Design features

Most often, a metal tank with a capacity of up to 5 liters with built-in pipes acts as a heat exchanger. There is no direct contact with fire. The device allows you to heat cold water, which then enters the radiators or a removable tank of a larger capacity located in the same or an adjacent room.

As a result, by heating the stove in one room, it will be possible to heat another. According to its design, the heat exchanger for the furnace can be external and internal.

This type is very similar to a tank filled with a coolant. Inside the tank there is a part of the pipe used to remove the combustion products. In terms of its design, the external heat exchanger is more complex than the internal one, since it makes increased demands on the performance of welding.

However, its maintenance is much easier. If necessary, the tank can be dismantled in order to remove scale or repair a leak.

Interior

It is mounted above the firebox directly inside the furnace. It is characterized by ease of installation, but certain difficulties may arise if maintenance is required. Especially if the stove is made of bricks.

To avoid this, at the time of design development, it is worth taking care of the maintainability of the future heat exchanger.

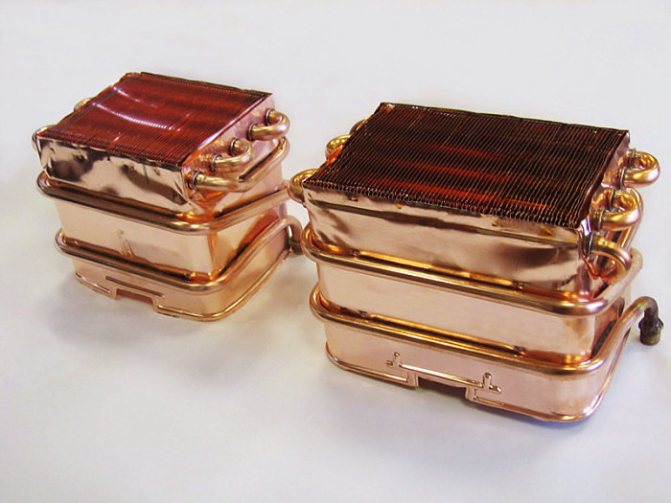

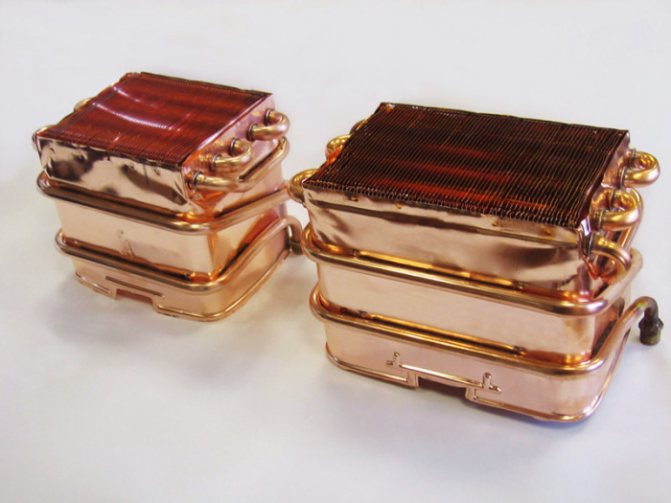

Coil for ovens

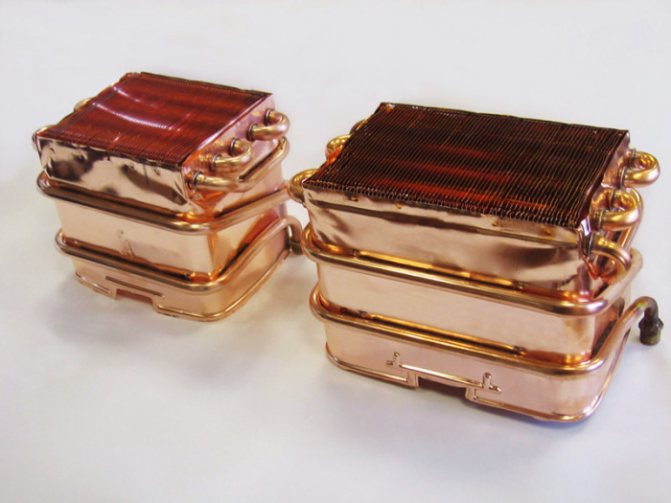

One of the easiest heat exchangers to manufacture is a coil. All you need is to find a pipe made of sufficiently ductile metal. Copper or aluminum is most commonly used, as both metals are resistant to corrosion and bend easily. Then the pipe is bent, and the shape, in principle, can be any.

In order for the water to actively move by gravity (without a pump), the total length of the coil should not exceed 3 meters (this is taking into account the connection to the remote tank). When creating your heat exchanger, “try on” it to the furnace: it should not come into contact with an open flame, but should be heated with hot air. An external thread is cut at the ends, to which a remote tank is then connected through fittings.

The coil can be located not only inside the firebox, but also outside. Winding the stove is hardly worth it, but a metal chimney will heat water quite effectively. Indeed, if the furnace is without an afterburner, then the temperature at the outlet of the furnace can be up to 500 ° C. An example of such a heat exchanger on a pipe, see the photo.

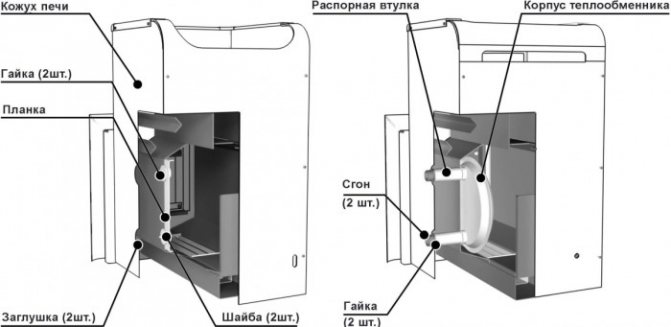

In its simplest form, the heat exchanger can be shaped like a horseshoe. Then you can use a stainless steel - so it can be bent. For example, the video clearly shows a similar shape, which was used in the Vitra sauna stove (for a video on how to move the heat exchanger in the Vitra stove from the left side panel to the right, see the end of the article).

The simplest type of heat exchanger for a bath network is a curved tube with threads at the ends

One of the types of coil is a register. This is, as a rule, a welded structure made of pipes, which often resembles heating ones in some way. The register for a bath stove is most often made of stainless steel, since only it can withstand harsh operating conditions for a long time. Welded structures are large in size and weight, and therefore they are more often installed in brick ovens. In an iron furnace, it is not always possible to find a place to place a small heat exchanger tube, not like a bulky welded structure. And when designing brick sauna stoves, you can allocate space for the register.

Heat exchanger register. You cannot put such in a finished metal oven.This is an option either for a homemade iron stove or for a brick one (more likely, judging by the size)

Sometimes the heat exchanger is made in the form of a small container with water (volume up to 3 liters), which is also located inside the firebox without direct contact with the fire. The principle of its operation is no different from others. In order for such a tank-heat exchanger to serve longer, when making with your own hands, try to make the structure so that there are as few welds as possible. For example, take a sheet of stainless steel (1-2 mm thick is enough) and give the required geometry on the bending machine. There will be only one seam on the body, plus the side panels and inlet pipes will be welded.

Sauna stove heat exchanger - unique design

When making any of the heat exchangers located inside the furnace, you need to remember that they can take no more than 10% of the furnace power without prejudice to heating the room. So it is irrational to do too large registers. It is difficult to place them and they will negatively affect the air temperature in the steam room. It is better to calculate the system so that it is possible to heat the water several times during the entire visit to the bath: you do not need 150 liters of boiling water at once, do you? First you need a little hot water to steam the brooms, then a little more to wash in front of the steam room, and then some more to rinse. As a result, we need maybe 150 liters of hot water, but in portions. So why make a system for 150 liters and wait several hours until it is at an acceptable temperature, if you can make a tank for 50-70 liters and heat water in it several times, which will be consumed as needed ...

Pros and cons of the oven

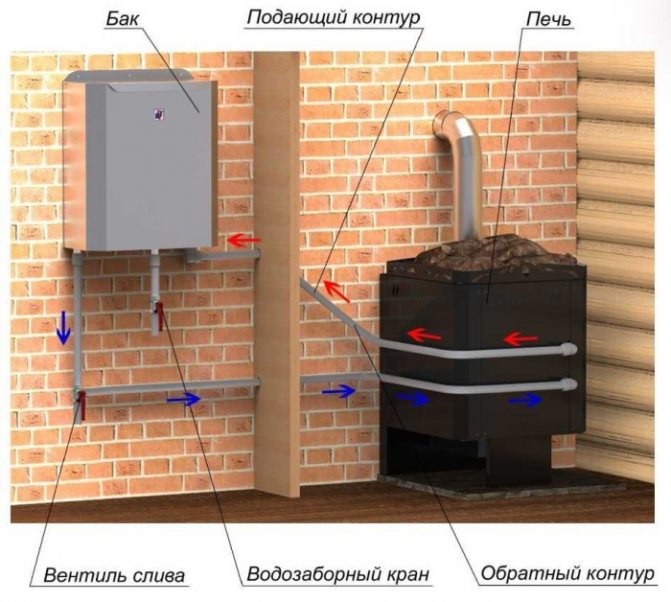

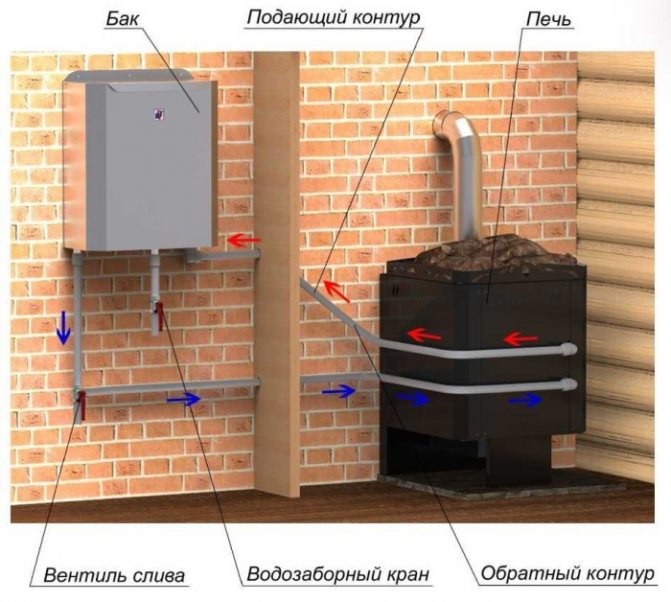

An ordinary stove distributes heat unevenly: it is very hot right next to the stove, and the further it gets, the colder it gets. The presence of a water circuit allows the heat generated by the stove to be evenly distributed throughout the house.

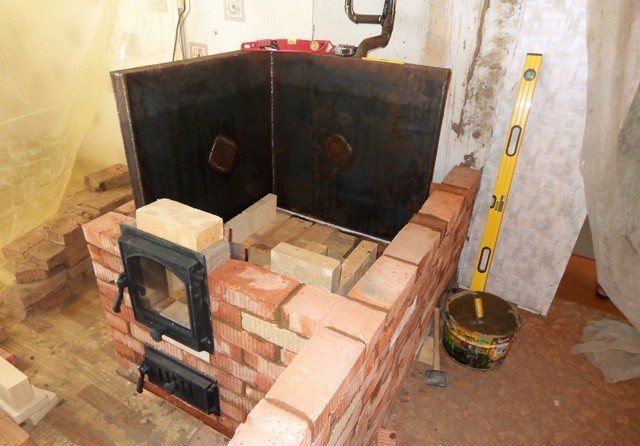

Construction of a heating furnace with a water circuit

Thus, only one stove is capable of heating several rooms in the house at the same time. The stove works in much the same way as a solid fuel boiler. Only it does not just heat up the coolant and the water circuit. In addition, the walls and smoke channels are heated, which also play an important role in the heating process.

The heat exchanger (coil) is the main element of the stove. It is installed in the fuel part of the stove, and there the entire water heating system is connected to it.

The advantages of a furnace with a water circuit include the following features:

- First of all, for such a furnace, you do not need to purchase expensive units and components.

- A properly built stove will serve you for a long time without requiring expensive repairs. Sometimes, you may only need a little cosmetic.

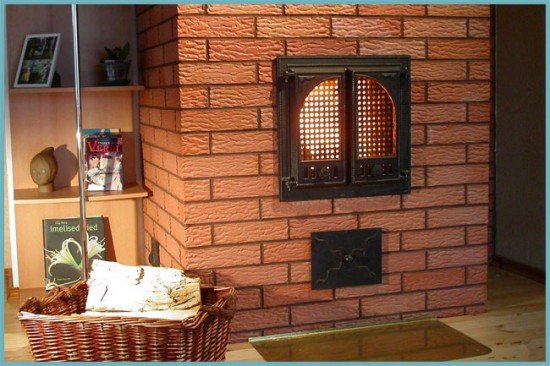

- The stove can be created in any design: shape, size, decoration - all this to your taste and financial capabilities.

- If we compare a stove equipped with a water circuit and a solid fuel boiler, then with the help of the first one, not only the coolant is heated, but also the smoke outlets.

- The coil can be equipped with an already built stove. It can also be inserted into the cooking stove.

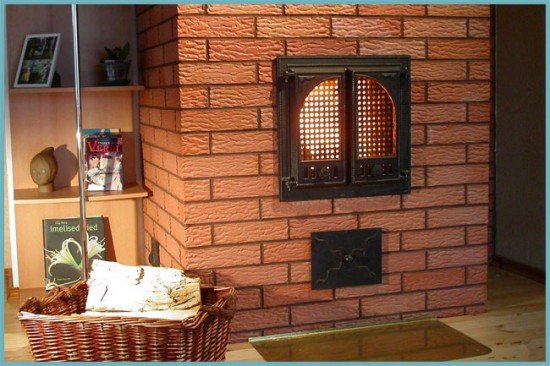

A variant of the stove that fits perfectly into the interior of the room

There are also disadvantages to this type of heating.

- When the heat exchanger is inserted into the fuel end, the precious space of the latter is greatly reduced. The problem can be solved if the heat exchanger is built into the furnace at the stage of its construction. It's just that this part needs to be increased. Well, if it is inserted into an already built structure, then there is no other way out, except for incomplete filling of fuel, but in parts.

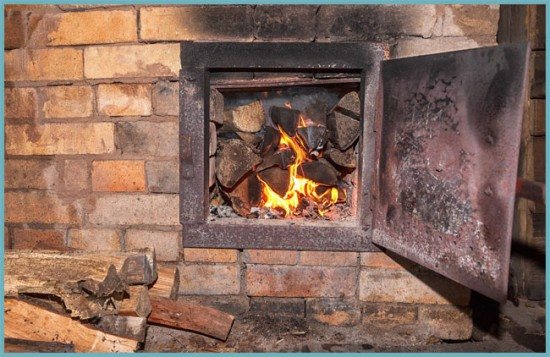

- With such a stove, the fire hazard increases.An open fire burns in the stove and fireplace, plus extra firewood is often kept nearby. Do not leave this unit unattended.

- If the stove is used incorrectly, then the ingress of carbon monoxide into the premises of the house can lead to very sad consequences.

An image from which it becomes clear that it is better not to leave the unit unattended

Experts advise using non-freezing liquid in such structures if people do not live in the house permanently, but, for example, only in the summer.

How to flush the coil of a gas boiler?

Mechanical methods include flushing and cleaning the coil from a gas hose through which water is supplied under high pressure. You can read about it here. As with the options discussed above, this technique increases the risk of damage to the heat exchanger. Consideration should be given to the limited strength of copper models. However, in steel modifications, rupture of welded joints is not excluded.

The designated problem is solved with the help of aggressive chemical compounds. Select means for flushing the heat exchanger of a gas boiler, destroying the scale layer during prolonged contact. Special equipment or improvised means ensure the circulation of the working mixture in a closed loop. Full immersion of the heat exchanger in an acid solution is also used. To speed up the process, heat is used to clean it.

Special reagents

For professional washing, the composition of the preparations is selected taking into account the parameters of the scale. The material, wall thickness, and design features of the heat exchanger are studied separately. As a rule, a complex of several reagents is used:

- corrosion inhibitor;

- acid in a certain concentration;

- substances that slow down the formation of foam;

- surfactant mixtures that form a protective layer at the final stage of cleaning.

The quantitative calculation is carried out on the basis of data on the total working area of the treated areas.

The procedure for flushing the gas column coil is performed using special equipment. The control indicator for color change quickly determines the quality of descaling in hard-to-reach places. If the acidity does not change for a long time, then the chemical reactions are complete. Maintain optimal temperature conditions.

Be careful! The reagents are toxic and can be harmful to health!

For self-service using this method of a gas boiler, you need to buy not only reagents, but also technical equipment. The total cost of such an investment would be too high given the infrequent use of expensive equipment. For this reason, it looks more preferable to call the foreman at home for the qualified performance of routine maintenance.

To clean the coil in the gas water heater yourself, you can use:

- specialized drug;

- hydrochloric, phosphoric or aminosulfonic acid.

The recommendations on the permissible concentration of active substances must be observed in order not to damage the heat exchanger and the boiler. The procedure is recommended to be performed with active ventilation indoors or outdoors. When choosing improvised means for circulating liquid, attention is paid to the resistance of functional components in contact with aggressive chemical compounds.

Lemon acid

How to flush the coil of an Electrolux gas column at no extra cost and in a safe mode for health? Citric acid is used to fulfill the indicated conditions. The required amount of the drug, if necessary, can be purchased at the nearest grocery store. A concentrated solution is created in the proportion of 200 grams of active ingredient per liter of warm water.It is poured inside the heat exchanger, or the part is immersed in a liquid.

A significant drawback of the method of how to clean is the slow dissolution of scale. For speeding up, some instructions advise using constant heat. Such procedures pollute the atmosphere with harmful acid fumes.

Latest announcements

Gas boiler Protherm (Proterm) Medved 20 klom

New in the box, everything is sealed, warranty receipt from 1.09.19. I sell because I did not fit our old system, but return ...

- Region: Moscow region

11.09.19

Hot water gas boiler VK-21 (KSVa-2.0 GS)

We offer a steel hot water boiler KSVa-2.0 Gs (VK-21). A price discount is possible for a bulk order (from 2 boilers) Type ...

- Region: Kirov region

05.08.19

Steam generator KV-300

We offer a steam boiler KV-300 (KP-300). Steam capacity for normal steam, kg / hour - 300; - permissible excess ...

- Region: Kirov region

28.06.19

Steam generator for 500 kg of steam

Technical characteristics: - steam capacity - 500 kg / h; - boiler type - two-pass, fire-tube with reversible ...

- Region: Kirov region

28.06.19

Steam generator for 1600 kg of steam

Technical characteristics: - steam production - 1600 kg / h; - boiler type - two-pass, fire-tube with reversible ...

- Region: Kirov region

28.06.19

Hot water boiler KSV-0.63

We offer a hot water boiler KSV-0.63. Technical data and characteristics: - nominal heating capacity, ...

- Region: Kirov region

28.06.19

Hot water boiler 850 kW gas diesel

Technical characteristics: - nominal heating capacity - 0.85 MW; - efficiency - 92%; - boiler type - two-pass, ...

- Region: Kirov region

28.06.19

Automatic coal-fired boilers Lugatherm

The boiler model combines three main parts: a water-cooled firebox, a heat exchanger with an automatic mechanical ...

- Region: Moscow

15.03.19

SOLID FUEL WATER BOILERS ON SHAFT FURNACE KVR

Fuel type: firewood of any humidity Power from 0.2 to 2.5 MW Purpose: to obtain hot water with a nominal temperature ...

- Region: Kirov region

05.02.19

WATER BOILERS FOR WORK ON WOODWORKING WASTE AND FORESTRY KVM

Fuel type: woodworking waste (sawdust, wood chips, bark) - no humidity limitation Power: from 0.2 to 2.5 MW Purpose: ...

- Region: Kirov region

05.02.19

Announcements by topic:

- Boilers and boiler equipment

- Cooling towers

- Heating networks (all about pipelines)

- Materials (edit)

- Water treatment

- Cogeneration

- Autonomous heat supply

- Pumps, fans, smoke exhausters

- Pipeline accessories

- Heat exchange equipment

- Metering devices

- Instrumentation

- Repair equipment

- Heating devices

Design features

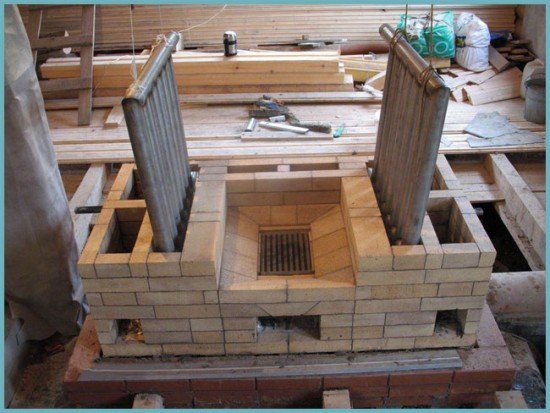

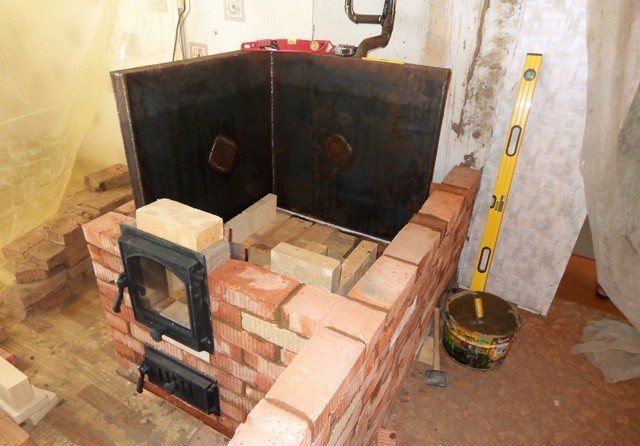

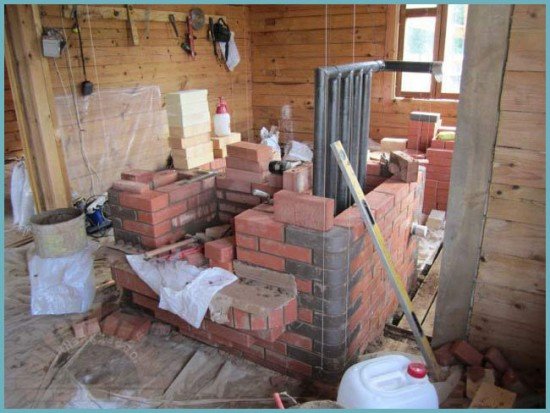

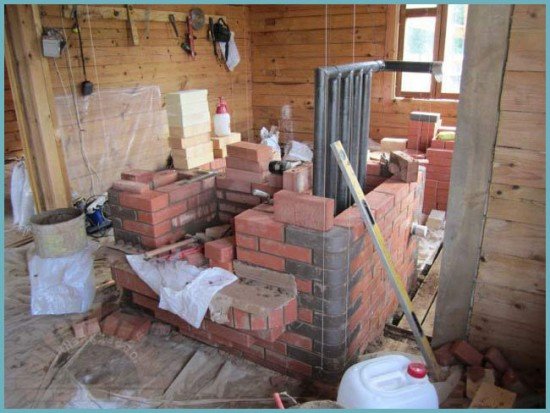

If the owner of the building has experience in bricklaying or oven work, the installation can be done by hand. Before connecting a water heating system, you will also need to make a heat exchange unit.

Despite the fact that the construction market offers a large selection of ready-made structures, self-production is more profitable. A hand-made installation allows you to take into account all the parameters of this particular furnace, its location and the dimensions of the fuel compartment.

Heat exchanger made of pipes

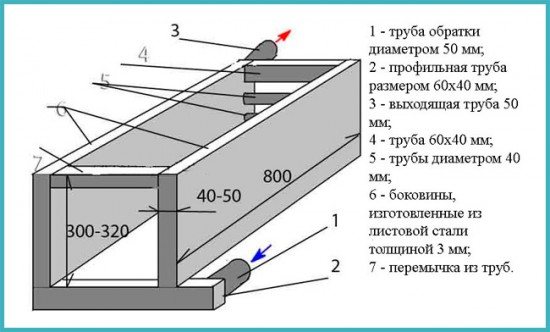

The device of a furnace heating system with a water circuit implies the installation of a heat exchanger in the fuel compartment of the furnace and the connection of pipes to it for supplying the working fluid. Coils welded from pipes and placed in metal containers are well suited for heating and cooking stoves and kitchen stoves. Their manufacture requires professionalism, and cleaning from combustion products is rather laborious, but the winding surface will provide rapid heating.

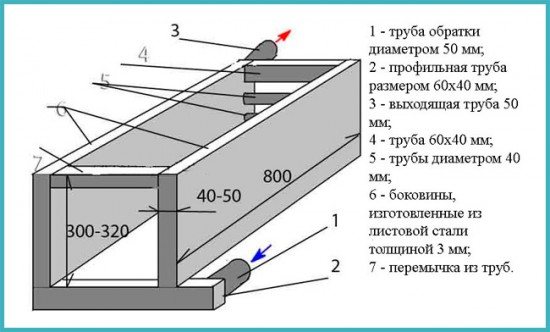

The U-shaped 50 mm pipes used in the construction can be replaced with sections of 40x60 mm shaped pipes. This will simplify the welding work and greatly facilitate the installation.If the oven is not used for cooking, additional small diameter tubes are welded to the top of the heat exchange unit. A self-improved design will give off much more heat.

Sheet steel heat exchanger

Devices of this type are used in ovens designed exclusively for heating a room. For their manufacture, you will need sheet metal half a centimeter thick, pieces of rectangular pipes 40x60 mm, as well as round tubes of the same diameter for supplying water to the working surface. The dimensions of the heat exchangers depend on the dimensions of the furnace compartments for fuel.

A similar heating system can be used for a heating and cooking stove or a simple kitchen stove. For this, the structure must be mounted so that the heated gases from the fuel chamber move towards the upper shelf of the register, flow around it and enter the smoke channels.

The device and features of the heat accumulator

By design, a typical heat storage tank is a steel tank with nozzles at the top and bottom, which are at the same time the ends of a coil made of copper tube. The lower branch pipes are connected to the heat source, the upper ones - to the heating system. Inside the installation there is a liquid that the consumer can use to solve the tasks he needs.

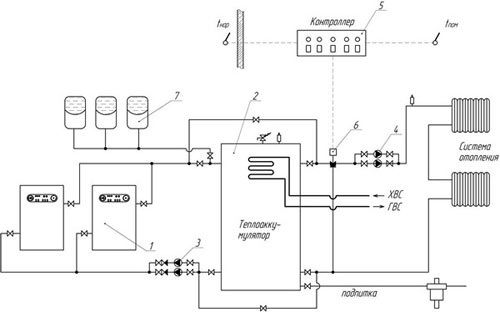

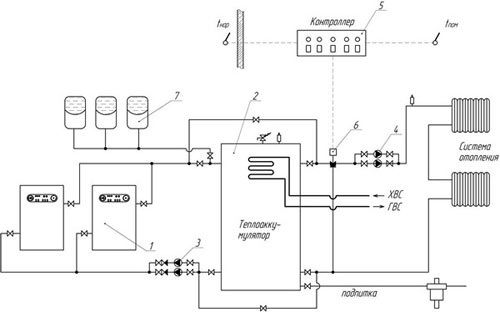

Connection diagram

The principle of operation of the unit is based on the high heat capacity of water. In general, the mechanism of action of the heat accumulator can be described as follows:

- two pipes are cut into the side walls of the container. Through one, cold water enters the tank from the water supply system or from the tanks, through the second the heated coolant is discharged to the heating radiators;

- the upper end of the coil installed in the tank is connected to the cold water pipe of the boiler, the lower end to the hot pipe;

- circulating through the coil, hot water heats the liquid in the tank. After turning off the boiler, the water in the heating pipes begins to cool down, but continues to circulate. When the cool liquid enters the heat accumulator, it pushes the hot coolant accumulated there into the heating system, due to which the heating of the premises continues for some time (depending on the capacity of the accumulator) even when the boiler is off.

Important! To ensure the movement of the coolant, the system is equipped with a circulation pump.

Prices for heat accumulators for heating systems

Heat accumulators for heating systems

Inspection of welded joints and bends

Each welded joint is subjected to external inspection and measurement to detect displacement of the edges and fracture at the joint (Fig. 8). The displacement b of the edges to be welded is understood to mean the parallel displacement of the pipe axes between each other. Fracture k is a deviation in the form of a skew of the axes of the abutting pipes. The displacements of the edges and fracture of the joint are measured with a special ruler 400 mm long with a cutout in the middle, which is installed tightly along the generatrix of one of the pipes with a cutout at the joint, and the deviation is determined along the other pipe with a probe at a distance of 200 mm from the axis of the joint. Measurements are carried out in 3 - 4 places around the circumference of the joint.

Inspection reveals such defects as arson (melting) of pipes at the points of contact with the sponges and the machine body, creeping edges, incomplete removal of the outer burr.

a - offset; b - break;

Figure 8 - Deviation of the welded pipe edges

To check the quality of welded joints, as well as devices for automatic control of the parameters of the welding process, express tests of control welded joints (samples) are carried out. Samples are obtained before the start of each shift. Welding is allowed to be performed only if there are positive results of express tests of control samples. As a rule, express samples are subjected to metallographic examination.

Verification of mechanical properties and metallographic examination of welded joints are carried out on samples made from control welded joints, or on samples of welded joints cut from the manufactured product. In the case of cutting out of finished products, the volume of control joints must be at least 1% (but not less than three joints) of the total number of identical welded joints performed by each welder in one shift.

By running the ball with compressed air, the completeness of removing the internal burr (or metal leakage) is checked - ensuring a given flow area in welded joints. When inspecting welded joints on straight pipes (strings), a ball with a diameter of 0.86 dB is used, on coils of 0.8 dB of pipes. A decrease in the diameter of the ball when controlling the flow area in the coil is caused by the ovality of the pipes in the bends. A ball trap is put on the free end of the coil, which ensures a safe operation.

Ovality control of pipe bends and heating surface coils is selective (at least 10% of bends of the same standard size). The maximum ovality along the entire length of the bend should not exceed the permissible value. The measurement of the maximum and minimum outer diameters of the pipe at the bend point is carried out in one control section.

The ovality of the section at the places of pipe bends can be determined

where and are, respectively, the maximum and minimum outer diameter of the pipe at the bend point, measured at one point of the section, m.

For boiler heating surfaces, permissible ovality

where R is the radius of the pipe bend, m;

- pipe outer diameter, m.

Thinning of the pipe wall at the bend on the stretched (outer) side is determined selectively by an ultrasonic thickness gauge. It is recommended to check the thinning when changing the bending tool, setting up the machine and accessories.

For pipes with a diameter of up to 60 mm, bent without heating, high-frequency currents (HFC), waviness (corrugations) on the inner side of the bend and bulges on the extended side should not exceed 0.5 mm in height with a minimum step of at least three heights.

Choosing a material

The coil is traditionally made from a pipe, the length and diameter of which is determined by the desired level of heat transfer. The efficiency of the structure will depend on the thermal conductivity of the material used. The most commonly used pipes are:

- copper with a thermal conductivity coefficient of 380;

- steel with a coefficient of thermal conductivity of 50;

- metal-plastic with a thermal conductivity coefficient of 0.3.

Copper or metal-plastic?

With the same level of heat transfer and equal transverse dimensions, the length of metal-plastic pipes will be 11 times, and steel pipes 7 times longer than copper ones.

That is why it is best to use annealed copper pipe for making the coil.

Such a material is characterized by sufficient plasticity, and therefore it will be easily possible to give it the desired shape, for example, by bending. The fitting is easily threaded to the copper pipe.

We are looking for improvised means

Given the high cost of materials, it will be appropriate to consider the possibility of using products that have already served their purpose, but have not yet fully developed their resource. This will not only reduce the cost of manufacturing the heat exchanger, but also reduce the time spent on installation work. As a rule, preference is given to:

- any heating radiators that do not have leaks;

- heated towel rails;

- radiators from cars and other products of a similar design;

- flowing water heaters.

Selection of materials and tools for the coil

If you want to buy a coil for a stove or do it yourself, the first thing you need to pay attention to is the materials from which it will be made:

| Coil photo | Material selection | Description of materials |

| Copper | A high-quality pipe made of such a material should have an optimal indicator and coefficient of thermal conductivity, which ideally will be about 380. |

| Steel | Steel variations differ in average cost. This variety must also have a certain coefficient of thermal conductivity. For such a metal, it will be 50. |

| Metal-plastic | The simplest option, the thermal conductivity of which is minimal, only 0.3 is metal-plastic. |

At the heart of any coil is a pipe that is made of one of the materials described above. The thermal conductivity and efficiency of such a structure depends on what diameter and length such a system will have.

With the same transverse size, at the same level of heat transfer, the length index of metal-plastic and copper pipes will be different. In the first case, the length will be 11. If we talk about the steel variation, then the length with the same characteristics will be 5-8 times larger in comparison with copper ones.

The best option and material from which the coil will be made is a fired copper pipe. The advantages of such a material include high strength and durability of the product, while you can easily give the material the required shape, as well as attach a fitting using a thread.

Since the cost of finished copper fittings and pipes is quite high, in order to save money, you can look for devices made of this material that you no longer use, but at the same time the material has completely retained all its characteristics. Alternatively, you can use:

- Heating radiators that have not previously leaked;

- Heated towel rails;

- Automotive radiators and other structures similar in structure and appearance;

- Ceiling-type water heaters.

Now, you need to get acquainted in more detail and view the main design features of such products:

- The device must not come into direct contact with a burning flame.

- The main element is a tank with a certain capacity, from which connecting pipes come out;

- In another room, pipes should lead to a second tank, the capacity of which will be slightly larger than that of the first. Thus, the heated water will be able to fully and safely circulate through the carriers;

- Also, heat exchangers may differ in type, they are external and internal;

- The internal heat exchanger is more difficult to install than the external one, however, the external one, in turn, is easier to maintain;

- The internal heat exchange element is mounted directly in the structure of the furnace itself and is located above the combustion chamber. It is installed at the stage of construction of a brick oven or is mounted in a portal, in the event that you have chosen a ready-made steel or cast-iron fireplace insert.

The coil for the furnace must be quite effective, which is why, during the development process, care must be taken that the indicator of the total surface area of the structure is very large.

Also, for the manufacture of a heat exchanger, you can use smooth-walled pipes, which have a diameter of about 4-5 centimeters. If we consider them, then it can be noted that in their shape they resemble a large letter G.

The return and outlet, from which hot water comes out, can be positioned with equal success on either side. You can also give preference to installing a rectangular or cylindrical tank indoors. In these cases, the coil is located directly inside the structure, the length of this variation depends on the heating unit itself, its dimensions and power.

Also, the heat exchange element can be installed directly on the chimney hood. In this case, it will have a characteristic cylindrical shape, the pipes are placed in the lower part, and from above it passes into the chimney, which has a similar diameter and shape.This variation is ideal both for generating heat used for heating rooms and for heating hot water.

However, if you decide to install a heat exchanger on the chimney, it must be remembered that due to the rapid cooling of the combustion lanes, the draft in the hood may be disrupted and become insufficient for the effective removal of waste products of combustion and decay.

The coil can also be placed next to the oven, which not only performs a heating function, but is also used for cooking. In this case, it is important that the heated gas moves over the upper shelf and is discharged through the chimney. Thus, the oven with the hob will be located above the heat exchange medium. If necessary, you can not install the upper shelf, in this case, the lower and side parts will be connected to each other using pipes.

Methods for making coils

There are three main schemes for obtaining coils of boiler heating surfaces (Fig. 7): element-by-element, whip and by the method of sequential build-up. Regardless of the method, the technological process for the manufacture of coils includes: incoming inspection of pipes; sorting the original pipes by length; development of schemes for cutting pipes into elements; cutting of pipes, trimming and stripping of pipe ends. Choosing the element-wise method.

Figure 7. Element-by-element diagrams for the manufacture of coils

With the element-by-element manufacturing method, prepared straight pipes are first bent on machine tools, followed by plating, then the bent elements are welded together into a coil (Fig. 7).

Disadvantages of stove heating with a water circuit

- Loss of usable space. The heat exchanger built into the firebox significantly reduces its size, therefore this factor must be taken into account when laying the firebox. Well, if the heat exchanger is built into an existing structure, the only solution is the frequent filling of fuel.

- Increased fire hazard. Since a stove or fireplace suggests the presence of an open fire and a supply of fuel nearby, it is not recommended to leave such a stove unattended for a long time.

Having organized stove heating in the house, you must constantly monitor fire safety.

Carbon monoxide. If used improperly, carbon monoxide can penetrate into living quarters, which is dangerous to human life.

Advice. If heating with a water circuit is installed in a country house in which no one lives regularly, especially in winter, then in order to avoid freezing water in the circuit, it is better to use an anti-freeze liquid.

The choice of material for the upcoming work

The coil is usually created using a pipe that has a suitable length and diameter... During the selection, it should be borne in mind that all the parameters of this element will directly affect the quality of heating in the house, as well as its efficiency. Therefore, the material from which the heat exchanger will be formed must have a good an indicator of thermal conductivity.

The most popular types of pipes for these purposes are:

- copper products, the thermal conductivity of which is 380;

- pipes made of steel with a thermal conductivity equal to 50;

- elements made of metal-plastic, the thermal conductivity of which is equal to 0,3.

Most often used copper pipes, from which a high-quality coil with all the necessary elements is obtained. The material is plastic, therefore, if necessary, it can be given absolutely any shape and configuration, for which the bending process is used. It is considered quite simple, so it is easy to implement all the stages with your own hands. Also, copper pipes differ in that they are easy to various fittings are connected.

However, often, for full heating in every room of the house, the owners prefer to use improvised elements that have already served for other purposes to connect to the stove.For this, old heating radiators or instantaneous water heaters can be used, however, work with these objects hard enoughmoreover, they will not provide perfect heating result.

Getting started with installation

The sequence of work performance depends on the design features of the heat exchanger.

Installing the device with register

When installing in an old oven, you will have to disassemble part of the masonry. The sequence of work is as follows:

- We are preparing the foundation for the coil directly in the furnace cavity.

- Install the coil.

- We lay the disassembled row of bricks, leaving space for the inlet and outlet of the pipes.

- We connect the heat exchanger to the heating system.

Before starting operation, it is imperative to check the tank for leaks. You can make sure there are no leaks by filling it with water, preferably under pressure.

Mounting the device with a container

The best option for a stove or fireplace. Manufactured from a metal tank and two copper pipes. The volume of the tank is usually about 20 liters. In the absence of a finished product, a reservoir of sufficient volume is made by hand by welding sheet steel.

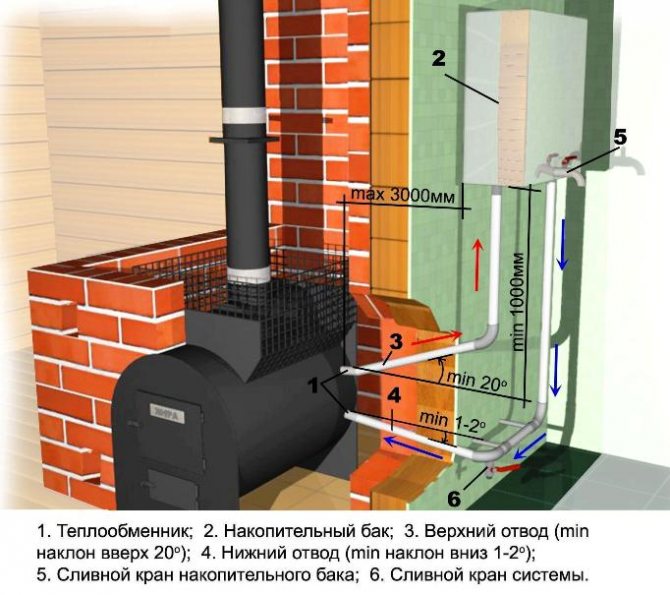

For the manufacture of the heat exchanger, a material thicker than 2.5 mm should be used. Welding should be done in such a way that the thickness of the formed seam is minimal.

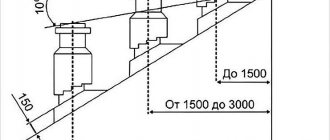

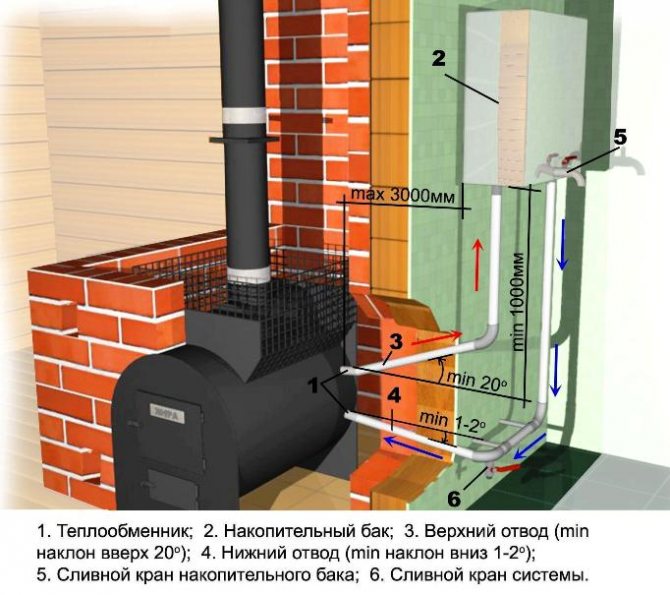

The tank must be installed 1 meter above the floor, but no further than 3 meters from the oven. Two holes are made in the tank: one near the bottom, the second at the highest point on the opposite side. The efficiency of heat transfer depends on the location of the lines.

It is necessary to strive to ensure that the minimum deviation of the lower elbow in the direction of the floor is 2 degrees. The top one should be connected at a 20 degree angle in the opposite direction.

The drain valve is being installed in the storage tank. Another valve is provided for draining the entire system, which is installed at the lowest point. After the leak test, the system is ready for operation. The efficiency of such a furnace with a heat exchanger can be appreciated at its true worth in the cold season.

Structural elements of equipment

As a rule, a holistic system is used to create a full-fledged home heating. It consists primarily of a metal tank, having a fairly substantial capacity. Special pipes are connected to it. This element does not come into contact with open fire in any way. Furnace equipment is used to produce water heating, after which it enters the separate rooms of the building along the coil. In this case, uniform and high-quality heating of the entire house can be provided. Here it is important to correctly connect the equipment to the oven, and the device itself can be connected outside or inside ovens.

Do-it-yourself stove heating with a water circuit step-by-step construction

First, before you start building the stove, you need to prepare the foundation. To do this, you need to dig a pit, the depth of which is 150-200 millimeters. At the bottom, fill in layers of broken brick, gravel and rubble. Then fill everything with cement mortar. The foundation should rise several centimeters above the floor. Lay the waterproofing material on the screed.

Water loop furnace construction process

The main features of brickwork

The stove must be built from quality materials. Walls can be built from bricks with normal firing, but for the furnace part, get refractory bricks.

- Before starting laying, the bricks must be moistened. To do this, immerse them in water for a while. When air bubbles stop coming out from them, you can start laying.

- All rows and corners must be snapped.

- Apply the cement mortar immediately to all glad.Its layer should be about 5 millimeters. Refresh the mortar at the end just before laying bricks on it.

- When you get to the furnace part, do not apply the clay with a trowel. Do it with your hands.

- Every five rows, carefully scrape off excess cement from the joints and wipe them down with a damp sponge.

- The walls of the stove must be vertical and horizontal. Use the building level constantly during masonry to check this.

What can the furnace heat exchanger be made of?

In order to make a heat exchanger for a furnace with your own hands, you can use sheet "black" steel 3-5 mm thick or steel pipes (round or shaped) with the same wall thickness and a diameter of 30-50 mm. Alternatively, stainless steel or copper sheet or pipes can be used for this purpose. But, due to their high cost, these materials are rarely used in the independent manufacture of furnace boilers.

It is easier to make such registers from sheet metal. They are easier to clean during use. But, as a rule, they have a smaller area of contact with a flame or hot gases, since for the most part they are solid and only their inner surface, facing the flame, participates in heat exchange. Furnace boilers made of pipes, with the same overall dimensions, as a rule, have a large heat exchange area (although this also depends on the number and diameter of the pipes), since they allow the flame or hot gases to contact, practically, with their entire surface. But they are more difficult to manufacture. This is especially true for structures consisting entirely of circular pipes.

If pipes are used to make a heat exchanger for a furnace with a water circuit, then it is best if they are seamless (seamless). If seam pipes are used, then the seams will have to be additionally reinforced with a weld seam and placed on the outside of the register (on the side of the brickwork).

Very often pipes and sheet metal are combined in the manufacture of furnace boilers. This is done in order to use their positive qualities: to make it easier to manufacture, and the heat exchange area was sufficient.

Specificity of application

Standard stove heating implies an uneven distribution of heat energy - the farther from the source, the colder. After connecting radiators and filling with water, the stoves act as analogues of solid fuel boilers, providing heating of the coolant, smoke channels and walls. Such a system during the firebox will allow heat to be transferred from the coil to the radiators, and after the fuel is extinguished, it will use the energy of the heated walls of the furnace.

When installing the heat exchanger, it should be borne in mind that its installation will reduce the useful volume of the fuel compartment and the fuel will have to be added much more often. Correct design of the water circuit and its relationship with the dimensions of the heating chamber will help to eliminate this problem. A good alternative would be a long burning oven.

Such an upgrade of the heating system has its own nuances. The energy that is released during the combustion of firewood will heat the heat exchange unit and the working fluid placed in it, but the walls of the furnace will not change their temperature.

The upper part of the housing with smoke channels will undergo heating. If the building is used for temporary residence, the stove will be turned on irregularly and may freeze the liquid inside the pipes. In order to prevent accidents, it is recommended to replace the water with antifreeze.

Quality indicators

Quality indicators are used to assess the operational merits of the unit, the main ones being: technical level, reliability and durability, structural, aesthetic and ergonomic characteristics of the unit.

A. Technical level.

Distinguish between absolute, relative and prospective technical levels.

The absolute technical level of the product is characterized by its performance. Their number should be minimal. In order to avoid multiplicity and ambiguity in assessing the absolute level, it is necessary to restrict ourselves only to the most important of them - productivity, efficiency, process continuity, and the degree of automation.

The relative technical level characterizes the degree of perfection of the product when comparing (according to the relevant indicators) its absolute technical level with the level of the best modern world - domestic and foreign - samples and models of a similar purpose.

The prospective technical level determines the planned and planned trends in the development of this industry in the form of a set of its prospective indicators.

B. Durability and reliability.

These indicators are the most important quality indicators.

Durability - the property of the unit to remain operational with the shortest possible interruptions for maintenance and repairs to destruction or to another limiting state. The main quantitative indicators of durability are technical resource and service life.

Technical resource - the total operating time of the unit for the period of operation.

Service life - the calendar duration of the unit's operation until destruction or until another limiting state (for example, before the first major overhaul). The service life is limited by the physical and moral deterioration of the unit.

Reliability is a property of the unit, determined by the reliability, durability and maintainability of the unit. Quantitative indicators of reliability: operating time, probability of no-failure operation, availability factor.

Operating time - the duration or volume of work of the unit, measured by the number of cycles, the number of manufactured products or other units.

Probability of failure-free operation - the probability that no failure occurs under certain operating conditions and operating conditions within the specified duration of operation. Availability factor is the ratio of the unit's operating time in units of time for a certain period of operation to the sum of this operating time and the time spent on finding and eliminating failures during the same period of operation.

B. Ergonomics and technical aesthetics.

Creation of modern heat exchangers that meet the best models and world standards for quality, ease of maintenance and appearance. The design of an industrial heat exchanger should be based on technical conditions and, at the same time, on the requirements put forward by new scientific disciplines - ergonomics and technical aesthetics.

Ergonomics is a scientific discipline that studies the functional capabilities of a person in labor processes in order to create perfect tools and optimal working conditions for him. Technical aesthetics is a scientific discipline, the subject of which is the field of activity of an artist-designer. The goal of artistic design is (in close connection with technical design) the creation of industrial facilities that most fully meet the needs of the service personnel, as closely as possible to the operating conditions, with high aesthetic qualities, in harmony with the environment and the situation.

The attractive appearance corresponds to a generally rational and economical design. The appearance of a product depends to a large extent on its color. Color is the most important factor that not only determines the aesthetic level of production, but also affects the worker's fatigue, labor productivity and product quality.

Furnace heat exchangers

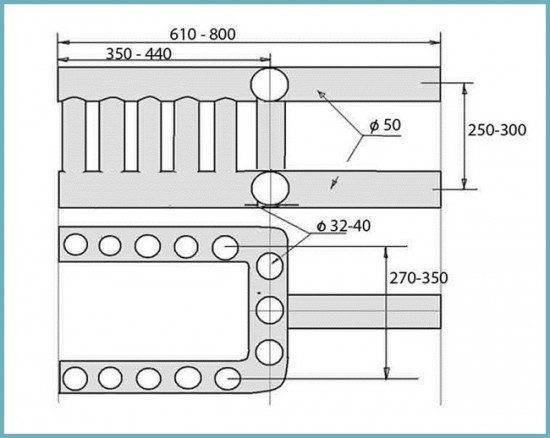

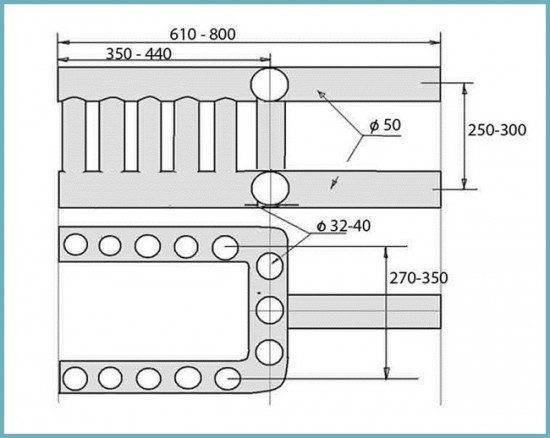

Coil arrangement diagram

The diagram shows one of the coil options. It is good to place this type of exchanger in heating and cooking stoves, because its structure easily allows you to place a stove on top.

In order to reduce the complexity of the manufacturing process, you can make some changes to this design and replace the upper and lower U-shaped pipes with a shaped pipe. In addition, vertical pipes are also replaced with rectangular profiles if necessary.

If a coil of this design is installed in ovens where there is no hob, then to increase the efficiency of the exchanger, it is advisable to add several horizontal pipes. Water treatment and withdrawal can be done from different sides, it depends on the design of the furnace and the device of the water circuit.

Economic indicators

A. Thermal hydrodynamic perfection.

The power spent on pumping heat carriers in a heat exchanger largely determines the heat transfer coefficient, that is, the overall heat output of the apparatus. Therefore, an important indicator of the perfection of the heat exchanger is the degree of use of power for pumping the coolant to ensure the required heat exchange.

The thermohydrodynamic perfection of the apparatus can be characterized by the ratio of two types of energy: the heat Q transferred through the heat exchange surface and the work N spent on overcoming the hydrodynamic resistance and expressed in the same units for all flows. Thus, the measure of the use of the work expended on heat transfer can be expressed by the ratio

E = Q / N

The greater the value of E, the more, all other things being equal, the heat exchanger or its heat exchange surface is more perfect from a thermohydrodynamic (energy) point of view. The energy coefficient E is a dimensionless quantity, therefore the numerator and denominator of the expression E = Q / N can be attributed to an arbitrary, but the same unit, for example, to a unit of heat exchange surface (heat index), to a unit mass of a heat exchange surface (mass index) or to unit of volume (volumetric indicator). When comparing apparatuses, the value of E can be related to all the heat and to all the work expended, or to a unit surface, mass or volume of the apparatus.

The analysis shows that, all other things being equal, a change in the speed of the coolant has a different effect on various quantities characterizing the operation of the heat exchanger: the heat transfer coefficient changes in proportion to the speed (or flow rate) in the power of 0.6-0.8, the hydrodynamic resistance in proportion to the speed in the power 1.7-1.8, and the power for pumping the coolant is in the 2.75 degree.

With an increase in the speed of the coolant, the power for pumping it grows much faster than the amount of transferred heat, i.e., for a certain apparatus or a certain heat exchange surface, the value of the energy coefficient E decreases with an increase in the speed of the coolant. Therefore, the absolute value of the coefficient E cannot serve as a measure of the thermohydrodynamic perfection of the heat exchanger, but is useful only when comparing two or more devices.

B. Coefficient of efficiency.

The thermal indicator of the perfection of a heat exchanger is its efficiency (efficiency):

n = Q2 / Q1

where Q1 is the maximum possible amount of heat that can be transferred from a hot coolant to a cold one under these conditions; Q2 - the amount of heat transferred from the hot coolant to the cold one, or the heat spent on the technological process.

The maximum possible amount of heat, or available heat, depends on the initial temperatures and the water equivalents of the heat transfer fluids.

Currently, the issue of heating without the use of gas has become especially relevant. Naturally, we all begin to pay attention to solid fuel boilers. The design of simple household solid fuel boilers can be so different that, at times, it is difficult to figure out where the truth is. Consider the most controversial issues that arise from an ordinary consumer.

one.Models with a design with cooled grates and cast iron, placed in the lower part of the boiler combustion chamber.

Cast iron grate construction.

It is used in almost all types of solid fuel boilers. The beginning of their application is the 20s of the last century, when they were installed in the simplest ovens. This design implies the operation of the boiler, both on wood and solid fuel. Due to the simplicity of their design, they are easily replaced, and the transfer of heat to the coolant occurs due to the heat removal of the water jacket along the walls of the firebox. Do not forget that the boiler firebox with a water jacket is structurally made in such a way that the coolant in the heat exchanger washes the heated firebox from four sides (top, right, left, back side). The task of engineers when creating and designing any boiler is to raise the efficiency of the heating device itself as high as possible. Unfortunately, the construction of a solid fuel boiler is such that it is practically impossible to remove the maximum temperature of the flue gases, since during the combustion of solid fuel, an increased ash content and tar content of the flue gases is observed (depending on the type of fuel). That is, if we go according to the principle of increasing the efficiency in gas boilers by installing turbulators in the heat exchanger closer to the exhaust, then literally after a few days of using such a system on solid fuel, we will find that the boiler has stopped working altogether, i.e. the outlet channels are clogged and coked , but due to the small diameters (after all, we wanted to increase the efficiency and remove heat from the flue gases as much as possible). As a rule, in this situation, it is almost impossible to service - clean the chimney system in the boiler….

Which exit? Only increase the chimney channels, thereby reducing the heat in the boiler heat exchanger (efficiency). In this case, we will avoid quick coking of the heat exchanger and give the consumer the opportunity to clean (maintain) it if necessary. But where, in this case, is the savings and maximum efficiency of the solid fuel boiler?

Refrigerated grate design.

In order to remove as much heat energy as possible in a solid fuel boiler, experts came to the conclusion that since we cannot remove heat from the flue gases, we must go along the path of increasing the area of the heat exchanger. By what means? You cannot increase the side planes of the boiler heat exchanger, the size of the boiler will proportionally go towards increasing the power of the device itself - after all, we will not, for example, make 30 kilowatt boilers out of all 10 kilowatt boilers, just because we need to increase the heat removal area in the heat exchanger ?!

What do the manufacturers of imported gas boilers, or the same heating radiators do? The principle of the coil - multi-pass heat exchangers (pipes or channels with water in 2-3 rows increase the heating area) allow you to remove as much heat as possible from the coolant.

The principle is the same - instead of cast iron grates, pipes made of seamless heat-resistant steel up to 5 mm thick are welded into the lower part of the boiler furnace. Now we ourselves can imagine what this gives - we get an additional surface of heat removal in the boiler furnace, i.e. burning firewood is located directly on a water jacket with a coolant, which constantly circulates and "carries" heat through your heating system - hence the name "cooled" (the inflow of chilled water in your system constantly picks up the temperature in the combustion chamber and carries it around the system).

The result is the following - increasing the efficiency (efficiency) of the boiler up to 15%, and in some cases - manufacturers also install additional water jacket pipes in the upper part of the furnace to achieve maximum efficiency.

There are several common misconceptions about this design:

1. They burn out quickly.

How? After all, the water inside, which constantly circulates, removes the "excess" temperature, besides, the wall thickness of the pipe itself is almost twice the thickness of the wall of the boiler heat exchanger jacket itself. Here's an example:

We put a pot of water on the comfort of a gas stove - how much can we use the pot in this mode? 10, 20, or even 30 years, and the thickness of the steel of the pan is a maximum of 0.8 mm !!! The pan will burn out quickly in one case - if we put it on fire without water ...

2. Do not use coal in the COOLED grate system.

What does fuel change change? An increase in combustion temperature - yes, but the design is designed for critical conditions (if we are talking about manufacturers). In this case, we recommend laying cast-iron grates of either type-setting or block type on top of the existing ones to calm the consumer (and maybe extend the life of the boiler). It will not be worse..

3. What to do when the grate burns out from the pipe with the circulation of the system in the heating.

Even if this happened, it can be welded using electric welding (although for the entire experience of our work since 2000, there has not been a single such case). I can also say the following - grates of this type almost certainly survive the boiler itself, because the shirt itself inside the firebox also works at extreme temperatures, why not pay close attention to the boiler itself - the quality of its welds, the grade of metal from which it manufactured, manufacturer's warranty, etc.

How to mount a water circuit

Installation takes place in the same way as installation with any other heating system. The only point that needs to be taken into account is that the "return" for stove heating is located higher.

The circulation of the coolant is of three types:

- Natural. For natural circulation, the installation of pipes must be carried out at the maximum permissible slope. In addition, in the place where the pipe leaves the furnace, it is necessary to arrange a "acceleration collector": for this, the pipe is directed vertically to a height of 1–1.5 m, and then down to the radiators along the slope.

Forced. This type of circulation increases the efficiency by up to 30%. A circular pump is added to the circuit, which creates the pressure of the coolant. However, it is undesirable to arrange a system with only one type of forced circulation, because in the event of a power outage or a pump failure, water circulation will not occur, which will lead to the boiling of the coolant in the system.

Combined. For this type of circulation, it is necessary to combine the installation of pipes with a slope, as described in the first paragraph, with a pump. In this case, the pump is connected to the system via a parallel line, as shown in diagram 4. With this combination, the pump will operate in the presence of electricity, in the absence of electricity, circulation will take place naturally.