Specifications of HDPE pipes

SDR coefficient for HDPE pipes

SDR is a standard dimensional ratio that determines the size of the wall and the circumference of the pipes. This information is needed to determine the water pressure that a pipe of a given size can withstand. If the ratio is low, it is necessary to use a lower pressure head compared to a pipe with thicker walls.

When buying products, pay attention to the data that is indicated in the documents for the goods

PE pipe weight

The weight of a PE pipe also depends on the degree of density, because the thicker and wider the PE product, the naturally and higher its mass.

| Nominal outer diameter, mm | Estimated weight of 1 m pipe, kg | |||

| SDR 21 | SDR 13.6 | SDR 9 | SDR 6 | |

| S 10 | S 6.3 | S 4 | S 2.5 | |

| 10 | 0,052 | |||

| 12 | 0,065 | |||

| 16 | 0,092 | 0,116 | ||

| 20 | 0,134 | 0,182 | ||

| 20 | 0,134 | 0,182 | ||

| 25 | 0,151 | 0,201 | 0,280 | |

| 32 | 0,197 | 0,233 | 0,329 | 0,459 |

| 40 | 0,249 | 0,358 | 0,511 | 0,713 |

| 50 | 0,376 | 0,552 | 0,798 | 1,10 |

| 63 | 0,582 | 0,885 | 1,27 | 1,75 |

| 75 | 0,831 | 1,25 | 1,79 | 2,48 |

| 90 | 1,19 | 1,80 | 2,59 | 3,58 |

| 110 | 1,78 | 2,66 | 3,84 | 5,34 |

| 125 | 2,29 | 3,42 | 4,96 | 6,90 |

| 140 | 2,89 | 4,29 | 6,24 | |

| 160 | 3,77 | 5,61 | 8,13 |

| Nominal outer diameter, mm | Estimated weight of 1 m pipe, kg | ||||||||||

| SDR 41 | SDR 33 | SDR 26 | SDR 21 | SDR 17.6 | SDR 17 | SDR 13.6 | SDR 11 | SDR 9 | SDR 7.4 | SDR 6 | |

| S 20 | S 16 | S 12.5 | S 10 | S 8.3 | S 8 | S 6.3 | S 5 | S 4 | S 3.2 | S 2.5 | |

| 10 | 0,051 | ||||||||||

| 12 | 0,064 | ||||||||||

| 16 | 0,090 | 0,102 | 0,115 | ||||||||

| 20 | 0,116 | 0,132 | 0,162 | 0,180 | |||||||

| 25 | 0,148 | 0,169 | 0,198 | 0,24 | 0,277 | ||||||

| 32 | 0,193 | 0,229 | 0,277 | 0,325 | 0,385 | 0,453 | |||||

| 40 | 0,244 | 0,281 | 0,292 | 0,353 | 0,427 | 0,507 | 0,600 | 0,701 | |||

| 50 | 0,308 | 0,369 | 0,436 | 0,449 | 0,545 | 0,663 | 0,786 | 0,935 | 1,47 | ||

| 63 | 0,392 | 0,488 | 0,573 | 0,682 | 0,715 | 0,869 | 1,05 | 1,25 | 1,47 | 1,73 | |

| 75 | 0,469 | 0,543 | 0,668 | 0,821 | 0,97 | 1,01 | 1,23 | 1,46 | 1,76 | 2,09 | 2,45 |

| 90 | 0,630 | 0,782 | 0,969 | 1,18 | 1,40 | 1,45 | 1,76 | 2,12 | 2,54 | 3,00 | 3,52 |

| 110 | 0,930 | 1,16 | 1,42 | 1,77 | 2,07 | 2,16 | 2,61 | 3,14 | 3,78 | 4,49 | 5,25 |

| 125 | 1,25 | 1,50 | 1,83 | 2,26 | 2,66 | 2,75 | 3,37 | 4,08 | 4,87 | 5,78 | 6,77 |

| 140 | 1,53 | 1,87 | 2,31 | 2,83 | 3,35 | 3,46 | 4,22 | 5,08 | 6,12 | 7,27 | 8,49 |

| 160 | 1,98 | 2,41 | 3,03 | 3,71 | 4,35 | 4,51 | 5,50 | 6,67 | 7,97 | 9,46 | 11,1 |

| 180 | 2,47 | 3,78 | 4,66 | 5,47 | 5,71 | 6,78 | 6,98 | 8,43 | 10,1 | 12,0 | 14,0 |

| 200 | 3,3 | 3,82 | 4,68 | 5,77 | 6,78 | 7,04 | 8,56 | 10,4 | 12,5 | 14,8 | 17,3 |

| 225 | 3,84 | 4,76 | 5,88 | 7,29 | 8,55 | 8,94 | 10,9 | 13,2 | 15,8 | 18,7 | 21,9 |

| 250 | 4,81 | 5,90 | 7,29 | 8,91 | 10,6 | 11,0 | 13,4 | 16,2 | 19,4 | 23,1 | 27,0 |

| 280 | 5,96 | 7,38 | 9,09 | 11,3 | 13,2 | 13,8 | 16,8 | 20,3 | 24,4 | 28,9 | 33,9 |

| 315 | 7,49 | 9,35 | 11,6 | 14,2 | 16,7 | 17,4 | 21,3 | 25,7 | 30,8 | 36,6 | 42,8 |

| 355 | 9,53 | 11,8 | 14,6 | 18,0 | 21,2 | 22,2 | 27,0 | 32,6 | 39,2 | 46,4 | 54,4 |

| 400 | 12,1 | 15,1 | 18,6 | 22,9 | 26,9 | 28,0 | 34,2 | 41,4 | 49,7 | 59,0 | 69,0 |

| 450 | 15,2 | 19,0 | 23,5 | 29,0 | 34,0 | 35,5 | 43,3 | 52,4 | 62,9 | 74,6 | |

| 500 | 19,0 | 23,4 | 29,0 | 35,8 | 42,0 | 43,9 | 53,5 | 64,7 | 77,5 | 92,1 | |

| 560 | 23,6 | 29,4 | 36,3 | 44,8 | 52,6 | 55,0 | 67,1 | 81,0 | 97,3 | ||

| 630 | 29,9 | 37,1 | 46,0 | 56,6 | 66,6 | 69,6 | 84,8 | 103 | 123 | ||

| 710 | 38,1 | 47,3 | 58,5 | 72,1 | 84,7 | 88,4 | 108 | 131 | |||

| 800 | 48,3 | 59,9 | 74,1 | 91,4 | 108 | 112 | 137 | ||||

| 900 | 60,9 | 75,9 | 93,8 | 116 | 136 | 142 | 173 | ||||

| 1000 | 75,4 | 93,5 | 116 | 143 | 168 | 175 | 214 | ||||

| 1200 | 108 | 134 | 167 | 206 | 242 | 252 | |||||

| 1400 | 148 | 183 | 227 | 280 | |||||||

| 1600 | 193 | 239 | 296 |

What pressure can HDPE pipes withstand?

According to GOST, four brands of the most common sizes of polyethylene pipes are distinguished:

The last figure denotes the degree of density pnd of the products, on which it depends exactly what pressure this or that PE pipe can withstand.

Limit deviations of the sizes of polyethylene pipes

GOST 32415 establishes the permissible deviations of the diameter and ovality of PE products.

Table 3

| Diameter, * 1 thousand mm | Tolerance upward, * 10-1, mm | Ovality mm * 10-2 no more |

| 0,016 | 3 | 120 |

| 0,020 | 3 | 120 |

| 0,025 | 3 | 120 |

| 0,032 | 3 | 130 |

| 0,040 | 4 | 140 |

| 0,050 | 4 | 140 |

| 0,063 | 4 | 150 |

| 0,075 | 5 | 160 |

| 0,090 | 6 | 180 |

| 0,110 | 7 | 220 |

| 0,125 | 8 | 250 |

| 0,140 | 9 | 280 |

| 0,160 | 10 | 320 |

| 0,180 | 11 | 360 |

| 0,200 | 12 | 400 |

| 0,225 | 14 | 450 |

| 0,250 | 15 | 500 |

| 0,280 | 17 | 980 |

| 0,315 | 19 | 1110 |

| 0,355 | 22 | 1250 |

| 0,400 | 24 | 1400 |

| 0,450 | 27 | 1560 |

| 0,500 | 30 | 1750 |

| 0,560 | 34 | 1960 |

| 0,630 | 38 | 2210 |

| 0,710 | 64 | — |

| 0,800 | 72 | — |

| 0,900 | 81 | — |

| 1,000 | 90 | — |

| 1,200 | 108 | — |

| 1,400 | 126 | — |

| 1,600 | 144 | — |

For the wall thickness of the PE pipe, GOST provides such data (in millimeters).

Table 4

| Polyethylene pipe wall, * 10-1 | Deviation upward in quality V | |

| > | ≤ | |

| 10 | 20 | 0,3 |

| 20 | 30 | 0,4 |

| 30 | 40 | 0,5 |

| 40 | 50 | 0,6 |

| 50 | 60 | 0,7 |

| 60 | 70 | 0,8 |

| 70 | 80 | 0,9 |

| 80 | 90 | 1,0 |

| 90 | 100 | 1,1 |

| 100 | 110 | 1,2 |

| 110 | 120 | 1,3 |

| 120 | 130 | 1,4 |

| 130 | 140 | 1,5 |

| 140 | 150 | 1,6 |

| 150 | 160 | 1,7 |

| 160 | 170 | 1,8 |

| 170 | 180 | 1,9 |

| 180 | 190 | 2,0 |

| 190 | 200 | 2,1 |

| 200 | 210 | 2,2 |

| 210 | 220 | 2,3 |

| 220 | 230 | 2,4 |

| 230 | 240 | 2,5 |

| 240 | 250 | 2,6 |

| 250 | 260 | 2,7 |

| 260 | 270 | 2,8 |

| 270 | 280 | 2,9 |

| 280 | 290 | 3,0 |

| 290 | 300 | 3,1 |

| 300 | 310 | 3,2 |

| 310 | 320 | 3,3 |

| 320 | 330 | 3,4 |

| 330 | 340 | 3,5 |

| 340 | 350 | 3,6 |

| 350 | 360 | 3,7 |

| 360 | 370 | 3,8 |

| 370 | 380 | 3,9 |

| 380 | 390 | 4,0 |

| 390 | 400 | 4,1 |

| 400 | 410 | 4,2 |

| 410 | 420 | 4,3 |

| 420 | 420 | 4,4 |

| 420 | 440 | 4,5 |

| 440 | 450 | 4,6 |

| 450 | 460 | 4,7 |

| 460 | 470 | 4,8 |

| 470 | 480 | 4,9 |

| 480 | 490 | 5,0 |

| 490 | 500 | 5,1 |

| 500 | 510 | 5,2 |

| 510 | 520 | 5,3 |

| 520 | 530 | 5,4 |

| 530 | 540 | 5,5 |

| 540 | 550 | 5,6 |

| 550 | 560 | 5,7 |

| 560 | 570 | 5,8 |

| 570 | 580 | 5,9 |

| 580 | 590 | 6,0 |

| 590 | 600 | 6,1 |

| 600 | 610 | 6,2 |

| 610 | 620 | 6,3 |

| 620 | 630 | 6,4 |

| 630 | 640 | 6,5 |

| 640 | 650 | 6,6 |

| 650 | 660 | 6,7 |

| 660 | 670 | 6,8 |

| 670 | 680 | 6,9 |

| 680 | 690 | 7,0 |

| 690 | 700 | 7,1 |

Relationship with other size characteristics

Products made of solid polymer materials can be manufactured in a wide variety of sizes - from the smallest to the largest. As for their size, it can vary in the range from 10 to 1600 mm

... Their sizes can change at the same time.

Length of the product

Tubular products, which have a diameter of up to 160 mm, are usually supplied by manufacturers in spools or coils. Their length can vary from 100 to 500 meters. However, sometimes they are simply cut into specific sections. Products with a large wall thickness, starting from a diameter of 160 mm, are produced in the form of segments of a certain length. It usually ranges from 3 to 12 m.

For small and large products, the wall thickness may vary:

- for products with an outer diameter of 10 mm, the wall thickness is not more than 2 mm;

- this thickness is not applicable for products with a diameter of 90 mm. The smallest is 2.2 mm;

- with increasing diameter, the wall thickness also increases.

Diameter

I would like to draw your attention to the fact that the most important indicator is the ratio of the product diameter to the thickness. Focusing on it, you can determine the strength of a particular pipeline

This characteristic of the marking is recorded by the SDR index.

In the case of HDPE products, the diameter will be as follows:

- if the product has the same diameters, then the presence of a lower SDR in the polyethylene pipe indicates a greater wall thickness;

- for pipe products of the same thickness, the smaller value of this indicator will be for pipes with the largest diameter. For example, for pipe products with a thickness of 2 mm and a diameter of 10 mm, the working pressure will reach 25 atmospheres. That is, they will be more durable than tubular products with a similar wall thickness and 50 mm diameter. For such structures, the working pressure will reach a maximum of 6 atmospheres.

Formulas for calculating the weight of HDPE and LDPE pipes

How much does a PND pipe weigh? It is easy to answer this question by looking at the formulas for calculating the weight of HDPE and LDPE pipes below. To calculate the weight of the pipe, you must ask the manufacturer for some technical characteristics:

- W - pipe wall thickness

- p - density of HDPE or LDPE material

Step-by-step method for calculating pipe weight:

- Let's calculate the circumference of the HDPE or LDPE pipe: L = π * D

- Let's calculate the area of the outer surface: S = L * l

- We calculate the amount of material spent on the production of the pipe: V = S * W

- Calculate the weight of the pipe P = p * V

P.S. Additional explanation

- Density of HDPE pipe = 940-960 kg / m3

- Density of LDPE pipe = 910-930 kg / m3

- L (m) - circumference

- π

-3,14 - D

(m.) - Pipe diameter - S

(m2) - Pipe surface area - l

(m.)

- pipe length - V

(m3) - the volume of "material spent on the pipe" ... - W

(mm)

- pipe wall thickness - p

(kg / m3) - material density - P

(kg.) - material weight

An example of calculation on a HDPE pipe d32: wall thickness 3mm.

- L = 3.14 * 0.032 m. = 0.10048 m.

- S = 0.10048m. * 1m. = 0.10048m 2

- V = 0.10048 m2 * 0.003m. = 0.00030144

- P = 0.00030144 * 950kg. = 0.286kg. weight of one meter

A source

HDPE pipes are often used in the installation of heating and water supply systems.

When choosing, they pay great attention to the linear dimensions of the products. The strength and permeability of the pipeline largely depends on these indicators.

It is important not only to choose the right pipes for the installation of the communication system, but also to carry out the installation with high quality. There are various ways to connect these pipes

Choosing a suitable option, you can facilitate the task of the pipeline device and ensure the reliability of its operation.

Dimensions of polyethylene sewer products

Sewer pipes (GOST 22689) are characterized by the dimensions indicated in the table.

Table 10

| Nominal size, * 10-1 mm | Outside diameter (nominal), * 10 mm | Average value of the outer diameter, * 10-1 mm | |

| maximum | minimum | ||

| 320 | 3,2 | 323 | 320 |

| 400 | 4,0 | 404 | 400 |

| 500 | 5,0 | 505 | 500 |

| 630 | 6,3 | 636 | 630 |

| 750 | 7,5 | 757 | 750 |

| 800 | 8,0 | 808 | 800 |

| 900 | 9,0 | 909 | 900 |

| 1 thous. | 10,0 | 1009 | 1 thous. |

| 1100 | 11,0 | 1110 | 1100 |

| 1250 | 12,5 | 1262 | 1250 |

| 1600 | 16,0 | 1615 | 1600 |

| 2 thous. | 20,0 | 2018 | 2 thous. |

| 2500 | 25,0 | 2523 | 2500 |

| 3150 | 31,5 | 3179 | 3150 |

The standard also establishes the value of the wall thickness.

Table 11

| Outside diameter (nominal), * 10 mm | Wall, * 10-1 mm | |||

| For 12.5 series | For series 16 | |||

| maximum | maximum | minimal | minimal | |

| 3,2 | 35 | 30 | 35 | 30 |

| 4,0 | ||||

| 5,0 | ||||

| 6,3 | ||||

| 7,5 | ||||

| 8,0 | 36 | 31 | ||

| 9,0 | 41 | 35 | ||

| 10,0 | 44 | 38 | 38 | 32 |

| 11,0 | 49 | 42 | 40 | 34 |

| 12,5 | 55 | 48 | 45 | 39 |

| 16,0 | 71 | 62 | 56 | 49 |

| 20,0 | 87 | 77 | 71 | 62 |

| 25,0 | 108 | 96 | 87 | 77 |

| 31,5 | 136 | 121 | 109 | 97 |

Other wall thicknesses of products at any of the points are also acceptable, but not more than 1.25 of the minimum limit.

For the installation of pressure sewer systems, smooth and corrugated pipes with thick walls are used.

Which pipes to choose

Most often, steel pipes for cold water supply are installed in houses. The disadvantages of such a pipeline are obvious:

- unpleasant taste, color and odor of water due to corrosion of the material;

- rapid destruction of pipes at joints.

Slightly better in terms of the quality of water supplied to the house are zinc coated pipes

... But galvanizing also has an unpleasant property to interact with water and saturate it with zinc compounds. In addition, at the joints of the pipes, the zinc coating breaks down very quickly, and the pipes begin to rust again.

Stainless steel pipes are almost perfect:

- do not rust, do not change the color and taste of water;

- do not pollute water;

- will last long enough.

The only reason they are not used as widely as steel cold water pipes or galvanized pipes is because of their cost. But if you want to have clean water in your home, then you have to spend money.

Cast iron pipes

- a unique and most popular material for trunk pipelines. The service life of such pipes is almost 100 years. If you want to bring water into the house and almost forever forget about the plumbing, stop at this material.

The advantages of cast iron include the fact that it does not interact with water, does not rust and does not affect the taste of water. An important advantage of cast iron pipes is their ability to withstand heavy loads: at factories they are tested at pressures of over 50 atmospheres.

It is possible to use pipes made of cast iron both for domestic drinking water supply and for installing sewerage systems.

Another option is plastic pipes. Quite a popular and budget option, and the ease of installation and long service life made them the favorite material of builders. It is believed that plastic does not interact with water.

Features of the installation of metal pipes

As mentioned earlier, when buying pipes for water supply, you need to pay attention not only to the cost and technical parameters, but also to the complexity of installation. As for pipelines made of metal, there can be two ways of mounting here

- Demountable assembly

Collapsible way

the installation of the pipeline involves the connection of pipes by means of special threaded fittings. At the same time, the pipe is screwed into the fitting, and the joint itself is clamped with a locknut. In other words, there are no fittings with unions, as is the case with plastic pipes, here.

For installation, you only need an ordinary wrench, but this simplicity also has a downside - if the diameter of the pipes exceeds 6.3 cm, then collapsible installation will not be possible, since the locknuts, as well as fittings, of such a diameter do not exist.

- Non-dismountable installation

As you probably already guessed, non-separable method

consists in welding or soldering joints. It is characteristic that in this case the diameter of the pipeline will not play any role.

Such a versatility of the method requires the use of special tools - a welding machine, a gas cutter, etc. This is where the main disadvantage of non-separable installation "surfaced" - not all welders know how to weld pipes.

Basic performance characteristics of HDPE pipes

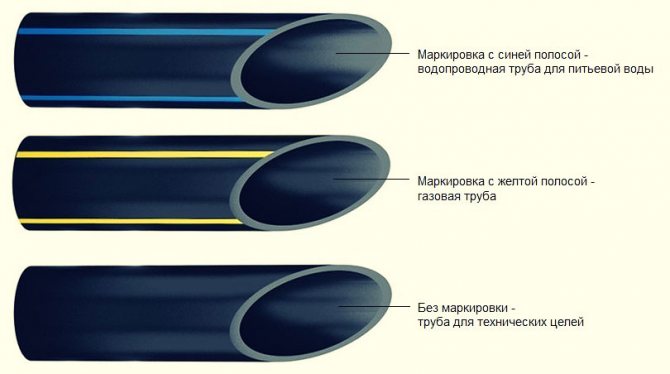

Pipes are delivered to the counters of specialized HDPE stores in coils or coils, in which a pipe with a diameter of 16 to 110 mm and a length of up to 1000 m is laid, as well as in the form of straight segments having a length of 12 m and a diameter of 110-1200 mm. The manufacturer's marking, in addition to the blue stripes, contains the following data:

- the name of the manufacturer, his contact phone numbers, the date of manufacture and the batch number;

- the grade of polyethylene used (PE63, PE80, PE100, PE100 +);

- purpose;

- the thickness and diameter of the walls;

- SDR;

- GOST or TU.

- When choosing HDPE pipes for any specific needs, the following characteristics must be considered:

- the brand of polyethylene used during the creation of the pipe;

- pipe diameter;

- SDR or the ratio between wall thickness and pipe diameter, reflecting the degree of resistance of a material to internal pressure.

In addition to the characteristics listed above, for polyethylene pipes there is a parameter such as nominal or working pressure. This value reflects the numerical value of the pressure created by the flow of water on the inner walls of the pipeline at a temperature of 200 ° C. Depending on the specific value of this value, HDPE pipes are divided into the following categories:

- pressure pipes;

- medium-pressure pipes;

- pipes working under vacuum.

It should be borne in mind that of the existing varieties of HDPE pipes, only for water-pressure pipelines there is GOST 18599-2001, which describes all the necessary technical parameters and scope. HDPE water-pressure pipes can be used in the following areas:

- when creating communications for domestic water supply;

- for water supply to industrial reclamation plants;

- to create sewerage systems;

- for gas supply communications.

Unfortunately, with sufficiently high performance characteristics, HDPE pipes, nevertheless, are not devoid of certain disadvantages. In particular, pipelines created on the basis of polyethylene water pipes have a very low compressive elasticity, and they also lose their basic properties during prolonged contact with ultraviolet radiation.

Non-metallic pipes

Should you replace old metal pipes with more modern non-metal pipes? This question is of interest to many, let's try to figure it out. The main advantage of a non-metallic plumbing is its resistance to rust formation. Moreover, the inner surface is flat and smooth, which will prevent the appearance of build-up characteristic of metal on it.

Plastic pipes are able to withstand high temperatures (but not more than 95 ° C) and pressures of the order of ten atmospheres. Plastic plumbing will last more than half a century (only copper pipes have such an operational durability).

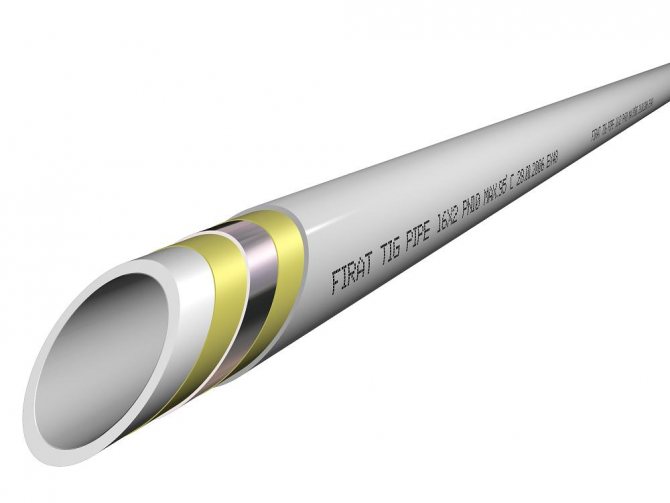

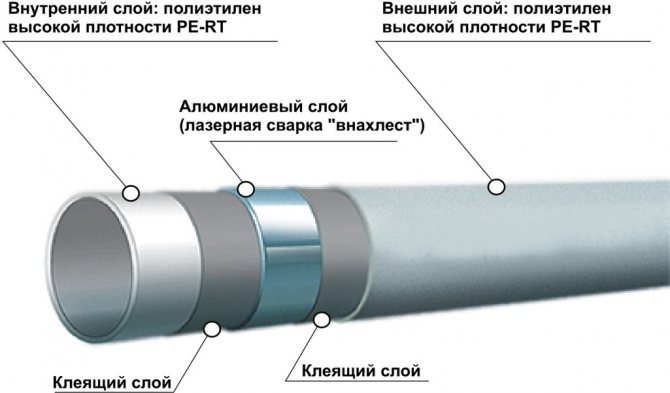

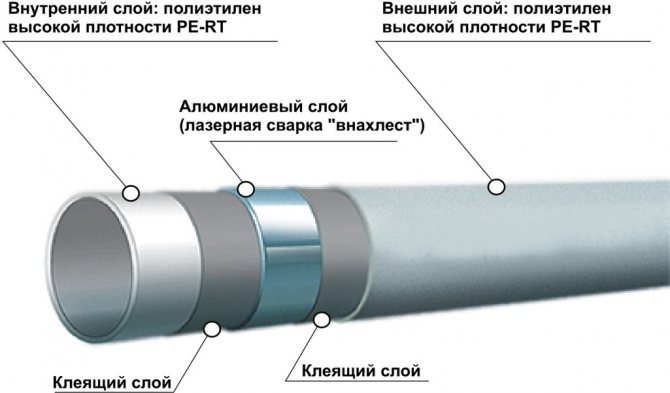

Reinforced plastic pipes

The construction of metal-plastic pipes is multilayer.Outside and inside they have plastic, and in the middle there is a layer of aluminum. The advantage is high strength combined with low weight. For example, 20 m of such a pipe weighs no more than 3-4 kg.

Pipes made of metal-plastic are resilient, they can be given any shape. They also conduct heat well. When installing metal-plastic pipes, welding is not required, they are connected together with a wrench and special fittings.

Among the shortcomings, I would like to note the fact that with a sharp temperature jump in water passing through the pipeline, aluminum will shrink faster than plastic. Plus high blood pressure. It turns out that the “Achilles heel” of pipes is precisely the joints.

Note! When purchasing metal-plastic pipes, be aware that blue products should only be used for cold water supply (the water temperature should not exceed 30 °). White pipes are used for hot water supply.

Polypropylene pipes

Polypropylene pipes do not have the disadvantages that metal-plastic pipes have, although their technical characteristics are almost the same. The advantage is that the pipes are connected to each other by thermal welding, due to which high strength of the joints is achieved. At the same time, polypropylene is significantly stiffer, which is why it will not work to change the direction of the water supply system by ordinary bending - this is provided by fittings.

Polypropylene pipes are characterized by durability and low cost. They can serve for more than 50 years (if we are talking about hot water supply, then this figure is halved). Moreover, the characteristics of polypropylene remain unchanged even when the water freezes.

The main disadvantage of such pipes is considered to be a high rate of linear expansion, that is, at high temperatures, the pipeline lengthens and sags somewhat. They are also negatively affected by ultraviolet radiation, and temperatures above 75 ° C can even cause a water pipe to rupture.

Polyethylene pipes

Polyethylene pipes can withstand pressure up to 16 atmospheres and temperatures from -40 ° to + 40 °. As we can see, their heat resistance is rather low, which, together with a high linear expansion index, can be considered a negative quality.

For this reason, polyethylene is not often used in water supply, its "relative" is much more popular - cross-linked polyethylene

... This material appeared not so long ago, but has already managed to acquire thousands of supporters. Indeed, the installation of XLPE pipes is very simple, because the fittings used for this do not have rubber seals - for density, the pipe is crimped with a special fitting.

So, the advantages of XLPE are as follows:

- it perfectly tolerates subzero temperatures;

- cross-linked polyethylene is inert to various substances in the circulating water;

- PE pipe connections are very durable;

- the fittings used here do not impair the flow of water.

PVC pipes

PVC (polyvinyl chloride) surpasses all previous versions of plastic pipes both in strength and in resistance to chemicals. Indeed, such pipes are able to withstand a pressure of about 46 atmospheres. Moreover, the material does not burn, it can be used to supply both hot water (tolerates a temperature of 90 °) and cold.

When installing PVC pipes, you do not need a welding machine or other specific tools, so it is quite possible to carry out all the work on arranging the water supply with your own hands. Pipes are connected only by means of couplings and corners, which makes the process of installing a water supply system more economical.

Durability parameters of pipe connections

Polyethylene pipes connected by means of fittings must meet the requirements of the standard.The welded joint of products and its technical parameters of resistance are checked during tests with a temperature of 80 ºС for at least 165 hours at a hydrostatic (ring) stress of 5.4 MPa (for PE 100) and 4.5 MPa (for PE 80).

Mechanical connections of polyethylene pipes are checked under the conditions indicated in the table.

Table 7

| Test scheme | Pressure, bar | Temperature, degrees | Test time, not less, h |

| Without bending PE pipes | 1.5 * nominal pressure | 20 | 1 |

| With a bend | 1 |

Mechanical joints are also subject to a tensile load test (at a temperature of 20 degrees for at least an hour), which is calculated by the formula:

PH = 1.5 * H * π * (ND-TS) * TS,

where РН - tensile load, N; Н - permissible stress: 8 MPa (for PE 80), 10 MPa (for PE 100); ND is the nominal value of the outer diameter, mm; ТС - average value of wall thickness, mm.

The bending radius can be 15 outer diameters of the pipe (in mm) if the nominal pressure is ≤10 and 20 outer diameters if greater than 10. The nominal pressure should be selected from the table.

Table 8

| Series | SDR | Nominal pressure for polyethylene grade, * 10-1 | |

| 80 | 100 | ||

| 20 | 41 | 32 | 40 |

| 16 | 33 | 40 | 50 |

| 12,5 | 26 | 50 | 60 |

| 10 | 21 | 60 | 80 |

| 8 | 17 | 80 | 100 |

| 6,3 | 13,6 | 100 | 125 |

| 5 | 11 | 125 | 160 |

| 4 | 9 | 160 | 200 |

| 3,2 | 7,4 | 200 | 250 |

| 2,5 | 6 | 250 | — |

If compression fittings are used for the connection, then the test pressure must correspond to the values in the table (symbol: ND - nominal pressure).

Each of the methods for connecting PE pipes must comply with accepted standards.

Table 9

| Test temperature, degrees | Time, h, not less | Pressure, bar, for fittings made of | ||||

| PP-R | PP-B | PP-H | POM | ABS | ||

| 20 | 1 thous. | 1.2 * ND | 1.5 * ND | |||

| 40 | 0.8 * ND | 1.1 * OD | ||||

During the installation of HDPE water pipes of various diameters, there may be some differences

- For pipes with a diameter of 20-50 mm, it is necessary to partially disassemble the fitting, then prepare the parts to be connected, that is, clean them from contamination, chamfer from the outside, make the necessary marking of the depth of immersion of the pipe into the fitting cavity, insert the pipe into the fitting with the required force and then tighten the nut to the end of the threaded connection.

- For pipes with a diameter of 63-110 mm, it is necessary to properly prepare the pipe and the compression fitting, for which disassemble it into separate components, such as a split retaining ring, a thrust cup, an O-ring. Then perform preliminary assembly without using the split ring, and after its successful completion, make the final assembly, during which the split ring must be put on the pipe and moved to the coupling, tighten the nut with a wrench.

During the implementation of the second, one-piece method, it is necessary to strictly adhere to all the requirements related to the installation of HDPE pipes, and also take into account that the technology of electrofusion welding and butt welding have rather serious differences between themselves. The most technologically advanced method is butt welding of HDPE pipes.

To implement this method, you will need not only the appropriate skills of the installer, but also the presence of a special welding machine. This method is most often used when installing HDPE pressure pipes of the PE100 brand with a large diameter

The most technologically advanced method is butt welding of HDPE pipes. To implement this method, you will need not only the appropriate skills of the installer, but also the presence of a special welding machine. This method is most often used when installing pressure head HDPE pipes of the PE100 brand with a large diameter.

When butt welding, the ends of the pipes to be connected are thoroughly cleaned, then degreased, after which the ends are chamfered at an angle of 45º, heated with a soldering iron to a state of ductility and joined. Further, leaving the pipes to be connected in their original state, they are waiting for their complete cooling. It should be noted that this method cannot be used for joining pipes of different diameters and pipelines made on the basis of different materials.

The most practical is the method based on the use of welded couplings or fittings that have a special spiral inside, which heats up when connected to an electric current source. When implementing this method, special skill is not required. All that is needed is to place the ends of the HDPE pipes to be welded into a coupling or fitting, connect the spiral to a power source, and then wait until the parts to be joined are fused.

Weight of polyethylene pipe for sewerage

GOST 18599 sets the values for the mass of 1 meter of a pipeline made of PE products.

Table 12

| Outside diameter, * 103 mm | Weight, g | ||||||||

| SRO - 41, series 20 | SRO - 26, series 12.5 | SRO - 21, series 10 | SRO - 17.6, series 8.3 | SRO - 17, series 8 | SRO - 13.6, series 6.3 | SRO - 11, series 5 | SRO - 9, series 4 | SRO - 6, series 2.5 | |

| 0,010 | — | — | — | — | — | — | — | — | 52 |

| 0,012 | — | — | — | — | — | — | — | — | 65 |

| 0,016 | — | — | — | — | — | — | 92 | 92 | 116 |

| 0,020 | — | — | — | — | — | — | 118 | 134 | 182 |

| 0,025 | — | — | — | 151 | — | 151 | 172 | 201 | 280 |

| 0,032 | — | — | 197 | 197 | 197 | 233 | 280 | 329 | 459 |

| 0,040 | — | 249 | 249 | 286 | 297 | 358 | 432 | 511 | 713 |

| 0,050 | — | 315 | 376 | 443 | 456 | 552 | 669 | 798 | 1100 |

| 0,063 | 401 | 497 | 582 | 691 | 724 | 885 | 1060 | 1270 | 1750 |

| 0,075 | 480 | 678 | 831 | 981 | 1020 | 1250 | 1490 | 1790 | 2480 |

| 0,090 | 643 | 982 | 1190 | 1420 | 1480 | 1800 | 2150 | 2590 | 3580 |

| 0,110 | 946 | 1440 | 1780 | 2090 | 2190 | 2660 | 3200 | 3840 | 5340 |

| 0,125 | 1240 | 1870 | 2290 | 2690 | 2810 | 3420 | 4160 | 4960 | 6900 |

| 0,140 | 1550 | 2350 | 2890 | 3390 | 3520 | 4290 | 5190 | 6240 | — |

| 0,160 | 2010 | 3080 | 3770 | 4410 | 4600 | 5610 | 6790 | 8130 | — |

| 0,180 | 2500 | 3850 | 4730 | 5570 | 5830 | 7100 | 8590 | 10300 | — |

| 0,200 | 3090 | 4770 | 5880 | 6920 | 7180 | 8750 | 10600 | 12700 | — |

| 0,225 | 3910 | 5980 | 7450 | 8740 | 9120 | 11100 | 13400 | 16100 | — |

| 0,250 | 4890 | 7430 | 9100 | 10800 | 11200 | 13700 | 16500 | 19800 | — |

| 0,280 | 6090 | 9290 | 11500 | 13500 | 14000 | 17100 | 20700 | 24900 | — |

| 0,315 | 7630 | 11800 | 14500 | 17100 | 17800 | 21700 | 26200 | 31500 | — |

| 0,355 | 9740 | 14900 | 18400 | 21600 | 22600 | 27500 | 33300 | 40000 | — |

| 0,400 | 12300 | 18900 | 23400 | 27500 | 28600 | 34900 | 42300 | 50700 | — |

| 0,450 | 15600 | 23900 | 29600 | 34800 | 36300 | 44200 | 53600 | 64200 | — |

| 0,500 | 19300 | 29500 | 36500 | 42900 | 44800 | 54700 | 66100 | 79200 | — |

| 0,560 | 24100 | 37100 | 45800 | 53700 | 56100 | 68500 | 82800 | — | — |

| 0,630 | 30500 | 47000 | 57800 | 68100 | 71200 | 86688 | 104800 | — | — |

| 0,710 | 38800 | 59700 | 73600 | 86400 | 90300 | 110000 | — | — | — |

| 0,800 | 49300 | 75600 | 93300 | 109700 | 114500 | 139700 | — | — | — |

| 0,900 | 62100 | 95700 | 118100 | 138900 | 144700 | — | — | — | — |

| 1,000 | 76900 | 118100 | 145900 | 171300 | 178900 | — | — | — | — |

| 1,200 | 110800 | 170100 | 209800 | — | — | — | — | — | — |

High-quality pipes during butt welding should not deteriorate

When calculating the mass, the density of polyethylene is taken as 950 kg / m3.

Features of HDPE pipes

Technological requirements for products

HDPE water pipes are manufactured in strict accordance with low-pressure polyethylene brands PE 80 and PE 100. According to regulatory documents, polyethylene pipes must meet the following basic requirements:

- the surface of the products, both internal and external, must be perfectly smooth;

- the formation of bubbles, cracks, cavities or foreign inclusions on the inner, outer and end surfaces is not allowed;

- products must withstand working pressure (maximum) up to 16 or 20 atmospheres.

Products that meet the stated requirements are manufactured with a diameter of 16.0 to 1600.0 mm and are supplied in coils of 100 and 200 meters or in straight lengths of 12.0 m.

HDPE products are painted black and marked with longitudinal blue stripes, which are evenly distributed around the circumference of the pipe (usually at least three).

HDPE pipes for water supply

Parameters of PE products

The HDPE pipe for cold water supply, as well as for the transportation of hot water, is characterized by several very important parameters that determine the scope of product use:

- Manufacturing material. Pipes made of PE 80 have good consumer qualities and can withstand a sufficiently high internal pressure of the working medium. Therefore, most often such products are used for the construction of pipelines with a cross section of no more than 90.0 mm. Pipeline products made of PE 100 grade polyethylene make it possible to provide the required throughput with a smaller diameter. Such pipes are mainly used for laying cold water systems.

- Coefficient of resistance of HDPE pipes to working internal pressure (SDR). It is equal to the ratio of the cross-section of the polyethylene pipe to the wall thickness of the product. The lower the coefficient of stability, the stronger the pipes are considered.

- Diameter of low pressure polyethylene products. For laying a private pipeline (in a country or country house), it is enough to use pipes with a diameter of 20 or 25 mm. With a large daily water consumption, you can use pipes 32 mm in diameter.

The main advantages of HDPE products

The demand for these products for laying a water supply system is due to the following advantages:

good resistance to aggressive media such as acid, alkali, salt (except nitric acid); rather long service life (not less than 50 years); neutrality in relation to the transported liquid, therefore, the composition and other properties of water remain unchanged; resistance against various fungal microorganisms; non-susceptibility to corrosion, which is very important in the case of laying pipelines in swampy areas or in soil with high humidity; light weight, which facilitates the process of laying the pipeline.

Another important advantage of polyethylene pipes is their frost resistance down to minus 70 ° C, therefore, when laying the pipeline, there is no need to insulate it.

Features, advantages and disadvantages

Polyethylene, as an organic material, has special properties.Polyethylene pipes gained their relevance in the communications market due to a number of indisputable advantages:

- elasticity, flexibility, resistance to deformation

- chemical neutrality, resistance to aggressive environments

- no corrosion

- simple piping installation, the ability to easily make changes to the system configuration (add / remove elements)

- butt welding requires less time and resources than metal counterparts

- smooth inner wall surface creates minimal resistance to flow, facilitating the operation of the pumping system

- environmental Safety

- durability

- low thermal conductivity

- do not conduct electricity and impede the propagation of sound

The cost of communications based on polyethylene is 30-40% cheaper in comparison with a similar system made of steel.

But there are downsides. The disadvantages of polyethylene pipes include the following:

- the material is flammable when exposed to an open flame and temperatures above 400 ° C, releases hazardous substances

- "Afraid" of exposure to ultraviolet radiation, when open it needs additional insulation

- has a high coefficient of thermal expansion (10 times higher than that of steel), requires the organization of compensating units

- loses elasticity at low temperatures

The disadvantages somewhat limit the scope of application, but this does not interfere with the widespread use of polyethylene in main and local pipelines.

The production process of HDPE polyethylene pipes on video:

Metal pipes

Metal pipes are a classic. They have been serving for many decades and have not lost their popularity to this day. Among them there are those that are used exclusively for cold water, and there are also for hot water supply. Consider the pros and cons of each type of pipe.

They are ordinary and galvanized. During installation, the pipes are connected by threads, for which tees, adapters, couplings, etc. are used. Steel pipes have gained considerable popularity due to their reliability and durability. They are not afraid of sudden temperature drops and high pressure, and according to the method of manufacture, they are divided into:

- welded;

- seamless.

If we talk about which steel pipes are of the highest quality, then there is only one option - seamless with a galvanized coating. Zinc is known to prevent the formation of corrosion, so there is no need to paint or prime these pipes.

We examined the advantages of steel pipes, now let's see what their disadvantages are.

- Large weight, as a result - difficulties in transportation and installation.

- Corrosion.

- The installation of the pipeline requires welding, which further complicates the process.

- There will be foreign impurities in the water passing through the pipes.

- All seams must be carefully sealed.

- With prolonged operation, the inner diameter of the pipes decreases, since build-ups are formed. As a result, the pressure drops significantly.

Not so long ago, pipe manufacturers were surprised by a unique production technology. The fact is that steel pipes have appeared, coated from the inside with a non-metallic layer, which prevents the formation of build-ups and the formation of corrosion. The outer layer of the products remains metallic for strength.

Stainless steel pipes

There are no technical flaws in stainless steel pipes. They can be used at a wide variety of temperatures, elevated pressures, etc. But such pipes are rarely found due to their only drawback - very high cost.

Copper pipes

Copper pipes also have excellent corrosion resistance, moreover, their inner surface is less rough than other metal counterparts. For this reason, such pipes have a higher flow capacity, due to which the copper pipe can be of a smaller diameter compared to steel.

Copper is distinguished not only by its long service life (copper pipes can last more than fifty years), but also by its disinfecting characteristics - water, in contact with it, is cleared of harmful microorganisms. Also, the copper pipeline is quite easy and quick to install. In general, copper is the optimal material for plumbing, because it does not change the taste of water, but, on the contrary, improves it.

The main disadvantage of copper is considered to be its high cost.