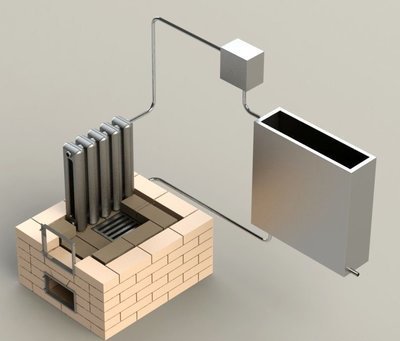

Installation of heating equipment equipped with a heat exchanger saves you the need to purchase a boiler for heating water. Thanks to him, the bath room will be constantly provided with hot water, and if you additionally connect a radiator, you can achieve an optimal temperature regime even in severe frosts.

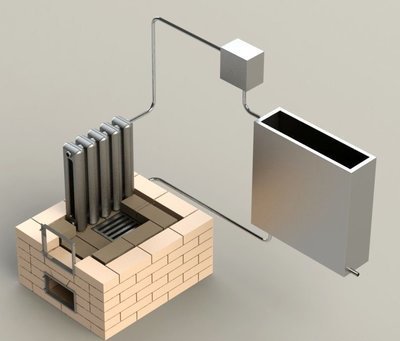

A sauna stove with a heat exchanger for heating is the best solution if the steam room and the washing room are located separately. If you connect a remote tank, you can heat the room from an adjacent room.

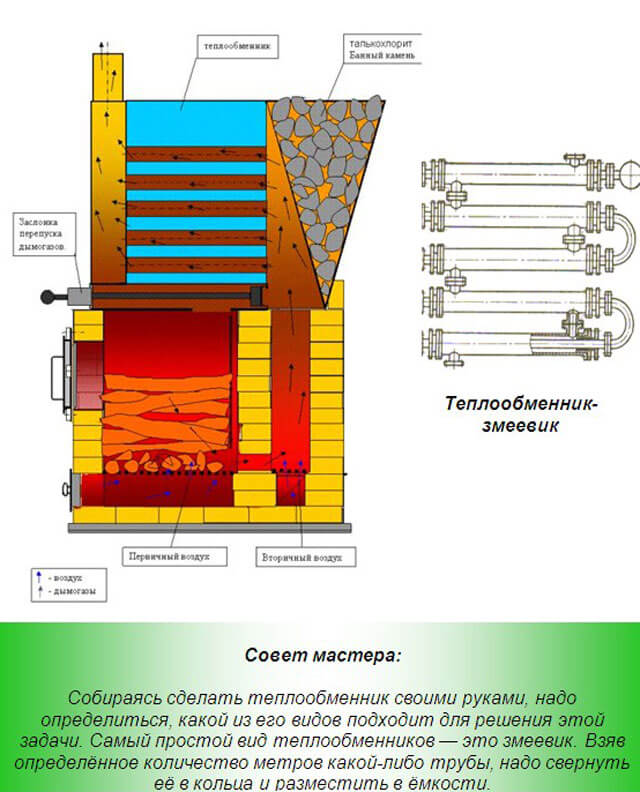

The device of heat exchangers for a sauna wood-burning stove

High heat transfer of sauna stoves, increased intensity of fuel combustion in them are actively used for placement in them water heating devices for washing.

Heat exchangers for baths are a hollow sealed container for water, coil-shaped (register)placed in the firebox, as well as sealed tankplaced on its wall or chimney.

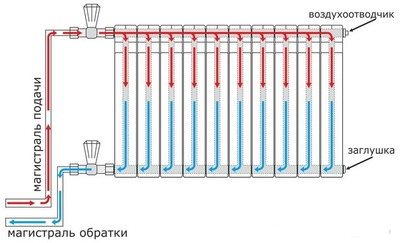

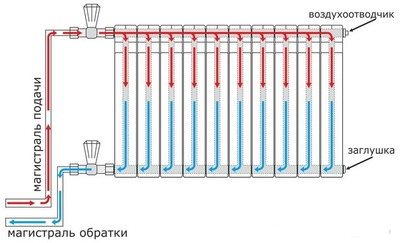

Water heating device circulation type connected by a piping system with a hot water storage tank.

The principle of operation of devices for indirect water heating based on fluid circulation as a result of its natural convection.

Reference. Natural convection of liquid occurs when the lower layers of liquid heat up and become lighter, rising upward, and heavy and cold ones sinking, taking the place of the heated ones.

For the operation of an open liquid recirculation system (without the use of a circulation pump), the diameter of the pipes supplying water to the storage tank, should not exceed one inchto ensure the required circulation rate.

Length of pipes from the heat exchanger to the storage tank should not exceed 3 meters. This length is often sufficient to move the storage tank from the steam room to the adjacent room for washing.

The capacity of hot water, according to the laws of natural convection, is set above the level of the heat exchanger.

Threaded nozzles are welded to the water heating equipment from the inlet and outlet sides for connecting circulation pipes connecting the device to the tank.

The most commonly used steel storage tank volume of 60-120 liters, depending on the power of the oven.

A drain valve for washing is installed on the storage tank, and a drain valve for draining the liquid from the system is installed on the cold water circulation pipe (bottom).

Important! Specialists do not recommend install a circulation pump in water heating systems for sauna stoves.

Views

The following types of devices are commonly used:

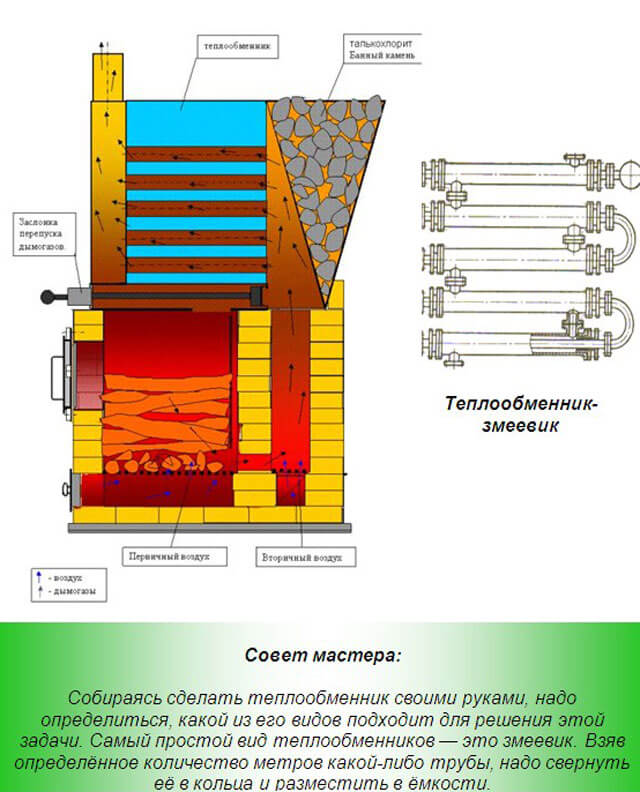

- Interior. The simplest option, made in the form of a coil built into the furnace, is directed to the active use of the heat generated by the fuel.

- External. It is a water tank mounted on the outer side wall of the oven. The high wall temperature heats the tank by transferring thermal radiation to it. This option is easier to manufacture than an internal heat exchanger.

- Outer. A water tank installed on the chimney pipe is an effective way of installing a heat exchanger, which does not require much effort in its installation and does not take up much space in the steam room.

- External flow (economizer). It is a small flow-through heater of medium capacity from 5 to 10 linstalled on the chimney and connected to the storage tank by a piping system. This is perhaps the best heat exchanger for its installation and use.

Photo 1.External heat exchanger for a sauna stove. The device is made of stainless steel and fits over the chimney.

- Combined models. At the same time, a coil built into the firebox and an external container with water installed on the chimney pipe are included in the design. Both units are connected by a piping system and have a separate plug-in tank for collecting hot liquid.

What are they made of

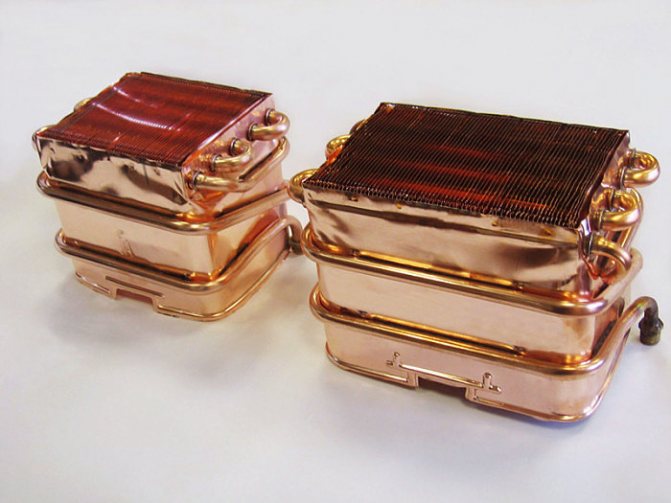

Internal heat exchangers (registers) in the form of an L-shaped lattice are made of bent steel, cast iron or copper smooth-walled pipes with a diameter of 40-50 mm.

The water tanks are made of cut and welded sheet steel with a thickness exceeding 2.5 mm.

The most popular material for the manufacture of water heating devices - stainless steel, since it is an inexpensive metal with high temperature resistance.

Attention! In the manufacture of heat-heating devices of this type undesirable use galvanized steel, because at a temperature above 200 degrees Celsius zinc begins to evaporate.

Disadvantages of cast iron units - their fragility and weight, and copper - increased price and insufficient heat resistance.

Do-it-yourself heat exchanger for a bath

The heat exchanger is made of metal of at least 2.5 mm or pipes bent with a snake or spiral.

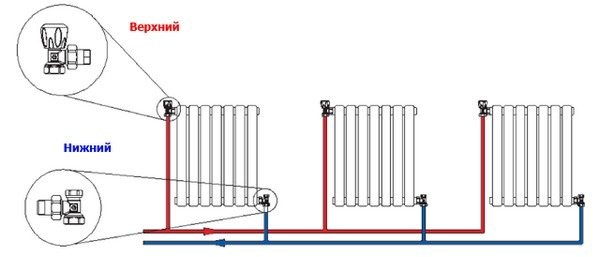

The water tank is located above the oven level to circulate the water. Then these elements are connected to each other by pipes: the upper and lower contours.

To drain the water (when flushing the system or during periods of long downtime in winter), a tap is cut into the return circuit at the lowest point of the pipe.

Installing a heat exchanger on a sauna stove requires a high-quality connection of all elements, tightness of welded seams. The heat exchanger itself can be checked with compressed air by immersing it in water. After assembly, check the tightness of the joints of the entire system.

Note: to heat adjacent rooms, the water tank can be thermally insulated - in this case, it will carry the additional function of a heat accumulator.

Location: on the chimney, inside the firebox, on the side wall

Internal structures are located inside the firebox of the stove along its contour so that they are not in the zone of the maximum temperature of the flame and the incandescent gases escaping from it, so that the device will last as long as possible.

Outdoor units heating is installed on the side wall of the stove so that they do not interfere with the use of the stove.

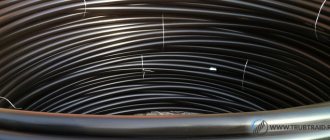

Outdoor, including flow (economizers), are installed directly on the chimney pipe, encircling it in a circle.

Do-it-yourself heat exchanger for a bath

The heat exchanger is made of metal of at least 2.5 mm or pipes bent with a snake or spiral.

The water tank is located above the oven level to circulate the water. Then these elements are connected to each other by pipes: the upper and lower contours.

To drain the water (when flushing the system or during periods of long downtime in winter), a tap is cut into the return circuit at the lowest point of the pipe.

Installing a heat exchanger on a sauna stove requires a high-quality connection of all elements, tightness of welded seams. The heat exchanger itself can be checked with compressed air by immersing it in water. After assembly, check the tightness of the joints of the entire system.

Note: to heat adjacent rooms, the water tank can be thermally insulated - in this case, it will carry the additional function of a heat accumulator.

Selection recommendations

Advantages and disadvantages of options heat exchangers:

- Interior. Directly in contact with the combustion zone, therefore, the heating rate of the coolant is high.However, the efficiency of fuel combustion in such a system is low, since the coolant takes away part of the generated energy from the fuel, which leads to its overconsumption when the steam room is heated. According to calculations, the efficiency of internal heat exchangers does not exceed 50%.

- External. It heats up more slowly than the coil due to its distance from the heat source, however, it also removes heat from the wall of the firebox, reducing the efficiency of the system. Disadvantages of the scheme - a tank located on the wall of the furnace requires the constant addition of cold water due to its rapid heating, as well as the possible danger of burns when touching the tank.

- Outer. Increases the efficiency of fuel combustion in the furnace up to 60% by cooling the hot gases passing through the chimney, which reduces the heating time of the steam room and the amount of fuel required. The disadvantage of the outdoor option is the need to add cold water when it boils in the tank.

- External flow (economizer). When using an economizer, the water in the tank has time to warm up to the temperature required for washing during the heating of the steam room, which makes this scheme the best option for using for baths.

Important! In the manufacture of a heat exchanger and a storage tank, the choice of shape and size is best done by comparing them with ovens from renowned manufacturers of similar powersince these ovens have passed the necessary performance tests.

Combined models include the disadvantages of the listed options and are not very popular today.

A great solution for your bath

If you are tired of heating water for your bath in the old fashioned way, using buckets and other improvised means, then a design with a heat exchanger will be the perfect solution for you. You can skip buying an expensive broiler by getting one device that performs two functions at once.

The assortment of the online store "VashBani" presents various types of heating equipment. In the catalog you will find sauna stoves with a heat exchanger for heating the steam room, which are also designed to heat the bathing water after visiting the steam room.

On the site, you can buy any product you like by adding it to the cart. There are convenient forms of payment for you, as well as the ability to deliver products in Moscow, as well as to any other city in our country. Check the cost of this service for your region with our operators by phone.

Varieties of devices in pictures

Photo 2. External heat exchanger installed on the tube of a sauna stove. The device is filled with water.

Photo 3. External flow-through heat exchanger for the furnace, made of copper. The device is put on the chimney.

Photo 4. External flow-through heat exchanger for a sauna stove. With the help of pipes, the device is connected to the water tank.

Installation methods

The internal structure of the heat exchanger for the stove on the chimney

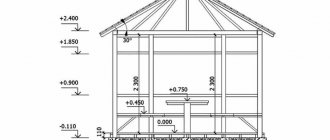

Installation of a heat exchanger is easiest to carry out if the element is supplied with the purchased furnace equipment. In this case, it is enough to study the instructions for servicing the unit and carry out the assembly taking into account the diagram. When installing a water circuit inside a gas duct or a brick furnace, the register is made in advance from stainless steel or a thick-walled tube, after which it is built in in accordance with the drawing of the heater.

If the element is made at home, it is better to focus on the models of similar devices, finding their technical characteristics and calculating the required area of the part. A do-it-yourself heat exchanger for a chimney, working as a water economizer, is purchased ready-made or welded from pipes with different diameters. The longer the circuit, the more efficiently it will transfer thermal energy to the chimney.

Recommended rules for installing a heat exchanger

By inviting specialists to install heat exchange equipment, the user can independently control the effectiveness of the work being carried out, knowing the following rules applicable to equipment of this type:

- The water tank must be selected with an appropriate volume. You cannot choose a large tank for a small stove (since a large volume of water will not have time to heat up) and a small tank for a large hearth (since an excessive amount of heat will be generated, creating a load on the hydraulic circuit)

- It is recommended to install large tanks as close to the furnace equipment as possible.

- The optimal ratio of the heat exchanger and the sauna stove is about 10%, which should go to heating hot water

- The fastening of pipes should not be carried out by rigid structures: dense metal parts tend to expand from exposure to high temperatures, which will lead to deformation in the future

- The joints between pipes and other structural elements must be well sealed. Select high temperature sealant and sealant for optimal sealing.

- If the pump for circulation in the design is excluded, it is recommended to install the pipeline at a slope of up to five degrees, and the heat exchanger above the furnace equipment for optimal movement of hot and cold water, as well as rapid heating

- First, the water tank itself is mounted directly, and then the pipeline

- It is necessary to provide for the installation of a drain valve at the bottom of the entire system in order to remove excess water

- The tank must be checked frequently to ensure that it is full. An empty tank is dangerous when heating the stove, as it can heat up excessively and cause a fire.

Attention! It is recommended to use flexible stainless steel hoses, for example, gas, when connecting the tank to the pipeline and heat exchanger. Such pipes have a longer service life, as they are less susceptible to oxidation, deformation, moisture and high temperatures.