Electric underfloor heating has recently become widespread, since it can be used both as the main and additional source of heat in the house. The arrangement of such a heating system has its own characteristics, therefore, we will dwell in detail on the installation of a warm electric film floor with step-by-step instructions and photo examples.

How does a warm film floor work?

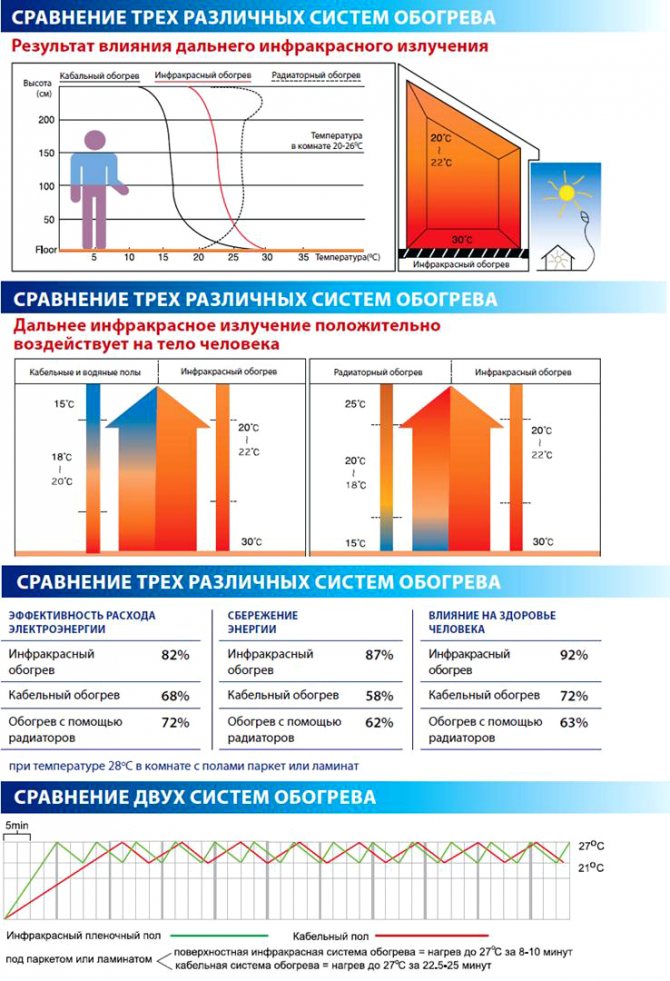

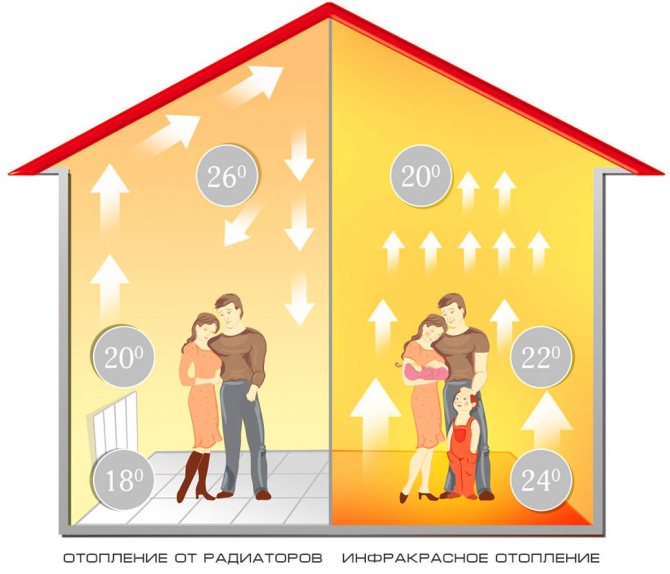

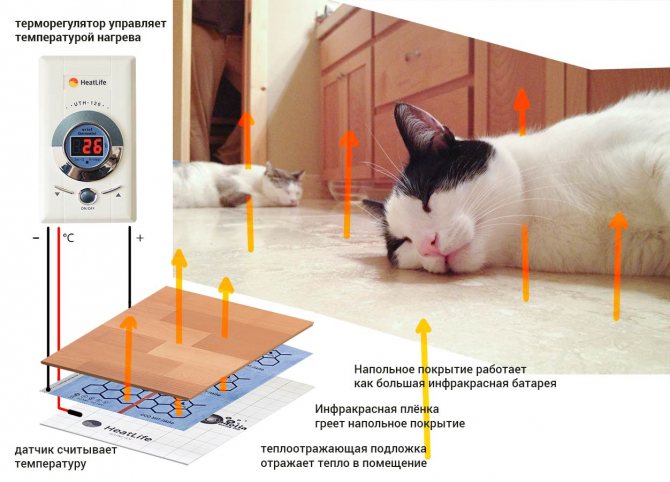

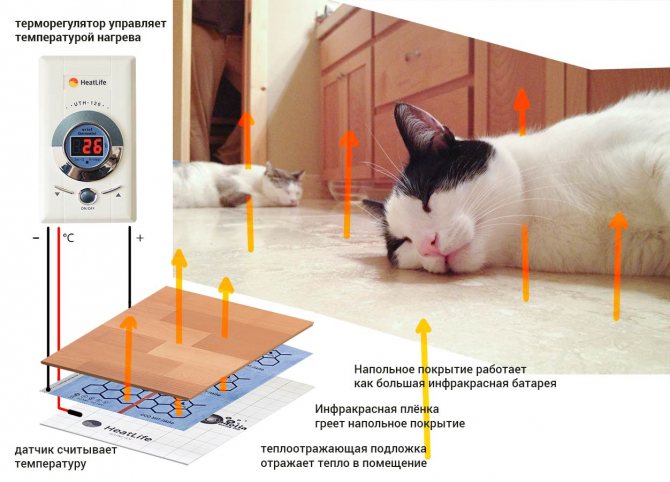

Electric underfloor heating made of foil works on the principle of infrared radiation. Today, this heating technology is widely used for various floor coverings: linoleum, laminate, carpet, ceramic tiles, etc. In addition, it is possible to use the film in wooden or plasterboard suspended ceiling structures.

Heating with a film warm floor is perceived by a person as heat from the sun due to the same nature of the source. Structurally, the system is made of several sheets of film, which are mounted on the floor surface. When the installation is completed, the finishing material is laid, after which the film is connected to the mains.

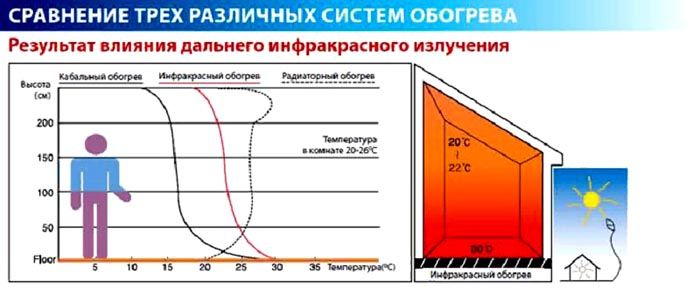

Such a warm floor works somewhat differently than conventional convection systems. Infrared radiation does not heat the air, which reduces the cost of heating furniture and other items located in the heating zone.

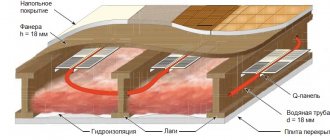

↑ Underfloor heating construction

Regardless of the type, underfloor heating consists of:

- heating system;

- sensor;

- thermostat.

The sensor records the heating of the room and sends a signal to the regulation system, which compares the set and actual values and decreases / increases the temperature.

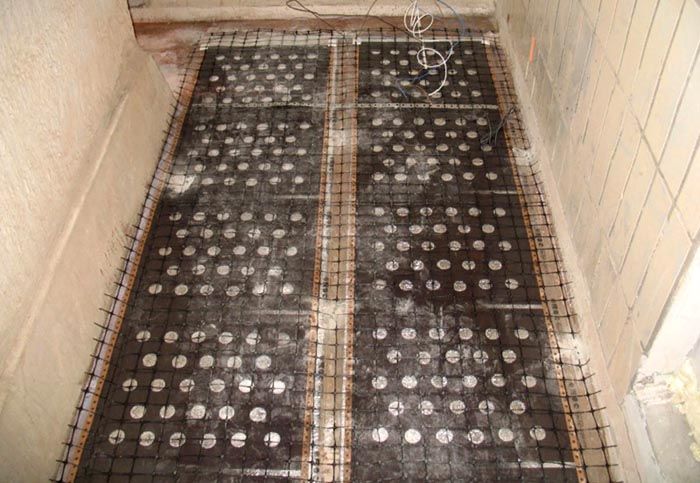

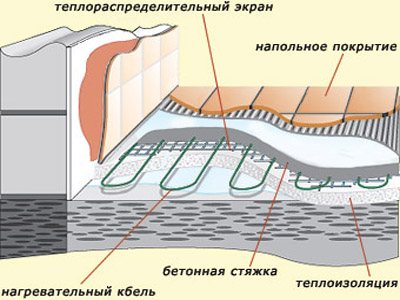

Underfloor heating construction

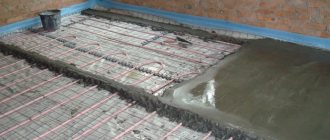

A pipeline or heating cable is distributed over the subfloor, through which the heat carrier will be supplied, and a finishing screed is installed on top and the floor covering is laid.

Pros and cons of IR film floor

A warm film floor has a number of advantages:

- relatively low cost of components;

- simple and quick installation, which can be performed even without special knowledge;

- the possibility of using the film for both additional and main heating source;

- according to experts, infrared heat has a positive effect on human health.

Among the shortcomings, it can be noted:

- high power consumption (depending on the area of heating, insulation);

- compared to a water-based heating system, the film cools down almost immediately after the power is turned off.

When choosing underfloor heating based on a film, you need to take into account that their functioning is directly related to the presence of electricity.

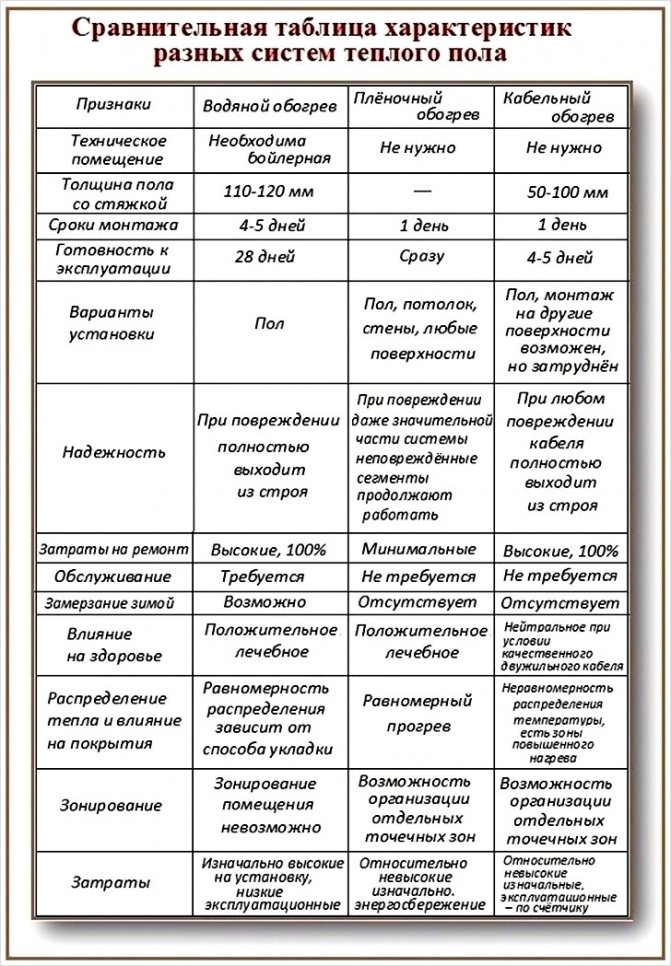

Which is better - a film or cable underfloor heating?

Of course, you can join either side, but the reality is that when choosing a specific electric floor heating, one should be guided solely by the expediency of its use. Therefore, in the question of which warm floor is better: cable or film, it is recommended to adhere to neutrality and decide according to the situation. But you can always highlight certain characteristics of the cable and film, compare them and choose the most suitable product. So, if a mobile system is required, then it is better to opt for the film version. This will provide zonal heating of the room. The use of an infrared underfloor heating of such a design will be advisable under a carpet, behind a painting or a mirror. The cable version has a high thermal potential and does not require additional electrical devices during operation. At the same time, consumables for cable floor heating will be cheaper.

Thermal film power consumption

Before installing an infrared heating system, many often have a question: how much electricity does a warm electric floor consume? For IR-film, the power per 1 m² of floor surface is about 0.2 kW. Energy consumption will largely depend on the thickness of the screed, heat loss, thermal insulation. To calculate the consumed power, use the formula:

W = S * P * 0.4,

where - S is the floor area of the room, P is the total power of all film elements, 0.4 is a coefficient that takes into account only the usable area for heating.

So, if the housing is not very well insulated, the film should be used with a maximum power, for example, 0.2 kW W per m². For a room with an area of 20 m², the power consumption will be as follows:

W = 20 * 0.2 * 0.4 = 1.6 kWh.

Most often, such heating is used for about 7-10 hours a day, usually in the morning and evening. According to calculations, electricity consumption per day will be 15 kW, per month - 480 kW. And this is the power of only one room! It is enough to multiply the obtained results by your tariff in order to calculate the financial costs for such heating.

How to choose accessories

The main elements of an IR-heated floor are a film and a thermostat with a temperature sensor.

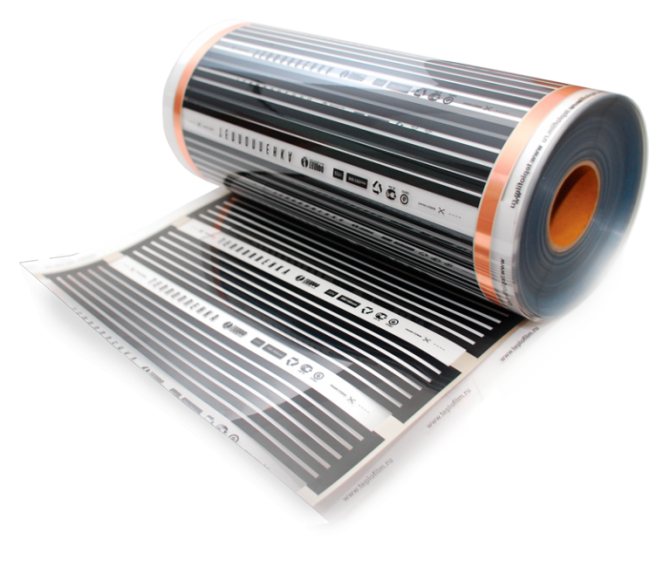

Varieties of film

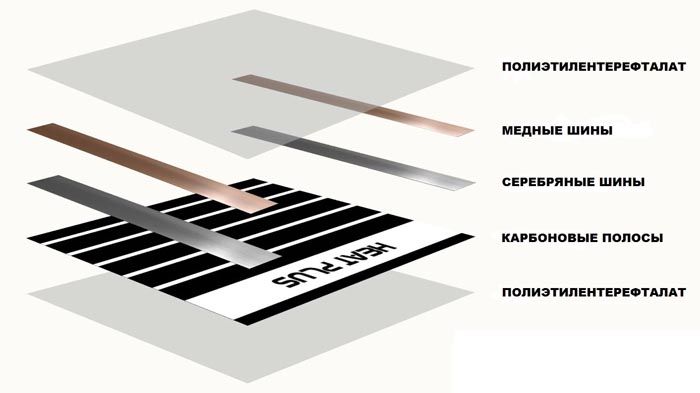

There are two main types of films offered today:

- solid - the material has a solid carbon coating;

- Stripe - Carbon fiber coating applied in stripes.

Since the infrared floor has different thicknesses, it is recommended to choose a thicker material to increase the reliability of the system. The thickness, as a rule, does not exceed 1 mm.

You can learn more about choosing a film from the video.

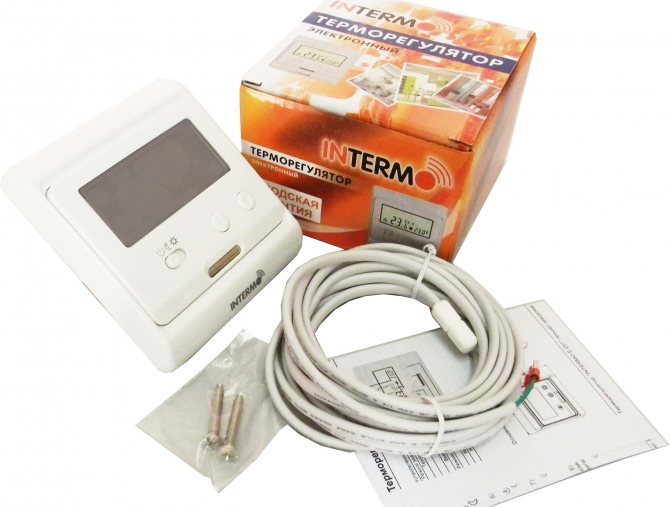

Thermostat

Using the thermostat, you can control the operation of the heating system. The kit includes a thermal sensor that is installed between the film mats and connected through the corresponding contacts. With the help of a temperature sensor, a signal is transmitted from the surface of the heating elements to the thermostat to turn on the system.

Thermostats are represented by such devices:

- mechanical - equipped with keys and mechanical wheels;

- electronic - equipped with a display and controlled by buttons.

Today, there are touchscreen devices that allow you to set multiple time modes to save energy. Inexpensive thermostats operate from the mains and cannot start work on their own when the power is turned off. In this case, it is better to choose models where a battery can be used.

Temperature sensors can be of two types. Their choice depends on the flooring and the type of device. If the coating is soft (carpet, linoleum), then the sensor looks like a small cylinder. For hard coatings, the thermal sensor has a larger size and is protected by a gel sheath.

Installation of film underfloor heating

Laying a warm floor based on a film has certain nuances that should be considered in more detail.

Preparation of the base

One of the crucial stages in the installation of an infrared coating is the preparation of the base for its installation. The process boils down to the following step-by-step actions:

- Remove old finish and floor screed. If the screed is in good condition, it may not be removed under the film floor. The base is cleaned of dust and dirt.

- If the floor surface has differences in height of more than 2 mm per linear meter, leveling is performed with a leveling mixture.

- Spread a layer of waterproofing. As such, you can use Penofol, which is also a heater. The substrate is laid over the entire surface of the floor, and the joints are fastened with aluminum tape.

When using underfloor heating as an addition to the main heating, foamed polyethylene with a foil layer can be used for insulation. In other cases, expanded polystyrene is used.

Drawing up an installation diagram

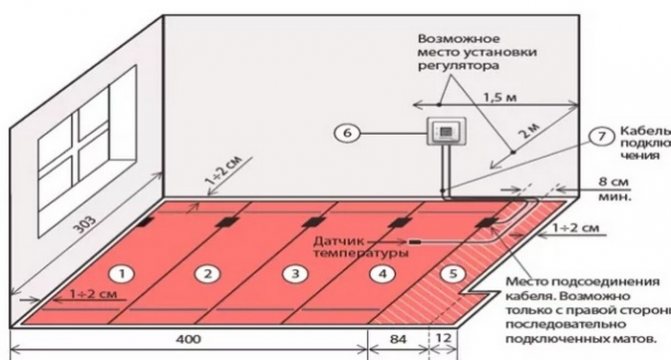

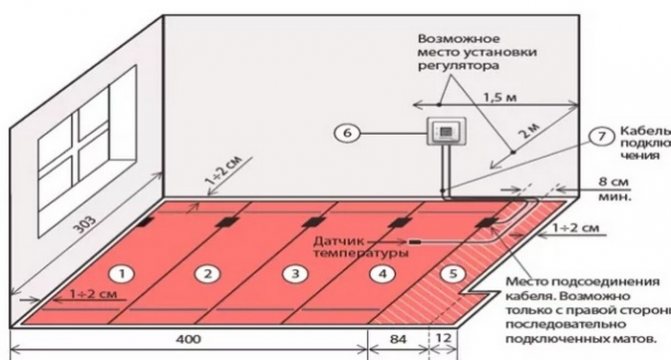

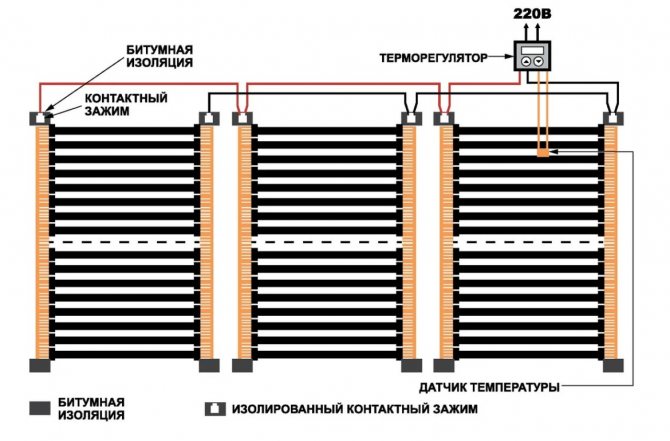

To connect the film floor heating with your own hands to be correct, you need a diagram and adherence to the installation technology. First you need to determine the location of the thermostat. Most often, it is mounted at a height of 15 cm from the floor. After that, they draw up a scheme for laying the film and make calculations of the material.

In the process of drawing up a diagram, you need to take into account a number of nuances:

- the laying of the first row of film is carried out with a distance from the wall of at least 100 mm and a maximum of 400 mm;

- when using the film as the main source of heating, it must be laid on 75% of the floor area;

- if a warm floor from a film is used as an addition to the main source of heating, then a coverage area of 40-45% will be quite enough;

- the strips of the film during installation must not intersect and overlap each other.

To determine the total length of the heating material, a layout diagram of the film on a sheet of paper is drawn up. After counting the length of each section and adding them, the total length of the coating film can be calculated.

When drawing up a diagram and calculating the length, it must be borne in mind that each strip in length must be a multiple of 17 cm, which corresponds to the cutting lines.

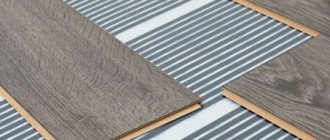

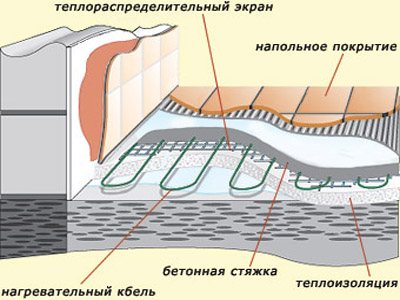

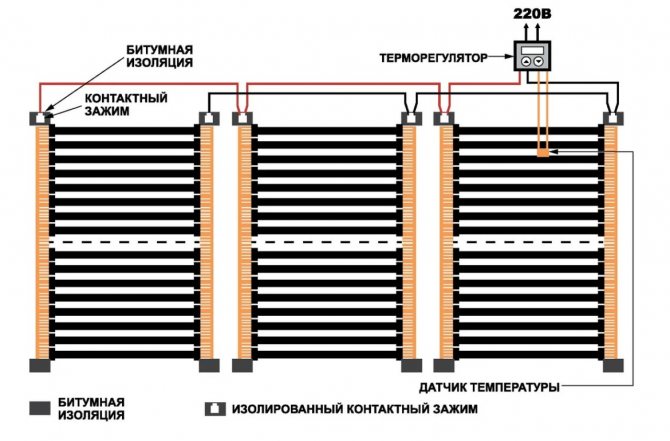

Laying and connecting thermal film

To figure out how to mount the film, you need to adhere to the following instructions:

- Lay the film on top of the insulation according to the drawn up scheme. If necessary, the film is cut along the lines applied from the factory. The mats are laid with the copper part to the floor towards the installation site of the thermostat, while the maximum length of the mat should not exceed 8 m.

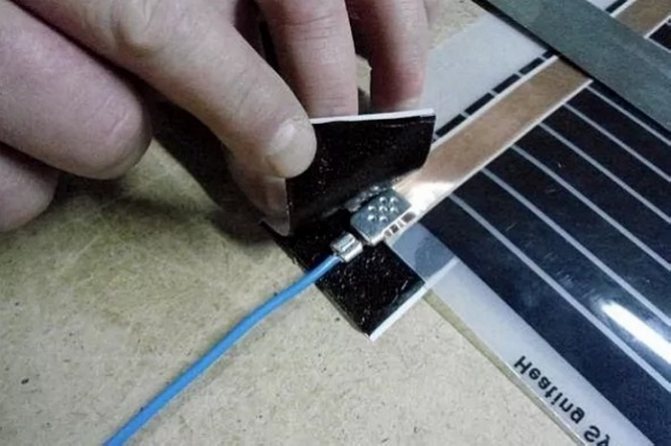

- Clips are fixed to the copper strip and the wires are connected.

- Areas of connection of clamps and wires are insulated using special mastic. Some of the clamps are mounted on a conductive surface, and the rest are placed inside the film.

- The temperature sensor is connected from the bottom of the film and is reliably insulated. The connection cables are best placed under the skirting board.

- After completing the installation and connection of the film, install the thermostat in the prepared place.

Underfloor heating electric film: characteristics

If there is a decision to install this heater, then you will need detailed information about it. The technical characteristics of the warm film floor will help to carry out the correct calculations of the required materials for installation and operating costs:

- The product is available in several variations: a roll with a length of 50 m, a width of 0.5 and 1 m and a thickness in the range of 0.23–0.47 mm.

- Power consumption per 1 m2 of film ranges from 25 to 35 W / h.

- The temperature on the plane does not exceed 33 ° C.

- The radiation length is in the range 7–20 µm.

- The total share of long infrared rays is 90.4%.

- Connection to a 220–230 V network at a frequency of 50 Hz.

It is important to know that the use of infrared thermal film will be advisable if it covers 70% or more of the floor surface of the room.

Experts do not recommend using film warm floors in regions with harsh climatic conditions, because their characteristics are not suitable for this purpose. In the event that the customer still wants to install such heating in the house, the device can only be used as an auxiliary or emergency source of heat. The size of the thermal film must be chosen wisely. This is due to the fact that it can be cut only in the marked areas. Most often, the distance between the possible incision sites is 25 cm. The characteristics of the underfloor heating film can always be checked with sellers or heating specialists. The device can be used in utility buildings and outbuildings where there is no possibility of supplying central heating.

Film floor testing

After finishing the installation of the infrared system, you need to make sure that it functions. First, they check the reliability of the insulation at the connection points, for which they use a special device. The values must correspond to those indicated by the manufacturer. Turning on the heating, check the uniformity of heating of each of the elements. If areas are found where there is no heating, troubleshoot or replace the film with a new one.

If, when the system is turned on, the film heats up evenly over the entire area, there is no sparking and no smell of insulation on the contacts, proceed to laying the finishing coating. It is advisable to save the previously drawn up plan for laying the film. It may be needed in case furniture is rearranged.

Positive qualities of warm electric floors

Warm electric floors can be used not only in apartments and private houses, but also in offices. They work well with almost all floor coverings, including ceramic tiles, linoleum, laminate and other floors. Concealed mounting technology allows you to hide the entire system and not spoil the interiors of the premises.

In the set of warm floors, there is always a thermostat that provides a temperature setting with an accuracy of 0.1 degrees. This appliance can turn the heating elements on and off at exactly the specified time. The power of the underfloor heating system allows them to be used not only as auxiliary, but also as the main heating.

For laying underfloor heating under ceramic tiles, no special knowledge and practical skills are required. Among other advantages, the uniform heating of the surface over the entire floor area should be noted. The entire system can function normally without installing additional equipment, unlike other types of heating using gas or electric boilers.

In the event of any breakdown, it is easy enough to identify. The safe operation of warm electric floors is of great importance due to the relatively low temperature of the heating element. All these advantages allow these systems to successfully compete with other types of heating.

Features of installation and operation of thermal film

To keep the infrared heating system working for as long as possible, it is recommended to adhere to the following tips:

- When cutting a strip, you cannot make a diagonal cut or make a rectangular cut. It is prohibited to cut the conductive strips;

- it is prohibited to place objects that can retain heat, for example, thick carpets, oversized furniture without legs, etc., on top of the floor covering above the heated film floor. Such items will lead to overheating and system failure;

- heavy furniture and other objects should not be located above the film material. Excessive pressure on the IR sheet can damage the heater;

- based on what kind of floor covering is used, for example, laminate, with combined heating, simultaneous heating may be prohibited;

- it is not recommended to lay the film material close to the walls and to the overall furniture: it is necessary to retreat about 3-10 cm. The indentation depends on the power of the heating elements.

Film electric underfloor heating, installation and step-by-step instructions with photo examples of which were considered in this article, is an effective way to heat your home. If you reduce heat loss to a minimum and properly lay the system, then the cost of such heating will not be so great. In addition, underfloor heating is often installed only in bathrooms and toilets, which will absolutely not ruin the owner.

Similar publications

- To read

Do-it-yourself floor insulation on the balcony

- To read

DIY infrared floor heating

- To read

Leveling the floor with your own hands

- To read

Do-it-yourself warm floor in the garage

- To read

Do-it-yourself water floor heating

- To read

Underfloor heating types

Globally, there are three types of underfloor heating in a house or apartment:

- water (liquid) warm floor;

- electric floor of wave heating (film or infrared);

- direct heating electric floor.

Each type has pros and cons and is used in different situations. To answer the question, which warm floor is better, you need to analyze the operating conditions. First, a project is necessarily developed by professionals, which indicates which area is planned to be heated, what type of underfloor heating will be used and what finishing materials are recommended.

Not all floor coverings can be installed with underfloor heating. For example, it is impossible to install underfloor heating under a cork. It is preferable to use PVC tiles, ceramic tiles, linoleum, carpet. Moreover, some types of finishes are categorically unsuitable for a film floor (we will discuss this below). Any warm floor is mounted on areas free of furniture, because otherwise there will be a waste of heat loss, and in the case of a film floor, there will also be damage to the furniture.