Experienced builders know that for thermal insulation of cold-type roof structures, they often use backfill insulation. They fall asleep in the space between the lags when arranging the attic floor. This measure will not seem superfluous if you know that more than 20% of heat loss occurs due to the fault of the non-insulated roof. Most builders agree that thermal insulation is necessary for any heated room. But the question of choosing a thermal insulation material does not cause such unanimity: some craftsmen use modern technological materials, while others prefer traditional roof insulation with sawdust. In this article, we will show you how you can use wood waste to optimize the temperature at home.

Insulation characteristics

Sawdust is a waste product of the woodworking industry, which can be purchased for a pittance at any sawmill. They are of organic origin, and therefore are absolutely safe for human health, and also do not cause allergies. Sawdust mixed with clay was traditionally used as a heater in Russia. Since all residential buildings were built of wood, which is still rich in Russian soil, a lot of waste remained during the construction process, suitable for thermal insulation of attic floors. Sawdust has the following advantages over other thermal insulation materials:

- Low price. Perhaps, the democratic cost of this material is the main reason for the popularity of sawdust insulation. Sawmills and sawmills utilize this production waste, so they often give it to anyone who wants it, subject to self-pickup. Therefore, the cost of the material is equal to the cost of delivering sawdust to the construction site.

- Guaranteed security. Wood shavings are absolutely safe for the health of people living in the house. It does not cause toxic poisoning, skin irritation upon contact, allergies, which cannot be said with certainty about modern heaters.

- Low thermal conductivity. Wood chips, unlike wood, due to their porous structure, have a low coefficient of thermal conductivity, that is, they retain heat well. And a mixture of sawdust with clay or lime increases the thermal insulation effect even more.

- Organic origin. Wood shavings have all the same qualities as wood. It allows steam and air to pass through, which is fundamentally important for insulating houses from a bar and a log with a mansard roof.

- Ease of installation. It is very easy to work with sawdust, you just need to mix them with clay or lime, and then pour them into the space between the overlap logs. Insulation laying technology does not provide for the use of special equipment, complex tools.

Note! The disadvantages of roof insulation with sawdust are the high flammability of this material and low resistance to biological factors. They are a favorable environment for the spread of mold and fungal microorganisms, rodents, insects. In addition, moisture has an extremely negative effect on sawdust, increasing the thermal conductivity of the insulation several times. To get the maximum effect from the thermal insulation of the roof with sawdust, they should be pre-treated with a fire retardant that prevents the spread of fire, as well as antiseptic preparations.

Insulation of ceilings from the inside

Such insulation can become relevant in the following situations:

- the presence of a residential attic;

- a house with several owners;

- engineering communications in the attic.

And this is only part of the circumstances that can be faced in practice.Bulk varieties are not suitable in this case, for obvious reasons.

Most of all they prefer such solutions:

- leafy;

- roll;

- sprayed.

The best option in most situations is expanded polystyrene plates, mineral wool with pressing. Such products are in a leading position in terms of speed of work, the ratio between price and quality.

If the budget is not limited, it is allowed to stop at Penoizol. Any buyer will figure out how to properly insulate the ceiling in a wooden house using this material.

Foam insulation

The material is the second most popular, next to mineral wool. This name was given by a whole group of mineral materials. Their structure includes cells filled with gas. Expanded polystyrene with polyurethane foam are most widely used in practice. 0.041 W / (mK) - thermal conductivity retained for materials.

Low prices and low weight are the main advantages of foam. But there are also disadvantages:

- Indoor greenhouse effect.

- For insects and fungus, foam will not become a breeding ground, but mice may appear inside the material.

- The release of a large amount of harmful substances, the maintenance of combustion.

Typically, the cost of work is from 400 to 2000 rubles, depending on the specific situation. Such indicators also influence the decision on how to insulate the ceiling in a wooden house.

Stages of work

Polyfoam can be mounted on a frame or glue. The first method works in the same way as with ordinary mineral wool. The difference is the use of liquid nails when the styrofoam sheets are laid on the sides.

The step-by-step instructions look like this:

- The surface is thoroughly cleaned. Be sure to get rid of any irregularities present. The primer is used if necessary.

- The foam sheets are covered with glue. It is recommended to use its tiled version. You have to wait about three minutes before the sheet is pressed against the surface of ceilings or attics.

- The same procedure is maintained for the rest of the sheets.

- The next layer is reinforcing plaster, fiberglass mesh laying. When everything is dry, apply another layer of plaster.

https://youtu.be/QLnc8eLzvb4

Ecowool

The eco prefix in the name of the material is used not only to attract attention. This product is truly environmentally friendly. After all, 80% of the composition is cellulose, of natural origin. The rest includes various additives that protect against negative environmental influences or change characteristics for the better.

Fire retardants in the composition make it so that combustion is not supported for a long time. 0.038 W / (mK) - an indicator of thermal conductivity.

Stages of work

In this case, installation also involves the use of one of two options. These are the so-called "dry" and "wet" options. The first case involves laying ecowool in special "cells" of the ceiling, prepared in advance. But then the thermal insulation properties will be only 80-90 percent of the total.

In the second method, ecowool is moistened with special equipment. Then spraying is carried out under high pressure. The insulation of the ceiling of a wooden house becomes sticky when it comes into contact with water. The disadvantage is that this particular method of installation requires additional costs, assistants are often invited.

Mineral wool

Fiber-type ceiling heat insulator. It is produced in roll or plate form.

Mineral wool is produced in three varieties, according to GOST:

- stone;

- slag;

- glass.

Due to its low weight, the mineral wool is convenient not only during installation, but also during transportation, storage under any conditions. This is a non-flammable base.

An additional advantage is complete protection against the development of harmful microorganisms and various insects and other types of pests. This is important for those who are interested in how to insulate the ceiling in a wooden house.

Stages of work

It also has its own step-by-step instructions.

Compliance with her recommendations helps to achieve goals with minimal losses:

- A vapor barrier film is laid on the floor of the attic. The main thing is that there should be no gaps on the base. Special vapor barrier tape is used for gluing seams. We insulate the ceiling in wooden houses further.

- At the top, the installation of the lathing with a base made of galvanized profile or wood is carried out. The insulation will be denser if the distance between the components is only a few centimeters. The height of the lathing should be 1-2 centimeters higher than the vapor barrier layer. Then the interlayer air circulation is easier to equip.

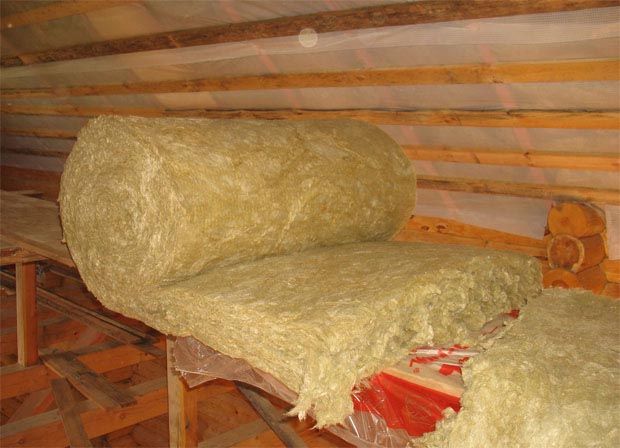

- Mineral wool is unpacked and placed on the crate. If there are several layers, the subsequent ones should overlap the previous ones.

- The waterproofing is attached to the very last layer. To do this, you can use a special furniture stapler. The main thing is not to forget that at least a small free space should remain between the elements in order to ensure air circulation after insulating a wooden ceiling in a private house.

Insulation of the ceiling with underfloor heating

In this case, various modern materials are also used. Some of them are the same as those already described above. The main advantage is that the heat will spread throughout the entire area.

Stages of work

The order of the project implementation depends on what kind of composition is used in a particular case. It is better to study the recommendations from the manufacturers in advance. Or talk to other buyers who already have experience in a particular job. And who use warm ceilings in a wooden house.

Preparation of the mixture

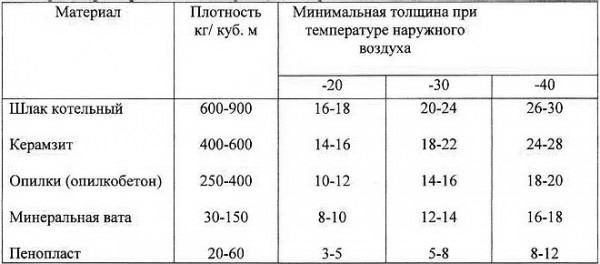

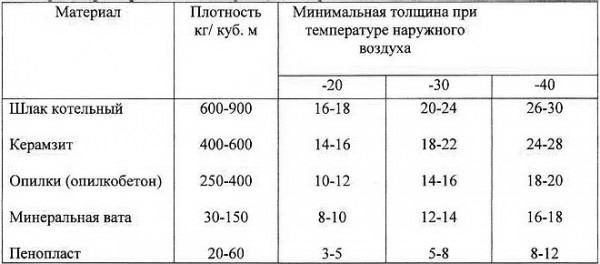

In the process of insulating the roof with sawdust, the prepared material is poured into the space between the lags of the attic floor with a layer of 15-30 cm. The guarantee of high-quality thermal insulation is a dense, non-flowing coating that settles throughout the entire period of operation. To improve the operational characteristics of sawdust, various substances are added to them, obtaining wet or dry thermal insulation mixtures. Most often, all professional builders use the following "recipes":

- Moistened sawdust (85% of the mixture volume) is mixed with fluff lime (10%), and then gypsum (5%) is added. The resulting mixture is thoroughly mixed until a homogeneous viscous mass is obtained, and then quickly laid, as it hardens extremely quickly. In order to have time to decompose the mixture before it dries, you need to cook it in small portions.

- In regions with a cold climate, backfill insulation should be laid in a layer of 30 cm or more. Therefore, for thermal insulation of the roof, sawdust is mixed with slag in a ratio of 1: 1 or 2: 3 to obtain a mixture with low thermal conductivity.

- The traditional mixture of sawdust and clay, which was used on the territory of Russia several centuries ago, is considered very effective. To prepare this insulation, a container with clay is filled with water to soak. Then, in a mixer or barrel, 2/3 of the bucket with sawdust is combined with a bucket of clay, mixing thoroughly.

Important! In terms of thermal insulation qualities, a 15-centimeter layer of sawdust is equivalent to a 10-centimeter layer of mineral wool. But the cost of warming with wood chips is 6-7 times less than the use of mineral and polymer thermal insulation materials. Experienced craftsmen recommend filling in 20-30 cm of sawdust, which will take 2-3 weeks to dry and shrink.

Load

During operation, the following negative factors affect the roof:

- sudden changes in temperature;

- precipitation;

- physical activity from the wind.

It is correct to carry out thermal insulation after the shrinkage of the log house - usually this period takes about six months, as a result of which construction defects may appear: cracks, distortions, which must be eliminated.

Correct insulation of the roof of a wooden house is based on the basic principle - you cannot save money, because only a structure made of high-quality materials can cope well with the same wind.

Requirements

Basic requirements for heat-saving materials:

- ease of installation;

- good thermal insulation properties;

- the possibility of insulating various roofing systems;

- long service life;

- fire resistance;

- acceptable price.

Specially designed materials such as glass wool and mineral wool are best suited for these parameters. In retail and wholesale networks, they can be purchased in rolls, in mats, which, if necessary, can be easily adjusted to the dimensions of the gap between the rafters.

The material can be cut, cut. It is suitable for a long period of use: it does not absorb moisture, has a sufficient level of sound insulation, and - unlike foam plastic - withstands the heat well in summer.

Popular materials for work on energy saving at home

Mineral wool

Mineral wool in the form of sheets or rolls is widely used in construction work. The characteristics of the insulation meet the technical requirements of thermal insulation. The use in residential premises is dictated by the absence of toxic substances in the composition and excellent thermal insulation properties. Mineral wool has components of limestone, basalt, diabase and dolomite.

Rocks endow the material with valuable qualities:

- low degree of thermal conductivity;

- resistance to temperature extremes;

- lack of flammability;

- ecological characteristics.

And yet the material has disadvantages:

- the ability to absorb moisture;

- during installation, be sure to use a waterproofing film;

- the seams of the joints are additionally treated with polyurethane foam for better sealing;

- for fastening the insulation, a lathing is made of wooden beams or profiles;

- relatively short service life (10-15 years).

Penofol

Penofol consists of foamed polyethylene and aluminum foil interlayers. Combines the properties of several insulation materials with a fairly wide range of applications. It represents the basis for innovative finishing of balconies and loggias.

It has low thermal conductivity, which will ensure energy savings. The protective qualities will prevent the penetration of cold air, drafts and radon into the room. In the summer, penofol will help keep the house cool and create a comfortable microclimate.

The light weight of the material makes installation convenient, and the structure of the structure does not become heavier. To work with penofol, you will need a minimum amount of available tools: a construction knife, scotch tape and liquid nails.

Along with the advantages, there are also disadvantages:

- flexible surface means finishing the ceiling with a suspended structure with a frame;

- fixing the material on some surfaces is problematic;

- to increase thermal protection, it is recommended to use mineral wool.

Expanded polystyrene

Expanded polystyrene is known to many more as polystyrene. The easy-to-use material creates strong heat protection in the room without harming the health of the household. With the correct installation, it fully justifies the costs and retains its qualities for a long time.

The advantages are:

- moisture resistance;

- good indicator of thermal conductivity;

- light weight, excluding reinforcement of the structure;

- simple installation.

The disadvantages include:

- easy flammability;

- instability to ultraviolet rays and solvents;

- low resistance to mechanical damage.

Penoizol

Penoizol is a liquid foamed plastic foam. For thermal insulation of the ceiling from the outside, it is necessary to use special equipment for applying an astringent substance to the surface.

Material advantages:

- affordable price;

- thermal insulation qualities;

- fire resistance;

- easily fills in hard-to-reach places;

- safe operation.

Disadvantages:

- lack of special equipment excludes self-assembly;

- weak resistance to mechanical stress;

- the first 2-3 weeks after installation, evaporates a small amount of a toxic substance;

- the ability to nourish moisture.

Principle of operation

The principle of insulation is based on the use of attic rooms: if the owner does not make the attic, then it is not necessary to carry out a full-fledged insulation of the entire system - it is enough to properly insulate the floors (then air from the lower floors will not penetrate upstairs, and cold will not leak from the attic). In the case of residential attic rooms, one cannot do without insulation materials. The total number of certain products is directly related to the selected scheme.

Preparation

First, it is necessary to study the current state of the system by examining all the constituent structures, paying attention to the rafter elements. It is imperative to eliminate all damage, fungus, rot, damp parts, and if significant damage is detected, the rafters generally need to be replaced or repaired.

You will need a comprehensive treatment of the entire wooden surface with antiseptic substances. If there are some communications in the roof area, then they should be checked too: many forget to do this, mainly working with rafters, as a result of which water later appears in the insulation system.

Complex isolation

This insulation method for a finished building is considered in the context of the absence of the need to dismantle the coating. The creation of an insulation system is very similar to the arrangement of a ventilation facade. This simple option does not require large financial expenses.

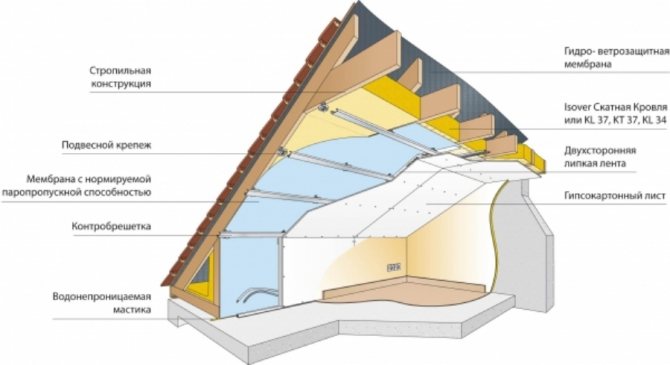

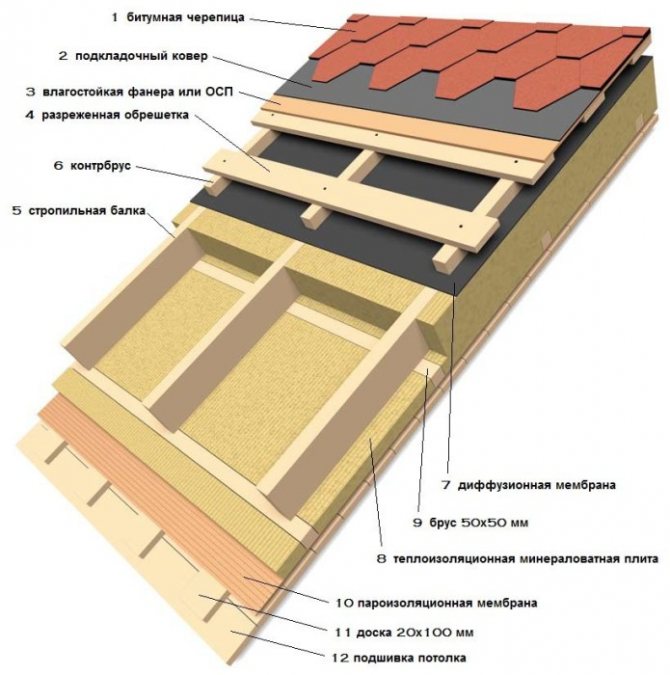

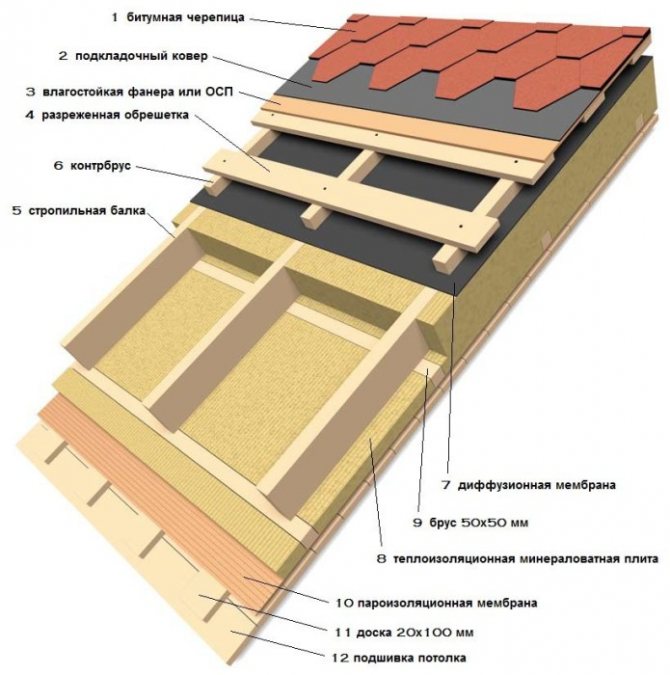

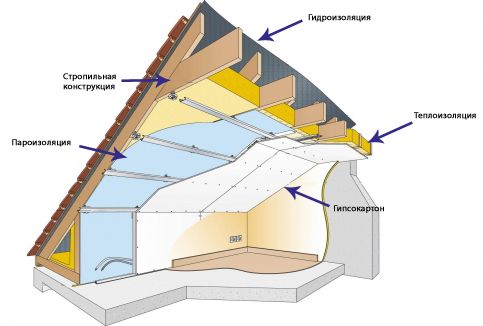

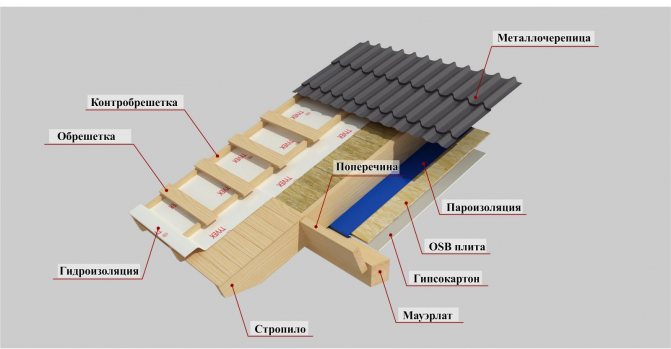

So, special attention should be paid to the layers of waterproofing and vapor barrier. The first layer is waterproofing. Sometimes it is present, since it was originally part of the roof structure. If it is not there, then you need to lay a hydro-barrier type film between the rafters and the roof: it perfectly retains moisture and allows steam to pass through. The rafter components are completely covered with a film, reinforcing it with a construction stapler.

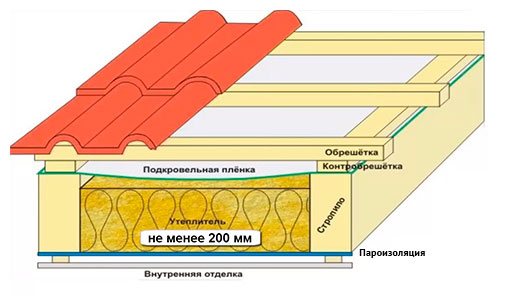

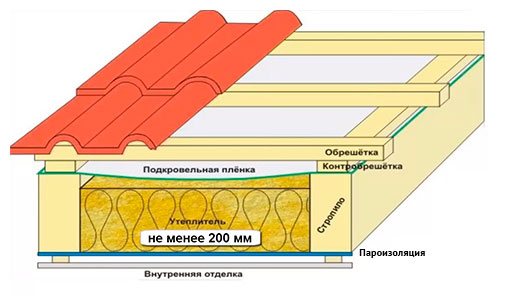

After waterproofing, the insulation material is laid directly. As a material, you should pay attention to mineral wool, which can be in the form of rolls and slabs with a minimum thickness of 10 cm. It is important that the interlayer does not exceed the thickness of the rafters.

Laying the material between the rafters should be tight, without gaps. Additional fastening to the insulation will be given by a stretched cord made of nylon or wooden slats, which are nailed perpendicular to the rafters.

Wooden house and roof insulation

Initially, the device of a gable roof cannot withstand the ingress of moisture into the house, and heat preservation also leaves much to be desired, respectively, the master will need to do both hydro and thermal insulation with his own hands. If everything is left as it is, then almost a quarter of the heat loss for the whole house will be attributed to the roof.

Thermal insulation of the roof of the house

The specific material is selected in advance, based on the allocated funds for the repair work, since this decision can significantly change the final estimate. Specifically for a wooden room and a roof on it, a stone mineral wool is suitable.Which vapor barrier is the best does not matter, since the characteristics of the materials are approximately the same.

The material is purchased either in the form of solid mats or in the form of separate plates, the size of which is selected from the distance between the rafters. In any case, all created gaps are additionally sealed with a sealant. You also need to take into account that the mineral wool device is such that after some time the material will shrink. A layer of waterproofing is applied on top - individual layers are placed with an offset, and the joints that result are treated with a sealant

You should pay special attention to construction tape, since a potential replacement of insulation with your own hands is very difficult.

The material itself must have a porous structure so that you can "breathe", since a certain amount of moisture will still accumulate in it. The fact is that in warm rooms, in any case, water evaporation will rise, and one should also not forget about the difference in temperatures, which is characterized by the appearance of condensation. The device of superdiffusion membranes makes it possible not to let water through, but allows steam to escape.

Waterproofing can be provided by installing reinforced film or polyethylene with your own hands, but then you need to leave a small space between the insulation and its layer. This is required for the wooden house itself, so that the air flows move freely through it - otherwise deformation of the wood, the appearance of mold, fungi, and decay are inevitable. Much depends on certain operating conditions, but it makes no sense to make such a gap more than 10 cm.

The fixation of the material to the rafters will take place with a construction stapler, and from the inside the roof is insulated with a layer without breaks and joints. The device of a wooden house involves the creation of a vapor barrier layer, otherwise the roof will suffer from rotting. It is required to cover the insulation on the opposite side, where the waterproofing layer is located, and the specific material is selected individually.

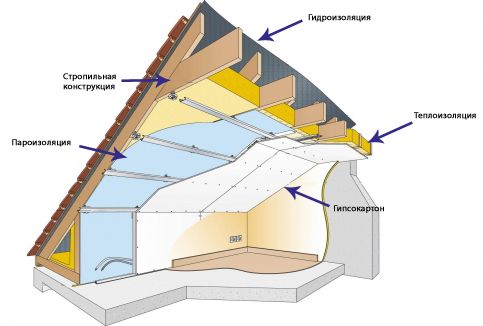

Vapor barrier

Steam insulation follows the insulation: a vapor barrier film should be used as a material. It fits on top of the heat-shielding layer, and is also strengthened along the rafters. If an attic is built from the attic, then it will be right to take care of the decorative finish of the insulated roof.

The finishing layer is sewn on top: it can be chipboards, gypsum cardboard. You can glue the wallpaper on top. You can finish with plasterboard or chipboard. When equipping an attic type roof, thermal insulation must be combined with a special reflective film on an aluminum base. The side of the film, coated with a special reflective compound, is attached from the outside.

The main purpose of the film is to reflect ultraviolet rays in the summer months - this will reduce the heating of the air in the attic. A waterproofing film to protect the insulation from fumes present in the heated air, on the contrary, is placed on the inside.

Some helpful tips

- There is a foam ceiling tile - it itself protects pretty well from the cold.

- Do not dwell on ceiling insulation. Walls and floors can also allow heat to pass through.

- If there are difficulties with do-it-yourself insulation, it is better to contact the masters who will do everything correctly. An unreliably insulated ceiling is practically useless.

- Plasterboard lining requires the use of a galvanized iron profile. Why is this needed? If you do not do this, you can soon suffer from a fallen structure.

- In a wooden house, it is better to insulate the ceiling in the summer months, so that excess moisture has time to evaporate by autumn and cold weather.

Insulation of the ceiling in a wooden house will protect the room from the inside from heat loss. If the ceiling is not insulated, all the work should be done immediately upon arrival.

domzastroika.ru

Materials for the outer part

External insulation of the roof of a wooden house no longer requires cotton wool - it is too soft - but a more durable material. Insulating foam is suitable in this capacity: it has very good heat-saving characteristics, it is durable and fireproof.

Laying steps

The technology does not require much effort and consists of a sequence of the following actions:

- creation of a barrier from a film with vapor-proof properties;

- arrangement of an insulating layer due to foam plates;

- lining of roofing material or synthetic analogue in protection from water (strengthened with mastic resin glue);

- backfilling of materials.

This is the classic version that is used all over the place.

Polyurethane coating

However, it is not the only one: modern owners also use polyurethane foam as a material, which is much more effective than foam.

It is not worthwhile to carry out insulation with your own hands: it is better to contact specialists who use the material in cylinders. The procedure is carried out as follows:

- the roof is being prepared - an inspection, a survey of the owners of the house and the development of a work plan;

- polyurethane foam is applied.

The final layer receives all the quality necessary for full-fledged insulation and lasts about 25-30 years. This technology saves a lot of time.

What materials are used to fill the ceiling

Of course, to provide good thermal insulation, it will not be enough to insulate the wooden roof of a house using only boards and clay. To save as much heat as possible, the ceiling is additionally covered with some of the heat-insulating materials. You can use wood chips, sawdust, clay or slag for this purpose, sometimes glass wool or foam is chosen. At a layer of insulation for thermal insulation of ceilings, the thickness is determined depending on the climatic zone in which the house is located, as well as on the material. Near the pipe in houses with stove heating, the backfill at a distance of 30 cm is made of non-combustible materials, the vapor barrier layer in this case is made of clay. Slag and earth keep heat very poorly, therefore, if it is impossible to choose any other material for backfill, the layer will have to be made at least 30-35 cm.

It is necessary to fill up the ceiling in a wooden house, having made a preliminary calculation of the load on the floor. For example, expanded clay is much lighter than earth, and other materials differ in weight. And if you cover it with a thin layer, in order to insulate the roof, this may not be enough.

When choosing boards for the ceiling and calculating the distance between the beams, this should be taken into account, since the weight of the insulation can be quite significant. It would be wrong to just fill the insulation with a layer on the wooden ceiling of the house; you need a vapor barrier device. For vapor barrier, roofing material is used more often than other roofing materials, but you can also use other similar material that will need to sheathe the room. It is not laid on top of the insulation, but under it. Here, the material from which the roof of the house was made and the height will also matter. In order for the insulating layer to be well ventilated, moisture must not accumulate in it. For more reliable thermal insulation, the ceiling can be sheathed with something.

Final stage

Insulation of the roof of a wooden house is completed with insulation of the floor and ceiling of the attic, which will not allow warm air, striving upward, to collide with the currents of cold air descending from the non-insulated ceiling. The thermal insulation layer is arranged with waterproofing elements.

First, all the gaps between the beams, beams are clogged with tow, felt, or foam insulation is used. Further, the space between the beams is filled with mineral wool, expanded clay and slag are placed on top.If the attic space is used as a living space, then it is correct to insulate the wooden floor, leaving a small gap between the boards and the insulation, which also helps to reduce the formation of condensation.

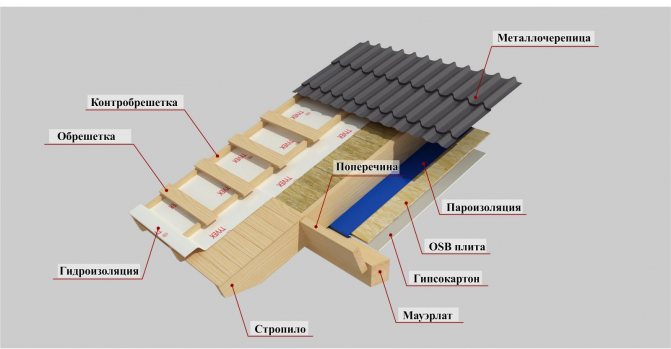

What elements does the roof structure of a wooden house consist of?

The roof structure of a wooden house consists of the following parts and assemblies:

- the main structure, which includes wooden beams, built (prefabricated trusses) a system of bevels and struts installed between them;

- bases for the roof;

- heat and waterproofing layer;

- actually the roof itself.

The roof girder structure is used with a span length of less than 4.5 m, and trusses - 5-10 m or more.

elements of the roof of a wooden house

The device of the roof of a wooden house requires from the homeowner certain knowledge and skills in working with wood. That is why, most often, outside specialists are invited for the construction of the roof.

Mauerlat

The structure that serves as the basis for the rafters is called a mauerlat. The service life of the roof depends on the quality of manufacture. It is laid along the perimeter of the walls. This design is designed to solve the following tasks:

- Uniform distribution of the load generated by the nodes entering the roof. In addition, the Mauerlat reliably ties the roof structure to the house.

- Reducing windage, that is, resisting the effects of the wind.

Mauerlat

In practice, there are houses built without it. That is, the rafters are attached directly to the last crown. In this case, in the places where the rafters are attached to the crown, there are places of stress concentration, while the Mauerlat distributes them evenly.

To create this structural element, pipes made of metal, timber or boards sewn together are used. The construction of the roof begins with the construction of the Mauerlat.

Rafters

On the surface of the rafters, a crate is installed, that is, a building, they take on the weight load that the roof will create. In addition, they resist rain and wind loads. Rafters are inclined and hanging. The rafter system of a gable roof of a wooden house should be treated with various compounds that will protect it from moisture, fire, fungus. Otherwise, after a fairly short amount of time, the roof may need to be reworked.

Runs

Parts such as purlins are also part of the roof structure. It is placed horizontally, resting on load-bearing units - walls, trusses, etc. It can be made of metal or wood. It is permissible to make it from reinforced concrete.

Three types of girders are used in the roof - ridge, side and Mauerlat.

Puffs

The tightening is used for the hanging system. She fixes the rafter legs together and allows him to creep.

Racks

The racks are installed vertically, they take the load from the ridge and redirect it to the non-load-bearing walls inside the house.

Braces

These parts are, in fact, the transmission link between the rafters and other load-bearing components. By connecting tightening braces, etc., the result is a solid structure

Sill

For the manufacture of this roof part, it is necessary to use a beam with a section of 100 * 100 or 150 * 150 mm. It must be installed on an internal load-bearing wall.

Lathing

At an angle of 90 degrees, boards or beams are laid on the rafters. They additionally fasten the entire structure. By the way, you can put an unedged board on the crate. But, the bark must be removed from its surface.

If it is planned that the roof will be covered with soft material, then the lathing should be solid. For this, it is permissible to use waterproof plywood.

Filly

This detail is responsible for obtaining the overhang of the roof. They are installed only when the lengths of the rafters are not enough. The fillets are boards with a smaller section than the rafters.

Heaters

108 votes

+

Voice for!

—

Against!

The construction of wooden houses is gaining popularity again, because many people like their unique air with a special scent of wood. If, for some reason, the building was not insulated during construction, this must be corrected. In order to keep warmth in a house made of wood, it is necessary to make thermal insulation of all surfaces: floor, walls, ceiling and roof. In this article, we will talk about how a wooden roof is insulated with our own hands using the most common methods.

The need to insulate a wooden roof

Wood itself is an excellent insulating material. And when operating a residential building, you should use these properties and try not to disturb the natural convection of air in the rooms. Due to the thermal insulation of the roof made of wood, the beams of the house floor will be protected from decay and will not deteriorate prematurely.

If you incorrectly insulate a wooden roof and disrupt the movement of air flows, then dampness will arise, a fungus will appear on the rafters, floor beams and the ceiling and other unpleasant consequences. To prevent this from happening, it is necessary to carefully consider the choice of heat-insulating material, taking into account the fact that the roofs of wooden and brick houses are very different from each other. Therefore, the materials used to insulate brick buildings are not suitable for wooden houses.

Special heat-insulating materials should be used for insulating wooden roofs, which are distinguished by a long period of operation, resistance to moisture and various loads, the ability to prevent the formation of cracks and deformation, and the absence of the risk of shrinkage, as this leads to the appearance of cold bridges.

For many years in a row, straw was considered the best insulation for wooden roofs. Today there is a wider selection of materials for thermal insulation of wooden house roofs. Since wooden houses can easily ignite, it is customary to use materials that do not ignite, say, fiberglass and mineral wool.

Features of the insulation of a wooden roof

If the house was recently built, insulation cannot be carried out until the wooden structure shrinks. After construction, at least a year must pass. In this case, you must completely complete the finishing of the roof. It is possible to undertake thermal insulation work only after the elimination of all defects that appeared as a result of subsidence of the house.

If the residential building is many years old, you need to approach the roof insulation of a wooden house more thoroughly. If the roof has been leaking and has been exposed to temperature fluctuations and moisture for a long time, it may require major repairs or a new overlap. Carefully inspect any areas that you doubt the integrity of, and check the wood for decay.

But if the attic will be used as an attic or as a storage room, or in your region winters are too harsh, then it is not enough just to insulate a wooden roof, you need to simultaneously insulate both the roof and the floors between the attic and the living quarters. Be sure to insulate both the ceiling inside the house and the floor of the attic.

When equipping a mansard-type wooden roof, it is advisable to combine thermal insulation with a special reflective film, which is made on an aluminum base. The reflective side is attached from the outside. The main purpose of the film lies in the reflection of ultraviolet rays in the summer months during the activity of the sun, which should reduce the heating of the air in the attic.

Do-it-yourself wooden roof insulation

It is not necessary to be a qualified builder to perform work that involves roof insulation.It is enough to watch a video about insulating a wooden roof and understand that you cannot save on thermal insulation materials.

Roof insulation with mineral wool

Thermal insulation of a wooden roof with mineral wool is highly efficient and durable. The low weight of the mineral wool determines the minimum mechanical stress on the roofing structure. Mineral wool is suitable for long-term use and in summer it withstands high temperatures well, unlike foam.

If you plan to insulate the roof with mineral wool, then it is advisable to use mineral wool mats, and not roll material, since they do not settle over time and keep their shape better. But even when buying material in mats, it can be easily adjusted to the dimensions of the gaps between the rafters. The material can be cut and cut.

When carrying out work, you must strictly follow the following scheme for insulating a wooden roof with mineral wool:

- The first layer is waterproofing. If you are looking for the most economical option, then you should use a conventional waterproofing film that does its job well. But if the effect is important to you, it is better to buy a superdiffuse membrane. The insulation can be attached to it close to it, without making an additional crate for ventilation. Its vapor permeability is much higher than that of conventional waterproofing.

- Insulation. The thermal insulation material must be laid in 2 layers in the cavities that are formed by the roof rafters. It is customary to lay it in a dense layer of 10-25 millimeters. Its thickness will depend on the climate in your area. The insulation should be laid so that there is a ventilation gap between it and the upper edge of the rafters, which serves to remove the warm moist air that enters from below. But at the same time, you need to ensure that the thermal insulation material does not crawl out of the rafter system. Do not cover cables and wires with mineral wool slabs.

- Vapor barrier. On top of the insulating material, a vapor barrier material is attached to the rafters, which is required to trap the moisture-saturated air that rises up. To exclude the penetration of moisture, it is customary to glue all the seams of the film with special construction tape. Therefore, the insulation will be in the so-called moisture-proof "bag", but the ventilation gaps will ensure the normal ingress of air. The roof covering can then be laid.

Thermal insulation of the roof with expanded clay

Expanded clay is called the most environmentally friendly material of all that is used for roof insulation. Therefore, it is ideal for insulating a wooden roof. Such insulation is considered durable, it does not shrink and is not spoiled by rodents. If you place the material correctly, the likelihood of cold bridges formation is minimized.

In addition, the cost of insulating a wooden roof with expanded clay is acceptable: there is no need to invest large sums, you just need to purchase roofing material in rolls and a sufficient amount of expanded clay.

And it is worth acting according to this technology:

- To begin with, close all the slots so that the material does not spill out. In this case, a special film will not work - it may not withstand the load. Therefore, it is customary to lay roofing material on the floor. In this case, an overlap should be made on the surface of the walls.

- Fill with material. Do this carefully, because the properties of expanded clay deteriorate with intensive filling: many particles can break, losing their thermal insulation capacity.

- From above, you can also cover the insulation with roofing felt, which will simultaneously act as a waterproofing material.

Roof insulation with expanded polystyrene

Expanded polystyrene is not the best insulation for a residential building made of wood, but if this particular material was chosen, then you should pay attention to its flammability group. The most optimal option out of the existing four groups is G1.Expanded polystyrene with this marking burns only when it comes into contact with a fire source.

Expanded polystyrene has a number of advantages: lightness, the ability to cut it without special equipment, the ability to keep warm well even at high humidity, resistance to fungal attack and harmful insects.

It is necessary to insulate a wooden roof with expanded polystyrene according to the same scheme as when using mineral wool. The only thing: at the joints of the slabs, it is imperative to fill in the gaps, as shown in the photo of the insulation of a wooden roof. It is most convenient to do this with the help of polyurethane foam, because it is able to be evenly distributed over the entire hole without gaps. In addition, this procedure does not take much time.

Final works on thermal insulation

If you have completely insulated a wooden house and its roof, then the ceiling must be insulated due to the peculiarities of wood as a material. Warm air in a wooden house, rising to the ceiling, will carry with it particles of moisture, which settle on the ceilings and ceiling and provoke the process of wood decay and the formation of mold. Thus, it is necessary to install a heater with waterproofing elements on the ceiling. The scheme of thermal insulation of the ceiling in a wooden house with a pitched or flat roof and an attic looks like this:

- Air cushion - the free space between the thermal insulation material and the ceiling slab to prevent condensation from forming.

- Thermal insulation using fireproof insulation material.

- Vapor barrier is a membrane or film that prevents the penetration of capillary moisture to the ceilings.

- Interior decoration.

After that, you can begin to warm the floor in the attic, which is done as follows:

- Eliminate gaps between beams and beams. You can caulk them with tow, jute or felt, or fill them with polyurethane foam.

- Lay a layer of vapor barrier on the floor of the attic, place a layer of insulation on top of it - without gaps. You can use polystyrene or mineral wool as insulation.

- Sprinkle the floor surface with a shawl or expanded clay, followed by a screed. If you plan to use the attic, you can arrange a wooden floor.

In addition, you can use foam insulation or liquid polyurethane foam to insulate a wooden roof, which is an inexpensive and effective material. It is customary to apply it by spraying directly onto the insulated surface. The whole procedure takes a minimum of time. The price of insulating a wooden roof with penoizol is low. In this case, there is no need to additionally prepare or dismantle the base. The work is completed as soon as the desired layer thickness is reached.

How to properly insulate the roof in a wooden house from a bar

Before insulating the roof, the homeowner must understand from which side this work will be carried out. The roof can be insulated both outside and inside. Based on this, it will be possible to decide which insulation is best for the roof.

But it is necessary to understand that internal insulation is fraught with a number of difficulties. External insulation is easier, but you need to stock up on the means to do the work at height.

After choosing the method of insulation, it is necessary to prepare everything you need:

To execute the sectors, in appearance, this is a crate, its width should be of such dimensions that it will allow laying both insulation, hydro and vapor barrier. In addition, you must have an adhesive tape, a stapler on hand. That is, it can be said that, with appropriate preparation, roof insulation is not such a difficult operation.

The insulation procedure looks like this.

After the rafter system is built, its crate must be upholstered with a board. The result should be a structure consisting of many cells, which are intended for laying insulation.

Before laying, the resulting structure must be treated with impregnation. Then, at the bottom of the boxes, it is necessary to arrange a vapor barrier for the roof; you can use, for example, a diffusion membrane. And only then the insulation is punctured. Its dimensions should be slightly larger than the size of the mesh in which it will be laid.

If, instead of mineral wool or foam, a loose insulation is used, then it must first be prepared. Sawdust can be used as a base, to which cement can be added. The stacking order looks like this. The box for the heater, in which the steam protection has already been placed, is closed with boards and thus a cavity will be formed, where the mixture is poured.

When performing work on insulation from the inside, all work is performed in the reverse order.

How to improve the yard of a private house

Everyone knows that the inner content is no less important than the outer one. But when it comes to a private home, good looks are a must. Crumpled lawns and old decorations tell a story of negligence. That is why we must not forget about the appearance of the house and the yard area - it becomes even more important when you are trying to sell a house. When it comes to showing your home to a potential buyer, it is important that you focus on both the interior and the exterior of the property itself. With well-groomed lawns and clean paths, you can paint a picture of comfort and well-being.

See also: What are awnings for?

Roof types

Before you build a roof, you need to make the final choice of the roof structure, it makes sense to get acquainted with those types of roofs that are often used in suburban construction.

Varieties of forms

The key factor to be considered when choosing a roof structure is the climate zone. It is the climate that will affect the slope, shape and roofing material.

Indeed, it makes no sense to construct a roof with a low slope in regions where heavy snowfall is common.

A wooden house with a flat roof has its advantages - they are quite cheap in construction, such a roof will not be blown away by the wind, but water and snow will linger on the surface of such a roof. Sooner or later, it will lead to damage and replacement of the roof.

The mansard roof gable roof has a more complex structure, but its construction will allow you to organize an additional room in the under-roof space.

Thermal insulation methods for wooden ceiling structures

Numerous technologies for insulating ceilings in wooden houses are divided into two groups according to the place of installation of the insulation:

- from the side of residential premises (from the inside);

- from the side of the attic (outside).

Both approaches have their advantages and disadvantages. So, insulation of the ceiling in a wooden house from the inside will save money, but will reduce the useful volume of living quarters, and insulation laid outside will require additional protection from mechanical damage and more powerful hydro and vapor barrier, which will entail an increase in insulation costs.

In the classic version, the thermal insulation layer has the following structure:

- external vapor barrier;

- insulation material;

- lathing;

- internal vapor barrier;

- sheathing.

Roofing material

During the construction of a wooden house, any homeowner is faced with the question - what is the best roof covering. On the market, a wide selection of roofing materials is presented to the attention of the consumer. Let's consider the main ones.

What should be guided by when purchasing roofing material. In the first place is the load that occurs during operation. It must withstand snow and wind loads. The mass of material also plays an important role. And of course, it is necessary to take into account the technical characteristics of the material - durability, strength, resistance to corrosion and to the action of fire. In the construction of wooden houses, such groups of materials are used.

Leafy.The main advantage of this type is the relative ease of installation, on the other hand, these materials are difficult to use when working on roofs of complex shapes.

Metal tiles. Hot-dip galvanized steel sheets are used for manufacturing. Many manufacturers coat such sheets with a polymer coating. It can be used in the construction of any buildings. It can even be laid over an old roof.

Slate. For its production, cement and asbestos fibers are used. Sheets made from this material can be flat or wavy. It can be used for all types of roofing. When dwelling on this material, the homeowner should remember that in some countries, slate is prohibited. It is considered a carcinogen.

Ondulin is a sheet made of cellulose fibers that are impregnated with bitumen. The front side can be coated with a polymer coating. This material is most often used in the construction of small houses.

Having carefully understood the methods of assembling the roofing structure, you can come to the conclusion that the roof of a wooden house with your own hands is not such a complicated operation.