Even after a fleeting acquaintance with the copper and aluminum splendor displayed in the window, the owners of cast-iron batteries risk losing sleep and appetite.

But how, after all, to decide which radiator is better: copper or aluminum?

In this article we will weigh all the pros and cons and find out the winner.

Advantages and disadvantages of an aluminum radiator

Aluminum batteries are of two types:

- Cast: aluminum is better than other metals compatible with injection molding technology, which manufacturers successfully use. The cast radiator turns out to be one-piece, and therefore as durable as possible.

- Prefabricated welded: such batteries are made from a profile that is obtained by pressing an aluminum billet (extrusion method). Each section consists of two parts welded together. The radiator is assembled from several sections, fastened to one another by means of a thread. Such devices are less durable than cast ones.

The popularity of aluminum radiators is due to the following advantages:

- Great appearance.

- High thermal conductivity - the heat transfer of the section can reach 212 W.

- Light weight: with dimensions 80x80x380 mm, the section weighs only 1 kg.

- The product is guaranteed for a period of 10 to 20 years.

The strength of modern aluminum radiators, thanks to the addition of silicon, is quite acceptable: you can easily find a model designed for pressures up to 16 atm. And some manufacturers produce radiators capable of operating at a pressure of 24 atm.

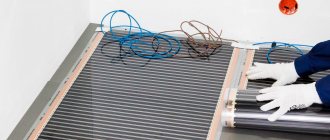

Aluminum heating coil

Aluminum batteries also have disadvantages:

- They do not like high temperatures - the coolant should not be hotter than 110 degrees.

- Corrosion susceptibility.

Prefabricated models cannot be used in systems in which antifreeze acts as a working environment.

Which radiators are more suitable for which systems

1. Now, having examined and compared the main characteristics of radiators, we can draw conclusions. First, let's find out which heating radiators are better - aluminum or bimetallic - for an apartment in a multi-storey building. It uses central heating.

This means that:

- The pressure in the system can change dramatically, reaching exorbitant values. Water hammer is possible.

- The temperature will also not be stable, sometimes varying greatly during the heating season and even during the day.

- The composition of the coolant is not clean. It contains chemical impurities as well as abrasive particles. It is hardly possible to speak of a pH not exceeding 8 units.

Based on all this, you can forget about aluminum batteries. Because the central heating system will ruin them. If electrochemical corrosion does not eat, then the pressure with temperature will be finished. And the water hammer will make the last, “control shot”. Therefore, choosing from two types of radiators (aluminum or bimetal), stop only on the latter.

2. Now consider a heating system installed in a private house. A well-functioning boiler produces a constant low pressure, not exceeding 1.4 - 10 atmospheres, depending on the boiler and the system. Pressure surges, let alone water hammer, are not observed. The water temperature is also stable, and its purity is undeniable. There will be no chemical impurities in it, and the pH can always be measured.

Therefore, in such an autonomous heating system, it is possible to put aluminum batteries - these devices will work perfectly. They will cost inexpensively, have excellent heat transfer, and their design is attractive.In stores you can find batteries made in Europe. It is preferable to choose models made by casting. Bimetallic batteries are also suitable for those who live in the house itself. If there is a desire and enough funds, then you can put them.

Just remember that there are many fakes on the market. And if the model (it doesn't matter whether it is aluminum or bimetallic) has a suspiciously low price, then you can already be on your guard. In order not to get into a mess, check that both on each section and on the packaging (high-quality and full-color) there is a manufacturer's mark.

Advantages and Disadvantages of Copper Heatsink

Today, for the manufacture of a copper radiator, only the purest copper is used: according to the technology requirements, the amount of impurities should not exceed 0.1%. This approach provides the following benefits:

- High thermal conductivity of the material, resulting in an equally high heat transfer.

- Good durability, allowing the device to work in systems with high pressures - up to 16 atm.

- High corrosion resistance.

- The ability to maintain working qualities at coolant temperatures up to 250 degrees.

It is possible to connect a copper radiator to the pipeline either by means of a threaded connection or by means of soldering. Thanks to this versatility, the cost of installation work can be significantly reduced.

Copper heating radiator

Another important advantage of copper is its high ductility at low temperatures. If a filled heating system freezes, then the copper elements will only deform, but will not burst.

Copper radiators, unlike steel appliances, are not afraid of the effects of chlorine salts, which are very often found in quite abundant quantities in our heating systems.

All of these advantages determine the durability of this type of heating device.

At the same time, the buyer should take into account some disadvantages:

- High cost - a copper radiator costs about 4 times more than a steel one.

- Simultaneous connection of such devices with galvanized steel pipes in the direction of movement of the working medium is not allowed - the electrochemical reaction that occurs in this case can cause destruction of the material.

- It is undesirable to use copper batteries in systems where the coolant contains a large amount of hardness salts or has a high acidity.

Problems can be avoided if copper batteries are connected to steel pipes using brass adapters.

What kind of water do radiators like?

Aluminum is very sensitive to water quality. With increased acidity or alkalinity, gas is formed in it, which creates an air lock and impairs heating efficiency. it is necessary to periodically expel air from the battery manually or with the help of a Mayevsky crane.

In addition, aluminum can react with chemicals in water or poor quality coolant. It starts to corrode, which does not happen with steel radiators.

Steel is a chemically inert metal; it does not react with heat transfer fluids and chemicals dissolved in water. The only danger is corrosion, which can form while the water is drained from the heating system. But good manufacturers cover the internal channels with an anti-corrosion coating or paint.

Which heater radiator is better: copper or aluminum?

As you can see, copper and aluminum radiators are very similar to each other. They are lightweight and have excellent design and increased heat dissipation. The latter quality allows the user to reduce the volume of the heating circuit and apply the temperature regime 80/60 (supply / return) instead of 90/70 without increasing the area of the radiators.

Both types of radiators, due to their low heat capacity, have low thermal inertia, which allows the boiler to remain in optimal mode during warming outside.

Aluminum batteries in the interior

At the same time, both copper and aluminum are soft metals, and therefore they do not tolerate the presence of solid mechanical impurities in the coolant, which have an abrasive effect.

At the same time, one cannot fail to notice that aluminum radiators are in many ways inferior to copper ones. We have already said above that high temperatures are contraindicated for them. To this can be added the ability to self-air: specific chemical processes lead to the formation of air locks, which must be vented from time to time.

Prefabricated aluminum radiators do not tolerate water hammer that occurs in heating systems during a sharp change in weather.

In addition, with frequent changes in temperature conditions, aluminum in contact with steel suffers from a significant difference in the coefficients of thermal expansion of these materials. For this reason, they are best used in regions with consistently cold winters.

Powerful copper heatsink

And the last thing is corrosion. In the heat supply conditions usual for us, aluminum is short-lived - it needs a coolant with a pH of 7 or 8.

Thus, copper radiators can be considered less moody.

It would seem that there are many varieties of heating batteries, but new items are still appearing. Vacuum heating radiators: device and varieties, as well as prices for devices.

You can find an overview of manufacturers of cast iron heating radiators here.

And in this article https://microklimat.pro/sistemy-otopleniya/montazh-sistem-otopleniya/sxemy-podklyucheniya-radiatorov.html the diagrams for connecting heating radiators are presented, as well as recommendations for the place of their installation.

Properties of metals. DjVu

| FRAGMEHT OF THE TEXTBOOK (…) We already know that in the spatial lattice of metal crystals there are positively charged metal atoms - ions. They are more or less firmly held in place. Free electrons move randomly around the ions. They can be represented in the form of "electron gas" washing the crystal lattice. Free electrons easily move inside the lattice and serve as good carriers of thermal energy from heated metal layers to cold ones. The high thermal conductivity of a metal is always easy to detect. In cold weather, touch the wall of a wooden house and an iron fence with your hand: iron is always much colder to the touch than wood, since iron quickly removes heat from the hand, and wood is hundreds of times slower. Silver and gold conduct heat better than all other metals, followed by copper, aluminum, tungsten, magnesium, zinc and others. The worst metal conductors of heat are lead and mercury. Thermal conductivity is measured by the amount of heat that passes through a metal rod with a cross section of 1 square centimeter in 1 minute. If the thermal conductivity of silver is conventionally taken as 100, then the thermal conductivity of copper will be 90, aluminum 27, iron 15, lead 12, mercury 2, and the thermal conductivity of wood is only 0.05. The higher the thermal conductivity of the metal, the faster and more evenly it heats up. Due to their high thermal conductivity, metals are widely used in applications where rapid heating or cooling is required. Steam boilers, apparatus in which various chemical processes take place at high temperatures, central heating batteries, car radiators are all made of metals. Devices that must give off or absorb a lot of heat are most often made of good heat conductors - copper, aluminum. The best conductors of electricity are metals. Metals, again, owe their good electrical conductivity to free electrons.When we connect a light bulb, tile or some other electrical device to a current source, in the wires, in the filament of the light bulb, in the spiral of the tile, large changes instantly occur: the electrons lose their previous complete freedom of movement and rush to the positive pole of the current source. Such a directed flow of electrons is the electric current in metals. The flow of electrons does not move freely through the metal - it meets ions on its way. The movement of individual electrons is inhibited. The electrons transfer part of their energy to the ions, due to which the speed of the oscillatory motion of the ions increases. This causes the conductor to heat up. Ions of different metals have unequal resistance to the movement of electrons. If the resistance is small, the metal is heated by the current weakly, but if the resistance is high, the metal may become hot. Copper wires supplying current to an electric stove almost do not heat up, since the electrical resistance of copper is negligible. And the nichrome spiral of the tile is red-hot. The tungsten filament of the electric bulb heats up even more. Silver and copper are distinguished by the highest electrical conductivity, followed by gold, chromium, aluminum, manganese, tungsten, etc. Iron, mercury and titanium conduct poorly. If the electrical conductivity of silver is taken as 100, then the electrical conductivity of copper is 94, aluminum - 55, iron and mercury - 2, and titanium - only 0.3. Silver is an expensive metal and is used little in electrical engineering, but copper is used for the manufacture of wires, cables, buses and other electrical products in huge quantities. The electrical conductivity of aluminum is 1.7 times less than that of copper, and therefore aluminum is used in electrical engineering less often than copper. Silver, copper, gold, chrome, aluminum, lead, mercury. We have seen that metals are in approximately the same order along with a gradually decreasing thermal conductivity (see page 33). The best conductors of electrical current are generally also the best conductors of heat. There is a certain relationship between the thermal conductivity and electrical conductivity of metals, and the higher the electrical conductivity of a metal, the higher its thermal conductivity is. Pure metals always conduct electric current better than their alloys. This is explained as follows. The atoms of the elements that make up the impurities wedge into the crystal lattice of the metal and violate its correctness. As a result, the lattice becomes a more serious obstacle to the electron flow. If copper contains trace amounts of impurities - tenths or even hundredths of a percent - its electrical conductivity is already greatly reduced. Therefore, in electrical engineering, very pure copper is mainly used, containing only 0.05% of impurities. And vice versa, in cases where material with high resistance is needed - for rheostats), for various heating devices, alloys are used - nichrome, nickelin, constantan and others. The electrical conductivity of a metal also depends on the nature of its processing. After rolling, drawing and cutting, the electrical conductivity of the metal decreases. This is due to the distortion of the crystal lattice during processing, with the formation of defects in it, which slow down the movement of free electrons. The dependence of the electrical conductivity of metals on temperature is very interesting. We already know that when heated, the range and speed of oscillations of ions in the crystal lattice of a metal increase. In this regard, the resistance of the ions to the electron flow should also increase. Indeed, the higher the temperature, the higher the conductor's resistance to current. At melting temperatures, the resistance of most metals increases by one and a half to two times. During cooling, the opposite phenomenon occurs: the random oscillatory motion of ions in the lattice nodes decreases, the resistance to the flow of electrons decreases and the electrical conductivity increases.Investigating the properties of metals with deep (very strong) cooling, scientists discovered a remarkable phenomenon: near absolute zero, that is, at temperatures of about minus 273.16 °, metals completely lose their electrical resistance. They become "ideal conductors": in a closed metal ring, the current does not weaken for a long time, although the ring is no longer connected to the current source! This phenomenon is called superconductivity. It is observed in aluminum, zinc, tin, lead and some other metals. These metals become superconductors at temperatures below minus 263 °. How to explain superconductivity? Why do some metals reach the state of ideal conductivity, while others do not? There are still no answers to these questions. The phenomenon of superconductivity is of tremendous importance for the theory of the structure of metals, and at present it is being studied by Soviet scientists. The works of Academician Landau and Corresponding Member of the USSR Academy of Sciences A. I. Shal'nikov in this area were awarded Stalin Prizes. MAGNETIC PROPERTIES Iron ore is known - magnetic iron ore. Pieces of magnetic iron ore have a remarkable property of attracting iron and steel objects to themselves. These are natural magnets. A light arrow made of magnetic iron ore always turns with the same end to the north pole of the Earth. This end of the magnet was agreed to be considered the north pole, and the opposite to it - the south. If an iron or steel rod is brought into contact with a magnet, the rod itself becomes a magnet, it will itself attract iron filings, steel nails. The rod is said to be magnetized. All metals are capable of magnetization, but to varying degrees. Only four pure metals are very strongly magnetized - iron, cobalt, nickel and the rare metal gadolinium. Steel, cast iron and some alloys that do not contain iron, such as an alloy of nickel and cobalt, are also well magnetized. All these metals and alloys are called ferromagnetic (from the Latin word "ferrum" - iron). Aluminum, platinum, chromium, titanium, vanadium, manganese are very weakly attracted to the magnet. They magnetize so little that it is impossible to detect their magnetic properties without special instruments. These metals are called paramagnetic (the Greek word for "steam" means about, near). |

sheba.spb.ru

Testimonials

When studying the discussions on the pages of online forums, no complaints about copper or aluminum radiators were found.

True, not many can afford copper radiators - the price of a device designed for heating 20 - 25 sq. m, reaches 23 thousand rubles.

Due to such a high cost, such devices have not become widespread, so there are many false rumors about them.

For example, some have expressed concern that copper will turn green, as happens with copper roofs or monuments.

Connoisseurs reassure: a greenish oxide (patina) is formed only with prolonged exposure to high humidity.

Many people consider aluminum batteries to be too light and unreliable, but they are being used more and more often. Aluminum heating radiators: technical characteristics, advantages and disadvantages, as well as types of structures.

Why do you need a thermostat for a heating radiator, how to install it and which one is better to choose, read in this topic.

The best brands of copper-aluminum batteries

As practice has shown, the best copper-aluminum convection radiators for water heating are made by domestic manufacturers, as well as neighbors from neighboring countries.

In stores you can find heaters from the following manufacturers:

Models of Russian and Ukrainian manufacturers are adapted to domestic conditions, therefore they better tolerate pressure drops and are more resistant to aggressive environments.