Recommendations for the selection of gas pipes

Most often, gas pipelines for honest houses and apartments are equipped with metal products. Steel pipes for gas supply are characterized by the ability to perfectly withstand internal pressure. Such a pipeline is completely sealed, which reduces the risk of gas leakage to zero. When choosing steel pipes for gas pipelines, it is necessary to take into account the pressure in the gas pipeline.

Conditions in gas pipelines can be as follows:

- With low pressure - up to 0.05 kgf / cm2.

- With an average pressure - from 0.05 to 3.0 kgf / cm2.

- With high pressure - from 3 to 6 kgf / cm2.

What pipes are used for the gas pipeline? The use of thin-walled metal pipes is only permitted on low pressure gas pipelines. This material is extremely lightweight, which makes it possible to equip systems with complex configurations from it. Also, thin-walled metal pipes are distinguished by good flexibility: if it is necessary to give such a product a small angle, you can do without a pipe bender, having done everything by hand.

If necessary, such a pipe for a gas pipeline is easily soldered. In addition, special connecting fittings can be used for threaded steel pipes. For connection of thin-walled bell-shaped elements, only hemp sealing fiber is used.

No. 7. Reinforced-plastic pipes for a gas pipeline

This is not the most popular option, but it is nevertheless encountered. With such pipes you can create only gas pipeline inside the apartment, connect gas appliances. SNiP 42-01-2002 allows the use of such pipes in buildings with a height of no more than 3 floors. Fittings can be used to connect to steel and polyethylene pipes.

The reinforced-plastic pipe is a multilayer structure. The outer and inner layers are plastic, with a thin layer of aluminum in between. Thanks to this design, numerous advantages:

- easy installation, so you can handle it even without the help of a professional and a special tool;

- flexibility, you can get by with a minimum number of fittings;

- good tightness;

- low price.

Among cons limited scope of use. Reinforced-plastic pipes are suitable only for laying inside buildings, they are afraid of prolonged exposure to ultraviolet rays, and when heated above + 40 ° C, the tightness of the pipeline is lost, as well as when it cools down to a temperature of -150 ° C.

Features of using different types of gas pipes

High pressure gas pipelines are equipped exclusively with massive pipes. If increased strength requirements are imposed on the line, the use of steel pipes without seams will be required. You should be prepared for the fact that welding such elements is a much more complicated procedure than brazing thin-walled pipes. From the point of view of optimal performance, copper pipes stand out: in many respects, they are preferable to thick-walled steel products. In terms of reliability, both of these varieties are almost the same, but copper weighs much less. Their high cost keeps copper pipes from mass use in everyday life.

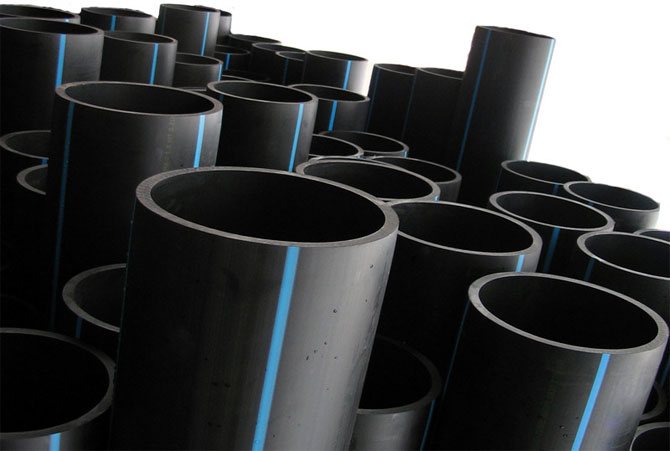

When using thin-walled pipes, one should take into account their high thermal conductivity, which is why condensation often occurs on their surface. It is recommended to coat the finished gas system with several coats of oil paint to protect against corrosion. Underground gas pipelines are organized using plastic pipes, which are characterized by flexibility, elasticity and low cost.Most often these are products made of polypropylene or polyethylene. For example, polyethylene pipes for gas perfectly tolerate underground conditions when gasifying private properties. If it is required to equip the summer cottage with a low-pressure gas pipeline, black polyethylene pipes with the corresponding yellow marking are used. High pressure polyethylene pipes are not used as a gas pipeline.

Indoor gas distribution is carried out with vulcanized rubber hoses with textile reinforcement. They are not suitable for high pressure: they are usually used to connect gas stoves to cylinders or gas water heaters.

The use of flexible hoses has the following limitations:

- If the air temperature in the area exceeds +45 degrees.

- If seismic activity of more than 6 points is possible on the territory.

- At high pressure inside the gas pipeline system.

- If you need to equip any room, tunnel or collector with a gas pipeline.

All of these situations are prohibited for using HDPE pipes as a gas pipeline. It will be safer to stop at a thin-walled or seamless type steel gas pipe.

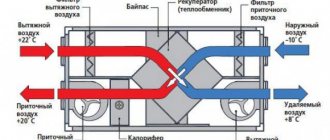

Ventilation and safety

When installing a gas water heater, an exhaust pipe must be used (read: "The nuances of installing exhaust pipes for a gas water heater - expert advice"). It is forbidden to use a flexible corrugated pipe made of aluminum for these purposes. Discharge pipes for the column can only be steel or galvanized. It is recommended to equip a gas column, like any other heating device, with fuses: they will cut off the gas supply in the event of a flame extinguishing.

Features of the arrangement of a gas pipeline in the kitchen from thin-walled metal pipes:

- Work begins by shutting off the gas supply valve.

- If the gas pipe in the kitchen needs to be moved, the gas pipe must be pre-purged to remove the remaining gas from their system.

- The gas pipe on the wall must be very well secured. To do this, the product includes clamps and brackets: they are used taking into account the diameter and length of the pipeline.

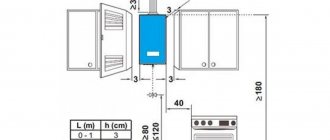

- When passing an electric cable near the gas pipeline, a distance of 25 cm should be observed between them.The gas system and the electrical switchboard should be 50 cm apart from each other.

- The gas piped kitchen system should not be adjacent to refrigeration appliances such as a refrigerator or freezer. If you close the gas pipes with a refrigerator, its radiator is likely to overheat.

- When installing thin-walled gas pipes, the heaters and the gas stove should be removed.

- It is forbidden to lay gas pipes in the kitchen on the floor surface, under the sink, near the dishwasher.

- When carrying out repair work, it is advisable not to use artificial light sources. The room must be constantly ventilated.

These standards can be guided by the operation of both ready-made gas systems and the installation or transfer of gas pipelines.

Gas heating installation

In the general scheme of a gas heating device, the installation of hot water boilers, automation systems, pumping groups, distribution manifolds are considered complex operations that require the experience and qualifications of installers. Working according to the installation plans of the heating project, the workers:

- install a concrete base for a hot water boiler;

- mount a boiler (single-circuit or double-circuit);

- install water filters, check the tightness of the connections to the water supply;

- chasing walls, making technological holes;

- laying an internal gas pipeline, pipelines of heating mains (for steel or propylene pipe rolling, the use of different welding technologies, masking of pipes is required);

- install shut-off valves;

- install radiators (according to the design specification);

- mount fittings, taps, tees for branching of the beam fittings;

- collect and install a chimney;

- install distribution manifolds;

- install boilers for hot water supply (for single-circuit systems);

- connect internal gas pipelines to the outlets of the gas main or gas holder;

- install automatic control panels, check the operation of sensors, the functionality of remote controls;

- connect uninterruptible power supplies to the wiring diagrams of the boilers;

- carry out commissioning, adjust heating parameters in trial runs:

- instruct the customer on the maintenance of the heating system.

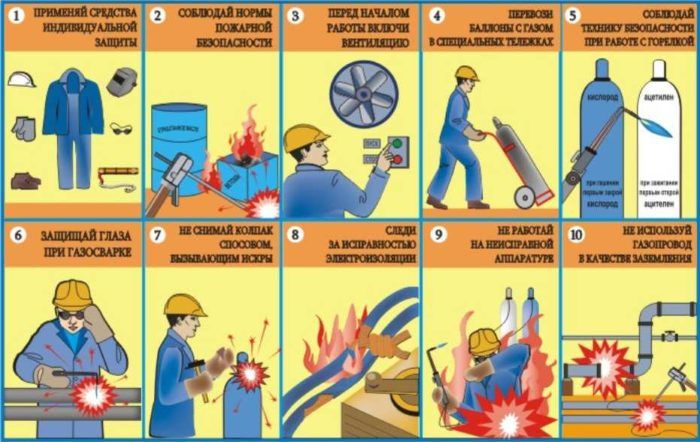

The installation of gas equipment for heating housing is accompanied by mandatory safety measures. Installers pass exams for admission to work, are certified, and receive special certificates. Safe operation of gas equipment prohibits the installation of hot water boilers in living rooms, bathrooms, toilets. Boiler room equipment in the basement or annex to the house is not prohibited.

For various gas heating schemes, technologically correct installation is required:

- batteries or panel radiators (cast iron, steel, aluminum, bimetallic);

- automatic air vents;

- radiator thermostats;

- shut-off valves;

- ball valves;

- gate valves;

- water centrifugal pumps;

- shut-off and metering and check valves;

- thermomanometers;

- fans for supply and exhaust ventilation;

- flange connections of pipelines;

- filters.

The cost of installing gas heating does not include the cost of purchasing pipelines, boilers, radiators, automation devices, boilers. The customer purchases heating equipment independently (on the recommendation of the designers). , as a dealer for a number of European manufacturers, offers equipment supplies at preferential prices.

Gasification standards for a private house

Notify the local gas service before starting work. The responsibility of this organization includes the provision of technical specifications to determine the procedure for gasification. When the technical agreement is completed, an individual project is being developed for the upcoming work. Permission for laying gas communication should also be obtained from representatives of the automobile inspection.

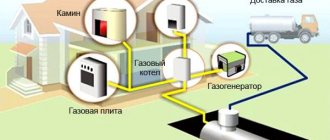

If some houses in this area are already gasified, then you only need to connect a gas pipe to the main highway. In this case, the gas service is obliged to notify about the parameters of the working pressure in the main pipeline. This will make it possible to choose the right pipes for arranging your site. The gas supply system can be autonomous or central: it depends on which source the given section will be supplied from. Private houses can be equipped with aboveground and underground gas pipelines. It is not very difficult to assemble and install gas pipes on the site - it is usually done much faster than obtaining the appropriate permits.

When laying the gas pipeline, the following sequence should be observed:

- Lay the piping from the distributor to the dwelling. If necessary, a tie-in is carried out into the main gas pipeline (for more details: "How is a tie-in into a gas pipe - a step-by-step guide").

- To enter the pipe inside the house, a cabinet with a pressure reducing reducer is used.

- Next, you need to organize the piping around the premises (kitchen, boiler room). For this, a pipe for a low pressure gas pipeline is used.

- Carry out commissioning procedures, commissioning of equipment, check the gas stove and the column for operability.Most often, this requires the presence of a gas inspector.

The structure of a gas pipeline in a private house consists of the same points as a similar system in an apartment.

Sequence and installation rules

Installation work should be carried out according to the following rules:

- When laying gas pipes underground, the optimum depth is 1.25 - 2 m.

- At the section where the pipe is inserted into the house, the depth should be reduced to 0.75 - 1.25 m.

- Liquefied gas can be transported at a depth below the depth of soil freezing.

- When installing a gas boiler, it should be borne in mind that one piece of equipment must have a room area of 7.5 m2.

- For the installation of boilers and dispensers with a capacity of less than 60 kW, rooms of at least 2.4 m are required.

An autonomous gas source in the backyard area is carried out in accordance with specific safety standards. This will ensure the normal functioning of the stove, column and boiler. The underground reservoir should be located no closer than 15 m from the well, 7 m from the outbuildings, and 10 m from the house. The most popular types of such tanks are 2.7 - 6.4 m3.

Rules for laying underground gas pipelines:

- What pipes are used for a gas pipeline in this case? With a positive result of soil testing for corrosiveness, it is better to refrain from laying underground communications. The exception is situations when high-voltage lines pass nearby: in this case, the pipes are carried underground using additional insulation.

- If a polyethylene pipeline is being laid, products with high strength (PE-80, PE-100) are used for this. PE-80 pipes are able to withstand working pressure up to 0.6 MPa: if this indicator is higher, it is better to use PE-100 products or steel pipes for high-pressure gas pipeline. The depth of penetration into the ground is at least one meter.

- Communications with a working pressure above about 6 MPa are allowed to be equipped with reinforced polyethylene pipes. Requirements for the depth of the bookmark here are also from one meter.

- In areas where arable work or abundant irrigation will be carried out, the depth of the gas pipeline will increase to 1.2 m.

If you adhere to all the above requirements and rules, you can do the construction of an underground gas pipeline with your own hands.

If you are already registered, please enter your login information!

Previous article Next article

Gas pipelines and gas equipment of residential buildings

Approved and put into effect by the Decree of the Moscow Government No. 758-PP

1. General Provisions

1.1. The requirements of this standard are aimed at ensuring the safe and efficient operation of internal gas pipelines and gas equipment in residential buildings.

1.2. This standard applies to the design and construction of new, operation and repair of existing in-house gas supply systems for residential buildings built according to standard and individual projects.

1.3. The requirements of this standard are mandatory for: owners, other legal owners of residential buildings; management and (or) organizations serving residential buildings; organizations - customers / contractors for construction, reconstruction, maintenance and repair.

1.4. This standard was developed by the State Housing Inspectorate of the city of Moscow.

2. Basic concepts.

For the purposes of this standard, the following basic concepts are used:

2.1. An internal gas pipeline (also known as an internal gas pipeline) is a gas pipeline laid inside a building from the place of its primary intersection of building structures to the point of connection of gas appliances and devices that use gas as a fuel for cooking, hot water supply, and decentralized heating.

2.2.Intra-house gas equipment - technical products of full factory readiness: gas meters; pipeline valves; gas appliances and apparatus.

2.3. Gas appliances and appliances are household gas appliances that use gas as a fuel for cooking, hot water supply and decentralized heating.

2.4. An intra-building gas supply system is a single system consisting of an internal gas pipeline and, installed on it, internal gas equipment.

2.5. A chimney is an element of the building structure designed to remove gas combustion products into the external environment from household gas appliances used for hot water supply and heating.

2.6. Cleaners' organizations are enterprises that carry out maintenance and overhaul of chimneys.

3. Requirements for in-house gas supply systems for residential buildings.

3.1. Design, construction, reconstruction and repair of gas supply systems are carried out by specialized organizations in accordance with the requirements of building codes and regulations, and standards.

3.2. The need to repair internal gas pipelines, gas equipment of residential buildings and chimneys is determined in accordance with the established procedure based on the results of inspection of their technical condition and taking into account the standard service life.

3.3. Gas pipeline entries into residential buildings should be provided for non-residential premises available for inspection and repair of gas pipelines. It is not allowed to enter the gas pipeline into basements, elevator rooms, ventilation chambers and shafts, garbage collection rooms, storage rooms, rooms classified as explosive and fire hazard categories "A" and "B", as well as into rooms removed from the housing stock. All basement gas pipelines located in residential buildings of the city must be placed on the facades of buildings.

3.4. Gas pipelines in places of passage through the outer walls of residential buildings are enclosed in cases. The space between the gas pipeline and the case is sealed to the full thickness of the wall to be crossed. The end of the case is sealed with an elastic material.

3.5. Disconnecting devices are installed for gas risers, as a rule, on wall gas pipelines of residential buildings, at a distance of at least 0.5 meters from door and window openings, as well as in front of each gas appliance.

3.6. Intra-building gas pipelines are laid through non-residential premises of apartments.

3.7. Laying of gas pipelines is not allowed: in basements; through ventilation shafts and chimneys, elevator shafts and staircases, waste bins; through rooms where the gas pipeline can corrode; in places where gas pipelines can be washed by combustion products or come into contact with heated metal; in premises taken out of the housing stock; by crossing ventilation grilles, window and door openings.

3.8. The installation of gas pipelines is carried out in accordance with the project after the arrangement of interfloor ceilings, walls, floor coverings and plastering of walls in kitchens, inspection and cleaning of chimneys and ventilation ducts.

3.9. Gas pipelines inside a residential building are laid openly. It is not allowed to close the gas pipeline with a false wall. When installing gas pipelines, measures are taken to prevent clogging of the pipe cavity. At the intersections of an electric wire and a cable with a gas pipeline, the clear distance between them should be at least 100 mm, with parallel laying - at least 400 mm.

3.10. The distance from gas pipelines and pipelines for other purposes should be taken from the condition of ensuring the possibility of installation, inspection, repair of gas pipelines and fittings installed on them. The distance from the gas pipeline to the sink must be at least 300 mm.

3.11.The deviation of risers and straight sections from the design position is allowed no more than 2 mm per 1 m of the length of the gas pipeline, unless other standards are justified by the project. All branches must be at a 90 degree angle.

3.12. It is forbidden to weld branch pipes in the locations of circular welded seams. When inserting branches with a diameter of up to 50 mm, the distance from the seams of the gas pipelines to be welded to the circular seams of the main gas pipeline must be at least 50 mm. The pipes are assembled for welding with displacement of the seams at the joints: - for gas pipelines with a diameter of up to 50 mm - 15 mm; - for gas pipelines with a diameter of 50 to 100 mm - 50 mm.

3.13. The distance from the weld to the end of the gas pipeline thread must be at least 100 mm. Sealing of welded and threaded connections of gas pipelines and fittings into walls, ceilings and cases is prohibited. Hidden work (laying a gas pipeline through walls, in a case, through an overlap) is carried out step by step. The distance from the weld to the case must be at least 50 mm. The welded joint of a gas pipeline with a diameter of up to 200 mm must be at a distance of at least 200 mm from the edge of the support.

3.14. When welding fittings, assemblies, fittings into a gas pipeline, the integrity of the welded elements with the gas pipeline is ensured. Skews in vertical and horizontal planes are prohibited. It is forbidden to install pipes and bent parts from pipes that have dents, folds (wrinkles), cracks, slag inclusions in the seams, scuffs. Ovality of bent parts is allowed within no more than 10% of the diameter of the gas pipeline. It is forbidden to equip a straight branch section, the length of which is less than the diameter of the pipe.

3.15. Gas pipelines are laid in places where people pass at a height of at least 2.2 m from the floor to the bottom of the gas pipeline.

3.16. Fastening of the gas pipeline to the walls is carried out using brackets, clamps, hooks in accordance with the requirements of the project. Fastening of the gas pipeline riser in houses with gas stoves is carried out on the 1st, 4th, 8th floors, in houses with gas water heaters on the 1st, 4th, 5th floors and in all cases on the top floor. Fastening the lowering of the gas pipeline to the device is carried out in front of each gas device. The distances between the support fittings of the gas pipelines are determined in accordance with the requirements of SNiP 2.04.12-86.

3.17. Vertical gas pipelines at the intersection of building structures are laid in cases. The space between the gas pipeline and the case is sealed with tarred tow, rubber grommets or other elastic material. The protrusion of the end of the case above the floor must be at least 3 cm, and its diameter is taken from the condition that the annular gap between the gas pipeline and the case is at least 5 mm for gas pipelines with a diameter of not more than 32 mm and at least 10 mm for gas pipelines with a larger diameter.

3.18. Domestic gas pipelines, including sections laid in cases, are painted. For painting, waterproof paints and varnishes are used.

3.19. When arranging a gas pipeline inside a residential building, pipes are used that are specially designed for laying a gas pipeline, having a metal version and a certificate of conformity. The connection of pipes should be provided for welding. Threaded connections are allowed only in places of installation of valves, gas appliances.

3.20. To seal threaded connections, a flax strand is used in accordance with GOST 10330-76, impregnated with lead red lead in accordance with GOST 19151-73, mixed with drying oil in accordance with GOST 7931-76, as well as fluoroplastic and other sealing materials with a passport or manufacturer's certificate. When installing disconnecting devices, a squeeze is installed after them. The valves must be installed so that the axis of the valve plug is parallel to the wall; it is forbidden to install the thrust nut towards the wall.When installing gas appliances, connecting them to gas networks, the requirements of the project and factory instructions should be followed.

3.21. The gas pipeline to the stove is allowed to be laid at the level of the connecting nipple. In this case, the shut-off valve is installed at a distance of at least 20 cm to the side of the stove. In the case of top wiring, the shut-off valve must be installed at the lowering to the slab at a height of 1.5 - 1.6 m from the floor. It is allowed to connect gas appliances to the gas pipeline through a flexible hose that does not have butt joints and has a temperature resistance of at least 120 degrees. The service life is set by the passport for the flexible sleeve, after which this flexible sleeve must be replaced.

3.22. The sections of gas pipelines that are disconnected during dismantling of gas appliances are cut off, freed from gas and welded tightly. When the gas pipeline is removed from the basement, the inactive basement gas pipeline and gas pipeline sections through the ceilings to the point of switching are dismantled, and the holes in the floor are sealed. When installing gas pipelines, it is forbidden to use previously installed gas pipes and cases to be dismantled as a case.

3.23. At all stages of construction, in order to verify the effectiveness of previously performed production control, inspection control should be selectively carried out. Based on the results of production and inspection quality control of construction and installation works, measures should be developed to eliminate the identified defects, while the requirements of field supervision of design organizations and state supervision and control bodies acting on the basis of special provisions should also be taken into account.

3.24. Gas stoves in residential buildings are installed in kitchens with a height of at least 2.2 m, with a window with a vent (transom), an exhaust ventilation duct and natural lighting. Gas stoves are installed in kitchens with an internal volume of at least: 8 cubic meters. m with a gas stove with 2 burners; 12 cubic meters m with a gas stove with 3 burners; 15 cubic meters m with a gas stove with 4 burners.

3.25. In existing residential buildings, it is allowed to install gas stoves: in kitchen rooms with a height of at least 2.2 m and a volume of at least specified in clause 3.24 in the absence of a ventilation duct and the impossibility of using chimneys as such a channel, but if there is a window with a window or transom at the top of the window; in corridors for individual use, if there is a window in the corridor with a window or transom in the upper part of the window, while the passage between the stove and the opposite wall should be at least 1 m wide, walls and ceilings of corridors made of combustible materials should be plastered, and living quarters should be separated from the corridor by dense partitions with a door; in kitchens with sloped ceilings with a height in the middle of at least 2 m, gas equipment is installed in that part of the kitchen where the height is at least 2.2 m.

3.26. In existing residential buildings, it is allowed to install gas stoves in rooms that meet the requirements of paragraphs. 3.24 or 3.25, but having a height of less than 2.2 m to 2 m inclusive, if these rooms have a volume of at least 1.25 times the standard. At the same time, in houses that do not have a dedicated kitchen, the volume of the room where the gas stove is installed must be 2 times larger than that specified in clause 3.24.

3.27. The possibility of installing gas stoves, heating and other devices in buildings located outside a residential building is decided by the design organization and the operating organization of the gas economy. At the same time, the premises in which the installation of gas appliances is envisaged must comply with the requirements for the premises of residential buildings where the placement of such appliances is allowed.

3.28.Wooden unplastered walls and walls made of other combustible materials in the places where the plates are installed are insulated with non-flammable materials: plaster, roofing steel on an asbestos sheet with a thickness of at least 3 mm, etc. The insulation should protrude 10 cm beyond the dimensions of the plate on each side and at least 80 cm from above ... The distance from the stove to the walls of the room insulated with non-combustible materials should be at least 7 cm; the distance between the slab and the opposite wall must be at least 1 m.

3.29. For hot water supply, instantaneous and capacitive gas water heaters are used, and for heating - capacitive gas water heaters, small-sized heating boilers or other heating devices designed to operate on gas fuel.

3.30. The number of storeys of residential buildings in which the installation of the indicated gas appliances and apparatus is carried out should be provided in accordance with SNiP 31-01-2003 "Multi-apartment residential buildings".

3.31. It is allowed to transfer to gas fuel small-sized (small-sized) factory-made heating boilers intended for solid or liquid fuels. Heating installations converted to gas fuel are equipped with gas burners with safety automation.

3.32. In one room, it is not allowed to provide for the installation of more than two storage water heaters or two small heating boilers, or two other heating devices.

3.33. The chimney arrangement must comply with the requirements of SNiP 2.04.05 -91 * "Heating, ventilation and air conditioning" as for heating stoves.

3.34. Water heaters, heating boilers and heating devices are installed in kitchens and non-residential premises intended for their placement and meeting the requirements of paragraphs. 3.40. 3.41.

3.35. The installation of these appliances in bathrooms is not permitted. The possibility of rearranging gas water heaters from bathrooms, in which they were placed in accordance with previously valid standards, to kitchens or other non-residential premises of a residential building during the reconstruction of a house or a gas supply system, is decided in each case by the design organization in agreement with the gas organizations operating in-house gas pipeline.

3.36. In existing residential buildings, it is allowed to provide for the installation in the corridors of heating gas appliances and heating devices for individual use that meet the requirements of paragraphs. 3.40. 3.41. The distance from the protruding parts of gas burners or fittings to the opposite wall must be at least 1 m.

3.37. Gas instantaneous water heaters are installed on walls made of non-combustible materials at a distance of at least 2 cm from the wall, incl. from the side wall. If there are no walls made of non-combustible materials in the room, it is allowed to install a flow-through water heater on plastered walls, as well as on walls lined with non-combustible or slow-burning materials at a distance of at least 3 cm from the wall. The surface of fire-resistant walls is insulated with roofing steel over an asbestos sheet with a thickness of at least 3 mm. The insulation should protrude 10 cm beyond the dimensions of the water heater body.

3.38. Gas heating boilers, heating devices and gas storage water heaters are installed against walls made of non-combustible materials at a distance of at least 10 cm from the wall. In the absence of walls made of non-combustible materials in the room, it is allowed to install the above heating devices near the walls protected in accordance with the instructions in clause 3.28, at a distance of at least 10 cm from the wall.

3.39. The horizontal distance in the light between the protruding parts of an instantaneous water heater and a gas stove should be at least 10 cm.When installing a gas stove and a storage water heater, a gas stove and a heating boiler or heating device in the kitchen, as well as a gas stove with built-in devices for heating water ( heating, hot water supply), the volume of the kitchen should be 6 cubic meters more than the volume provided for in clause 3.24.

3.40. The room intended for the placement of a gas water heater, as well as a heating boiler or heating apparatus, the removal of combustion products from which is provided in the chimney, must have a height of at least 2 m.The volume of the room must be at least 7.5 cubic meters. m when installing one device and at least 13.5 cubic meters. m when installing two heating devices.

3.41. The kitchen or room where boilers, appliances and gas water heaters are installed must have a ventilation duct. For air flow, a grate or a gap between the door and the floor with a free cross-section of at least 0.02 square meters should be provided in the lower part of the door or wall opening into the adjacent room. m.

3.42. It is not allowed to place all gas appliances in the basement floors (basements), and in case of LPG gas supply - in the basement and basement floors of buildings of any purpose.

3.43. It is allowed to transfer heating and heating and cooking stoves to gas fuel, provided that the stoves, smoke and ventilation ducts meet the requirements of the standards for the installation of heating furnaces converted to gas fuel, approved in the prescribed manner; gas burners installed in furnaces of heating and heating-cooking stoves are equipped with safety automatics in accordance with the requirements of GOST 16569-86 “Gas burner devices for household heating stoves. Technical conditions ".

3.44. When installing gasified stoves, their furnaces must go out into non-residential (unofficial) premises. In the absence of non-residential (non-office) premises, the furnaces of gasified furnaces may be located on the side of residential (office) premises. In this case, the gas supply to the furnaces should be provided with independent branches, on which a disconnecting device is installed outside the above premises at the point of connection to the gas pipeline. The premises into which the fireboxes of gasified heating and heating-cooking stoves go out must have an exhaust ventilation duct or a window with a vent, or a door leading to a non-residential premises or a vestibule. The passage in front of the oven must be at least 1 m.

3.45. For space heating, it is allowed to install gas fireplaces, air heaters and other factory-made devices with the discharge of combustion products into the chimney. Gas burner devices of these devices must be equipped with safety automatics. The room in which it is planned to install a gas fireplace or air heater must have a window with a vent and an exhaust ventilation duct. When installing these devices, it is necessary to comply with the requirements provided for in clause 3.38.

3.46. The possibility of using and the conditions for placing household gas appliances not specified in this section should be determined taking into account the purpose of the devices, their heat load, the need to remove combustion products and other parameters established by this section.

3.47. Foreign-made gas appliances must have warranty coupons indicating the addresses and phone numbers of service centers performing their installation, repair and maintenance.

3.48. When transferring residential premises with the presence of gas pipelines to the non-residential fund, the issue of their removal must be resolved at the same time. The location of gas pipelines in the non-residential stock of residential buildings is not allowed.

4. Requirements mandatory for persons using gas equipment in residential buildings.

4.1. Persons using household gas appliances and apparatus are obliged to:

4.1.1. When carrying out annual maintenance of gas equipment by specialists of a gas utility company, receive instructions from them on the rules for using gas in everyday life, observe safety measures for working and non-working gas appliances.

4.1.2. Maintain and keep gas equipment clean. Monitor the operation of gas appliances, chimneys, ventilation, check the presence of draft before switching on and at the end of the operation of gas appliances with the removal of combustion products into the chimney. Clean the chimney pockets.

4.1.3.At the end of using gas, close the taps in front of the gas appliances.

4.1.4. In the event of a malfunction of the gas equipment, call the employees of the gas utility company.

4.1.5. If you smell gas, immediately stop using gas appliances, turn off the taps on the lowering to the appliances and appliances, ventilate the room and call the emergency service. Until then, do not light a fire, do not smoke, do not turn on electrical equipment and other electrical appliances.

4.1.6. If a smell of gas is detected in the basement, entrance, or street, it is necessary to: - inform the gas service and take measures to remove people from the gas-polluted environment, prevent the switching on and off of electric lighting, the appearance of an open fire and a spark; - before the arrival of employees of the gas service, organize the ventilation of the room.

4.2. Persons using gas equipment in residential buildings are prohibited from:

4.2.1. Carry out unauthorized gasification in the house, rearrangement, replacement and repair of gas equipment.

4.2.2. Redevelop the premises with the presence of gas equipment without coordinating this issue with the relevant organizations.

4.2.3. Use gas appliances in the absence of draft in chimneys and ventilation ducts.

4.2.4. Make changes in the design of gas appliances, smoke and ventilation systems, in the laying of gas pipelines.

4.2.5. Leave working gas appliances unattended, except for appliances with appropriate automation, allow children and persons who do not control their actions and do not know the rules for using these appliances to use gas appliances.

4.2.6. Use the gas equipment and the room where the gas appliances are installed not for their intended purpose. Use gas stoves to heat the room.

4.2.7. Use an open flame to detect gas leaks (use a soapy emulsion for this purpose).

4.2.8. Store flammable, poisonous and explosive substances in rooms with gas equipment.

4.2.9. Build up the gas pipeline with walls, panels, brick them up in the walls and cover them with tiles. The gas pipeline must be accessible for inspection and maintenance.

4.2.10. Store empty and filled with liquefied gases cylinders in rooms and basements.

4.2.11. Close the valve on the gas riser.

5. Requirements for the safe operation of residential chimneys.

5.1. Maintenance and repair of smoke channels is carried out by specialized cleaning organizations under contracts with the organization that manages the residential building.

5.2. Chimneys should be tight, detached, vertical, without ledges. The slope of the chimneys from the vertical at an angle of 30 degrees with a horizontal distance of no more than 1 m is allowed, while the channel cross-section must be maintained along its entire length. The cross-sectional area of the chimney should not be less than the area of the branch pipe of the gas appliance connected to the chimney. In existing buildings, no more than two water heaters are allowed to be connected to one chimney, provided that combustion products are introduced into the chimney at different levels, no closer than 75 cm from each other or at the same level with the device in the chimney, cut to a height of at least 75 cm. be produced with the simultaneous operation of two water heaters. The crossing of smoke and ventilation ducts with gas pipelines, water pipes, electric cables is prohibited.

5.3. Quality control of the performed repairs of smoke channels is assigned to housing maintenance organizations.

5.4. Chimney repair works are carried out according to the schedules agreed with the contractor.

5.5. The smoke channels are checked on time: brick - once every 3 months; asbestos-cement, pottery and heat-resistant concrete blocks - once every 12 months.The initial check (for density and isolation, for the absence of blockages and for the presence of traction) is carried out annually in the third quarter during the period of preparation of houses for winter. In newly built houses, the initial check is carried out at the time of acceptance of the house into operation.

5.6. In the period from November to April, it is necessary to inspect the chimney heads in order to prevent them from freezing and blocking with a note of the results of the checks in a special journal. Control over the implementation of inspections is carried out by the heads of the housing maintenance organization.

5.7. If faulty chimneys are found, the devices connected to them are subject to immediate disconnection from the gas supply, residents are warned against signature about the dangers of using gas water heaters.

5.8. Before the start of scheduled work on the repair of chimneys, the gas appliances connected to them must be turned off by the employees of the gas supply company in accordance with the notification received from the contractor.

5.9. The connection of gas appliances after the repair of chimneys should be carried out only after the receipt of an act on the technical condition of the chimney by the employees of the gas supply company.

5.10. Based on the results of regular, extraordinary and post-repair inspections and cleaning of smoke channels, acts of the established form are drawn up.

5.11. When carrying out maintenance:

5.11.1. The technical condition of iron connecting pipes (hereinafter - ZhST) is checked according to the following parameters: - the total length is no more than 3 m in new buildings and no more than 6 m in existing ones; - the number of turns - no more than three, with a radius of curvature not less than the pipe diameter; - the links must fit tightly into one another along the exhaust gases by at least 0.5 of the pipe diameter; - when connected to the chimney, the ZhST should not cross the channel section and have a restrictive washer or corrugation; - the height of the vertical section is at least 50 cm, in rooms with a height of 2.7 m - at least 25 cm is allowed; a slope of at least 0.01 (1 cm per r.m.) towards the gas appliance; painting - fire-resistant varnish; - the presence of a fire cut at the intersection of hard-to-burn partitions; - the distance from the ZhST to the ceiling and walls: non-combustible materials - at least 5 cm; made of hard-to-burn materials - at least 25 cm.

5.11.2. The presence and compliance with the standards of a "pocket" for collecting garbage in a chimney with a hatch for cleaning is established - at least 25 cm from the lower edge of the ZhST.

5.11.3. The technical condition of the smoke channels within the attic is monitored: - the presence of grouting, whitewashing and numbering; - the presence of a fire cut equal to 50 cm to the building structure made of combustible materials and 38 cm for structures made of non-combustible materials.

5.12. When carrying out repair work and maintenance of chimneys, it is necessary to comply with fire safety requirements.

5.13. When monitoring the technical condition of the smoke ducts above the roof, the following are checked: - the condition of the plaster, whitewash, ironing of the heads; - the presence of umbrellas and deflectors on the chimneys, the numbering of the smoke channels; - the correct location of the head with respect to the ridge of the roof and closely located structures, trees - the absence of a zone of wind support: - 0.5 above the ridge of the roof when they are located (counting horizontally) no more than 1.5 m from the ridge of the roof; - to the level with the ridge of the roof, if they are 1.5 - 3 m away from the ridge of the roof; - below the ridge of the roof, but not below a straight line drawn from the ridge downward at an angle of 10 degrees to the horizon, when they are more than 3 m from the ridge.In all cases, the height of the pipe above the adjacent part of the roof must be at least 0.5 m, for houses with a combined roof (flat roof) of at least 2 m.

5.14. The roofs of gasified houses should be equipped with ladders, scaffolding and parapet gratings.

6.The procedure for pre-commissioning tests and acceptance into operation of internal gas pipelines and gas equipment of residential buildings after the completion of construction, reconstruction, repair and overhaul of gas supply systems.

6.1. After the completion of the construction and installation work, the work performed is monitored, which includes:

6.1.1. Verification of the conformity of the laying of gas pipelines and gas equipment to the project and the requirements of regulatory documents. In case of a forced deviation from the design solution, appropriate changes must be made, agreed with the author of the project and the gas supply company.

6.1.2. Tests of gas pipelines and gas equipment for strength and tightness. The tests should be carried out by the construction and installation organization in the presence of a representative of the operating organization. The test results should be recorded in the building passport. Gas equipment, including foreign-made equipment, must be certified and have a permit from Gosgortekhnadzor of Russia for use. The presence of a certificate of conformity and permission must be reflected in the passports (forms) of the equipment.

6.2. Acceptance of gas pipelines and gas equipment for operation after completion of construction, reconstruction, repair, overhaul is carried out in accordance with the requirements of regulatory documents. The procedure for organizing and the sequence of work on switching gas pipelines and starting gas are determined by the instructions of the gas supply company.

6.3. Gas hazardous work on in-house gas equipment is carried out in the presence of a gas hazardous work order, drawn up taking into account safety requirements; technological instructions, orders and instructions issued by the management of the gas supply company for each type of work.

6.4. Completion of work on conducting pre-commissioning tests and acceptance of internal gas pipelines, gas equipment of residential buildings and chimneys after construction, reconstruction, repair and overhaul of gas supply systems, as well as activities and work of the next cycle of maintenance of gas pipelines, gas equipment and chimneys should be documented for each residential building by the organization , which performed the specified work.

7. Composition and frequency of maintenance and repair of gas equipment inside the house.

7.1. The composition and timing of maintenance are determined by the type of gas equipment and the conditions of its operation. Maintenance work on gas pipelines and gas appliances in residential buildings is carried out in accordance with the instructions developed by the gas supply company.

7.2. During the operation of gas equipment, maintenance of gas equipment is carried out; replacement of units and parts; connection and disconnection of gas equipment; emergency recovery work.

7.3. The task of maintenance is to ensure the operation of in-house gas supply systems, to instruct the population. Types of maintenance: - periodic maintenance (hereinafter - PTO); - unscheduled repairs upon request (hereinafter referred to as VRZ). PTO is carried out according to the annual and monthly schedules of the service enterprise of the gas economy under contracts with the owner of the building, unscheduled repairs - at the request of the population.

7.4. Unscheduled works at the request of the population are carried out in the following terms: - elimination of gas leaks immediately; - elimination of malfunction of gas equipment within 24 hours. When performing the maintenance work, the malfunction indicated in the application is eliminated, and the entire scope of work provided for during the PTO is performed.

7.5. The service life of gas equipment is established in accordance with the passports (instructions) of the manufacturers.For domestic gas pipelines, this period is 30 years. After the expiration of the standard service life, diagnostics of the technical condition of gas pipelines and equipment should be carried out in order to determine the residual resource with the development of measures to ensure safe operation for the entire period of the extension of the operating cycle, or to justify the need for replacement.

7.6. The given compositions of measures and works are mandatory for performing in the mode of repeated annual cycles of maintenance of gasified residential buildings.

Download Gas pipelines and gas equipment of residential buildings

Previous article Next article