Any engineering communications, including heating systems, gradually wear out and fail. Malfunctions are of a different nature, but when the heating battery leaks, this leads to unpleasant consequences. The sooner the leak of a cast-iron, steel or bimetallic radiator is eliminated, the less likely it is to flood your apartment and flood your neighbors.

- Why are heating radiators leaking?

- A heating radiator is flowing: what to do

- How to fix a leak in a weld

- Eliminate leakage between battery sections

- How to repair a leak in a heating battery: repair methods

Why is the heating battery leaking

Before figuring out how to fix a radiator leak between sections or in another place, you need to understand the causes of the problems that arise:

- Cast iron radiators are heavy and mounted on strong hooks. With a minimum error, the radiators sag under their weight, and a misalignment of a few millimeters causes air pockets to form. In these places, corrosion begins - the cast iron becomes thinner and after a while a fistula forms. A slight leak appears, which it is desirable to quickly eliminate.

- In houses with a centralized heating system, water shocks often occur, due to which heating batteries sometimes leak at the joints (this is especially true for bimetallic radiators).

- Pig-iron radiators are rough inside, so all kinds of debris and foreign inclusions are retained on the surface: pieces of metal, rusty sediment, etc. Gradually, the channels begin to clog, and the deterioration in the circulation of the coolant leads to the risk of a breakthrough or leakage. This is another reason why batteries, both cast iron and steel, leak.

- Gaskets and nipple threads are weak points of heating radiators, so leaks can form in these places.

When calling the master online

Practice shows that the leakage of aluminum, steel and other radiators does not appear suddenly. First, characteristic signs appear: the air temperature in the room decreases, a deposit forms on the radiator, and corrosion spots form on the surface.

Don't be idle when you see these signs, but decide what to do - the battery is already leaking. If you ignore the situation, an accident may occur. Also, soon you may find a puddle of water under the radiator, and the level of humidity in the room will noticeably increase. You can repair the leak in the heating radiator yourself or contact the craftsmen. An experienced plumber of our company will quickly eliminate the leakage of any radiator: aluminum, steel, bimetallic, cast iron.

Many are worried about the question, if the battery is leaking, who to call? If you live in an apartment with central heating, contact the management company or us. In other cases, you can do without the management organization - it will not help you.

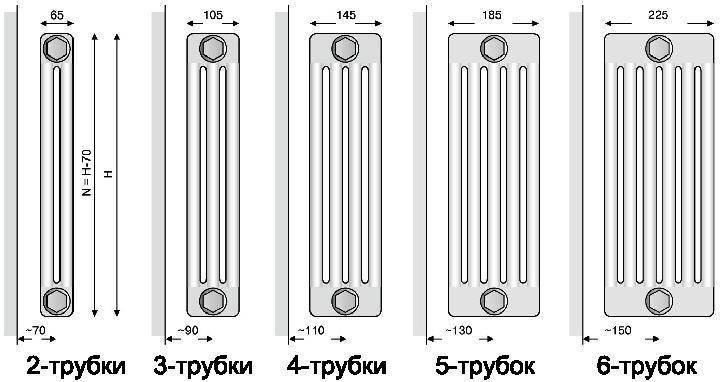

What does the battery consist of?

If we are talking about old-style radiators, then outwardly they resemble accordions, and modern models are flat, due to which they heat up more evenly. Cast iron is a very strong material, but even it is not eternal, it has a limit of stability.

So the service life varies from 20 to 30 years old, depending on the operating conditions. If maintenance is carried out on time and in a timely manner, then the service life will increase several times and the battery will last for almost a hundred years.

Unfortunately, in the places where the sections are fastened to each other, problems often arise, they sway from the water or crack from old age.This is where the leak begins, which is better to localize as soon as possible.

Substituting a basin or saucepan under a dripping battery is not an option, since a crack tends to grow so one day there might be a flood! If we are talking about the winter period of time, then there is generally boiling water in the pipes, which poses a serious danger to the life and health of people.

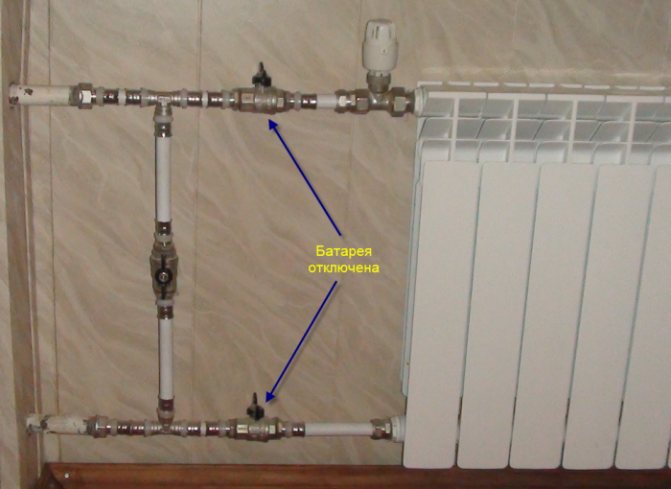

How to fix a leak in a heating radiator

What to do when the radiator begins to ooze at the joints, between adjacent sections, or a tap is leaking? Many people, finding a leak, get lost and do not understand what to do. First of all, you need to shut off the coolant supply and substitute something under the place from where the water is dripping or flowing. In a private house, this will not be a problem, and apartment residents may have to go to the basement in order to shut off the supply valves on the entire riser (if the apartment does not have taps on the radiators).

We must warn you right away: if you do not have a set of tools and spare parts, do not even think about how to fix a leak in an apartment or house on your own. Otherwise, you can only make things worse. It is better to call the master by calling our company. If you decide to act on your own, try to follow the instructions for each specific situation.

Pipe connection leaking

It is possible to eliminate the leak at the joints of the pipes with the same home-made or factory clamps. If there is a difference in diameter, you can first wind up the rubber band and then make or put on a clamp.

If the connection is threaded and drips from under the winding, you can pour alcohol on the tow, and then spread it with BF glue. It is alcohol-soluble. Once on the alcoholized tow, it liquefies and can leak into the compound. Then, when the alcohol evaporates, the glue dries up, the "drops" stop. But this method works only if you have exactly "drops", and not a "fountain". And one more thing: such a processed connection is very difficult to disassemble later.

If it is possible to stop the system or turn off the radiator (if it leaks at the point of connection with it), it is better to repack the threaded connection. To do this, carefully and slowly unscrew the nut (lock nut). It needs to be turned away and then wrapped. Do not make significant efforts - there is a great chance of breaking, and then you will definitely have to stop the system and redo everything. Having turned the nut, remove all the tow or fum tape, remove the remnants of the sealant, in general, thoroughly clean the threads. Wipe it to a clean state, you can treat it with a degreaser (acetone or pure gasoline).

If it leaks under the locknut, it can be repacked

Please note that there is no excess tow - just a little, and on top there is a paste. Take a roll and paste (sealant), wind up flax and grease everything with paste. Now you can twist

First with the hand, then with the key. But here, too, you need to work carefully: it is very easy to break the thread. Therefore, do not hold the key by the edge, but in the middle - it is easier to calculate the efforts this way. Do not overdo it with the amount of tow. If cast iron, in principle, does not matter how much winding you wind, then aluminum and bimetallic, as well as steel from a large amount can crack. A microcrack first appears in the collector, into which water seeps. Metal corrodes, paint swells, a section (or the entire radiator) is damaged

Now you can spin. First with the hand, then with the key. But here, too, you need to work carefully: it is very easy to break the thread. Therefore, do not hold the key by the edge, but in the middle - this makes it easier to calculate the efforts. Do not overdo it with the amount of tow. If cast iron, in principle, no matter how much winding you wind, then aluminum and bimetallic, as well as steel from a large amount can crack. A microcrack first appears in the collector, into which water seeps.Metal corrodes, paint swells, a section (or the entire radiator) is damaged

Take a roll and paste (sealant), wind up flax and grease everything with paste. Now you can spin. First with the hand, then with the key. But here, too, you need to work carefully: it is very easy to break the thread. Therefore, do not hold the key by the edge, but in the middle - this makes it easier to calculate the efforts. Do not overdo it with the amount of tow. If cast iron, in principle, no matter how much winding you wind, then aluminum and bimetallic, as well as steel from a large amount can crack. A microcrack first appears in the collector, into which water seeps. Metal corrodes, paint swells, a section (or the entire radiator) is damaged.

But this is all in those cases when the threaded connection is flowing. If the fitting has leaked under the press (metal-plastic pipes), you can try to simply tighten it. In the case of copper pipes, only the option with soldering will work. If there is a leak at the junction of polypropylene pipes, there is also only one option - cut out the damaged piece and weld a new one.

It doesn't matter what you use. The result is important

What to do if a weld seam is leaking

A heating radiator often leaks in a weak spot. it may appear if, when installing the battery, a fragile weld was made at the junction with the pipe. a leak can provoke a pressure jump (the so-called water hammer) or an increase in the temperature of the coolant.

What to do with such a leak? Use a metal strap with a rubber pad over the hole (a bicycle tube will do). Wrap the pipe with the leak with a rubber strip and fit the clamp on top. It needs to be tightened well, and the leak will disappear. If there is no clamp, use plain wire, tightening with pliers.

Leakage actions

When urgent measures do not give a positive result, you need to drain the water from the system and make high-quality repairs to the damaged area.

For this:

- turn off the tap on the riser, warning your neighbors if this is a common valve;

- drain the water from the system.

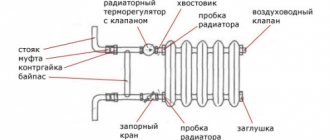

Node near the riser

One of the most common damage is the junction of the riser and pipe. Leakage in this area can come from poor joint sealing. Perhaps, when attaching the pipe to the thread, little winding was laid or the locknut was not tightened.

The connection must be disassembled and twisted again. Use tape or sealing thread to wind the FUM. It is advisable to replace the locknut. If the weld seam leaks, then the water from the riser must be drained and the seam must be re-made. This requires the involvement of a welder.

Radiator sections

The radiator sections are pulled together. In places of their docking there are rubber gaskets. Over time, the screed may loosen or the gaskets become unusable. Water makes its way at the junctions of the sections. First, using adjustable wrenches, tighten the connection without removing the radiator.

If it does not help, then dismantle the faulty battery. Shut off the water supply, drain the water from the system and unscrew the radiator. Disassemble into elements, put new gaskets. You clean the sections from slags. Reassemble and install.

Battery entry

Warm water flowed out where the pipe enters the battery. This is a threaded connection, consisting of a squeegee, a coupling and a locknut. These elements are made separately and sometimes not of high quality metal. In addition, if the battery is cast iron and poorly fixed to the brackets, it creates pressure that deforms the connection over time.

This unit must be replaced unambiguously. It happens that it is impossible to unscrew the rusted parts, then they are heated with a gas burner. This operation is carried out with extreme caution, having prepared fire extinguishing means and fencing the place of work with protective screens made of non-combustible materials.

Battery fin

If a crack forms in the accessible area of the rib of the battery, it can be temporarily neutralized. There are 2 types of welding of heating batteries: hot and cold.

If the battery registers are metal, then hot welding can help repair the leak. If they are aluminum or cast iron, then you can forget about it. In this case, cold welding will help. This requires a high-temperature, water-resistant plastic mass that chemically reacts with these metals.

Thoroughly clean, degrease and dry the place for welding. Knead the substance until a homogeneous composition, apply in a small layer and allow to harden. Welds such as ABRO STEEL or POXIPOL do their job perfectly. The range of such adhesives is wide. You can choose a welding for the material from which the radiator is made.

Faucet or joint

When the faucet is the source of the leak, it must be replaced. If the crane has not been used for a long time, then it becomes clogged with deposits and does not fulfill its task. However, its swivel part, moved from its place, can also leak. When choosing a new shut-off device, give preference to non-ferrous metal ball valves.

Leakage at the joints can be eliminated by wrapping the damaged area with a bandage soaked in saline solution. After drying, pull it off with a bandage soaked in a mixture of gypsum and cement.

Modern industry offers consumers plate glue for this purpose. Wrap the leak with the finished strip. On contact with air, the polymer solidifies and fixes the problem. When using silicone sealants to seal leaks at the joints or threaded connections of the valve, select neutral compounds. An acid-based sealant can promote subsequent metal corrosion.

How to repair a leak between radiator sections

A breakage of the radiator plate made of thin material is not excluded. Corrosion over time will corrode the battery from the inside (especially for steel radiators), a fistula with a leak will appear - you will immediately see how the water seeps out.

In this case, you need to act quickly. If the radiator is bimetallic, replace one of the leaking sections. As an emergency measure, cold welding is suitable, which needs to close up the leakage, having previously shut off the water. You will hardly be able to disassemble a bimetallic or cast-iron radiator to replace individual sections on your own, so it's better to call a master.

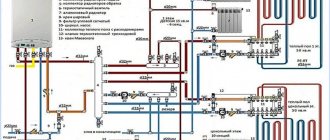

Setting up the heating system

After filling the system, you need to go through all the radiators and bleed the air through Mayevsky's taps: open the Mayevsky's tap, first the air comes out, then the tap "spits" with air and water ... when only water has flowed, it means that the radiator is filled with water, we close the Mayevsky's tap. And so on for all radiators.

Most likely, the pressure after manipulating the radiators will drop, so we recharge the system to the operating pressure. If there is a second floor, we bleed the air from its radiators in the same way. And - we feed the system up to working pressure.

We bleed air from the circulation pump. The pump has a screw, it needs to be slightly unscrewed with a screwdriver with a wide slot. First, as from radiators, air will come out, and then a thin stream of water. Then tighten the screw. Check pressure, top up heating fluid if necessary.

We start the pump.

Important! Before going any further, listen to see if the pump is running. It happens that it does not work because its rotor has soured.

We turn off the pump and fix it, for which it is necessary: 1) unscrew the screw in the center of the pump motor; 2) inside, at the end of the rotor, there is a slot, insert a screwdriver into it and turn the rotor; 3) screw the screw into place. Let's turn on the pump again, it just has to work now.

For 10-15 minutes.Moreover, after 1 ... 2 minutes of work, we unscrew the screw on the pump again, if there is water, everything is in order. When the pump is turned on, you will hear that air has flowed out of the air vents again, this is also normal. And the pressure will drop, and we will feed the system to the 1.5 atm we need.

While the pump is running, we go through all Mayevsky's taps and check for the presence / absence of air in the radiators. And again we supply the system to the required pressure.

Now we believe (so far we only believe) that the system is completely filled with a coolant (but we are not very deluded, air can leave the system up to 3 weeks and even up to a month, especially if there is a water-heated floor; air will come out of the warm floors itself through the air vents on the manifolds).

Troubleshooting methods

Now we will consider how and how you can seal the leak if the above cases do not fit or do not help for some reason. The main ways to solve the problem if the battery is leaking are as follows:

- Cold welding

- Application of a cement-plaster cast

- Using table salt

- Heat and moisture resistant adhesives

Cold welding

There are high strength and easy to use 2-component epoxy adhesives. A certain variation of cold welding has been created for each metal, but there are also universal options. For example, you can buy a repair rod to seal cracks, seal holes, and seal leaks in cast iron, steel, and bimetallic radiators.

Before covering up the leak, you will have to dry and degrease the surface. If necessary, remove corrosion with a brush or sandpaper. Then cold weld according to the instructions on the package.

Cement and plaster filling

If there is no cold welding, and a cast-iron or other battery has leaked heavily - what to do in this case? Use a cement-plaster cast. You will need a bandage, plaster of Paris, or cement. Dilute the dry mixture to a creamy consistency, saturate the bandage with it and wrap it over the place where the cold or hot battery flows. Apply several layers to form a strong bandage. If it is not possible to drain the coolant, replace the cement with alabaster or gypsum. It is recommended to apply 1-2 layers of a bandage impregnated with a cement mixture on top.

Table salt

The simplest way to remove a radiator leak at home without the help of a technician is to use table salt. Suitable for threaded leaks. Soak a pharmacy bandage in water and dip in salt, then wrap it around the leaking spot. When the salt is dry, the hole will be securely closed. A cement dressing is applied on top for reliability.

Adhesives

When the leak is minor, heat and moisture resistant adhesives can be used. They are applied to gauze or bandage, and then wound on a leaking place (for example, the joint between two sections). When the glue dries, the leak will be preserved. Such repairs do not last long, therefore, after the end of the heating season and drainage of water from the system, it is better to repair the radiator in a more reliable and durable way.

If the problem could not be fixed on your own, in order to avoid trouble, it is better to contact the professionals. Masters of the San Remo company inexpensively and in a short time will eliminate the cause of the leak. And if necessary, they will install a heating radiator with high quality.

Leak elimination process

There are several ways to fix a leak. The choice of method depends on where the problem occurs.

If a leak appears on a flat area, then the most common way to eliminate it is hauling the material. Wrap the damaged area with a piece of soft elastic, the size of which is larger than the size of the leak. Tighten the pipe over the material clamp or wire.

Important! To make the screed strong and eliminate the problem for a long time, it is recommended to use special plumbing pipe clamp. It is sold at any specialized outlet.

If a leak is formed on fitting or thread, then a screed is also used to eliminate the leak.

The first layer instead of a compacted gum is used a long piece of rubber. Material is wrapped around the fitting along with the end of the pipe to help align this section of the system.

Then the bandage is fixed with clamps. This manipulation eliminates the problem.

When a leak occurs at the junction of sections and the defect is small, it will eliminate the problem fabric impregnated with glue. The bandage is applied to the problem area. When the glue hardens, the flow will stop.

Attention! Each of the proposed methods only temporarily will solve the difficulties. At the end of the heating season, it is recommended to carry out full renovation with the replacement or welding of the leaky area.

How to cover up a radiator that has dripped

To eliminate leaks, use special mixturesensuring the sealing of the pipe. The so-called cold welding is in high demand. The composition is applied to the material and after it has solidified, the flow stops. To solve the problem, apply and other synthetic materials. Such funds are sold in specialized retail outlets.

Features of repairing current batteries in winter

If there is a leak in the heating system in summer, then the problem is solved replacing a leaky pipe. The structure is disconnected from the water supply and repairs are carried out.

In winter, it will not be possible to turn off the heating system for a long period. To solve the problem, use only temporary measures.

With the end of the heating season, the pipes where the defect has formed are replaced or welded.

If a breakthrough occurs, then it is eliminated by replacing the pipes, regardless of the season.