Heating equipment is regularly improved by designers, which allows manufacturers to produce attractive solutions for a variety of performance characteristics. For example, most consumers are interested in compact convector-type devices. They differ in their small size, original design style and ergonomics, but at the same time, such devices are not able to fill large rooms with heat. For such cases, it is recommended to use diesel heaters, also called heat guns. These are more massive units that require regular fuel filling, but at the output they provide high heat transfer with minimal financial costs.

General information about diesel heat guns

At first glance, the design of such a heater may seem overly complicated and impractical. While the same convectors and radiators are almost invisible wall panels, diesel heaters include several working components, including a combustion chamber, a fuel tank, a fan and several communication channels. The multi-component structure is due to the principle of operation, the effectiveness of which just justifies the design flaws.

During operation, fuel is burned with heat generation. A fan is used to dissipate the generated heated air currents - it must be directed to the target area. Actually, such a principle of operation led to the second name of the unit - a heat gun. An important advantage of the equipment is independence from energy sources. As a rule, a standalone diesel heater does not require a power supply from the mains, since its function is provided by energy from the combustion chamber. However, there are also combined models, in which the fan is separately supported by electricity.

Homemade ovens: assembly options

If you want to save money, you can try to make a diesel stove for the garage on your own. Consider the most basic options for structures of a similar plan and understand the specifics of their manufacture.

Option number 1 - from a used gas cylinder

A diesel fuel stove can be made from a used gas cylinder. And if there is one, then consider that half of the structure is already ready. The main requirement for the manufacture of such a structure is the wall thickness of the cylinder - it should not exceed the 1.5 mm mark.

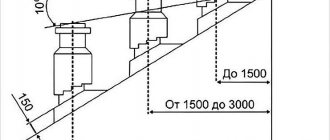

The next step is the selection of a pipe for the chimney. A piece of pipe with a diameter of at least 10 cm will do. The chimney must be at least 4 meters long. Recommended metal wall thickness is 2 mm.

In this case, the fuel tank can be made from any tank with a volume of no more than 15 liters, but no less than 8. The remaining components are purchased in a specialized store - steel corners with a shelf size of 20 cm - for future legs, and a copper burner.

To make a diesel stove for a garage on your own, in this case, you will need the following tools:

- Bulgarian;

- drill;

- welding machine;

- roulette;

- building level.

The principle of the gas cannon.

Algorithm for creating a diesel heater:

- We release the container from condensate and rinse it from the odorant.

- Using a grinder, cut off the upper part where the valve is located.

- The lower part of the cylinder will act as a camera - we weld the legs to it, which are steel corners. The upper part is the cover of the future stove. In order to ensure the possibility of adjusting the fuel supply, a special valve is mounted in it.

- After the stove is assembled and installed in the required place, we proceed to the installation of the chimney. It should be positioned strictly vertically. This nuance should be taken into account when choosing a place for installing a heater: it should be located only in the place where it is possible to mount the chimney without bends and slopes.

For reference! The balloon can be placed both vertically and horizontally. In the first case, it is possible to use the metal legs of the structure as air ducts.

Advice! Firing up a stove is a process that requires special attention. The cylinder must be filled 2/3 with fuel, on top of which a paper sheet is placed. Then you should lower the lid and wait for the diesel fuel vapor to light up. It is also prohibited to add fuel while the heater is in operation.

This type of construction works exclusively on diesel fuel or purified waste oil without water and alcohol impurities. The use of gasoline and kerosene as fuel is strictly prohibited.

Option number 2 - from a welded tank

The structure can be made by welding heat-resistant steel sheets, 4-6 mm thick. The only thing is that you need to purchase or rent a bending machine. Other consumables and tools are more freely available.

Most of them are in the arsenal of any man, while others can be purchased at a hardware store.

It is possible to implement this version of a diesel furnace with the following tools and consumables:

- steel corners with a shelf size of 20 mm - future legs of the structure;

- burner pipe;

- smoke exhaust pipe - Ø10 cm and 4 m long;

- roulette;

- Bulgarian;

- file;

- welding machine;

- building level;

- a hammer.

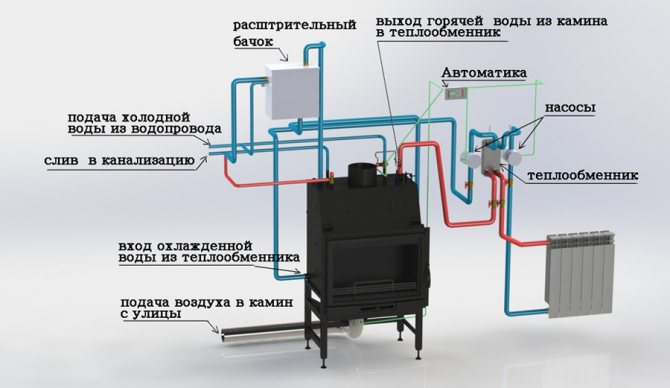

The result should be a compact -70x50x35 mm and a relatively light heater - about 26 kg. The structure, when properly assembled, is stable, easy to use and effective in terms of the speed of heating the room. Also, if there is an opportunity and desire, such a device can be connected to a water heating system.

For reference! Stoves made of heat-resistant steel are distinguished by high indicators of durability. Garages and workshops are often equipped with these. Such devices are capable of operating on diesel fuel, waste oil and diesel fuel.

Heat gun device.

The bottom of the fuel tank and its lid are made of a thick steel sheet - 6-7 mm, and the tank itself is cooked from 4 mm thick sheets. First of all, it is worth choosing a scheme for the future design - it can be found on the Internet.

According to the selected scheme, sheets are cut out, which then need to be welded together, and the seams are processed with a file.

The tank tube is not difficult to manufacture: we cut out a strip of metal 4 mm thick and 115 mm wide, bend it with a ring and weld it to the tank. You should get a pipe of Ø34-34.5 cm. It must be equipped with a lid: it is cut from a 6 mm thick sheet and welded to the pipe. And then we move on to making the legs.

The fuel tank is made of 6 mm steel sheets. We cut out a round piece Ø35.2 cm and a strip 6 mm wide. In the center of the circle we drill a hole for the future chimney - its diameter depends on the diametrical size of the chimney.

The optimum hole size for the structure will be 100 mm. You will also need another oil fill hole. It is slightly smaller in size from the previous one - 50-60 mm, and is located at a distance of 40 mm from the flue duct.

The lower part of the body is made of thicker metal - we need a circle of Ø35.2 cm. In it we make a hole for a pipe Ø100 mm, positioning it in such a way that between the center of the circle itself and the center of the hole it is 110 mm.

Cut out a 7x33 cm rectangular partition from a 6 mm thick sheet and weld it to the circle, moving it closer to the branch pipe. The exhaust pipe is made from a piece of chimney - 13 cm in length will be quite enough.

For the manufacture of the burner, we drill 48 holes Ø9 mm in the pipe with a pitch of 60 mm from each other. As a result, we should get 6 rows, each of which has 8 holes.

Now we turn to the installation of the burner: we put it evenly and tightly in the tank lid, correcting inaccuracies with a file. A 16 cm pipe is inserted into the fuel tank, after which we connect the upper and lower parts without using a welding machine.

To seal the structure, it is advisable to use a Ø35.4 cm ring. It remains only to completely assemble the structure and install the sliding plate in it.

Option number 3 - drip-type model

To implement this version of the stove, you will need a conventional rubber burner with a 2-liter hose. We attach a copper tube 1-1.5 meters long to the hose, having previously bent it with the letter "G".

Then we bend the hose in half and fix it with screw clamps. The burner itself is placed on the wall and fuel is already poured into it. The fuel delivery rate is regulated by means of a screw.

The wick will be made of rags: we form it with the help of a flexible metal wire, which must be wrapped in a rag and soaked in diesel fuel. The best option would be to use an old mattress, which must be chopped into 20x10x4 cm fuel briquettes.

Such briquettes impregnated with fuel will burn perfectly. If the stove is large, then it is advisable to put a brick under the wick, thereby increasing the efficiency of the heating equipment.

The oven can have any configuration. It can be crafted from a piece of an old metal barrel. The main thing is to weld or visit the door and equip it with a chimney. A hole is made for fuel, which is equipped with a copper pipe coming from the burner.

If you make this hole on the side of the barrel, then the stove can be used not only for heating the room, but also as a hob.

Basic selection parameters

Thermal power is a key parameter to be guided by during the selection. And here it is important to carry out the correct calculations of the ratio of power and area of the room. To begin with, it should be noted that the main array of diesel heat guns has a potential of 10 to 100 kW. The calculation is made in this way: 1 kilowatt is able to provide about 10-12 cubic meters of heat. m. That is, a 10 kW unit will be enough for a small house. But much of the efficiency of the equipment will also depend on the performance. The power base of the fan installation is already responsible for this parameter.

Diesel heaters, which direct air at a speed of 250-300 m3 / h, are considered the best solution for private houses. If we are talking about technological heating of a specific area within the framework of the production process, then this value increases. And if, in addition to the combustion chamber, an electric motor is provided in the design, then it is important to initially assess the power supply needs of the installation, that is, to determine the number of phases. Single-phase models are powered from a 220 V power supply, and more powerful three-phase models are powered from 380 V.

Diesel stove for a garage - do-it-yourself selection and production

For most men, a car garage has become a second home. Here it is possible not only to do car repairs, but also to make something, save tools and materials, fishing tackle, and also just spend time in the company of hobby employees.

For a comfortable stay of a person in this room, like a small car garage, it is required to maintain a good air temperature in it.To cope with the difficulties of heating can help, according to pechnoy.guru, a diesel oven for the garage.

Devices of this type are both factory-made and home-made. The main type of fuel on which they work is diesel fuel, but you can also use fuel oil and waste engine oil.

Varieties of diesel heaters

It is possible to conditionally divide the entire range of diesel heaters by areas of application. Thus, the usual indoor, industrial, automobile and suburban models will be highlighted. Indoor rooms are small in size and often provide for a combined principle of energy supply - this allows you to minimize the amount of harmful emissions. Industrial units are characterized by high power, dimensions and can also be powered from the mains - as a rule, 380 V.

Diesel car heater is also widespread, which, on the contrary, has a modest design and low power. The heat output of automobile "guns" rarely exceeds 6 kW. They have their own characteristics and models, designed for use in conditions remote from the city. These are suburban units, in the creation of which the emphasis is on autonomy and complete independence from the power supply.

With a direct or indirect principle of operation?

This is a fundamental difference in diesel heaters that is important to consider when choosing. The direct operating principle assumes that harmful emissions will be carried out directly into the open space of the working area. That is, in the room where the unit is installed. Such models are used either in open street areas, or in production workshops. For domestic purposes, use indirect diesel heaters. The complete set of heaters of this type includes a filter system and a special branch pipe for the ventilation duct. It is through this channel that waste substances are released, preserving the ecological cleanliness of the working space.

Advantages and disadvantages

Any option for creating or buying a stove to maintain the required temperature in the garage has both positive and negative sides. There is no need to dwell on the first option that comes across.

Only after considering and analyzing them, and also, taking into account all the positive and negative aspects, you can fully determine the choice in each specific situation.

Good points are:

- The low price of the fuel used and its low consumption when compared with wood or coal.

- A small amount of harmful emissions into the room space and weather air. But never forget about safety, every process of burning hydrocarbons is accompanied by the release of a life-threatening, insidious and invisible gas - carbon monoxide, which does not have an odor. Thanks to this, the issues of airing the room must be taken very seriously.

- The availability and materials are inexpensive to build such a furnace, all that is required is a little metal.

- The ease of making a similar stove, even a person who is far from the intricacies of metalworking can handle such work. All you need is to know how to use an angle grinder and inverter.

- Possibility of good operation in cold and warm seasons.

- Small dimensions of the heating unit.

There are fewer negative factors, but they also exist:

- The stove emits aroma from burnt oil products, and the effect of carbon monoxide on the human body was described above.

- The radiator needs constant cleaning, at least once a week.

- In the absence of care for a diesel stove, it very often fails.

- Heating appliances and other hot surfaces must not be used near a similar stove.

back to contents ^

What is the difference between a diesel infrared heater?

If in conventional fan models heat dissipation is carried out by directed supply of air flows, then in infrared equipment this problem is solved with the help of special emitters. With the help of reflective elements, the same energy supply occurs, but with a different effect. Thanks to active radiators, a diesel infrared heater does not heat the air, but the objects located near it. The principle of such heating has long been recognized as the most efficient and uniform. Already from the objects themselves, the air environment is heated, and the temperature remains longer than with fan heating.

Diesel Sheet Metal Heater

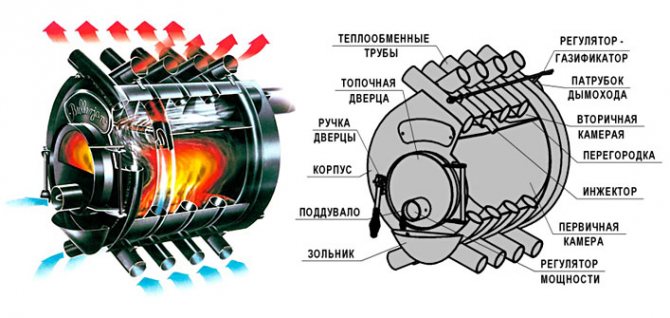

Outside, diesel ovens for a garage made of metal look like two discs docked together by a tube with a large number of holes and a discharge pipe for combustion products from above. The device is assembled from 2 containers, which are combined with a wick bowl, in other words, a wide pipe with holes for air supply and chimney.

Diesel fuel enters the wick container from the fuel tank independently. In it, diesel fuel is heated and converted into a mixture of gas and air. It enters the combustion chamber, where it ignites. A spiral placed on top of the furnace acts as a heat exchanger. It can heat up to 800? Waste is discharged through the chimney.

Such a design is harmless, economical and does not harm the external environment. For assembly, 2 metal sheets of 5 mm are required. The chimney is installed far from the door, it has two elbows nested into each other. The tank at the bottom is the combustion chamber and the fuel tank. Fuel is poured into it through the hole. The volume of the container is from 2 to 12 liters.

Manufacturers and prices

Diesel heat guns can be found from domestic and foreign manufacturers. In Russia, the production of high-quality equipment of this kind is carried out by the specialists "Prorab", "Interskol" and "ProfTeplo". Models of these manufacturers are available on average for 15-20 thousand rubles. A powerful, technological and functional diesel heater is presented by the world famous companies FUBAG, Master, Elitech, etc. These manufacturers specialize in engineering equipment, offering high-quality, but not cheap solutions with an average cost of 40-50 thousand rubles.