Insulation requirements

Thermal insulation of pipes provides for a number of technical regulatory documents, the observance of which is mandatory in the design, installation and operation of engineering systems of residential and public buildings, and other facilities for various purposes.

More information can be found on the website:

https://www.ktto.com.ua/norm/teplo_pot

It should be noted that industrial thermal insulation refers to the thermal insulation of pipelines, tanks, as well as equipment and tanks.

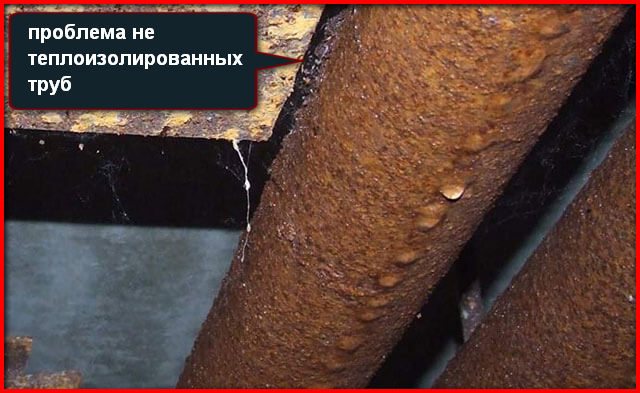

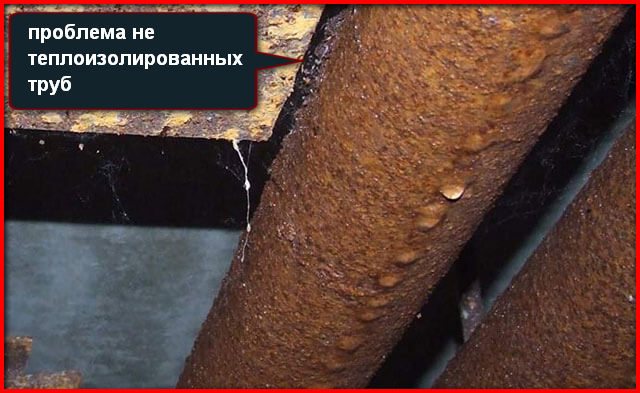

Thermal insulation is carried out to prevent cooling of the liquid present in the pipes or to avoid the formation of condensate on the equipment. If heat loss is not so important, then this technological process is necessary to comply with safety standards.

Different versions of insulators are being considered for insulating pipes used to transport gas.

The thermal insulation of the gas pipeline is carried out by means of a special varnish or paint, but usually they resort to modern protective materials that meet all the requirements for this, namely:

- an insulator for a gas pipeline must be endowed with the potential of a monolithic, uniform device on the pipe;

- the material for the thermal insulation of the pipeline must be characterized by a low coefficient of water absorption and have high waterproofing qualities;

- protect the structure from destructive ultra-radiation.

Rules for choosing insulation materials

Experts recommend taking into account a number of nuances:

- Highway laying area. It is more convenient to cover the contours in the room with light foam modules or mineral wool.

- Problems with rodents, mold. Metal sheets, paint, glass wool resist mice and rats. The rest of the materials are used by rodents for their nests.

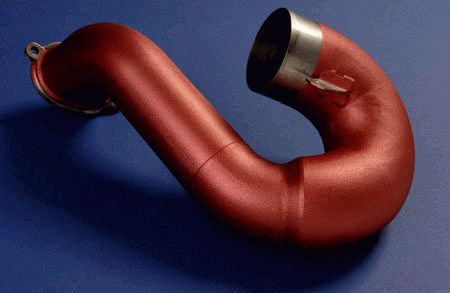

- The complexity of the shape of the highway, its size. The more complex knots, bends, turns, the more flexible and durable the coating should be. Foam and other ready-made modules are not suitable here, paint or mineral wool is better.

- Indicator of limiting heating. When hiding the contours in the floor screed, wall panels must ensure the strength of the insulation. Most often, polyethylene is used for warm floors - a waterproof insulation will withstand heating up to +55 C without deformation.

Simplicity of installation must be taken into account. For example, it is more convenient to work with dispersed mixtures and paints on complex units, but PPU is sprayed with a special device - it is easier to take paint. If the line is located in areas with unstable soil, has butt joints, it is more practical to use polyethylene and foam.

Important! Mineral wool slabs have their own weight, therefore they load pipelines. For insulation of pipelines on moving soils, mineral wool cannot be laid out. If the pipe is overloaded, the circuit will burst.

Types of thermal insulation materials

Thermal insulation is subdivided into types with certain properties and is produced in the following forms:

- senments;

- cylinders;

- mats;

- half-cylinders;

- rolls.

Types of insulation:

- mineral wool;

- shell;

- polyurethane sealant;

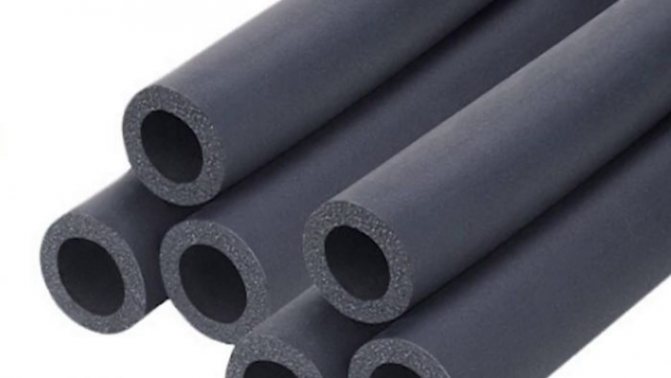

- tubular insulation;

- liquid ceramic composite;

- basalt insulation.

The list above is not limited to this, the market is regularly updated with new options in this area.

Work inside the building

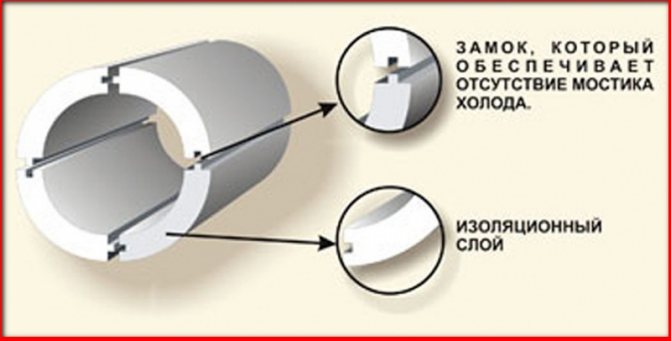

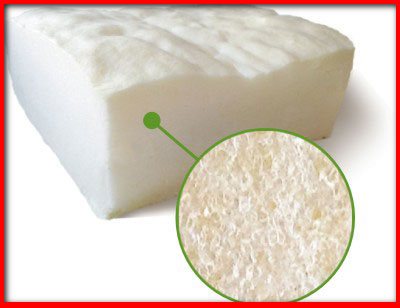

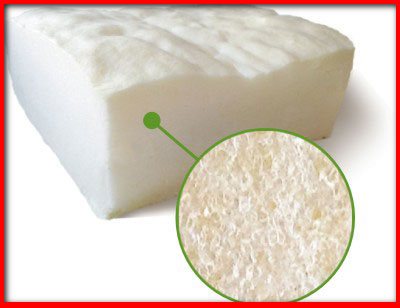

Thermal insulation of indoor water pipes can be made with fiberglass, basalt and mineral materials and expanded polystyrene.Expanded polystyrene is optimal for insulating a water supply system in a house: it is produced in the form of two shells, fastened together at the junction.

Fiberglass and mineral wool are used to insulate metal-plastic pipes. The use of cylindrical basalt insulation is accompanied by protection with a layer of roofing material and glassine. However, basalt materials are expensive, so they are rarely used.

Basalt and expanded polystyrene shells are mounted as follows:

- the halves are put on the pipeline with an offset for an overlap of 15 cm;

- wrapped with plumbing tape;

- for branch points, special segments cut to the required length from the sections are used;

- the insulation is wrapped with protection - roofing material or foil-insol;

- the shells are finally secured by tightening.

Thermal insulation with mineral wool

Mineral wool of all the types of insulation presented today is characterized by the lowest cost, and the advantage is the ease of installation of insulation. Thermal insulation of pipelines with mineral wool - process:

- a roll of cotton wool is cut into strips 200 mm thick (across) and they are then wrapped around the pipes, first with a layer of mineral wool (100 mm thick), on top - tightly with a layer of fiberglass;

- mineral wool should be laid evenly, it should not wrinkle.

Mineral wool is considered as thermal insulation of pipelines of significant diameter, applicable for heating routes of urban networks and for sewerage systems, for sewerage systems of small diameter and for water supply pipes - not practiced.

Thermal insulation of external pipelines

The choice of thermal insulation materials for external laying of heating pipes is quite large and are offered in the form of roll-type mats.

The pliability of the material allows you to give them a figured shape for ease of installation, heaters are offered, applied in a liquid form, their further qualities are manifested after solidification.

Removable thermal insulation in a galvanized casing is widely used in linear pipeline sections.

Foam rubber in the form of tubes or rolls, depending on the diameter of the pipes, is used as thermal insulation for pipes and parts of technological pipelines, installed in several layers, depending on the required thickness of thermal insulation.

An interesting method for thermal insulation is considered to be a cover layer, the types of which are really familiar on the site:

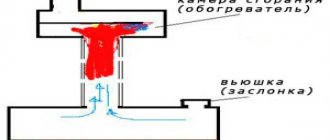

For heating

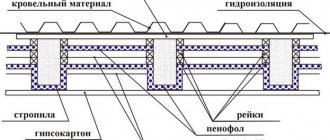

Thermal insulation of heating pipelines consists of the following stages:

- foil adhesive tape is glued to the pipes using spiral technology;

- insulation in the form of mineral wool is wrapped around the pipe so that the seams coincide and are carefully fixed - this will help to exclude the formation of "cold bridges";

- the insulation is fixed by wrapping it with plumbing tape - it is important to wrap it as tightly as possible, otherwise groundwater will get into the cracks and the insulation will be ineffective.

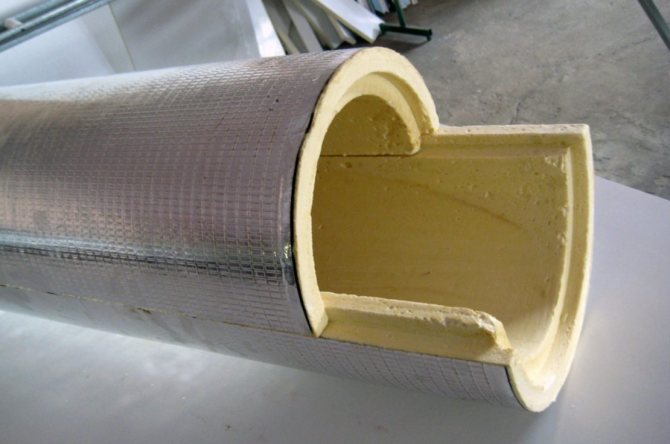

Solid materials - polystyrene, polyurethane foam - are made in the form of two connecting halves, which are superimposed on the pipe and glued together with a special super-strong compound.

It has become very convenient to use liquid materials - penoizol and heat-saving paint. In this case, the process of warming consists in applying them to the pipes.

Polyurethane foam

Polyurethane foam as a pipeline insulation is an environmentally friendly and efficient insulation. It is characterized by a neutral odor, is not susceptible to fungus, endowed with increased resistance to harmful environments, does not collapse, is completely harmless to humans and the environment.

Directly for large-diameter pipes, a spraying method is used, as a result of which a seamless continuous insulation is formed, a peak reduction in heat loss is guaranteed. Spraying is carried out at the place of work, using special equipment for thermal insulation of pipelines, the simplicity and speed of the procedure is a clear advantage. For work on pipes of small diameter, shells based on polyurethane foam are considered, which provide a high level of thermal insulation, this method is affordable at its cost.

Pipe wrapping

How to insulate heating pipes? The installation of all the components of the thermal insulation layer is quite simple, but it must be carried out as carefully as possible. Cold air can penetrate even a small gap, and in the same way hot air will escape from the heating pipe under the screed. Almost any type of mineral wool is suitable for winding the pipe, and silk thread is required to fix it.

Thermal insulation of heating pipes with mineral wool

After that, the structure will need to be wrapped with a material such as roofing felt, and simple wire will be used as clamps. From above, the entire structure is wrapped with fiberglass, and if necessary, it can be closed additionally with adhesive tape. This insulation of heating pipes is a little old-fashioned, but it has not lost its effectiveness and reliability to this day. Sometimes, however, it will be necessary to carry out minor repairs.

Based on modern standards and technologies, it is required to produce not only heat, but also sound insulation of heating pipes. Some additional components are used to insulate the heating pipes.

For sewer channels, foam plastic with an increased level of density or extruded polystyrene foam is often used.

The same material can be successfully used for water pipes or heating pipes. However, such insulating materials are used for heating pipes mainly in the private sector, since the installation can be done by hand.

Site search otoplenie-doma.org

Foam cover for pipe insulation

Foil-clad materials for thermal insulation are especially popular. They can be used not only outdoors, but also in trenches. The heat channel can simply be wrapped with polyethylene foam, or you can pack it in plain mineral wool, and then close it on top with foam foil, which additionally has a layer of aluminum foil.

Insulation of heating pipelines of heating pipelines can also be performed by means of 4 atmospheric compressors and equipment with which it is possible to apply polyurethane foam.

This method requires the work of a specialist dressed in a specialized suit. The specialist must also have the necessary experience in this area. This material will be used to make heat insulation for heating pipes, which will have the appearance of a pipe shell.

Application of polyurethane foam to the pipe

In the private sector, more often all thermal insulation of heating pipes in the basement is made using materials such as dense cellophane film, foamed polyethylene foam, mineral wool or roofing felt. These materials serve as insulation for heating pipes.

The use of foil-type heaters in combination with other materials makes it possible to increase the efficiency of the insulator several times. Metal, even a thin layer, plays the role of a reflector and does not allow warm air to pass from the inside, and cold outside.

How are pipelines insulated

Thermal insulation must be carried out in accordance with applicable rules and regulations, which guarantees effective energy savings and an increase in the duration of the useful life

.

The installation of thermal insulation of pipelines, based on the article, can really be done using various materials, but taking into account certain factors and, above all, from the direct purpose of the future laid system.

For example, thermal insulation of pipelines with a high temperature of the medium transported through it is best done using cylinder insulation (polyurethane foam shell), additionally lined with foil cardboard or foil.

Formula for calculating heat loss when using the Flexihit pipe heater

To accurately calculate the heat loss of a pipeline in air, you can use this formula. The important characteristics are pipe diameter, insulation thickness and ambient temperature.

- D [m] - outer diameter of the pipe with thermal insulation;

- d [m] - outer diameter of the pipe;

- L [m] - pipe length;

- tвн [C] - product temperature inside the pipe;

- tout [C] - ambient temperature;

- lambda - coefficient of thermal conductivity of thermal insulation, usually 0.03-0.05;

- 1.3 - safety factor;

Brief device for thermal insulation of pipelines

Preliminary stage:

- complete completion of installation work (locksmith, welding);

- cleaning with steel shields (manually) or using sandblasting machines of the surface and joints of the pipeline, degreasing;

- testing the strength and tightness of welded seams (visual inspection, pressure testing, control (if necessary) using special equipment));

- application of special compositions - epoxy primers (as an example).

It is interesting to get acquainted visually with the installation process:

List of materials for work

There was a time when pipes were wrapped with fur coats, furs, sweatshirts and other items that were at hand in order to protect them from freezing. But this is all the past century. To date, progress has gone far ahead. Now in hardware stores and plumbing supermarkets, you can purchase a variety of materials that can be used to produce thermal insulation.

In order to avoid mistakes during installation, you need to choose the right material. When choosing, one should be guided by the technical characteristics and properties, as well as the level of complexity of the installation. The material for insulating water supply in an apartment must exactly correspond to the following factors:

- Firstly, the product must conduct heat energy poorly, but at the same time have excellent heat-saving characteristics.

- Also, the metal or plastic that was chosen must have a sufficiently long period of performance of direct functions, as well as normally tolerate direct or indirect contact with bacteria and environmental factors.

- Also, the thermal insulation coating must repel water and other moisture, as this significantly increases the amount of heat conduction.

- The product should not lose its original properties, technical characteristics, shape and condition when exposed to high temperatures.

If the owner of a house or land plot knows all the advantages, negative and positive aspects, as well as many other nuances of this or that insulation, then he will be able to make an informed choice, as well as determine which installation technology will be most appropriate in this situation. It is recommended to install thermal insulation products inside a building, building or structure.

In order to protect the water supply system from frost, the following items are used, which are excellent for this purpose:

- Basalt based material. This type is made in the form of small cylinders, so that the installation activities take place as easily and quickly as possible.For greater strength and protection, certain layers of other substances are placed on the basalt. Accordingly, if there are such positive working properties, then such an item has a fairly significant value.

- Glass wool. In most cases, fiberglass is used in relation to metal-plastic parts. There are at least three popular brands that account for the majority of the global construction market. Since this substance is not very dense, additional products should be laid on top of it, for example, roofing material. This means that such actions incur additional financial costs, as well as a large amount of personal time spent.

The pipe is painted with heat-insulating paint

- Heat insulating paint. It is a thick paste-like mass that comes in two colors, gray and white. On the construction market, this substance is relatively new, therefore it has not yet had time to take root in people's everyday life. The composition includes acrylic dispersion, water, varnish and some other elements. The larger the layer of paste applied, the more significant the insulation level will be.