Italian gas boilers Baxi occupy a solid place in the heating equipment market due to their high efficiency, stable operation. even in adverse conditions and thoughtful stylish design... But, despite their high reliability, sometimes in the operation of Baksi boilers malfunctions occurcaused by violation of operating conditions or failure of individual elements of the boiler. Most often, you can eliminate them yourself, without resorting to calling specialists.

Work algorithm

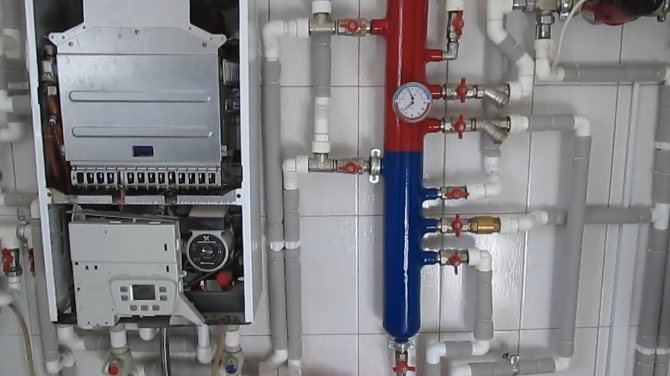

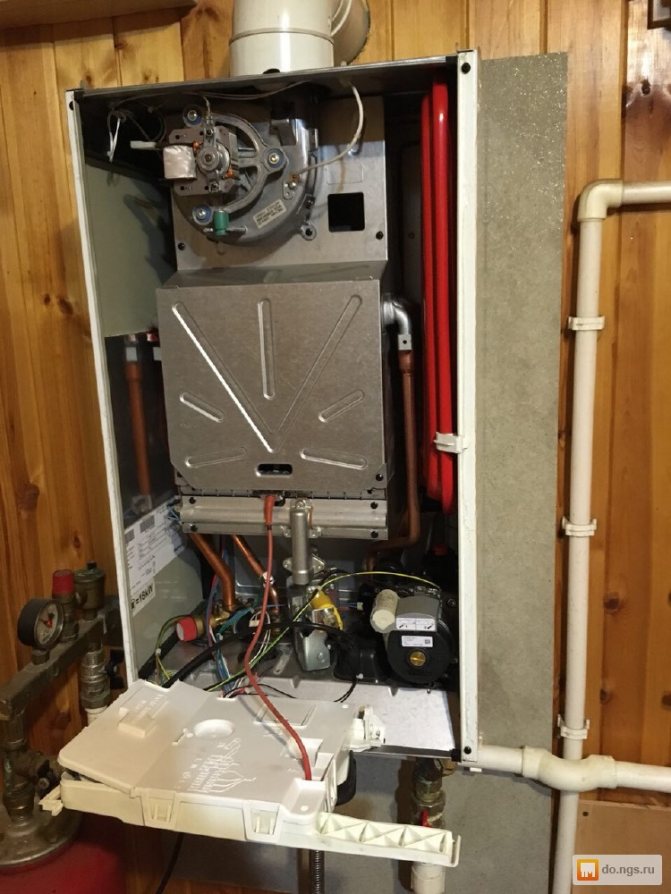

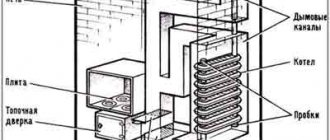

manufactures metal combustion chambers for its boilers. From the outside, the part is protected by a heat-insulating layer. There is a copper heat exchanger just above the chamber. When the heated room gets warmer or colder, the thermostat turns on. Its work is automated. The thermostat sends a signal to turn on the water pump. He begins to pump water due to the creation of a vacuum in the pipes. Then warm water enters the pipeline.

Boiler power increases gradually when switched on. This happens before the water temperature rises to the required value. Then the heating mode goes into modulation mode. When the coolant cools, the temperature sensor gives a signal to open the inlet valve. This starts the electric ignition, and the water temperature reaches the desired level again.

If the room does not need to be additionally heated, the boiler starts operating in the DHW mode. It consists in the fact that cold water enters the secondary circuit through a three-way valve, which, in turn, blocks the heating line. Gas is supplied to the burner using a special valve, and the power of the appliance gradually increases. When the water is already heated to the desired temperature, its regulation mode is activated.

Malfunctions and their causes

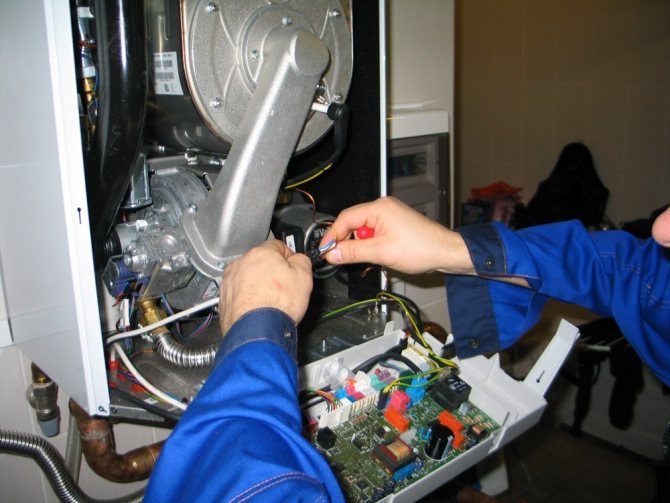

Boilers are good because in the event of a malfunction, it is possible to cope with the repair yourself, without resorting to calling specially trained people. True, it is acceptable to do this only if the malfunction is typical and can be eliminated according to the scheme. For those who have not had the chance to repair gas equipment, it is better not to repair Baksi boilers with their own hands, but to call a specialist. Among the typical malfunctions of units, the following are found:

- the burner does not ignite or constantly goes out;

- ignition does not work;

- there is a knock in the combustion chamber when the boiler is operating;

- exceeding the permissible temperature inside the device;

- the maximum water temperature becomes lower;

- the occurrence of loud noise during operation;

- breakage of temperature or pressure sensors.

The reasons for the failure of the Baksi boiler may be as follows:

- water ingress into the boiler;

- insufficient quality of the applied coolant;

- weakening or sudden change in gas pressure;

- power surge in the network;

- initial inaccuracies in the installation of equipment.

Possible breakdowns of baxi boilers

Repair work in baxi boilers should be done with your own hands only if there are visible and easily removable reasons for the breakdown. In the absence of experience in handling the units or in the absence of special tools, it is better to entrust the boiler repair to a competent foreman.

- - the boiler burner does not turn on or goes out;

- - ignition becomes impossible;

- - pops are heard in the combustion chamber;

- - the boiler overheats;

- - the maximum heating temperature of the coolant becomes insufficient;

- - boiler operation becomes noisy;

- - one of the sensors or system elements fails.

Reasons for the breakdown of baxi boilers:

- - moisture has entered the boiler;

- - water (heat carrier) of poor quality;

- - there was a drop or decrease in gas pressure in the gas pipeline;

- - there was a voltage drop in the mains;

- - the heating system has been installed incorrectly.

Troubleshooting Tips

The following points can be used as instructions for troubleshooting the Baksi gas boiler:

- The burner is not functioning at full capacity. Such an error in the operation of gas equipment may appear in a situation where the pressure inside the system is incorrectly adjusted. A similar problem also appears if the gas modulator is damaged. Or the diode bridge may be faulty. You can cope with this problem by adjusting the system parameters according to the equipment operating instructions.

- The heater turns off immediately after being turned on. This problem occurs in gas appliances due to low pressure in the gas pipeline. Possible remedy: it is necessary to adjust the gas pressure down to 5 mbar.

- The coolant does not heat up when turned on. To fix it it is worth rechecking the gas valve. Perhaps the minimum and maximum values have been reversed.

- The modulation mode is defective. This problem can be solved by reinstalling the valve.

- Temperature sensors show incorrect data. In this case, you should also dismantle the sensor, replacing it with a new one.

- The hot water supplied to the taps does not heat up sufficiently. To restore water heating, make sure that the three-way valve is fully open. This sometimes happens if this device is damaged. To be sure that the malfunction is caused by the valve, you need to wait a little until the system has cooled down. Then close the shut-off valves. Then switch the device to hot water supply mode. If, as a result, the heating system heats up, then it was in the valve, and it needs to be replaced.

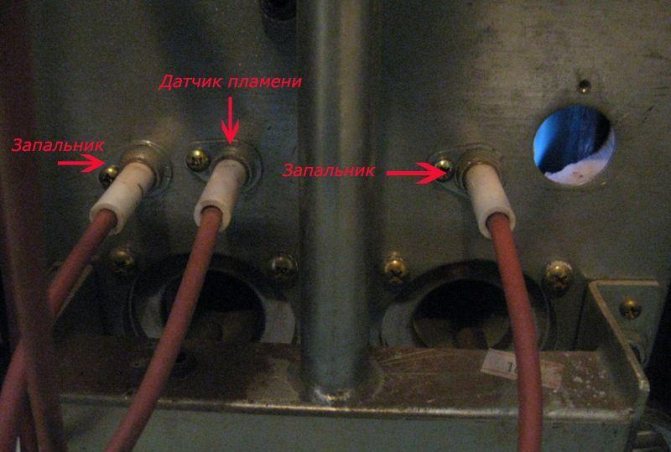

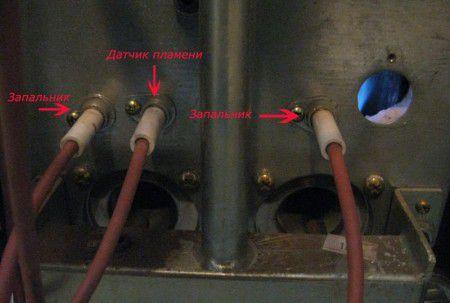

- Harsh jerks are heard when the burner is ignited. Abnormal noises can occur due to various factors: one of them is too low pressure in the gas pipeline. Another, it happens, happens due to improper transportation of the boiler, when the igniter is displaced, and the distance from it to the gas supply becomes more or less. The solution to this problem is to set the correct distance. It should be approximately equal to 4-5 mm.

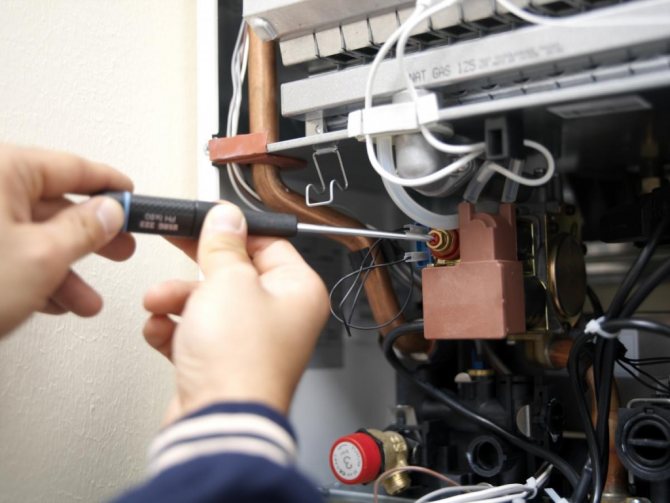

- You can adjust the gap between the igniter and the burner on the Baksi gas boiler as follows: the front panel is opened and removed from the device. When this is done, the shutter is removed from the inspection hole. There is an igniter. To give it the correct position, you need to unscrew the screw with which the electrode is attached to the boiler. The igniter must be removed, carefully folded and then returned to where it was, and then the damper must be closed.

- Strong decrease in the temperature of the coolant. This is often due to dirty filters. The only way to eliminate them is to clean them. Sometimes, in case of severe clogging, the filters must be replaced. It is also worth checking for damage to the pipeline. If, for example, the radiators are clogged or exposed to low temperatures, only repair will help. The damaged segment will need to be replaced or cleaned.

DIY Baxi boiler repair - Video lesson

Burner flame does not reach maximum power

The cause of the malfunction may be an incorrect setting of the pressure in the heating system, a malfunction of the gas valve modulator or a breakdown of the diode bridge.

Remedy: adjust the system parameters using the boiler operating instructions.

The boiler starts up and stops working immediately

The reason is the low gas pressure in the gas pipeline.

Remedy: reduce the value of the incoming gas pressure to five mbar (standard - twenty-five mbar).

Weak heating in the hot water system

The reason for this is the incomplete opening of the three-way valve or its breakage. To confirm a valve malfunction, let the system cool down, close the shut-off valves of the heating system, then turn on the boiler in hot water supply mode. If the valve is faulty, then simultaneously with DHW heating will occur in the heating system.

8450a73603b914af9982af52fad3309c.jpe

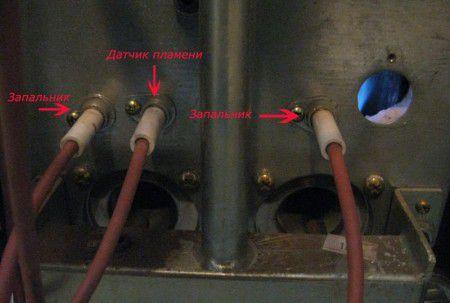

"Pops" are heard in the boiler during firing up

Such noise appears due to: insufficient combustion of the gas (adjustment of the minimum pressure is required); changes in the distance from the gas supply to the igniter during inaccurate transportation of the baxi boiler (you should adjust the size of the gap by setting it to 4-5 mm); excessive draft (using the damper to reduce the draft in the boiler).

How to adjust the gap between the burner and the pilot

Open the front panel and completely remove it from the boiler. Remove the flap from the inspection hole. Behind it is the igniter

To change the size of the gap, it is necessary to unscrew the screw to which the ignition electrode is attached, then remove and carefully bend the electrode. Then we put it in place and close the hole flap.

A sharp decrease in the temperature of the coolant in the circuit

The reasons for this are: clogging of filters (cleaning or replacement is required); damage to pipes, radiators, their clogging or freezing (the malfunction must be identified and replaced or cleaned the defective section of the pipeline).

How to clean the primary heat exchanger with your own hands (video)

We drain the water by unscrewing the tap on the boiler on the right. If possible, drain the water from the heating system. For cleaning we use a device called Jel. We connect the pipes of the device to the heating pipes of the baxi. We unscrew the lid on the device, fill in the cleaning liquid. We include Jelly in the power grid. Within a couple of hours, use the knob on the device to switch the direction of the flushing liquid "forward - backward". After two hours, turn off the device, turn off the tap to drain the water from the boiler. We remove the hoses, making sure that the flushing fluid is glass back into the device. We connect the boiler to the system, fill it with a coolant. Cleaning the boiler will remove scale from its parts and prevent clogging and breakdowns.

Cleaning the secondary heat exchanger (heating circuit)

We use the flushing device again. We connect it to the boiler, turn it on. Close the gas tap and open the hot water tap. And after that we turn off the device for cleaning. Thus, the liquid will be driven along the short circuit of the system.

Before installing the boiler, its operation and repair, be sure to consult with a specialist. Despite all the positive qualities of baxi boilers, they, like all equipment, have their own margin of safety and service life. In this article, we examined the main types of breakdowns, and also saw how to repair baxi boilers with our own hands. We wish you and your boilers success.

Cleaning the primary and secondary heat exchangers

First, the water must be removed from the heater. There is a tap on the right of the boiler, if you unscrew it, then the liquid will be drained. It would also be good to drain the water from the heating system. A special flushing device is used for cleaning. The branch pipes are connected to the pipes of the gas boiler. Then the cover is unscrewed on the flushing device, and then the cleaning liquid must be poured inside. Then you can connect the device to the network.

Cleaning the heat exchanger is not a quick process and can take several hours. During this time, it is necessary to switch the direction of the flushing fluid. Stop cleaning after two to three hours.After that, the tap opens and the water is drained, and then the hoses are removed. When doing this, you need to be sure that all the liquid is glass in the instrument. After all the manipulations, the boiler is reconnected to the heating system. The pipes are filled with a coolant. Rinsing the parts of the device should dissolve scale, which will increase the life of the system and optimize its performance.

Similar to the primary one, to clean the secondary heat exchanger, a flushing device must be connected to the boiler. Having connected it to the network, it is necessary to close the gas tap, and move the tap with hot water to the open position. Then turn on the device for cleaning so that the reagent moves along a short circuit.

To install Baksi gas equipment, you should definitely use the services of gas service workers. They will also help in the event of a malfunction in the boiler. Parts of the heating devices of this company can also wear out over time, so sooner or later, repairs will still be inevitable.

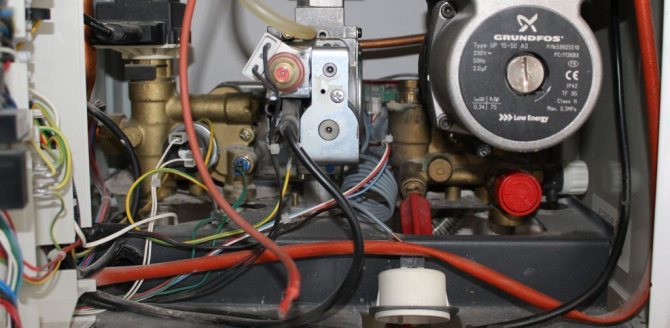

Actuators and control devices

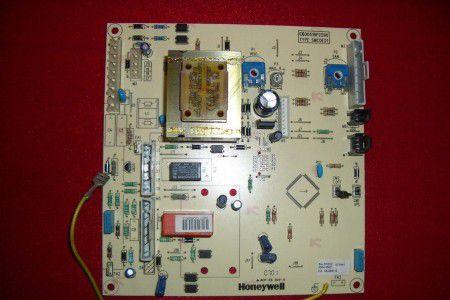

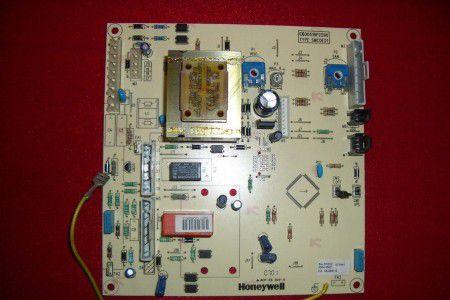

Any gas equipment is a device of increased danger, therefore it is equipped with protective automatic systems and is controlled by electronics. The gas valve is normally closed and opens with a signal from the control board, therefore, in case of any malfunctions from the safety system, the supply to the burner will be interrupted. The sensors themselves, pressure gauges, thermistors, thermostats, electronic board can also fail, and the equipment will not start.

It is worth noting that the parts of the boilers are usually reliable and rarely the reason for the breakdown is a factory defect. Mostly this is a consequence of non-compliance with the operating conditions (overvoltage, poor water quality) and the lack of regular maintenance.

Most likely, when defects are detected, the user will receive information in the form of an error code indicating from which sensor exactly the signal about a breakdown came.

System errors

When malfunctions occur in the double-circuit wall-mounted gas boiler "Baksi", an error code is displayed on its electronic display, which can mean one of two things: either blocking the operation of the heating device, or turning on the standby mode.

In the first case, it is necessary to manually restart the boiler. The device can be blocked at the moment of detection of problems affecting the main parts of the system, which can harm not only the equipment, but also the health of its owner. Such errors include excessive heating of the boiler, insufficient or reverse draft, as well as its absence. If no gas is supplied to the storage tank, the equipment is also blocked. Sometimes this problem clears up by itself, and then the device turns on the automatic startup mode.

Code E01 - burner sensor

Code E01 appears on the display when a sensor monitoring the burner is responding. This error can be caused by a number of reasons:

- gas is no longer supplied to the burner;

- there is no correspondence between zero and phase;

- the sensor is disabled;

- the sensor needs cleaning or repair;

- malfunction in the igniting device;

- the gas supply valve is out of order;

- the electronic board does not work;

- there is not enough air to support the flame;

- there is not enough gas pressure for combustion.

Having seen such a signal on the display, you first need to check if the flame sensor is working correctly. Then see if gas is supplied to the device. If there are no problems, press the R button or switch the toggle switch to neutral mode, which is also indicated by this letter.

If the sensor is triggered unintentionally, the boiler will continue to work as usual. In case of a repetition of the error, it is better to ask for advice from a gas equipment repairman.This fault code indicates a problem in the microcircuits, and trying to fix the problem yourself may lead to undesirable results.

E10 - water cycle indicator

Code E10 refers to sensors that monitor the functioning of pumps and regulate the water cycle in the system. Such a cipher can diagnose the following problems:

- decreased pressure;

- the conductivity between the relay and the board is broken;

- the pressure switch is not functioning properly;

- malfunctions in the pump sensor;

- the pump itself needs to be repaired;

- the heat exchanger is dirty.

Having noticed the E10 code, there is no need to rush to cope with the problems yourself. You can also replace the pump with your own hands, it is not very difficult. It is also easy to clean clogged filters with your own hands. It is better to entrust other malfunctions to the hands of a qualified worker.

E96−98 - electronic board problems

The rest of the codes E96, E97, E98 indicate problems in the operation of the electronic board. If they appear on the display, the owner should not take any action and immediately call the repairman, because only an experienced specialist can handle them without outside help.

Fixing problems with household appliances - this is a kind of treatment... There are simple diseases that a person can expel on their own, and with complex diagnoses, it is better to consult a doctor. But both can be prevented with the help of timely prevention. This also works in case of warning of malfunctions of the wall-mounted double-circuit gas boiler "Baksi".

Description and advantages of technology

In the offer of the Italian company Baxi, you can find various gas, electric and solid fuel heating boilers, which are intended both for small country houses and for full-size suburban buildings. Such equipment is technologically advanced. It is efficient and economical, characterized by reliability and complete operational safety.

The Baksi range of gas boilers has various capacities

The advantages of the technique of this brand include:

- ease of maintenance of Baksi boilers;

- high degree of automation;

- affordable cost;

- the ability to select installations of various capacities.

The Italian manufacturer manufactures equipment that can operate on a variety of fuels, including pellets, wood, coal, electricity or natural gas.

You can choose both installations with a capacity of several kilowatts, which will be an excellent choice for a summer residence, and equipment that can quickly heat a house with an area of 200-300 square meters.

This video will help you get acquainted with the Baksi brand: