How to choose pipes

When choosing products, you need to take into account the visual characteristics of pipes, as well as other features:

- Materials should be homogeneous, not contain any inclusions;

- The pipes must be marked and indicated by GOST, in accordance with which they were manufactured;

- There should be no unpleasant smell in such pipes;

- The wall thickness should be the same along the entire length of the product;

- The pipe surface must be smooth.

With the full compliance of the selected pipe with all the above points, the product can be called quite high quality. Such a pipe is great for installing a line in a cold water supply system. Low-quality products can only be used to meet the simplest technical needs.

A pipe that can be installed in a cold water supply system is marked with a blue stripe along the entire length of the product, painted black. Pipes used for such purposes are also painted blue.

HDPE pipes for cold water supply systems are often marked by embossing, or printed, the following information is indicated on the products:

- Purpose and GOST;

- Overall dimensions, or the ratio of wall thickness and diameter;

- Product strength factor. PE100 high quality manifolds. PE80 pipes of lower class;

- Manufacturer's name;

- The footage is not indicated by all manufacturers.

The cost of products also requires attention in the process of choosing the right product. If the price per meter of pipe is lower in comparison with the average market indicator, then the buyer is facing a fake, or a product intended for the simplest household needs.

Classification of plastic pipes

Due to their qualities, relatively inexpensive cost and reliability, non-metallic pipes are becoming more and more popular in the installation of water supply. They are represented by a wide selection, differ in their advantages and disadvantages. Many types of plastic pipes are used for plumbing, which are used depending on their characteristics. One of the most common options is polypropylene. When choosing, many nuances are taken into account:

- The color of the plastic is gray or white. This does not affect their properties, but are simply selected according to design preferences.

- There are reinforced and unreinforced polypropylene pipes. Associated with the thermal elongation properties of plastic. Reinforcement is carried out with the help of fiberglass or aluminum, which can significantly reduce the thermal elongation (almost 10 times).

Plastic pipes

- When installing, it is best to use unreinforced or fiberglass-reinforced pipes. If, nevertheless, they are selected with an aluminum interlayer, then the aluminum is cleaned off to the level of the end of the connection (a few centimeters around the entire circumference), otherwise a high-quality connection will not work. Referring to this characteristic, unreinforced is ideal for drinking and cold water, fiberglass reinforced for hot water and heating systems.

- Polypropylene pipes are manufactured in several countries, but very different pricing policy. For example, if we compare products of Turkish and Czech production, then the latter will be much more expensive.Although this does not mean that the quality will be inferior, the reinforcement will simply be more accurate, or the color is much better, but here you need to look at the means laid down for the water supply.

If, together with plastic, other types are used, then the diameter is selected using the correspondence table in accordance with GOST. If the inner diameter does not match, special adapters are used.

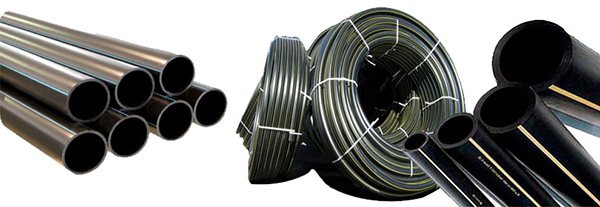

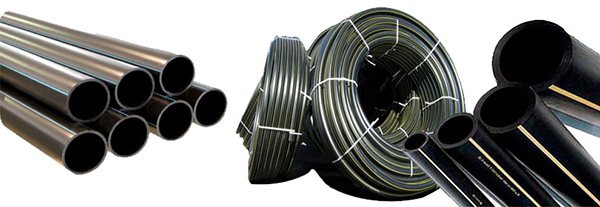

Polyethylene pipes

Polyethylene pipes are marked in accordance with their purpose, similar to products from other possible materials. Products can be reeled into spools and coils if they have a small diameter. The high elasticity of the pipe can be maintained even in frosty winter. Therefore, the polyethylene plumbing system is quite frost-resistant. The walls of the pipe will only be slightly stretched with ice. The pipes will be back to their original size after the ice has melted.

Consider the areas of application of polyethylene pipes:

- Underground water pipes;

- Water supply inlets;

- Summer cottage systems and temporary removable summer water pipes.

The service life of such devices is at least 50 years. The allowable working pressure is 6-16 kgf / sq. cm.

Polyvinyl chloride

Water pipes for cold water supply up to 45 ° C are made of polyvinyl chloride (PVC). For this, there are modifications that are called pressure. But more often this material is used in sewer systems.

PVC pipes are calculated for the following pressure:

- 6 atm - grade PN 6.

- 10 atm - PN 10.

- 16 atm - PN 16.

The connection is made in several ways. But for domestic water supply (pipe diameter from 16 to 40 mm), only the option using fittings that are fixed to the pipe with glue is suitable.

The material is cut with special scissors or a hacksaw, after which the edges are cleaned.

PVC plumbing has been serving for more than half a century.

The price of pipes of European and Russian production - from 90 rubles / m, fittings - from 45 rubles. per piece But buying products of small diameter (20–25 mm) is not easy. since the retail network is overwhelmed with products with d = 90 mm and more.

PVC does not corrode. Its appearance is quite delicate.

Polypropylene

Polypropylene cold water pipes are attracting many homeowners for their affordable price. The cost of products can reach 20-25 rubles per running meter with a standard pipe diameter of 20 mm. To connect such pipes, special fittings are used, which are also affordable.

Other quality characteristics can also please users:

- The duration of the operational period of products, the temperature of the working environment in which does not exceed 20 degrees, can be 50 years or more.

- The working pressure indicator can be from 10 to 20 kg / sq. cm;

- Welded joints are durable and tight.

Polypropylene pipes can be hidden in grooves or cement screed without any leaks in the near future.

Sizes of pipes for water supply

In order for the pipe to match the running water supply, it must be selected based on the size and price. For this, the inner diameter of the pipe is taken into account, which can be 15, 20 and 32 mm for steel pipes and 16-30 mm for metal-plastic pipes. In addition, the pipes are sold in special lengths from 4 to 12 meters in length.

The choice of diameter mainly depends on the water pressure in the pipeline. At low rates, large diameter pipes are used.

It is also worth taking into account the length of the pipeline, which directly affects the voltage. The number of corners in the plumbing system also reduces the pressure.

To calculate the required diameter of pipes for a water supply system, special formulas are most often used.Remember that it is not worth saving on pipes and it is better to choose a large diameter. In such pipes, the wall thickness will also be greater, which will allow it to calmly tolerate any water temperature.

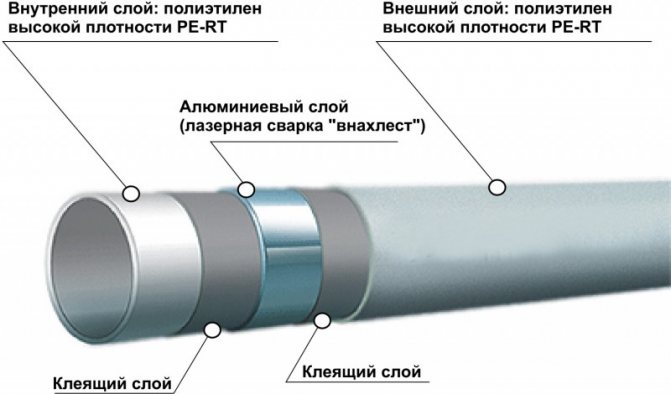

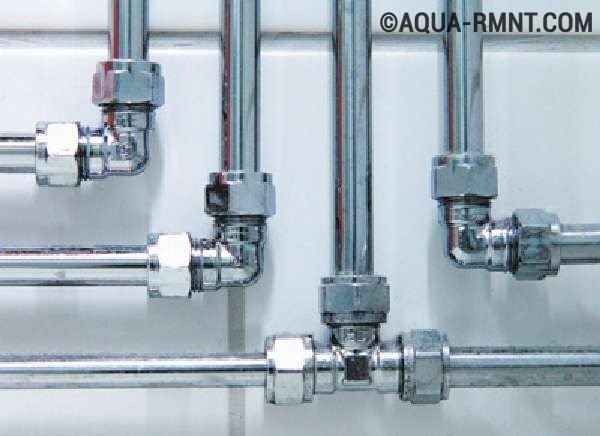

Reinforced plastic

These are composite products consisting of aluminum cores and several polyethylene shells, which are connected to the glue using a core.

For the shell, the following material can be used:

- Low pressure polyethylene PE;

- The crosslinked PEX material has a high mechanical strength and a fairly high temperature resistance

- PERT is a highly heat resistant material that can withstand operating temperatures up to 110 degrees.

The operating period is over 50 years. Working pressure indicator is 10-16 atmospheres.

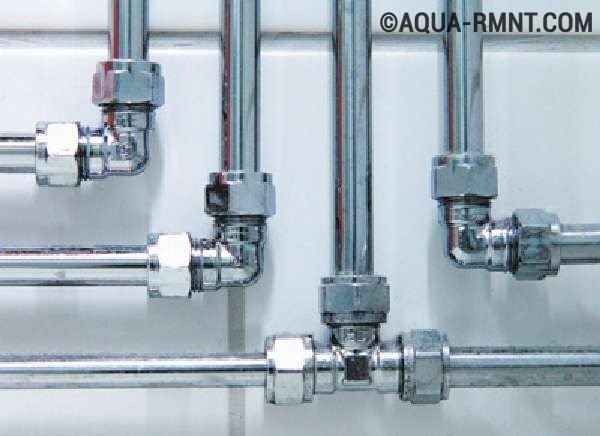

Several types of fittings can be used for installation:

- Compression, in which a pipe is put on the herringbone fitting, after which it is crimped using a special split ring. The main advantage of such devices is the absence of the need to use complex tools during installation.

- Press fittings, in which a special stainless steel sleeve is used instead of a ring. Installation requires electric pliers or similar mechanical aids. This type of connection cannot be disassembled and further serviced.

The second type of connection is highly reliable.

Reinforced-plastic pipes for water supply networks

Metal-plastic pipes are a good option for arranging the water supply system of an apartment, residential building or summer cottage. Such a pipe consists of three layers:

- outer polymer layer;

- aluminum foil;

- inner polymer layer.

Thanks to this design, the pipe is both strong and flexible. Able to withstand ambient temperatures up to +75 ° C.

The main advantages of metal-plastic products include:

- the ability to do it yourself. No special additional equipment is required for connection;

- the ability to bend pipes if necessary. However, it should be borne in mind that changing the configuration during bending degrades the throughput;

- high corrosion resistance, no risk of mineral deposits formation, long service life - up to 35 years.

Among the disadvantages, it is worth noting low frost resistance and the need for regular tightening of threaded connections.

Which pipes to choose for the water supply? Video:

HDPE pipes

Homeowners who are solving the problem of running a water supply system in a private house have heard of materials such as HDPE. For beginners in this matter, it is advisable to understand the types of HDPE pipes that can be used for installation.

The abbreviations indicated on the products (HDPE, PVC, etc.) help determine the material from which the pipe is made. HDPE is low pressure polyethylene. This is the initial raw material used for the manufacture of PE products, in particular for pipes.

The quality of HDPE products may vary. The basic properties of the raw material used have an impact on the characteristics of the pipes produced. The performance and potential duration of use are also influenced by these basic material properties.

Some developers are installing a HDPE pipeline that can be used for 45-50 years. Some products become unusable after 1.5-2 years of operation. The qualitative characteristics of the feedstock are decisive in this matter. Therefore, you need to understand how to choose the right polyethylene pipes.

Selection of metal pipes

The types of metals that are used for the production of water pipes have already been listed above. However, if we are talking about creating a water supply system in an apartment or a private suburban household, then the best option is still steel products (read: "Advantages and disadvantages of steel pipes for water supply, types and rules of installation"). The fact is that copper itself is a toxic material; the use of cast iron pipes in these conditions is impossible. The latter are mainly used to create a gravity sewer network in summer cottages, country houses.

In Soviet times, steel pipes without a protective coating against corrosion were used for the construction of water supply systems in apartment buildings. The starting material for the production of such pipes was structural steel. But in modern times, water supply in apartments is most often equipped with stainless steel products.

Cink Steel

The service life of steel pipes can be extended by zinc coating on the inside and outside. Galvanizing allows you to get a completely new material that is resistant to corrosion and blockages in pipes. Previously, in the so-called stalinka, galvanized products were installed without welding using cast-iron corners or special tees. Even after several decades of successful operation, galvanized steel pipes remained in good condition.

The relative complexity of the installation is one of the main disadvantages of such products. It is highly undesirable to use synthetic materials for sealing joints. Traditionally used substances like flax, impregnated with drying oil or paint, have proven themselves in the best way.

Steel pipes: out of date?

Steel pipes do not need a long introduction, since until recently they were most often used for installing a water supply system.

This material is referred to as relatively cheap, besides, in any store there is a large selection of compatible fittings. Their undoubted advantages include strength: they perfectly withstand both high pressure and high temperature, but these advantages are not the most relevant for domestic water supply.

The main disadvantage of a water supply system made of steel pipes is an expensive and complicated installation.

At the same time, metal pipes have a bad habit of becoming covered with condensation. Their installation is quite laborious, using welding or threaded connections, requires special skills and equipment, and is difficult for independent implementation. However, with a well-done work, such a water supply system will last up to 50 years, so it has enough fans.

Disadvantages:

- Corrosion susceptibility;

- Calcareous deposits, gradual "overgrowth" of pipes;

- High electrical conductivity;

- Time consuming installation.

Conclusion: you can use steel if you are reconstructing an old water supply system from the same material and do not want to "combine". In general, when deciding which pipes for water supply are better, steel pipes can be safely deleted. There are more worthy contenders.

Choosing the right diameter

To select a pipe of a suitable diameter, you need to use specially compiled hydrodynamic tables.

The tables contain the following information:

- Optimal water consumption;

- The material from which the pipes are made and the indicator of its roughness;

- Length of the plumbing structure;

- The number of turns provided in the pipeline;

- Decrease in internal diameter due to overgrowth with deposits.

Reinforced-plastic, copper or galvanized pipes are made in such a way that their inner diameter will not decrease over time.

For installation in a private house, you can use a galvanized steel pipe, the inner diameter of which is ¾; products made of polypropylene or polyethylene with an outer diameter of 25 mm are also suitable.

You need to understand that polyethylene can only be used for cold water supply systems. It is better to install copper and galvanized products with an internal section of ½ in the building. The outer diameter of metal-plastic products can be 16 mm. The outer diameter of polypropylene should be 20 mm.

Selection based on operating conditions

Communication that is mounted indoors is also called wiring. The main task of water pipes is to deliver water to plumbing fixtures and other equipment. The correct selection of materials depends on the operating conditions and the characteristics of a particular communication.

Note! Products made from various modern polymeric materials, namely polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC), polybutylene (PB), and metal polymers, as a rule, have operational limitations. These restrictions depend on the specific conditions of use.

In turn, some metal elements of pipeline structures can be used practically without restrictions. These products include: galvanized steel, stainless steel, copper, bronze and brass. Plumbing pipelines made of these materials can be used to transport hot and cold water under high pressure. In addition, such materials are excellent for organizing communications at various enterprises where process water is required.

Plastic products can be installed in special channels or under skirting boards. This will not only improve the appearance of the room, but also protect the communication from mechanical damage, which is very important, since the strength of such pipes is rather low. There are also special flexible pipes called liners. Such connections are allowed to be installed by open method in safe places (for example, behind the toilet cistern).

Each type of these products has limitations on the pressure they can withstand. The selection of parts for a specific system is carried out taking into account the pressure in it. In this case, it is recommended to select pipes with a maximum pressure value that exceeds the maximum pressure in the system.

Pipes are selected taking into account the purpose of the future system and the pressure in it

Consider a few more tips for choosing a pipeline for transporting water, depending on the operational features:

- in houses where there is a centralized water supply, pressure indicators can vary from 2.5-7.5 bar. The peak value in this case can reach 10 bar, and if the communication is checked - 12 bar. In this regard, it is recommended to provide a certain margin of safety when choosing pipes for water;

- the main factor that should be guided by when choosing elements of a water supply system for open (aboveground) installation on the street is the coefficient of ring stiffness;

- if the polymer pipeline will be laid in the soil, without using a protective channel, it is advisable to choose products equipped with a special protective coating.

General installation guidelines

When choosing suitable materials, it is advisable to give preference to products with a permanent connection. On sufficiently long sections, expansion loops or U-bends can be installed.

After the installation is complete, access to each installed joint should be open, excluding the soldered and welded seams. First of all, such requirements are imposed on metal-plastic products.The duration of the use of household appliances or individual elements of household plumbing will be extended in a situation when a filter device is installed at the entrance to the building in the water supply. Homeowners are given a choice of a large number of all kinds of communications, fittings, fixing elements, fittings, etc.

Advantages of polymer pipes and technical products

Let's consider the main advantages of technical pipes:

- Low weight makes the installation process much easier;

- The pipes are resistant to corrosion;

- The connection of pipe structures is carried out both by welding the seam and using special PVC fittings. This will greatly reduce the installation time;

- Long duration of the operational period;

- Due to the elasticity, the pipes will not burst when icing;

- Any homeowner can install a plumbing system from such pipes on their own without prior professional training;

- Absolute material safety. No toxic harmful substances are released;

- Relatively low cost of HDPE pipe structures.

Advantages of polymer products:

- Long duration of the operational period;

- Relatively light weight;

- Resistant to corrosion;

- Low thermal conductivity;

- No plaque builds up on a smooth surface;

- High throughput of products;

- Assembly and installation can be done without any difficulty.

Polymer pipes can be used for about 30 years. High flow rates are characteristic of propylene pipes. Metal structures can become clogged over time.

Varieties of pipes

Today there is a wide variety of parts for the formation of a water supply system, thanks to which it is possible to move away from stereotypes and make more modern and high-quality installations. Depending on the design, complexity, pledged funds, you can choose metal or plastic pipes. All of them differ greatly in their characteristics, they have a number of special qualities that become the main ones when choosing.

When deciding which pipes to choose for the water supply, you need to familiarize yourself with the types. In general terms, they are divided into two:

- metal (steel, copper, cast iron);

- polymer (metal-plastic, polyvinyl chloride, polypropylene, polyethylene).

Polymer pipes