Polypropylene pipes have recently appeared on the market of materials for the installation of heating and water supply systems, but have managed to gain popularity due to their high functional parameters, reliability and durability. The advantages of polypropylene pipes also include inexpensive, simple installation, which a non-specialist can handle, provided that a quality tool is used and the work technology is observed. Let's consider how to choose the right soldering iron for polypropylene pipes in order to purchase equipment with optimal functionality at a reasonable price.

Soldering iron for welding propylene pipes

Installation of plastic pipelines is carried out by welding system elements (pipes and fittings of the corresponding diameter) in the required order. It is recommended to use parts produced by the same company to ensure full alignment of the mating elements in terms of melting temperature. Overheating or underheating of the polymer material suffers from the quality of the weld.

To heat the inner surface of the fittings and the outer surface of the pipe end to melting, a special apparatus for welding polypropylene pipes is used. It is often called an iron or a soldering iron for polymer pipes.

Soldering iron for plastic pipes: how to buy a quality product

The main task of such a soldering iron is to maintain the required temperature for connecting a polypropylene pipe with a fitting, and its heating temperature is about 260 degrees.

According to buyers, choosing a soldering iron should be selected according to 3 criteria:

- The shape of the heating element;

- Thermal power;

- The price of the device.

- In terms of cost, soldering irons can be divided into 3 groups:

- Russian and Chinese-made soldering irons are cheaper;

- The average cost will most often have Turkish-made soldering irons;

- Expensive soldering irons will be models from European manufacturers, and German and Czech soldering irons will become popular among them.

A soldering iron for plastic pipes from a Chinese manufacturer is suitable for soldering a home heating system. Experts say that such a soldering iron will definitely be enough for two systems, and this is quite enough for the first job of a person who decided to make heating using polypropylene pipes, and you can even let someone use it.

Do not use Chinese-made soldering irons for commercial orders. The whole reason is not that it is not of high quality, but that it is not able to maintain an accurate temperature. The error in cheap spikes reaches 10 degrees and higher, and this contributes to a poor-quality connection, and you cannot visually check this. Defects of this kind are not acceptable when ordering.

For beginners, a Turkish-made pipe soldering iron is more suitable. The error of Turkish soldering irons is very small and the reliability of such a soldering iron is excellent. The medium-sized cost makes Turkish-made soldering irons popular even in firms that are engaged in the installation of heating from plastic pipes. In order to save money, firms assure that it is more profitable to purchase 3 Turkish soldering irons than one German or Czech one. Craftsmen who have been engaged in the type of such work for more than one year know that the Czech and German soldering iron will serve for a long time and will ensure the quality of soldering.

How the tool works

Immediately, we note that there are three types of plastic pipes on the market:

- Polypropylene.

- Polyethylene.

- Metal-plastic.

Any of the listed subspecies can be mounted with a soldering iron for polypropylene pipes. Polypropylene has a melting point of 200 ° C), it is to this point that the device is heated before starting work.

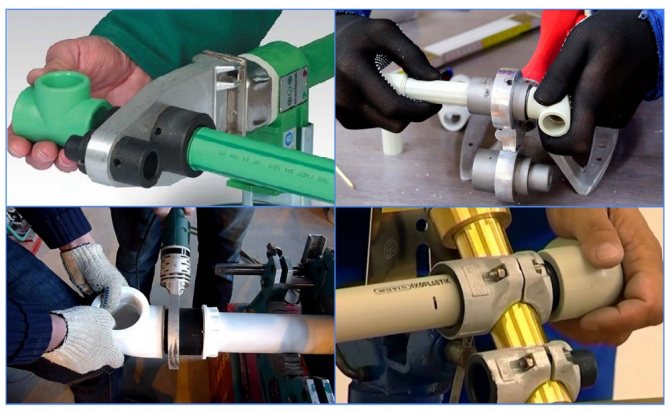

As a result of welding, a permanent socket joint is obtained. On one side of the soldering iron there is a nozzle that creates an expansion or a bell. A pipe is put on it. The second nozzle removes some of the plastic, creating a small seam at the end of the tubing groove.

The heated groove is inserted into the socket, and soldering takes place. Soldering is carried out before starting work at an ambient temperature of at least 5 ° C).

At temperatures below 5 degrees, the plastic becomes brittle, the connection will not work out sufficiently tight.

Self-made soldering iron for polypropylene pipes

The job of a soldering iron is to stick pipes that have been heated to the desired temperature. It is not always necessary to re-solder or repair half of the wiring of heating and water supply systems in the house. It often becomes necessary to work to replace two or three connections. And in this case, it is not necessary to buy a soldering iron, but you can make it yourself.

For an electrician who has plumbing skills, the manufacture of such a soldering iron will take a couple of hours.

Most often, water pipes are hidden from view, for this they are smoothed into canals and therefore you should not worry about beauty and aesthetics. But this is not important, it is important to incorrectly adjust the heating temperature and overheating of pipes or fittings, even if the overheating is not many degrees, it will lead to rejection. In such a soldering, the main issue will be the quality of the soldering of the parts. If, when performing soldering with a home-made soldering iron, a slight discrepancy in the appearance of the elements to be soldered is allowed, then when using a purchased soldering iron everything should be perfect.

To make a soldering iron for propylene pipes with your own hands, you will need such materials:

- Heating element;

- Required fitting for your pipe size and soldering iron nozzle;

- Nickel-plated bolts and nuts M8, they will serve for attaching nozzles to the heater;

- Thermocouple based;

- Mounting for secure fixing of the soldering iron to the auxiliary surface.

In addition to temperature, the power and heating rate of the pipe surface for the connection are also very important. If the heating of the connecting elements is long, then the parts that heat up lose their shape and geometric dimensions.

It is for this reason that the material should have a diameter of 15 to 30 millimeters, and the capacity of the apparatus from 700 to 900 units. need This power corresponds to the heating of the iron.

The scheme of work for plumbing is very simple, you need an outlet, a curling iron, a PVC pipe, which must be pre-cleaned and, of course, the desire of the master. The whole work will not take much time, because it is not difficult.

Rating of the best models of soldering irons in 2019

| Model name | Power, W | Qty nozzles | Producing country | Additional functions | Feedback on disadvantages |

| CANDAN CM-05 | 2 spirals 1200 each | 4 | Turkey | -In the set there are scissors for polypropylene pipes -Additional heating indicator | After some time, the nozzles need to be cleaned, the polypropylene pipelines begin to quickly adhere to the soldering iron. |

| Dytron Polys P-4a 1200 W | 1 spiral with a capacity of 1200 | Depends on equipment. You can purchase a separate soldering iron and a separate set of nozzles. | Czech Republic | -Microprocessor - heating indicator -Temperature sensor -Convenient clamp allows you to fix the device on the table | None. But it is worth noting that the manufacturer claims as an advertisement that it is possible to work with a soldering iron in the wind, freezing temperatures and in hard-to-reach places. |

| Resanta ASPT-1000 65/54 | 1000 | 6 | China (the birthplace of the brand is Latvia, but all production is located in China) | - Heating indicator -Temperature sensor | Only polypropylene pipes with a diameter of up to 63 mm can be soldered, which is generally enough for home use, but not enough for serious construction. |

| BRIMA TG-171 0010291 | 1500 | 6 | China (similar to the previous point, the homeland of the brand is Germany) | - Heating indicator -Temperature sensor -Power regulator heating element | The low weight of the heating element makes the soldering iron short-lived and unstable to aggressive conditions. Enough for 2-3 installations. If you don't need more, you can safely take it. |

| CALIBER SVA-900T Promo | 900 | 6 | Russia | Absent | -Low weight -Instability -Lack of rubber coating on the handle -Low power (which means a long warm-up time before first use) |

| SPETS PTP-1000 SPETS-3268 | 980 | 6 | China (the birthplace of the brand Russia) | - Heating indicator -Temperature sensor | Light installation weight |

| Rothenberger Roweld Rofuse Print + | Electrofusion butt welding | Not required | Germany | -Ability to weld in automatic mode and manually -Ideal device for work on a construction site -Large number of protocols and advanced software module -Welding of polypropylene pipes with a diameter of up to 1200 mm in any weather | The only drawback is the price, but it matches the level and quality of this professional construction equipment. One such machine can solder tens of thousands of kilometers of pipes. |

| Elitech spt 800 | 800 | 6 | China | - Heating indicator -Temperature sensor | -Low weight of installation -Very awkward support. |

| Wester DWM 1500 | 1500 | 6 | China | - Heating indicator -Temperature sensor -Good kit composition (medium quality gloves, tape measure, screwdriver, attachments and metal case) | -Very awkward support. |

| ENKOR ASP-1500 / 20-63 | 1500 | 6 | China (the birthplace of the brand Russia) | - Heating indicator -Temperature sensor | Recommended only for home renovations or small construction sites. The maximum size of the nozzle is 63mm. |

| Bort BRS-1000 | 1000 | 6 | China | - Heating indicator -Temperature sensor -Convenient, massive mount | The manufacturer has a disgusting attitude towards the build quality, devices often break down, thermostats fail, connections are often leaking |

| Wert WPT 1600 | 1600 | 4 | China | Absent | None. Just a good machine for soldering polypropylene water pipes |

Tips and tricks: how to choose a soldering iron for polypropylene pipes

Having determined the shape of the heating platform, we proceed to the selection of technical parameters. One of the first and most important is to choose the power. When choosing the power, you should not choose the largest, if more, it does not mean which is better. Since powerful soldering irons are designed for brazing large diameter pipes. If you need to solder pipes, the size of which is about 50 mm, that is, this is a standard heating system, then a soldering iron with a power of 600-800 W is suitable for such purposes. In general, the packaging indicates the number of nozzles and the diameter for which they are intended. You can navigate by such instructions.

It is important to note the thermostat, how accurately it is configured, how long it keeps the temperature, because the quality of soldering depends on this. This is especially true for beginners.

In the absence of experience and practice in this type of work it is worth it, it is based on norms and standards.

And that is why it is necessary to choose a soldering iron for pipes with a smooth temperature setting and study the instructions for using the soldering iron before work. Moreover, you need to study not only the instructions for using the soldering iron, but also the pipes and accessories you bought where not only the component of the pipes and other things is written, but also the optimal temperature for soldering is indicated. Then we set the required temperature on your soldering iron. If not, there are no instructions, then you can use the average holding time, but before starting soldering, you need to try your hand at pipe sections and more than once.

When testing on pipe lengths, you will also understand sufficient warm-up time, or whether you need to add or decrease. These pipes are not expensive, so they can be purchased with a margin for training. You also need to pay attention to the attachments. The nozzles must be covered with Teflon, because of the Teflon coating, heated elements of polypropylene pipes are very easy to remove. A high-quality coating should have a bluish-green color.

For propylene welding, it is better to choose an apparatus whose rating is trustworthy. So, for example, an electric soldering iron, which is produced in Turkey, has excellent quality. Turkish polypropylene electric soldering iron is a good choice if you need a professional approach and a reliable device. Plus, it looks like a blow gun and will catch the attention of your employers. If you are going to work with PPR once, then you can purchase Russian brands. A soldering tool can be provided by a plumbing store called Castorama or Stavr. In addition, you can buy such a product at the OLH, where you can find out its full full review and view photos.

No. 9 - CANDAN CM-03

Price: 2000 rubles

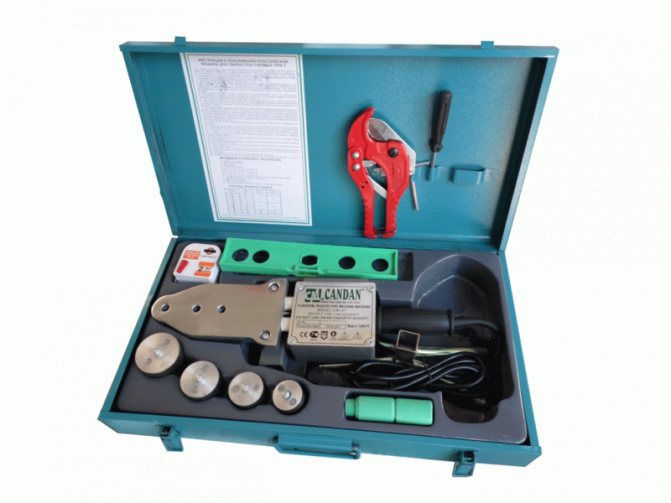

Soldering iron with a sword-shaped heater, 1500 W, a convenient thermostat and the widest range of pipes to be welded - from 16 to 75 mm. In the box, in addition to the device itself, you can find a medium-quality metal case, a key for nozzles, a level, a tape measure, a screwdriver and a pipe cutter - much of this should be thrown out due to its uselessness due to low quality, but something will come in handy on the farm.

The reliability and durability of the device is beyond doubt, in these aspects the device can compete with professional devices. Deserved hit rating of the best soldering irons for polypropylene pipes.

CANDAN CM-03

Soldering iron nozzles for polypropylene pipes

The minimum number of nozzles should be 3, they are the most popular, and their diameter is 20, 25 and 32 millimeters. But after a certain period of use, the attachments supplied with the kit will wear out and must be replaced.

The tips have a cylindrical shape made of aluminum alloy or copper, which are coated with a non-stick Teflon layer. When buying baits, pay your attention to the quality of the layer, and do not save too much on this.

The coating layer depends on the cost of the nozzle, that is, the smaller the layer, the lower the price and service life of the expensive one.

Wear of the nozzle manifests itself in such a way: the appearance of smoke, plastic residues on the nozzle, adhesion of parts and the occurrence of difficulties when removing pipes.

How to use a polypropylene pipe iron

The process of connecting pipes itself is very simple and therefore attracts many home craftsmen.

The work must be carried out in the following sequence:

- We prepare the pipe for soldering in this way: it must be cut evenly and cleaned, and if necessary, remove the foil layer;

- We turn on the soldering iron and set the temperature;

- After the soldering iron is heated to the temperature you selected, this will be indicated by a light indicator, we put on the pipe and fitting from different sides on the necessary nozzles;

- We hold the specified time without delay and carefully remove the parts from the soldering iron;

- We connect the pipe to the fitting without rotation and the whole connection is ready.

The time that must be maintained depends on the diameter of the pipe.