Increasing the thermal protection of a private house during construction is an important stage of work, while significant volumes are insulated, and the cost of thermal insulation materials becomes a decisive factor. One of the popular inexpensive types of heat insulators is Isover insulation, the technical characteristics of which are excellent for use in individual housing construction.

It should be noted that Isover is a modern, more technological version of the classic glass wool, which was widely used in the Soviet period for thermal insulation of public pipelines for heating and hot water supply systems. Isover is produced in several modifications depending on the purpose, each brand in the series has different parameters, differs in the way of installation. Knowledge of the characteristics and varieties of Isover will help you choose the right product without overpayments, install it in compliance with the technological process, which is the main requirement for installing any type of insulation.

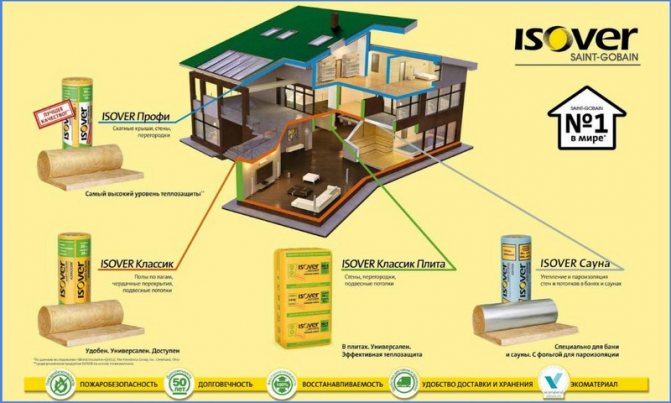

Izover - appearance

What is Isover, release form

The founder of the Isover brand is the international Saint-Gobain holding, whose roots were laid back in the 17th century, now the corporation includes more than 100 manufacturing companies and research centers conducting research in the construction industry. The company appeared on the Russian market 20 years ago; currently, a plant for the production of insulation works in the city of Yegoryevsk, Moscow Region. In 2011, the Saint-Gobain holding bought out the Chelyabinsk plant of Minvat, it has launched the production of insulation from stone fibers of mountain basalt.

Isover is obtained by processing sand (quartz), cullet, rock minerals (basalt), after melting the raw material in a high-temperature furnace, the mass is drawn into fibers using the TEL technology to obtain threads with a cross section of 4 - 5 microns and 110 - 150 microns in length.

Note: Saint-Gobain is the only manufacturer in the country with a patented crimping technology that allows the production of high mechanical strength fiberglass products.

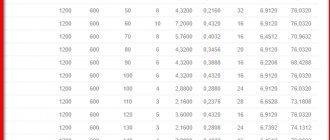

Hard fiberglass is placed in slabs, soft fiber is rolled into mats and rolls, products differ in thickness and dimensional dimensions, depending on the purpose and production technology.

Typical thickness of one-layer or two-layer Izover is 50 - 100 - 150 mm, rolls are produced with a total area of 2 - 20 m2, their usual width is 1200 mm, length is from 4000 to 12000 mm. The area of one Isover slab does not exceed 1 m2, its overall dimensions are kept within the limits of 600x1200 mm, the number in a pack is from 2 to 14 pieces.

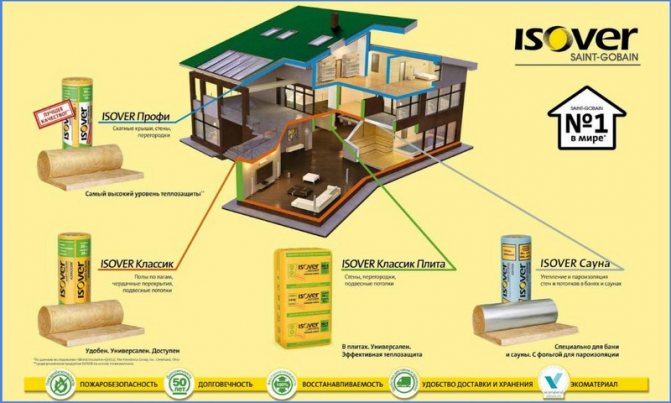

Insulation places of a private house

Scope and characteristics of Izover

Heaters made of fiberglass and mineral wool are widely used in individual and civil housing construction, with their help they protect roofs, walls, ceilings, floors and partitions of cottages and country houses, baths and saunas from heat loss, insulate pipes for supplying hot water inside premises for heating and hot water supply, heat-insulate ventilation ducts, chimneys.

Isover has the following characteristics:

- Is a brand supplying rigid fiberglass boards with a tensile strength of 15 kPa and a compressive strength of 60 kPa.

- Minvats are produced from natural raw materials (quartz, basalt), therefore, they are environmentally friendly and harmless to human health, they have been assigned the EcoMaterial Absolute environmental group and the international certificate of environmental purity ISO 14001: 2004.

- The coefficient of thermal conductivity (CT) depends on the shape of the product and lies in the range of 0.03 - 0.045 W / (m • K), this indicator for glass wool is slightly higher than that of expanded polystyrene (foam) and basalt fiber.

- The vapor permeability of products is also related to the shape and has an indicator of 0.3 - 0.55 mg / m • h • Pa, the parameter indicates that the heat insulator passes air well.

- The noise reduction of a sheet of 100 mm is 45 - 55 dB, which means that glass wool has a high sound insulation.

- The moisture absorption coefficient of glass wool with incomplete immersion in water for 24 hours is 1% or 1 kg / m2, a material completely immersed in a liquid for 72 hours absorbs 10% of the liquid from its weight, while its heat-insulating properties drop sharply. To combat this phenomenon, water repellents with water-repellent qualities are introduced into the composition of the heat insulator.

- The density of Izover depends on the form of release (soft mats or hard sheets) and ranges from 11 to 155 kg / m3.

- Mineral wool is classified as non-combustible; in accordance with GOST 30244-94, they are assigned the NG flammability index.

- The operational service life of the Isovero mineral wool set by the manufacturer is 50 years without losing its physical and chemical properties.

- Mineral wool is biologically stable, prevents the formation of mold and bacterial colonies, insects do not like to multiply and be in the mineral environment.

Isover laying options

The main characteristics of the insulation

Isover mineral wool thermal insulation materials inspire confidence and are in stable demand. Moreover, both slabs and rolls are rightfully considered one of the best thermal insulation on the market.

The main characteristics of the insulation include:

- Thermal conductivity.

- Soundproofing.

- Flammability.

- Water vapor permeability.

- Long service life.

- Environmental friendliness.

- Convenient release form.

- Low weight.

As a heat insulator, Isover insulation has managed to prove itself from the best side precisely due to the coefficient of thermal conductivity equal to 0.041 watts per meter per Kelvin. The coefficient does not change during the operation of the insulation throughout the entire period, the fibers do an excellent job with the accumulation and retention of air, preventing heat loss.

The material has excellent sound insulation performance. Air-spaced fiberglass insulation absorbs noise, guaranteeing an optimal level of silence, especially if specially adapted types of insulation are used for the soundproofing layer.

The flammability index is also important. Thermal insulation materials with technical characteristics indicating a density of up to 30 kilograms per cubic meter are classified as non-combustible. The materials are successfully used in premises of any type and purpose, without fear of the spread of fire in the event of a fire.

Thermal insulation boards made of mineral wool with special technical characteristics indicating the presence of an additional layer based on aluminum foil or fiberglass are classified as low-flammable.

Such materials are used subject to certain restrictions, which in fact are nothing more than a convention. In practice, insulators are appropriate almost everywhere, the main thing is to follow the fire safety regulations of structures prescribed in SNIP.

An important point from the list of technical characteristics of thermal insulation is vapor permeability. Insulation is able to maintain functionality even after contact with moisture. Unlike many modern counterparts for thermal insulation, Isover products based on stone wool simply and effectively deal with the problem of moisture penetration inside the thermal insulation layer.

The insulation gives off the absorbed moisture as quickly as it receives, the main thing is to leave a small gap (2-3 cm) between it and the wall to maintain ventilation.

Failure to follow this simple rule will lead to a violation of the material's ability to remove moisture, which over time will negatively affect the ability to retain heat. Isover heaters have optimal vapor permeability values - from 0.50 to 0.55 mg / mchPa.

Analysis of the technical characteristics of the material implies the mention of such an important parameter as the operational life.The material not only does not allow heat to pass through, but is also capable of properly serving for several decades. The manufacturer claims an operational life of 50 years for thermal insulation boards and rolls with full functionality.

The peculiarity of the material is the water repellents included in the composition, capable of repelling moisture, preventing the reproduction of insects, fungi and the formation of mold, which in turn ensures safety throughout the entire period of use.

Pros and cons

The positive qualities of insulation are directly related to its physical properties; the advantages of Isover include:

- The low cost of products, which gives tangible advantages over other heaters, is widely used in individual construction for thermal insulation of residential buildings, baths, outbuildings.

- Thanks to the Multipack technology, light weight and elasticity create additional convenience during transportation, soft cotton wool in rolls is compressed during production, after unfolding it increases in volume 5-6 times and completely restores its working shape.

- The manufacturer produces an extensive line of products in a wide price range, designed for various purposes; the consumer has the opportunity to choose between a budget fiberglass and a more expensive basalt product.

- The physical properties and forms of release of mineral wool allow them to be used for thermal insulation of any complex contours and planes: pipelines of various diameters, chimneys, ventilation ducts.

- It is convenient to work with insulation, due to its low weight and form of release, it is possible to cover significant volumes with rolls or sheets in a short time. Compared to traditional glass wool, the installation speed doubles due to the fact that when laying in the frame, no additional fasteners are required.

- Mineral wool material not only provides thermal insulation, but also absorbs noise well, performing a double useful function; brands specially designed for sound protection are sold in the trade network.

- High elasticity due to advanced production technology ensures that the material does not shrink, maintaining the same thermal insulation characteristics throughout its entire service life.

In addition to many positive qualities, Isover has quite tangible disadvantages:

- Since mineral wool absorbs moisture well, it cannot be used on objects with high humidity and underground. To protect against humid air, a vapor barrier film must be placed under the insulation or the space between the shells of the thermal insulator and the object is ventilated.

- Low-cost soft mats, when laid, require a rigid frame, otherwise they deform and cease to perform thermal insulation functions.

- When laying glass wool, protective equipment should be used against fibers that negatively affect the eyes and mucous membrane of a person, irritate the skin and cause itching.

- If glass wool is taken for interior decoration of premises, measures should be taken for its reliable sealing and isolation from the environment, otherwise small glass fibers will penetrate into the room, causing discomfort.

- Some environmentalists question the ecological purity of mineral wool, pointing out that binder resins are added during their production, which release formaldehyde, which is harmful to health, in small quantities.

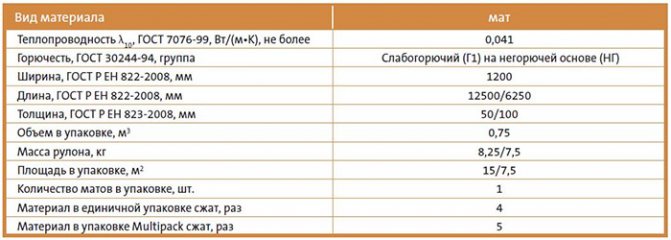

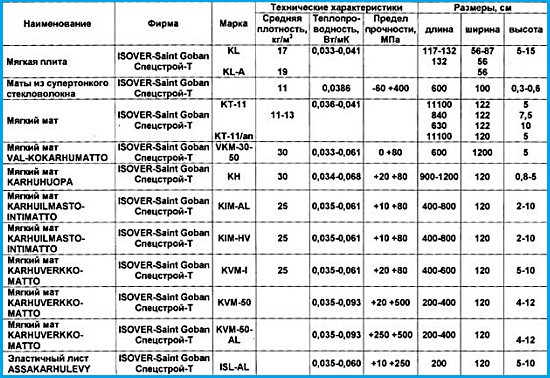

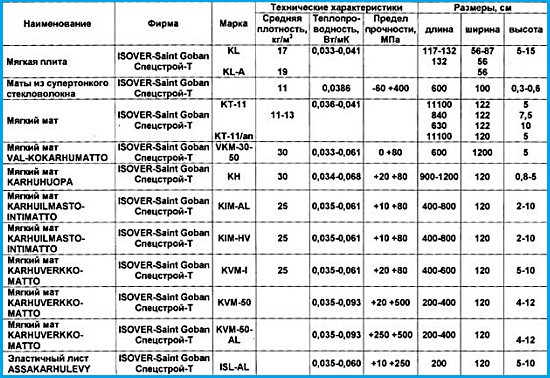

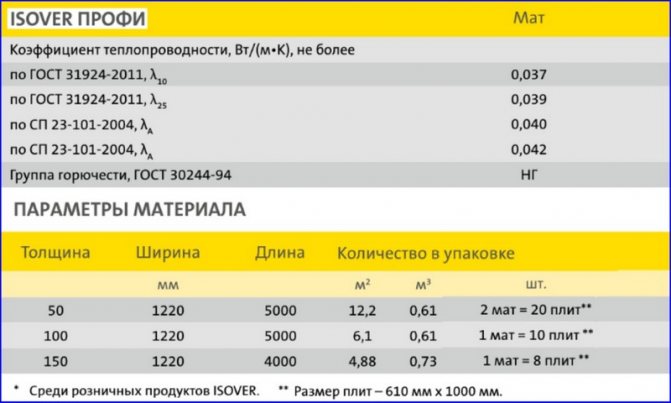

Specifications of some brands

How and from what is the ISOVER mineral insulation made | #Industrial scale

Insulation marking Izover

It is quite difficult to understand the labeling that Saint-Gobain puts on its product, depending on the physical properties, the following symbolic and numerical designations are found:

- CT scan - flexible rolled mats with a density of about 15 kg / mThe KT brand is supplied in rolls with a thickness of 50 or 100 mm, the standard length of KT37 is 6300 mm, width is 600 mm (for KT40, the dimensions are 7000x610 mm), the compression ratio of the roll is 1: 4 (the volume is 0.16 m3 in a packed state and 0.71 m3 in open).

- KL - plate heat insulator 50 or 100 mm thick with an average density of 20 kg / m3, designed for frame installation without fixing with dowels, parameters of the common brand KL34 - thermal conductivity 0.034 W / (m • K), vapor permeability - 0.53 mg / m • h • Pa, upon delivery, the package is compressed twice, the return rate after compression is 98%.

- RKL - rigid sheets, reinforced on both sides with fiberglass, with a density of 60 kg / m3 and a thermal conductivity of 0.030 W / (m • K), the RKLA type has a tongue-and-groove connection and performs the function of additional wind protection during installation.

- SKL - semi-rigid sheets with a density of 55 kg / m3 and a thermal conductivity of 0.031 W / (m • K).

- RKL-EJ - sheets of increased rigidity, mounted by the ridge method with a density of 95 kg / m3 and KT 0.031 W / (m • K).

- VKL - rigid sheets with a density of 130 kg / m3 and a thermal conductivity of 0.032 W / (m • K).

Important: From the given digital marking, it is enough for the consumer to remember that the letter T means rolled material, and the L indicates the plate, the digital designation is equal to the thermal conductivity, the lower it is, the better the product retains heat.

The Russian-language marking of Izover is often used, in which the symbol P means plates, M - roll insulation, AL (AL) - reinforced foil covering, OL - fiberglass base (glass fiber).

Product line, application features and characteristics of Isover

Isover, based on glass and basalt fibers, is produced for various purposes, so the products consist of almost three dozen items that have their own profile name depending on the object to be insulated. For a consumer who decides to purchase Isover insulation, it is useful to study its technical characteristics, get acquainted with the photo, find out the prices on the manufacturer's website, and master the installation methods.

On the market, products are marked with markings indicating their physical parameters, and are also broken down by field of application to facilitate the choice of the buyer; when ordering a large batch, the company can supply the goods in the dimensions specified by the customer.

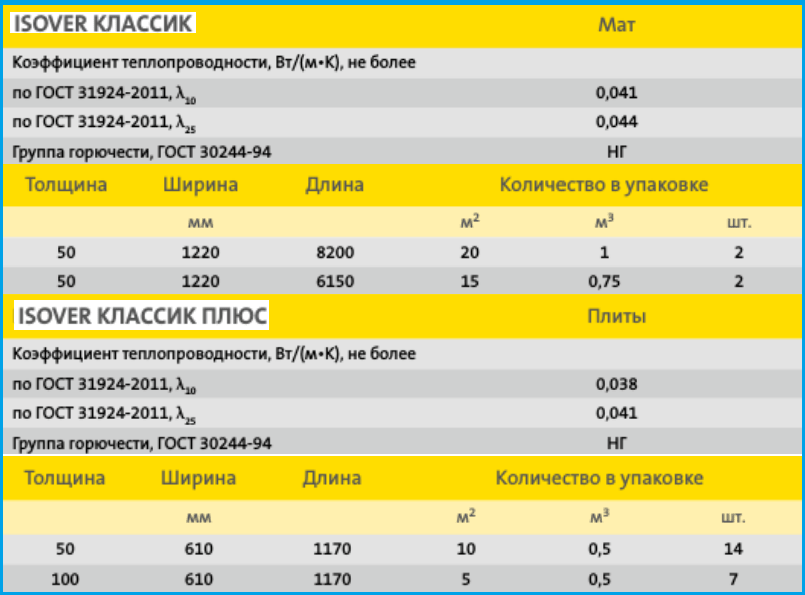

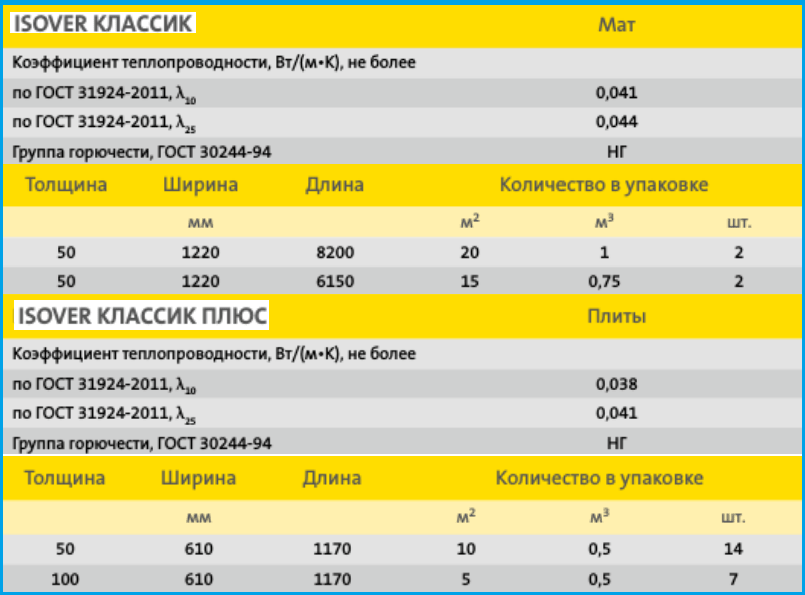

Classic series parameters

Classic

This brand of Izover on the basis of glass wool is produced in two varieties: Classic in rolls and Classic Slab, when using a product from Saint-Gobain for thermal insulation of an individual house, they achieve a reduction in heating costs of up to 65% compared to a non-insulated building.

Isover Classic parameters:

- The slab is designed for thermal insulation of external walls, ceilings and interior partitions, provides double insulation from heat loss and noise interference, the roll material is placed between the floor and attic logs.

- The CT of the slab insulator at 10 ° C is 0.038 W / (m • K), at 25 ° C - 0.41 W / (m • K), this indicator for thermal insulation properties with a thickness of 50 mm of mineral wool is equivalent to 950 mm of a brick wall. Rolls and mats at similar ambient temperatures have a thermal conductivity of 0.041 - 0.044 W / (m • K), respectively.

- Density: 15 kg / m3.

- Flammability according to GOST 3244-94: NG.

- Water vapor permeability: 0.55 mg / m • h • Pa.

- During installation, the sheets are placed in the frame without additional fastening, they have 100% recoverability, due to their elasticity, they tightly adjoin the frame without cold bridges.

- Standard sizes of 50 or 100 mm of sheet are 610x1170 mm, the package contains 14 or 7 pieces with a volume of 0.5 m3 and an area of 10 or 5 m2.

- Rolls are compressed 6 times, they are produced with a thickness of 50 mm with a size of 1220x6150 or 1220x8200 mm with an area of 15 or 20 m2 and a volume of 0.75 or 1 m3, respectively.

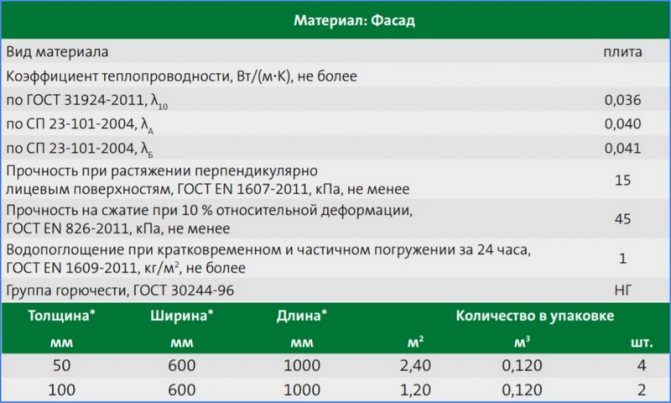

Facade series parameters

Facade

Slabs based on basalt fiber provide a high level of thermal protection of the building due to the homogeneity of the heat-shielding layer and its high mechanical strength, the Isover Facade brand has the following density and characteristics:

- Thermal conductivity: 0.036 - 0.041 W / (m • K).

- Perpendicular tensile strength: from 15 kPa, compressive strength: up to 45 kPa at 10% deformation.

- Density: 125 kg / m3.

- Flammability according to GOST 30244-96: NG.

- The Facade brand has a standard water absorption of 1 kg / m2 with partial or complete immersion in water for 24 hours.

- Packed in slabs of 60x1000 mm with a thickness of 50 or 100 mm in the amount of 4 or 2 pieces with a volume of 0.12 m3 and an area of 2.4 or 1.2 m2, respectively.

In addition to this brand, the manufacturer produces a product made of basalt fiber Isover Facade Master, which has similar characteristics and Isover Plaster Facade based on glass wool, which is the lightest base for plastering, with the following distinctive features:

- Fire hazard class KMO, flammability - NG.

- Tensile strength in the perpendicular direction relative to the front surface: from 15 kPa.

- It has a high modulus of elasticity and increased vapor permeability thanks to the use of the Weber therm Comfort technological development from Saint-Gobain.

- CT: 0.038 - 0.043 W / (m • K).

- Tiled insulation is supplied with a thickness of 50, 100 and 150 mm in packs of 8, 4, and 2 pieces, with an area of 5.76, 2.88, 1.44 m2, respectively, with a volume of 0.288 m3 and 0.216 m3 for sheets with a thickness of 150 mm, their standard size 600x1200 mm.

For thermal insulation of facades based on mineral wool, another brand Izover Ventfasad is produced in slabs with a standard thickness of 30 mm, dimensions 1190x1380 mm, 8 pieces in a pack with a total area of 13.14 m2 and a volume of 0.394 m3. VentFacade has a thermal conductivity of 0.032 - 0.037 W / (m • K), when custom-made it can be covered with black fiberglass on one side.

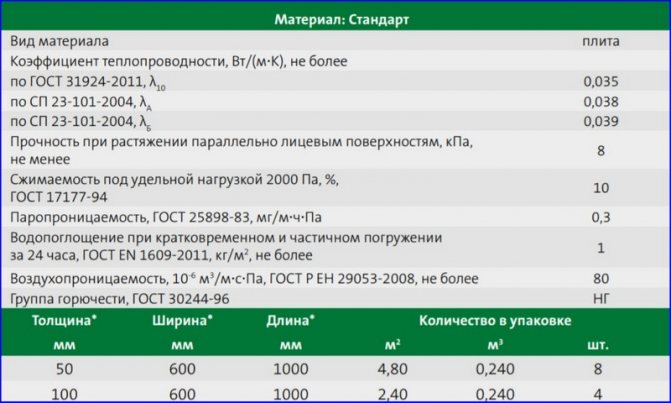

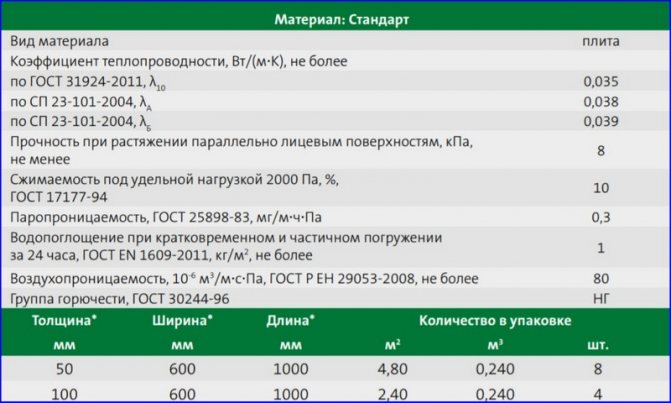

Series Standard - parameters

Standard

Isover Standard, based on basalt fiber, provides a high level of thermal protection, thanks to its high elasticity, it guarantees the absence of air pockets, during installation it is designed to be fixed to the surface with umbrella dowels, its main technical indicators are:

- CT depending on the temperature values of the medium: 0.035 - 0.039 W / (m • K).

- Flammability group: NG.

- High air permeability of the order of 80 10-6 m3 / m • C • Pa.

- Water vapor permeability: 0.3 mg / m • h • Pa.

- Basalt wool is supplied in slabs of 50 or 100 mm with dimensions of 600x1000 mm, in a pack, respectively, 8 or 4 pieces with a volume of 0.24 m3 and an area of 4.8 m2 or 2.4 m2.

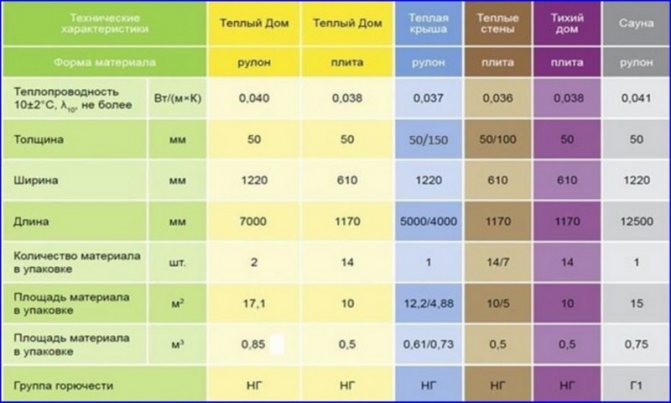

Features of Warm house and other types of Izover

Warm house

Insulation Warm House is produced in mats and is made of fiberglass, compressed 6 times, its main parameters:

- Thermal conductivity: 0.04 W / (m • K).

- Water vapor permeability: 0.55 mg / m • h • Pa.

- The thickness of the roll insulator is 50 (two mats in a bundle) or 100 mm, the width is 1220 mm with the lengths of 5490 or 7000 mm, their area is 13.4, 17.1 m2 with a volume of 0.67 or 0.85 m3.

- Isover Warm House Slab has standard dimensions of slabs in a package with a thickness of 50 or 100 mm - 610x1170 mm with an area of 5 or 10 m2 and a volume of 0.5 m3.

- Water vapor permeability: 0.55 mg / m • h • Pa.

- Density 11 kg / m3.

- Flammability: class NG.

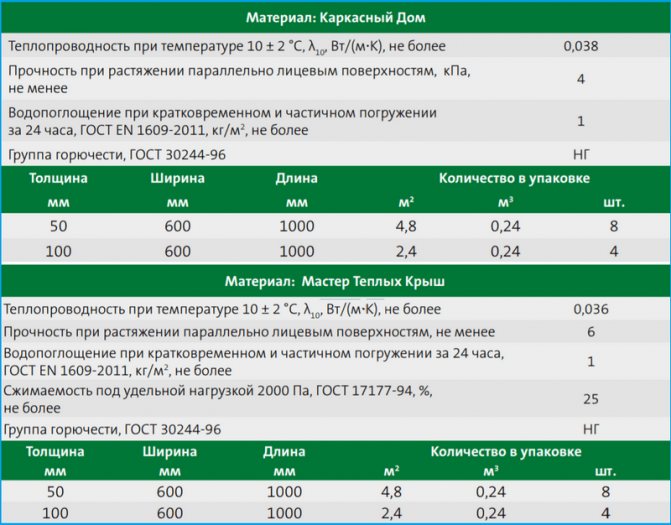

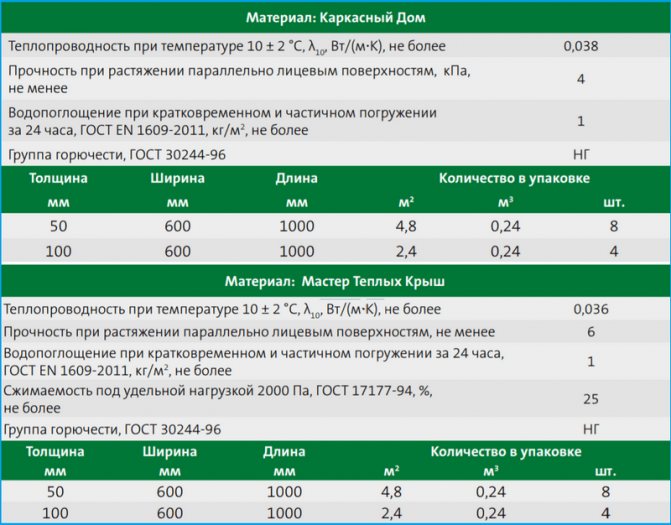

Frame house

Heat insulator A frame house based on basalt mineral wool is designed for insulating any frame structures of external walls, partitions, pitched roofs, floors and ceilings, has good elasticity and provides additional protection against noise, its main parameters:

- Thermal conductivity: 0.038 W / (m • K) at an ambient temperature of 10 ° C.

- Tensile strength in a direction parallel to the front surface: from 4 MPa.

- Water absorption: no more than 1 kg / m2.

- Flammability: class NG.

- Packing: slabs with a thickness of 50 or 100 mm, size 600x1000, 8 or 4 pieces each with an area of 4.8 or 2.4 m2 and a volume of 0.24 m3.

Frame house and Warm Roof brands - product properties

Warm Roof Master

Isover Warm Roof on the basis of basalt fiberglass is intended for insulating attics and pitched roofs, thanks to the elasticity of the slab, it retains its geometric dimensions for a long time and does not lose its physical characteristics under the influence of temperature extremes and high air humidity. The main characteristics of the insulation:

- CT: 0.036 W / (m • K) at 10 ° C of the external environment.

- Tensile strength in the longitudinal direction: from 6 mPa.

- Density: 15 kg / m3.

- Compressibility under a pressure of 2000 Pa in accordance with GOST 17177-94: 25%.

- Flammability: category NG.

- Dimensions and packaging of tiles: thickness 50 or 100 mm, in a package 8 or 4 pieces with dimensions of 600x1000 mm, an area of 4.8 or 2.4 m2 and a volume of 0.24 m3.

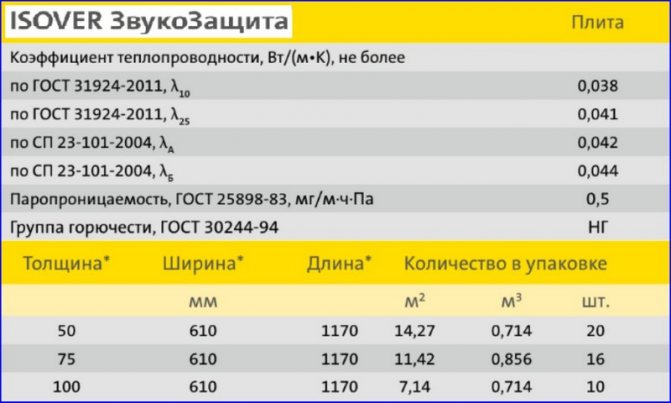

Material parameters Soundproofing

Sound protection

The ZvukoZashchita brand in the form of fiberglass-based tile elements is intended for use as sound insulation in interior partitions, ceiling ceilings and other frame-type structures, has the following features:

- Sound absorption on each side for a 75 mm thick partition, consisting of a profile metal frame for plasterboard and sheathed with plasterboard sheets of a standard thickness of 12.5 mm: 45 dB.

- Density: 15 kg / m3.

- Fire hazard class KO, flammability NG.

- Thermal conductivity coefficient: 0.038 - 0.044 W / (m • K).

- Water vapor permeability: 0.5 mg / m • h • Pa.

- Slab sizes: 50 (75.100) x610x1170 mm, in packs of 20, 16 and 10 pieces with an area of 14.27, 11.42 and 7.14 m2 and a volume of 0.714 or 0.856 m3.

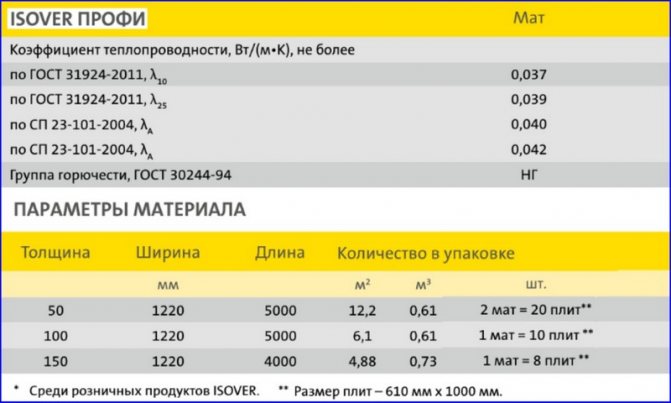

Properties of the Profi

Pro

The Roll-type Pro product is produced on the basis of fiberglass, intended for use in individual housing construction for insulating pitched roofs, external walls, frame-type partitions, has the following characteristics:

- Thermal conductivity coefficient: 0.037 - 0.042 W / (m • K).

- Density: 28 - 36.5 kg / m3.

- Water vapor permeability: 0.3 mg / m • h • Pa.

- Production form: mats or slabs, mats 50, 100, 150 mm thick, dimensions 1220x4000 (5000) mm, area 12.2, 6.1, 4.88 m2 and volume 0.61 or 0.73 m3, overall dimensions slabs 610x1000 mm.

- To facilitate cutting, the mats are marked with special markings.

Advantages and disadvantages

Among the advantages of building materials, the following factors should be noted:

- High quality thermal insulation. Isover is used in particular for facade insulation, which can significantly save on heating the house in the winter season.

- Resistant to extreme temperatures.

- Fire safety. Minvata does not burn, so it is used for insulating multi-storey buildings, where the spread of fire would have very serious consequences, as well as for the roof and attic floor, the structure of which consists of wooden elements.

- Resistance to mechanical and chemical attack.

- Tensile strength and no compression deformation.

- Excellent sound insulation allows the products to be used in plasterboard partitions.

- Resistance to the negative effects of rodents.

- Ease of installation.

These technical characteristics of Isover insulation speak in favor of its use in a wide variety of construction areas.

However, this material has its drawbacks. During installation, a full set of personal protective equipment must be used: glasses, gloves, a respirator, long-sleeved clothing that completely covers the body.

Even if it is very hot outside, you cannot neglect the above means, because the fibers cause irritation and itching when in contact with the skin.

If the insulation is moistened by 1%, its thermal insulation properties deteriorate by 10%. Therefore, when using the material on the roof and attic, it is imperative to carry out waterproofing work, because getting wet will lead to a loss of thermal insulation properties. And when installing slabs on the facade of a building, it is necessary to immediately tighten it with a net or plaster in order to avoid moisture due to atmospheric precipitation.

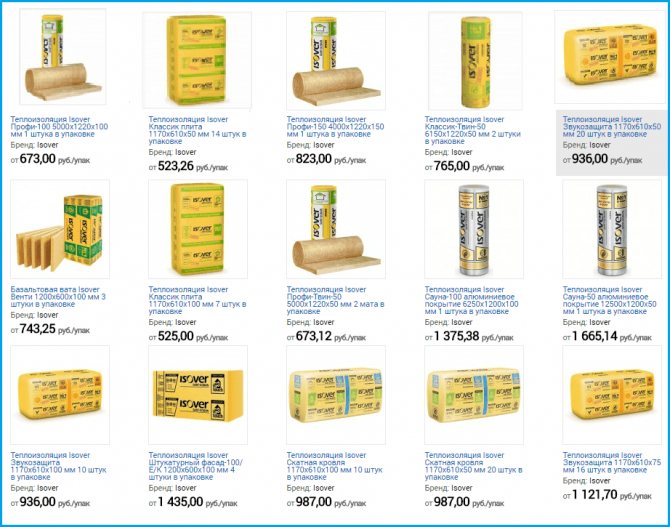

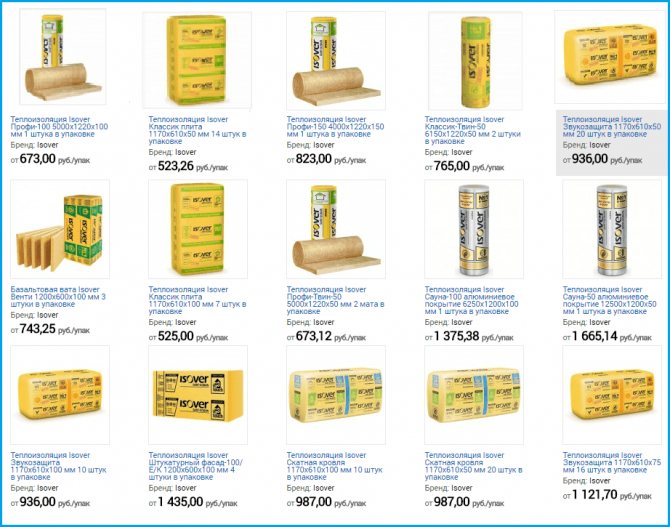

The approximate price of popular brands in the Russian market

The manufacturer Saint-Gobain supplies the domestic market with a wide range of products based on two types of mineral wool - fiberglass and rock basalt, the latter being more expensive due to its higher environmental friendliness, causing less harm to health during installation and operation.

The prices of plates and rolls differ for different suppliers of goods, usually the cost of one package is indicated, the average price for some types:

- 60 rubles for 1 m2 of a slab or roll of glass wool 50 mm thick (Warm House), the cost of a product with a thickness of 100 mm is 2 times higher;

- 85 rubles for 1 m2 of a slab of basalt wool 50 mm thick (Warm Roof series, Warm Walls, Quiet House);

- 125 rubles 1 m2 for quartz thermal insulation with a foil vapor barrier in one roll, intended for warming saunas and baths (Warm Sauna).

Price list for some brands

Effective thermal insulation solutions with ISOVER

How to install

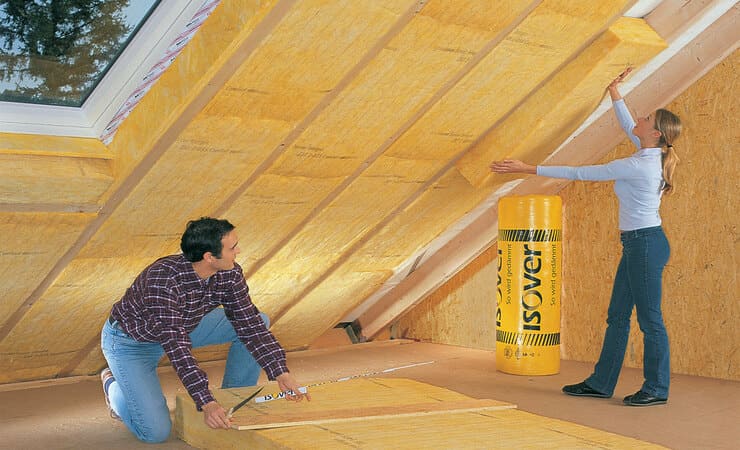

Figure 2. Installing Isover

Basalt facade Izover is supplied in slabs of the optimal size, which reduces installation time by 20%. Work can be carried out at any time of the year.

Insulation of the external wall with a plaster facade Isover:

- Prepare an adhesive composition. Dilute the solution with water according to the instructions, stir thoroughly with a construction mixer.

- Mark the cutouts for the windows and doors on the thermal insulation. Cut slabs.

- Install insulation in openings and corners. The joints of the slabs should be located at a distance of 10 cm from the opening. Do not install sheets at the corners using the bending method.

- Apply a thin layer of adhesive to the surface of the mineral wool. It is not possible to apply glue to the entire slab, but only to the edges, but not less than 40% of the slab area.

- Install thermal insulation from bottom to top. Remove excess adhesive. In the process of work, check the correctness of the level setting.

- If there are gaps of more than 2 mm between the plates, they must be closed with strips of thermal insulation.

- After the glue has completely dried, the boards must be fixed with disc dowels. They are installed at the joints. The depth of the hole must be 1 cm greater than the length of the dowel. When installing the disc dowel, it is not allowed to compress the mineral wool. Installation of dowel-nails with a bias is not allowed.

- Plaster and reinforcing fiberglass mesh are applied to the Izover facade insulation.

- After the plaster has dried, the surface is primed and decorative plaster is applied.

It is important to observe safety precautions: the body must be protected by overalls and gloves. Slabs should be cut in a ventilated area. The least amount of dust is generated by hand cutting with a sharp saw. After finishing work, you need to wash your hands and face with cold water.

All types of insulation have approximately the same cost - 3500-4000 rubles. But the main selection criterion should be the thermal conductivity coefficient, it is he who speaks about how warm the house will be. The Isover Facade brand is used in the construction of private and high-rise buildings throughout Russia, which testifies to its quality and reliability.