can be, depending on the power, from one to 14.

Parameters of aluminum radiators from Torex

The Italian company of the same name offers aluminum sectional heating devices, which are manufactured by casting. Their peculiarity lies in the presence of unusual light transitions on the front.For models that have a center distance of 350 millimeters, the depth is 78 millimeters. But for batteries with a gap between the axes of 500 millimeters, the depth of the radiators can be 70 or 78 millimeters. They can have one or an even number of sections. The mounting kit must be purchased separately.

Main parameters of Torex aluminum radiators:

- the permissible operating pressure is 16 bar, and when testing the device - 24 bar;

- limiting temperature - no more than 110 ° С;

- the required pH of the water is 7-8 (6.5 - 8.5 is acceptable).

For Torex B 350 models, according to the official sources of the manufacturer, with a distance of 350 millimeters between the axes, the height is 420 and the depth is 78 millimeters. At the same time, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the power can be at least 130, and at the maximum - 1820 watts. The number of sections can be from one and then an even number up to 14.

Torex radiators of the B 500 series have a center-to-center distance of 500 millimeters, the height of the devices is 570 millimeters, and the depth is 78 millimeters. At the same time, the minimum length of the devices is 80, and the maximum is 1120 millimeters. With regard to heat transfer, its minimum value is 172 watts, and the maximum is 2408 watts. The number of sections can be from one and then an even number to 14.

Torex radiators of the C 500 model range have a center-to-center distance of 500 millimeters, the height of the devices is 570 millimeters, and the depth is 70 millimeters. At the same time, the minimum length of the devices is 75, and the maximum is 1050 millimeters. With regard to heat transfer, its minimum value is 198 watts, and the maximum is 2772 watts. The number of sections can be from one and then an even number to 14.

Manufacturers: black and white list

Of the main manufacturers whose products are deservedly popular, many Italian firms can be noted:

- Global;

- Fondital;

- Nova;

- Florada;

- Radiatori;

- Sira.

Also noteworthy are the products of the Hungarian company. Nami.

Of the domestic companies, it is worth noting radiators from Anchor, Rifar (under the Global license) and Thermal.

Some Chinese manufacturers operating under the Global license were also whitelisted: Alltermo, Tianrun.

Also, we want to draw your attention to the list of companies (mainly Chinese), about whose products we found the most negative reviews:

- Oasis;

- Konner;

- Radena;

- Warma.

In addition, during tests carried out in 2020 in the Moscow laboratory "Vitaterm", in the products of the listed companies, inconsistencies in real parameters with the declared indicators were found from 22% to 34.75%.

Dimensions of the section of aluminum radiators from Rifar

The company manufactures aluminum batteries of BASE models with a distance between two axes of 200, 350, 500 millimeters. ALP products have an improved design, increased heat dissipation and a center distance of 500 millimeters. Alum models are specially designed devices that can be used both in standard heating systems and as an electric oil heater. The unique design of Flex allows you to give the device the desired radius of curvature.

The main characteristics of radiators made of aluminum Rifar:

- permissible working pressure is 20 atmospheres;

- limiting temperature - no more than 135 ° С;

- the required pH of the water is 7-8.5.

Aluminum radiator section volume

Knowing the volume of one section of an aluminum radiator is very important for autonomous heating systems. To determine how much antifreeze is needed to fill the heating system, use calculation tables.

To find out the volume of water in one section, use the information that is available in thematic reference books:

- in a standard device, the volume of the aluminum radiator section is 0.45 liters of coolant;

- a running meter of a pipe with a diameter of 15 millimeters contains 0.177 liters, and a pipe with a diameter of 32 millimeters contains 0.8 liters.

Radiator selection

Very often, many have doubts about which heating radiators are better than aluminum or bimetallic ones, and in order to answer this question, it is necessary to disassemble each type separately. In the modern market for heating devices, you can find cast iron, aluminum and bimetallic types of batteries.

Cast iron batteries have a traditional appearance, making them suitable for absolutely any room. Such a battery is distinguished by a good indicator of specific heat transfer. Moreover, such a heater is particularly resistant to rust. The downside of a cast-iron battery can be considered the occurrence of a periodic need for painting.

Bimetallic radiators have a more complex structure, since they consist of two layers. They are covered with aluminum on the outside, and steel pipes are installed on the inside. Due to the presence of steel in the structure, the resistance of the device to possible mechanical damage and the reliability of the radiator are significantly increased. Aluminum provides high heat transfer and quick warm-up. For a multi-storey building, this type of radiator will be an ideal option. This is due to the fact that bimetallic radiators are designed for higher pressure in the system than aluminum devices. The disadvantage is the high cost of such a radiator.

The steel radiator is a single panel made of steel sheets. Such radiators are perfect for installation in private houses or apartments in which the installation of an autonomous heating system is planned. Steel radiators are distinguished by a high heating rate, in conditions of slightly heated water. The disadvantage is that such heating devices are susceptible to metal corrosion, are designed for low pressure in the system and are exposed to mechanical stress. If steel radiators have been installed for the heating system, then in order to prevent the appearance of rust, shut-off valves should be made that will help to ensure that the radiator is constantly filled with water.

Calculating the number of sections

There is a simple option how to calculate the number of sections.

To do this, you need to know the area of the room and the standard capacity, which is equal to:

- if the ceiling height is 2.5 - 2.7 meters, there is one outer wall and one window - 100 watts;

- if the ceiling height does not exceed 2.7 meters, there are two outer walls and one window - 120 watts;

- if the ceiling height is not more than 2.7 meters, there are two outer walls and two windows - 130 watts.

Before calculating the number of aluminum radiators, you need to find out the power of one section in the passport for the device. Now you need to multiply the standard power by the area of the room and divide by the power of one section. The result obtained needs to be rounded up (about