This article is about homemade heating devices. Sometimes they do not shine with beauty; however, the ability to supply heat to a garage or workshop with your own hands at minimal cost will certainly attract many of our readers. We will get acquainted with several structures of varying complexity, made from recyclable materials, old pipes and other extremely affordable materials.

Homemade heating devices can have the most unexpected designs.

What is the essence of the idea of a free source of thermal energy

Copper pipe is used because of its excellent heat transfer properties. Let's warm up a little!

You will see a significant reduction in your electricity bill when you use this DIY copper pipe solar water heater. Many thanks to the creator of the video "desertsun02".

The video demonstrates how the master created an ingenious heat exchanger

Description of products

Design features

Model with tubular heat exchangers

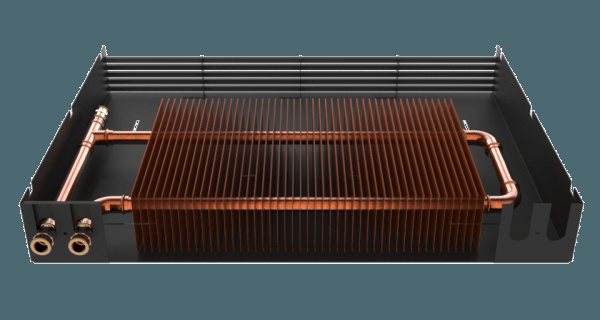

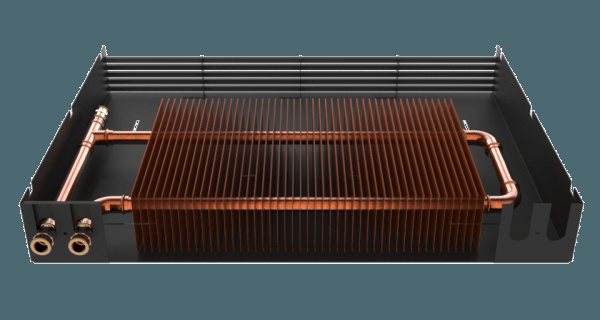

Copper heating radiators usually have a fairly simple design:

- The basis of the product is made up of curved pipes through which the coolant circulates.

- Copper plates or tubes are installed on the pipes - heat exchangers. Their significant area allows you to increase the amount of radiated heat and more efficient use of the energy consumed by the radiator.

Note! Some designer models are available without heat transfer plates. For their production, pipes of a smaller diameter are used, which have many bends. However, even in this case, the heat transfer of the device remains high enough to effectively heat the premises.

Photo of a homemade device without heat exchange plates

- At the inlet and outlet of the radiator, shut-off valves are installed that allow you to regulate the temperature in the room, reducing or increasing the amount of hot water passing through the circuit.

System advantages and disadvantages

Copper products used to heat a room have a very impressive list of advantages. We will analyze the most important of them in the table below:

Externally, the devices look quite stylish

| Advantage | Characteristic |

| Good heat dissipation | Due to the high thermal conductivity of the metal, radiators give off much more heat to the environment than batteries made of steel or cast iron. |

For comparison, the efficiency of copper products is about 5 times higher than that of cast iron radiators.

Copper tube water heater collects heat

The craftsmen decided to assemble a solar collector for water heating with their own hands. There is an old one with a garden hose. It heats well, but I would like it to be more efficient. Therefore, we bought blanks, copper will be used.

Main parts of the collector

There will be several sections. Tees, pipes, corners are used as material. From tools pipe cutter, tape measure, knife. Gas, silver-containing solder. A tape measure is used for cutting accuracy.

The wall thickness of the copper tube is 1 mm. Tee diameter 15 mm. Hose connectors. Measure with a tape measure, make notches with a knife. The knife leaves a clear line, unlike the marker; when the pipe cutter cuts, the edge bends slightly. In theory, it should be remade, as in water boilers. In our case, this is not necessary, there is no pressure. The device works by gravity only due to the difference in water temperatures. Warm goes up, cold goes down. This ensures circulation and heating of the barrel.

This is what the battery looks like.

Continued on video from 5 minutes

Comments below the video.

Max Xam From a copper tube it is wise to solder a copper strip to each tube and paint it with matte black paint (ideal for car calipers); and the glass did not burst inside too. In such a collector, in clear weather in winter -14, water boils. The cost is growing, but everything is cheaper than in the store. The vacuum does not allow the glass to warm up - which allows you to avoid the ice crust on the glass during snowfall in winter, just brushed it off with a broom and that's it. Plus in winter the sun is low above the ground, so my collectors are located 60-70 degrees and below the tank in height - so as not to use a pump, but to drive heated water by diffusion.

Vadim Yatsyna I see flaws. 1) There is practically no water circulation. Spontaneous circulation will occur if the heating circuit is placed below the tank, and the inlet and outlet of the circuit must have a difference in height 2) There is no orientation of the circuit to the Sun, - set it at an angle equal to the latitude of the area, at the same time there will be a difference in the installation height of the nozzles 3) Back side of the circuit not insulated - there are losses. The storage tank, nozzles and hoses are not insulated, the system is ineffective due to huge heat losses. I think I have the right to be smart, since I also have a solar collector. There are several videos on it on my channel.

How to solder a gas water heater radiator if the fistula is located in a place inaccessible for soldering

If the place of water leakage occurs on the wall of the heat exchanger adjacent to the base of the gas water heater, then repair of the heat exchanger by brazing in place is impossible, and it must be removed from the gas water heater. The designers of NEVA LUX-5013 "tried". To remove the heat exchanger for repair, you need to disassemble almost the entire gas column and, most unpleasant, disconnect the gas pipe. I didn't want to get involved with gas pipes, as it was dangerous.

Removing the heat exchanger for repair was hampered by an umbrella for evacuating gas combustion products, fixed with four aluminum rivets to the base of the gas column. I had to drill these rivets with an electric drill, remove the umbrella and only then it became possible to remove the heat exchanger. When assembling, instead of rivets, the umbrella was fixed to the base with two M4 screws. If the wall does not interfere, then you can fix the umbrella with self-tapping screws.

Further, the repair of the gas column was carried out according to the above technology. Over the past two years, I have had to repair the heat exchanger, sealing the fistulas, five times. For the last time, water began to flow from the side adjacent to the wall of the heat exchanger, and I decided to buy a new one, which I did. I'm going to repair the old heat exchanger of the gas column, I'll tin and solder the tube along its entire length. Photo of a view of the heat exchanger from the side of attachment to the base.

When buying a heat exchanger for a gas water heater, I was surprised to find that I was not given a new one, but already repaired. The heat exchanger tube had one of the same soldering as I myself did when repairing my old heat exchanger. As a result, of the four available in the store, only one heat exchanger was not soldered. It turns out that the factory ships for spare parts repaired heat exchangers that failed during the warranty period. Fistulas are sealed in them and sold again. The heat exchanger is given a warranty period of only 1 month. It turns out that in a few months the gas water heater will have to be repaired again!

If you have to buy a heat exchanger for a gas column, inspect it carefully. If you find soldering, it is better to refuse to purchase. In case of replacement of the heat exchanger in the gas column under warranty, make sure that you have installed not a previously repaired heat exchanger, but a new one.

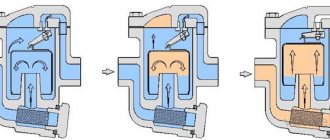

A man receives hot water from a thermosiphon and a wood-burning stove

The cold winter season increases the demand for hot water. Instead of installing an expensive water heater in your home, it is more economical to use a wood-burning stove to heat your water. This way, you don't have to charge huge electricity bills just to keep your water warm.

In this DY video, you will learn a simple, safe and effective way to use a stove to heat the water in your home. This method uses the laws of convection in a thermosyphon, so all you have to do is repeat the idea stated in the article.

Heated water can be expensive, especially if you use a purchased heater. If you want to reduce your heating costs, you can use a wood-burning stove. The video below will show you how to do this. Many thanks to the YouTube host "convectioncoil.com".

In general, after the repair, an extra floor battery connection point was formed. Conventional radiators did not follow the furniture layout. The idea came to make a decorative battery ala "grill grate" from a copper tube. The pipe was found quickly. Rigid quality copper 15X1mm, Germany. The fittings and consumables were helped by the guys from Romstal on the Levoberezhnaya metro station. By the way, very patient professionals - many thanks to them for that.

The story is as follows: 1. The size of the layout was made for a niche. 2. Connectors were cut and sawn into tees. 3. Everywhere, all chamfers of cuts inside-outside are processed. 4. Assembly of the structure and rigid fixation in the tree. 5. Soldering. 6. Pressure check 7. Roughing. 8. Pilot installation.

9. Continuation of rough cleaning. 10. Sandblast. 11. Varnishing. 12. Regular installation. 13. Admiring a bunch of wasted time and effort.

Shl. There are still 20 meters of pipe left. 2m cut. There is a gas burner, a hair dryer with nozzles, a good expensive eco-friendly flux paste with solder and the same solder. I will help you to make an "exclusive" beautiful outdoor copper plumbing.

This article is about homemade heating devices. Sometimes they do not shine with beauty; however, the ability to supply heat to a garage or workshop with your own hands at minimal cost will certainly attract many of our readers. We will get acquainted with several structures of varying complexity, made from recyclable materials, old pipes and other extremely affordable materials.

Repair of a replaced gas column heat exchanger

For almost three years, the NEVA LUX-5013 gas water heater worked properly after replacing the heat exchanger, but the happiness did not last forever, and suddenly water began to drip from it. I had to do the repairs again.

Removing the casing confirmed my fears: a green spot appeared on the outside of the heat exchanger tube, but it was dry, and the fistula, from which water was oozing, was on the side inaccessible for inspection and soldering. I had to remove the heat exchanger for repairs.

When searching for the fistula on the back of the removed heat exchanger, a problem arose. The fistula was in the upper part of the heat exchanger tube and water, oozing from it, flowed along all the tubes below. As a result, all the turns of the tube below the fistula from above turned green and were wet. Whether there was this single fistula or there were several of them, it was impossible to determine.

After drying the green plaque, it was removed from the surface of the heat exchanger using fine sandpaper. External examination of the heat exchanger tube did not reveal blackened spots. To find leaks, the heat exchanger had to be pressurized under water pressure.

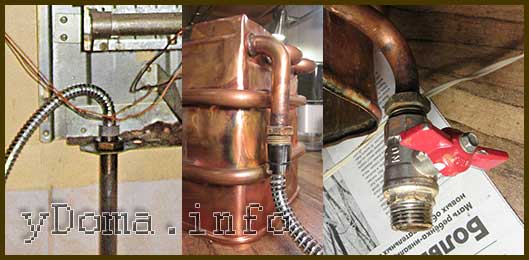

To supply water to the heat exchanger, the aforementioned flexible hose from the shower head was used. One end of it was connected through a gasket to the water supply pipe for supplying water to the gas water heater (in the photo on the left), the other was screwed onto one of the ends of the heat exchanger tube (in the photo in the center). The other end of the heat exchanger tube was plugged with a water tap.

As soon as the water supply valve to the gas water heater was opened, drops of water appeared in the supposed places of fistulas. The rest of the tube remained dry.

Before soldering the fistulas, it is necessary to disconnect the flexible hose from the water supply network, open the plug tap and drain all the water from the heat exchanger by blowing it through. If this is not done, then the water will not allow the soldering point to warm up to the desired temperature, and the fistula will not be able to be sealed.

For soldering the fistula, which was at the bend of the heat exchanger tube, I used two soldering irons. One, the power of which is 40 W, brought the tube under the bend for its additional heating, and the second - with a hundred watt - performed soldering.

Recently I bought a construction hair dryer on the farm, and I did the soldering of the fistula in the straight section, warming up the soldering place with it. It turned out that soldering with a hairdryer is much more convenient, since copper warmed up faster and better. The soldering is more accurate. It's a pity I didn't try to solder the fistula without a soldering iron, using only a construction hair dryer. The air temperature from the hair dryer is about 600 околоC, which should be enough to heat the heat exchanger tube to the melting point of the solder. At the next repair, I will definitely check it.

After the repair, the place of the heat exchanger tube, where the fistula is located, is covered with a millimeter layer of solder, and the water path is reliably blocked. Repeated pressure testing of the heat exchanger showed the tightness of the tube. Now you can assemble the gas column. No more water dripping.

I bring to your attention a short video on how to solder a gas column radiator.

It is worth noting that with the help of the presented technology, it is possible to successfully repair not only heat exchangers for gas columns, but also copper heat exchangers and radiators of any other types of water heating and cooling devices, including copper radiators installed in cars.

Radiators for hot water heating

First, we examine radiators designed to operate in central and autonomous heating circuits.

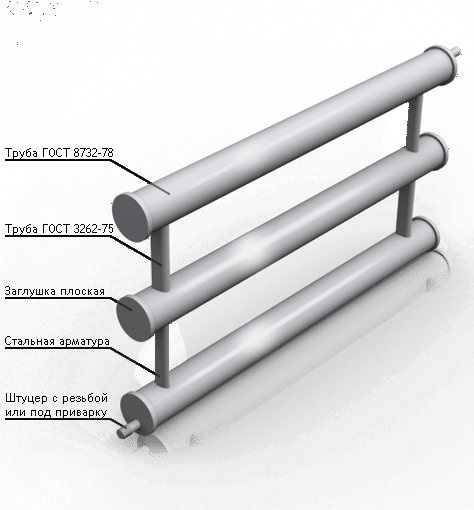

Register

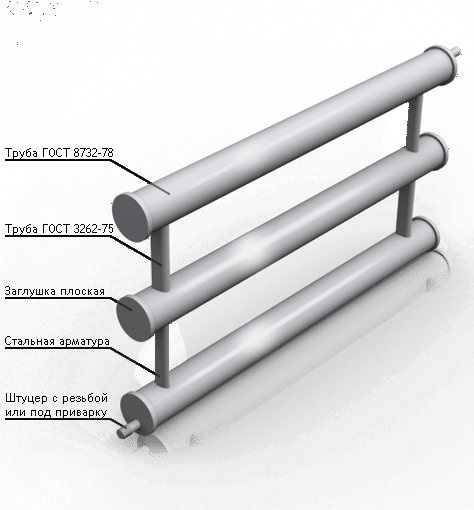

The simplest and most affordable home-made heating radiators are made of pipes of large (100 - 250 mm) diameter, muffled at the ends and connected by jumpers. These devices - the so-called registers - have a large internal volume and, accordingly, significant thermal inertia, which makes them an ideal solution for systems with solid fuel boilers.

Hint: A solid fuel boiler needs to be fired up every few hours. The greater the inertia of the heating system and, in particular, heating devices, the less the heated room will cool down between kindling.

How to make the simplest horizontal register?

- Pipes are cut in lengths of 1.5 - 4 meters (depending on the estimated length of the register).

- Holes for lintels are drilled or burned with a gas torch in them.... An important point: the configuration of the jumpers should create a closed loop inside the device, excluding stagnation of the coolant in dead-end areas.

- Pipes are connected by jumpers - pipes of size DU20 - DU32.

- Parallel to the lintels, pipe sections of the same length are welded, but already welded to the blind walls... They will add rigidity to the structure.

- The ends are muffled by bottoms cut from steel sheet 4 - 5 mm thick.

- Nipples are welded into the lower and upper sections, which will further connect the register with the eyeliner.

In most cases, an ordinary round water and gas pipe is used as register sections. It is attractive for its low price per running meter and maximum tensile strength with a minimum wall thickness, which is ensured by a circular cross-section.

Self-made register device.

However, sometimes you can find home-made heating radiators from a profile pipe - square or rectangular. Its advantages are the relative compactness of the register and a slightly larger surface area with the same cross-sectional area.

Important: at a constant temperature of the heater, its heat transfer linearly depends on the surface area on which heat exchange with air takes place.

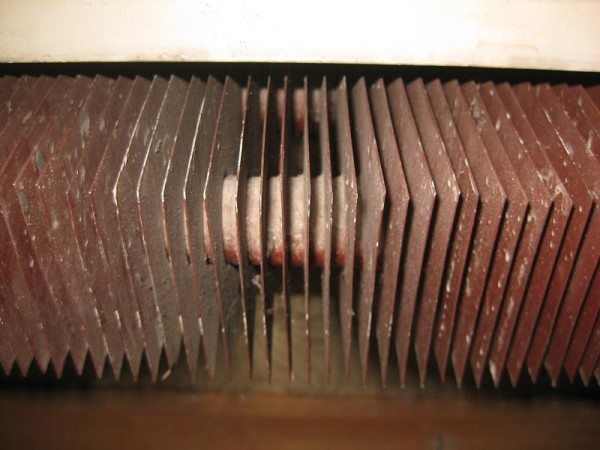

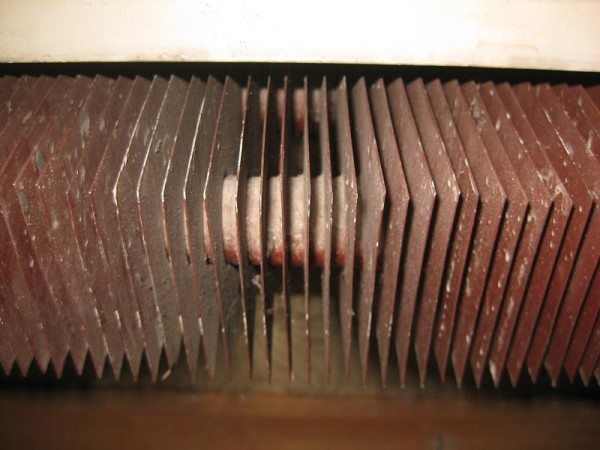

Convector

The simplest convector is a pipe coil with plates pressed onto it, increasing the notorious heat exchange surface. The most readily available material is steel. Houses - new buildings often act as sources of ready-made convectors for garage owners: the owners of apartments in them massively change the heating devices installed by builders for more attractive outwardly and with high heat transfer sectional radiators.

Residents of new buildings often remember the creators of this masterpiece with a quiet, kind word.

However, steel has a serious drawback - low thermal conductivity. In order not to be unfounded, we give the values of thermal conductivity for three metals, which are most often used in the manufacture of heating devices.

| 30.06.2014, 23:20 | #1 |

Advantages and disadvantages of devices

Homemade metal or aluminum appliances differ from conventional radiators in their own dimensions. They consist of some pipes with a diameter exceeding 32 mm. To organize the circulation of the coolant, the pipes are connected with each other by branch pipes.

What is the reason for the popularity of these heat supply devices? First of all, the prospect of independent production. You can make bimetallic devices, metal or aluminum pipes.

Before connecting the heating registers, you should carefully study all their sides.

Benefits:

- Long service life. For metal and aluminum modifications, it can be up to 25 years. In this case, the possibility of breakage will be the smallest.

- Significant heat dissipation. This is due to the fact that the power of the devices exceeds this parameter of traditional radiators and batteries. It is associated with the large size of the coolant.

- Simple installation and operation. Since the devices can be correctly identified by anyone who is at least a little familiar with the instructions for organizing heat supply, they can be used in buildings of all types. But most often they can be found in the heating system of industrial, administrative and commercial premises.

Read also: Which electric shaver shaves better

But apart from that, it is necessary to take into account the possible disadvantagesthat a register made of a metal smooth pipe can have:

- Large size of the coolant. This leads to its rapid cooling.

- The smallest indicator of air convection. Reduces the efficiency of the heat supply.

- Unattractive appearance. Most often this applies to self-made systems.

A correctly calculated heat transfer from heating directly depends on the design of the device. Currently, a number of types of these heat supply devices are used, differing not only in the used material of production, but also in appearance.

Autonomous heaters

What if there is no central heating and gas in the garage, and the frequency of your visits to the premises does not allow organizing a scheme with a solid fuel boiler?

In this case, it would be quite logical to use electricity for heating.

Oil radiator

The simplest home-made oil cooler is a welded register already familiar to us with several modifications.

- There are no welds for connecting to the liners.

- The register, as a rule, is made portable, which implies the presence of legs.

- There are jumpers between sections on both sides. Their diameter is made slightly larger than when assembling a register for water heating. The instruction is due to the fact that natural convection implies a minimum hydraulic head, and if so, hydraulic resistance should also be minimal.

- Heating elements or several parallel connected heating elements are installed at the end of the lower section.

- Oil acts as a heat carrier. Ideally - transformer, but even working out is suitable.

- The register is supplied with a small open expansion tank. Alternatively, the oil is not topped up a little to the top of the register, and the weld on its upper section is equipped with an automatic air vent.

Connecting the gas outlet pipe to the gas column umbrella

To repair the heat exchanger, it is necessary to dismantle the gas outlet pipe. When installing this pipe in place, it is necessary to ensure the tightness of its connection with the gas column umbrella.

Even a large gap of up to a centimeter can be easily sealed with asbestos soaked in water. It is a heat-resistant material that comes in the form of sheets. In water, asbestos becomes limp like cardboard and is a soft mass that sticks well. After drying, the asbestos becomes quite hard and dense again. Asbestos can be reused. It is enough to soak the extracted pieces in water.

If we want to install batteries with maximum heat transfer rates, then we will have to decide whether to purchase an aluminum or copper radiator. And if today aluminum products are presented in a fairly wide range, then copper is remembered mainly by specialists, and then only if it is necessary to solve non-standard problems.

In fact, this material is ideal for the manufacture of heating equipment. That is why in our article we will tell you what are the advantages of copper batteries, as well as give recommendations for their selection and installation.

The use of non-ferrous metals can significantly increase the efficiency of heaters

Recommendations for use

After choosing and purchasing copper radiators, we need to figure out how to install them correctly.

The process of soldering pipes itself is not too complicated, but nevertheless, the technology of arranging a heating system has its own nuances:

- First, it is undesirable to combine copper with steel or cast iron. On the one hand, we still will not be able to provide a sufficiently tight connection due to the different density of metals, and on the other hand, corrosion will develop at the point of contact of the materials.

At the junction of metals, corrosion is inevitable

- Secondly, both fittings and valves must be made of non-ferrous metals or alloys (copper, brass, etc.). The reason is the same as in the previous paragraph.

- Thirdly, an obligatory component of the system must be a filter designed to purify water from solid particles. If you do not install this part, then sooner or later, due to the abrasive effect from the inside, the soft walls will become rough, which will provoke the accumulation of salt deposits and the formation of a film of oxides.

It is highly advisable to use brass fittings

- All elements are connected by soldering. When designing a heating circuit, it is advisable to use high-quality solders: yes, they are quite expensive, but after solidification they provide maximum tightness and resistance to pressure drops.

- For the installation of radiators, wall or floor brackets are used. Despite the fact that the mass of products is relatively small, it is advisable to install plastic or rubber pads on the fastening hooks, which will protect the surface of the pipes from corrosion and deformation.

When connecting the radiator to the circuit, we use the highest quality solders