According to the official opinion of the Ministry of Natural Resources and Environment of the Russian Federation, in 2034 gas will be the main raw material for the energy sector. In this regard, the main task is to develop the extraction of this resource, as well as gasification of our homes. In the southern regions of our country, two types of energy have been used in parallel for a long time - electric and gas. This option is convenient and practical, especially in a private house. Whether you need gas equipment in your home is up to you.

Knowing that gas will perfectly be able to insure in case of interruptions in electricity, hot water, heating in an apartment, the choice is obvious. The only condition for the safe operation of gas equipment is the fulfillment of all regulatory rules, starting with the installation of the system.

How is the selection and design of chimneys regulated

Depending on your needs, you choose the right gas equipment, it can be:

- Gas boiler for home heating.

- Gas water heater.

- Gas stove for cooking.

Below we will take a closer look at the types of ventilation ducts suitable for gas equipment, and everything you need to know about built-in hoods. And also the installation of a smoke exhaust system, safe in operation, meeting the requirements of SanPin and fire inspection:

- SanPiN 2.2.4.548-96

- SanPiN 2.1.2.2645-10

- SP 89.13330.2012

- PPR instruction paragraph 2 chapter 1 of 2020

How to choose a corrugation for a chimney

Can corrugation be used to make a chimney and what should be considered when choosing?

The possibility of its application and the main selection criteria are determined by:

- NPB 252–98. The document regulates the requirements for heat-generating devices, methods of their testing and fire safety rules;

- SP 42-101-2003, which defines the rules for the construction and design of smoke exhaust systems;

- SP 60.13330.2012, which establishes the rules for the manufacture and use of air ducts, heating and air conditioning systems.

So, in accordance with the specified documents, in order to choose a corrugated stainless steel chimney, it is necessary to consider:

- diameter. For the maximum removal of combustion products, it is necessary that the diameter of the hood is not less than the corresponding parameter of the outlet of the installed equipment;

- equipment power. The parameter affects the determination of the length and diameter of the chimney;

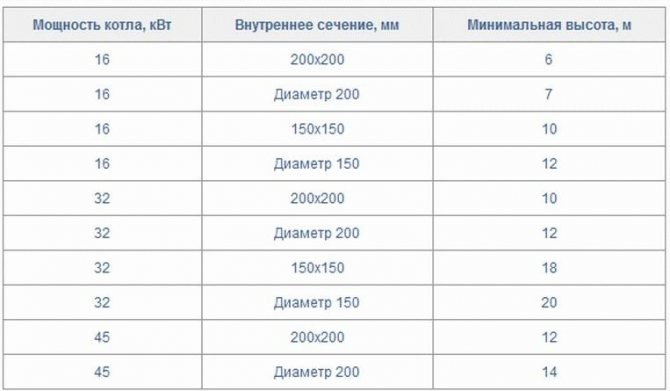

Dependence of the exhaust parameters on the boiler power

- tightness class.

The use of a corrugated pipe with a tightness class B is recommended.

How to choose the right pipes for the chimney, see the video.

Features of the chimney device

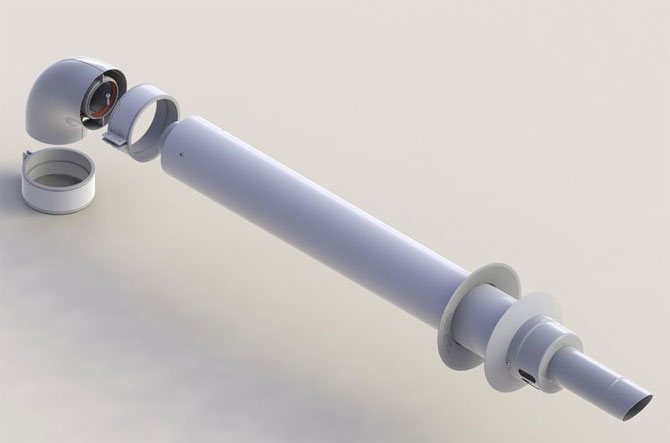

The ventilation system for removing waste products of combustion and ensuring the flow of air in the room has the same device, whether it is an exhaust from a corrugation for a gas water heater or a solid brick chimney. The chimney must be composed of the following parts:

- Lead-through pipe.

- Combustion products discharge pipe.

- Adapter for connecting the previous parts to each other.

- Clamps and mounting brackets.

- Telescopic tubes.

- T-piece with a condensate drainage hole.

- Taps.

- Tapered tip.

All parts can be connected one by one independently, without violating safety precautions, using special non-combustible materials. But it is better to turn to professionals.

What is the difference between chimneys after all? The material from which the parts are made, the choice of the pipe installation method and the geometry of the ventilation shafts.

Chimney from galvanized pipe

At the stage of designing ventilation for a gas column, choosing a material, opt for a galvanized pipe. Taking into account the heating temperature when disposing of combustion products from the room, the wall thickness is selected equal to 0.5 millimeters at a heating temperature of 400 °.

When choosing pipes for a gas column, the configuration of the future hood is taken into account - single-circuit or double-circuit.

In the second case, the pipe is applicable for sandwich and coaxial chimneys.

They differ in that in the sandwich system, basalt wool is laid between the two pipes, in the coaxial chimney, on the contrary, air circulates. Due to its properties and ease of installation for a gas water heater, chimney sandwiches are popular today.

Purpose and principle of operation

The exhaust pipe for the gas column - air duct - ensures the removal of combustion products that are generated during the operation of the heating device. Due to the difference in temperature and density, the flows of waste substances are directed upward through a sealed channel and are discharged outside. Due to the pressure drop in the gas outlet, a natural draft is formed, and air from the room is supplied to the furnace, which is necessary for continuous combustion.

The chimney for a gas water heater is a sealed line that is built between the combustion chamber and the entrance to the exhaust shaft of a multi-storey building. In a private house, the gas outlet is led directly to the outside through the wall or roof of the building.

Coaxial chimney for gas boiler

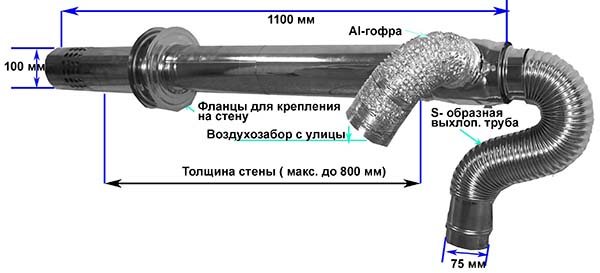

As mentioned above, a coaxial chimney is a double-circuit pipe. Its principle of operation is based on the inflow of clean air masses through the distance between the pipes, and the output of carbon monoxide through the inner pipe. The use of a coaxial hood for gas water heaters in an apartment will help bypass the public ventilation duct, removing the combustion products through the pipe to the street, and avoid a situation with a loss of boiler efficiency, which may occur when the ventilation duct is clogged.

It is important to know that when installing a closed-type gas boiler, only a coaxial chimney is installed.

This system uses a pipe with a diameter of 11 centimeters. Fans with sensors are often installed for greater thrust. This allows you to achieve high performance of the gas boiler at any time of the year.

Exhaust gas boilers: device, features

Gas heating boilers with a power of up to 30 kW are usually located in a kitchen with an area of 15 sq. Requirements for a window - an area of 0.3 square meters, a ceiling height of more than 2.2 m. In this case, the presence of a window in the room is mandatory.

Higher power equipment requires a special boiler room. In any case, a high-quality exhaust hood for a gas boiler is the most important condition for its efficient and safe operation.

The main elements of a reliable exhaust hood for a gas boiler:

- pass-through box;

- pipeline branch;

- adapter for fixing the branch pipe of the passage and outlet pipes;

- crimping clamps with brackets for fastening to walls and ceilings;

- telescopic pipes;

- tee equipped with a condensate drain;

- special bends;

- cone tip.

Exhaust materials

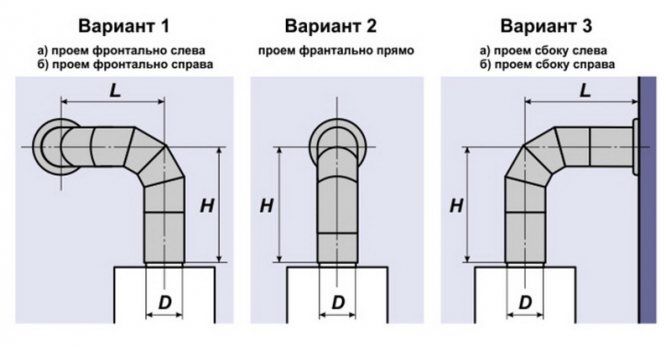

The temperature of gas combustion products is within 400 ... 450 degrees. Therefore, hoods for gas boilers and modern dispensers are made of heat-resistant materials. Due to insufficient tightness and reliability brickwork, which was previously widely used for chimneys, is now used as an element of decorative design for metal pipes.

Ceramic exhaust pipes wrapped with insulation in a expanded clay box are used relatively rarely due to their high cost. The key advantage of ceramic trails is durability.

Mainly used pipes metal thickness of about 0.6 mm. Lightweight aluminum is easy to install and reduces the risk of condensation. Aluminum foil is also popular for hoods, easy to install, condensation-resistant corrugated pipes. Strong, reliable steel pipes are made of stainless steel or protected with an enamel heat-resistant coating.

A highly efficient solution is to use coaxial pipes. Through the internal line, flue gases are discharged outside, and air is sucked in between the pipes. Heating up the air improves the efficiency and effectiveness of equipment, and reduces gas consumption.

Without fail, a coaxial pipe is used to exhaust a gas boiler, a closed column.

Insulation requirements

Thermal insulation must be used to eliminate condensation. Often, hoods for gas water heaters are made from double-circuit chimneys with an internal stainless, external galvanized pipe and thermal insulation between them.

Heat-resistant materials are used as thermal insulation - usually, mineral fibers. Galvanized pipes are used only for the outer coating of heat-insulated channels, since overheating of zinc over 419.5 degrees leads to its melting.

Ceramic chimney

When using a ceramic flue gas vent, it should be understood that ceramic has a high moisture absorption rate. To increase its service life, it is necessary to install additional exhaust ducts.

When installing the exhaust system, the ceramic pipe is wrapped in insulation and installed in an expanded clay or brick box.

It should be noted that this method of exhaust gas removal is expensive. And it is not suitable for the gas water heater in the apartment.

We recommend that you familiarize yourself with: How to choose and install a fan in an exhaust ventilation duct

Internal installation of the chimney

The characteristic features of indoor chimney installation are:

- preparation of places for the passage of the channel through the ceilings and the roof;

- the complexity of assembling the structure and its repair;

- the possibility of harmful gases entering the dwelling;

- compliance with fire safety and protection of wooden surfaces.

First, the markings are applied, a hole of the required diameter is cut in the floor and roof. Further, a ventilation pipe is assembled starting from the boiler. Brackets are installed to fix pipes to the wall with a pitch of 3-4 m. Fixation takes place with clamps. The section of the channel that passes through the roof is protected by a flexible metal sheet. The joint is insulated with insulation and sealant. The insulation must be resistant to fire. The outer part of the pipe ends with a tapered tip. If the building is under construction, a steel pipe ventilation system can be installed inside the brick ducts.

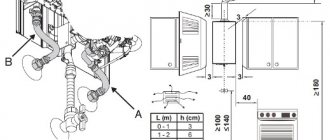

The distance from the gas water heater branch pipe to the horizontal section of the pipe must be more than 50 cm.When the ceiling height is less than 2.7 m or the use of draft stabilizers, the length of the vertical section is less than 25 cm.

The point of contact of the pipe with the roof is protected by a metal plate

Requirements for a smoke exhaust structure

The basic rules of SNiP 42-01-2002 and 2.04.08-87 approved the following requirements for the installation of gas boilers and their connection to the hood:

- The ceiling in the boiler room must be at least 2.5 meters high.

- The area of the premises for one piece of equipment must be at least 4 square meters.

- It is obligatory to have a window with a window with an area of at least 0.3 square meters.Otherwise, additional ventilation is required.

- The walls in the boiler room must be made of non-combustible materials.

- It is imperative that an inspection window be located in the chimney system, such a device is installed at a distance of 0.25 meters from the chimney hole.

- Several gas powered appliances must not be connected to the same ventilation.

- The gas stove must be located in another room, separate from the boiler at a distance of at least 6 meters. If these conditions are met, it becomes possible to cancel the previous comment.

Step-by-step instructions for the construction of a smoke exhaust system

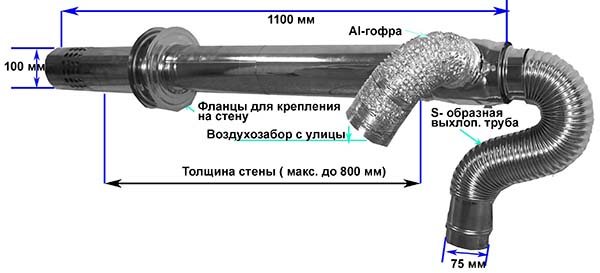

To commission the equipment, the ventilation of the room must be taken into account In the absence of air exchange, a forced turbo exhaust is required. Without it, putting the gas boiler into operation is impossible. We will consider how a gas boiler hood is installed in a private house using the example of a coaxial chimney. The length of the pipe from the boiler room to the street for this type of hood is not more than two meters.

- Before starting work, make sure that the installation of the gas boiler is in accordance with the rules and regulations approved by the inspection organizations in order to avoid reworking the entire power unit.

- Select a suitable material for the hood, taking into account the parameters of the flue gas outlet: gas boiler inlet = pipe diameter.

- Calculating the power of the fans and their number, taking into account how long the hood is, the number of elbows in its structure, and the position in space relative to the horizon, at what height the chimney is located in the room.

- Do not forget about the features of budget technology, indicated in the data sheet.

- All materials used in the work must be fireproof and not corrosive.

- After making sure that all the parts are intact, we proceed to the assembly. We attach the chimney elbow to the gas boiler pipe using a tee.

- To build up a coaxial pipe and connect all its parts, special crimping clamps and refractory sealants are used.

- Turbo exhaust is used when there are more than two elbows in the pipeline geometry. This helps to maintain the efficiency of the gas boiler.. The fan and all sensors are installed after installing the supply pipe.

- Mounting a coaxial pipe outside a building is no different from mounting a conventional chimney sandwich.

We recommend that you familiarize yourself with: Varieties of household fans for hoods - rules for selection and installation

Outside the building

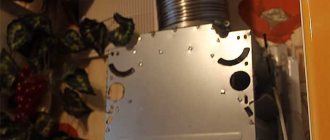

Having laid the line for the exhaust device in the house, the design of the exhaust for the gas boiler goes out into the street.

- As soon as the pipe has been brought out into the street through a hole in the wall, it must be closed with special metal plates. The remaining space between the pipe and the wall is filled with mineral wool.

- Now we install the tee. The bottom hole is closed with a plug with a revision for cleaning the pipe.

- We build up the chimney to the desired length by joining the parts with a special sealant and clamps with gaskets. As the pipe grows, we attach it to special brackets.

- We install a protective cone at the top of the chimney and additionally fasten it to the braces in those places.

- If the structure of the chimney was not coated with special paint in production, this can be done at home. This is done to protect the metal from environmental influences.

When ordering an outdoor chimney system, it is important to consider where the forced exhaust starts from the gas boiler or from the room where the turbo elements are installed.

You can see how to connect a gas water heater to the chimney system and how to assemble it in the video.

Inside the house

Inside the house, the installation of a coaxial chimney, in detail, with comments, was described above. The only step that remains for you to take is to connect the two pipes, street and indoor, by extension.For additional insulation, the use of special metal tape is recommended.

I would like to note an important advantage of a coaxial chimney - it is the absence of additional holes in the roof or wall of your home.

Insulation of the smoke exhaust structure

A gas pipe is often the cause of a fire. After checking the pipeline structure by the gas service for defects and microcracks, they must be immediately eliminated. Taking into account the rules of SNiP for the installation of gas equipment, it is necessary to use heat-insulating materials at the points of contact between the pipe and the frame of the house. Such as basalt, mineral wool, fire-resistant mastic will protect you from fire. It is very important not to ignore the recommendations of experts when choosing insulating materials for a built-in hood.

A poorly insulated hood from a gas boiler in a private house or apartment is harmful to health, not good. So do not save on your health, turn to specialists for help so that the gas water heater in the kitchen and other equipment will serve for a long time and properly.

Varieties of chimney

The primary criterion for choosing a particular type of chimney is the principle of operation of the column itself. Most of them have an open combustion chamber and take air from the room that enters the burner naturally. But there are more modern and expensive models of water heaters - turbocharged. Their combustion chamber is of a closed type, and air is blown into it by a fan. Accordingly, the chimneys for these two types are different.

Flow-through gas heaters with an open combustion chamber are called atmospheric, since the burner in them operates at natural air pressure. In turbocharged columns with a closed firebox, air is forcedly forced, as a result of which the burner operates under pressure. Hence the second name of water heating units - pressurized.

To remove gases from an atmospheric column in private houses and apartments, it is allowed to use exhaust pipes made of the following materials:

- Vertical brick channels with ceramic or metal insert. They settle in the thickness of the wall when building a house.

- Chimney pipes made of stainless or galvanized steel - conventional or insulated (sandwich).

- Enamelled steel chimneys - for internal lining.

- Corrugated stainless steel pipes - to connect the column to a vertical exhaust shaft (in common people they are called "stainless steel corrugation").

Steel enameled chimneys

Often, homeowners use the cheapest option for connecting a gas water heater using a corrugated aluminum foil pipe. On the one hand, a flow-through water heater is a batch-type apparatus and a foil corrugation can last for a long time.

Corrugated stainless steel

On the other hand, thin aluminum can burn out at any moment, which is fraught with waste for residents. Therefore, it is not recommended to use such gas chimneys to connect columns to vertical ducts.

Flue gases from pressurized water heaters are removed by means of so-called coaxial (double-circuit) chimneys. Their design is simple: a chimney of a smaller diameter is placed in a sleeve in such a way that there is a large enough gap between their walls for air to pass through. As a result, 2 streams move through the channels towards each other, exchanging heat.

Combustion products leave the gas column through the inner channel of the coaxial chimney passing through the wall, and the outside air moves from the street, sucked in by the fan. The structural diagram of the double-circuit channel is shown in the photo: