Plastic products have long entered our life, successfully replacing metal ones. Today, polypropylene pipes for heating are widely used, the technical characteristics of which made it possible to facilitate the work on the arrangement of heating systems. Even a non-professional will be able to make their installation on their own.

Features of polypropylene pipes

The main feature of polypropylene is considered resistance to high temperatures, and additional reinforcement is designed to protect it from expansion when heated. Due to the special hardness of the material, the pipes have a perfectly smooth surface, which positively affects their high resistance to corrosion and external factors.

Using polypropylene pipes for heating, taking into account the characteristics of the material and size, they carry out not only the installation of internal networks, but also the main ones.

Benefits

The popularity of polypropylene pipes is due to the following advantages:

- withstand pressure over 10 bar;

- aesthetic appearance;

- do not corrode, do not electrify;

- smooth inner surface eliminates dirt settling;

- attractive price;

- the chemical purity of the material allows it to be used in the food industry;

- ease of transportation, transportation is possible in bays.

disadvantages

Cons of polypropylene:

- does not tolerate direct exposure to ultraviolet radiation, under the influence of which it quickly collapses, additional protection is required;

- begins to melt at high temperatures;

- installation requires a special welding machine;

- difficulty in repair work and maintenance.

What pipes are suitable for the heating system

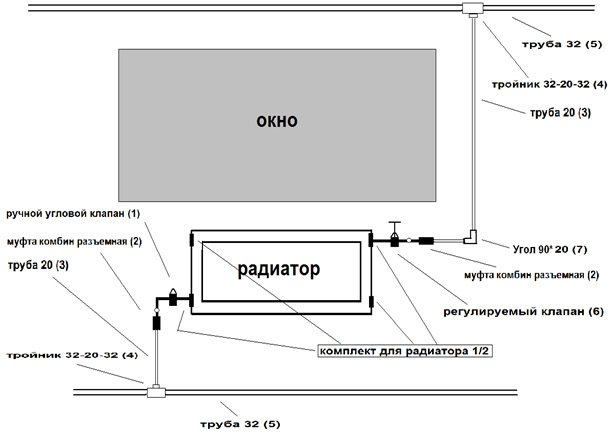

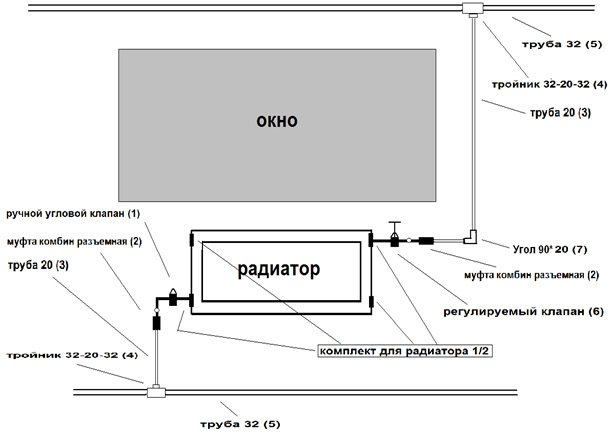

Any heating system involves drawing up a project diagram. After that, it is necessary to prepare and select in advance everything you need (materials and tools for installation work): pipes, fittings and the necessary tools. And only after that you can proceed with the installation of polypropylene pipes.

Elements are selected for a specific room, taking into account all its features and type of heating. It is important at the preparation stage to determine your strengths and understand what the job will be. After all, installation is not always easy with your own hands, sometimes you have to turn to professionals for help.

For heating systems, it is possible to use polypropylene, metal and metal-plastic materials. All these materials have their own advantages and disadvantages, which must be taken into account when selecting for your system. Polypropylene is considered the optimal material for heating system elements. In turn, metal ones are more overpriced, and also difficult to use, they are unstable to corrosion, which leads to a decrease in their service life. Reinforced-plastic materials are cheaper, easy to use, but their reliability and strength leaves much to be desired, so it is better not to consider this option for installing a heating system.

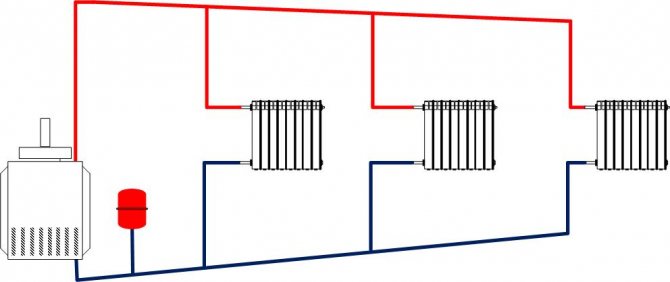

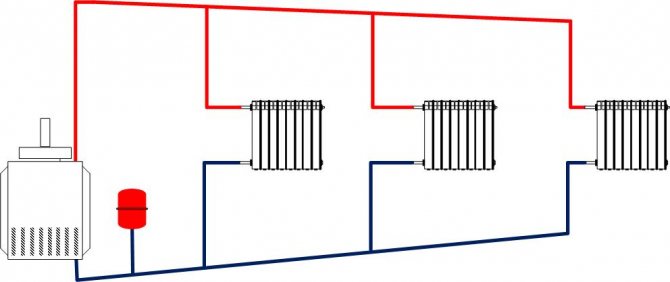

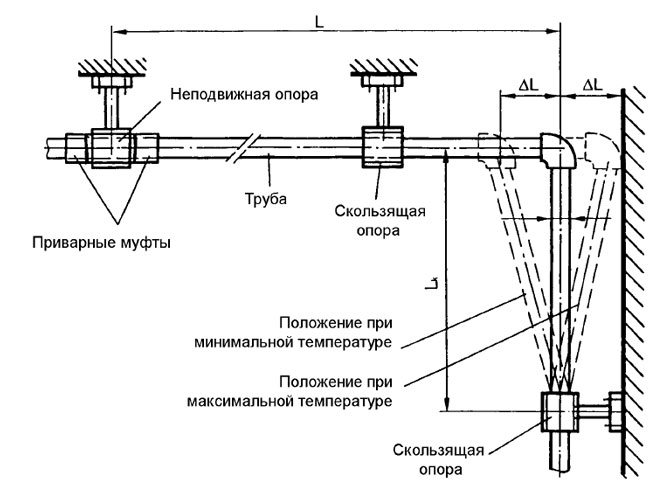

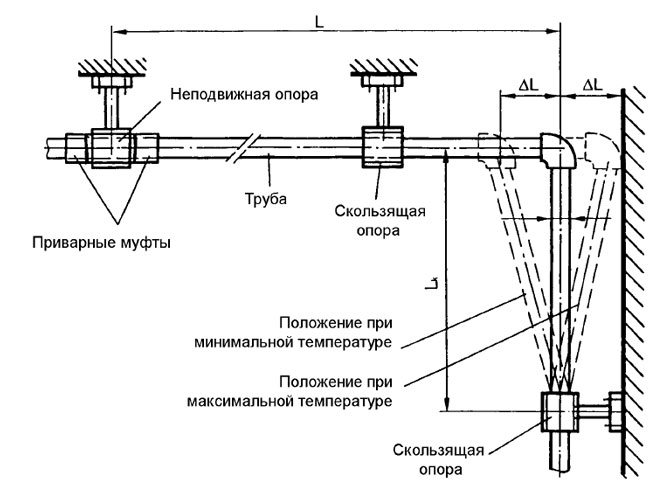

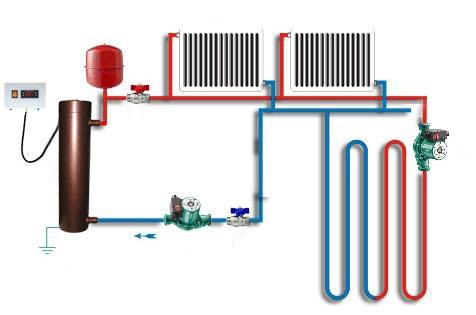

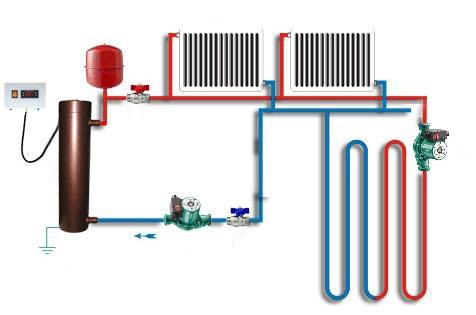

Heating scheme from reinforced polypropylene pipes.

From this we can conclude that polypropylene is best suited for the heating system, as it serves as a good option for installing pipes for water. It is important to know and be able to separate different types of polypropylene pipes, which are designed for hot or cold water. You need to use materials only for a certain type of work. For example, pipes for heating, where hot water will flow, should not be used for pipelines with cold water, since the temperature regime will be different and various violations and malfunctions in the system are possible.

For the installation of a warm floor or a heating system, you can safely choose polypropylene elements that have a large number of positive characteristics, among which the following points should be noted:

- Reliability.

- Durability (operated for 100 years).

- Resistant to corrosion.

- Lack of mineral deposits.

- High level of resistance to chemical compounds.

- Easy to mount.

- The possibility of carrying out repair work in cases of malfunction or breakdown.

- Affordability of the price.

The only, but the main disadvantage of this type of materials is flammability and instability to high temperatures.

Heating systems need the right choice, which depends on the correct diameter.

The diameter of the pipes should not be very small, but also not large, so as not to affect the cost of the system and the water pressure in it.

Views

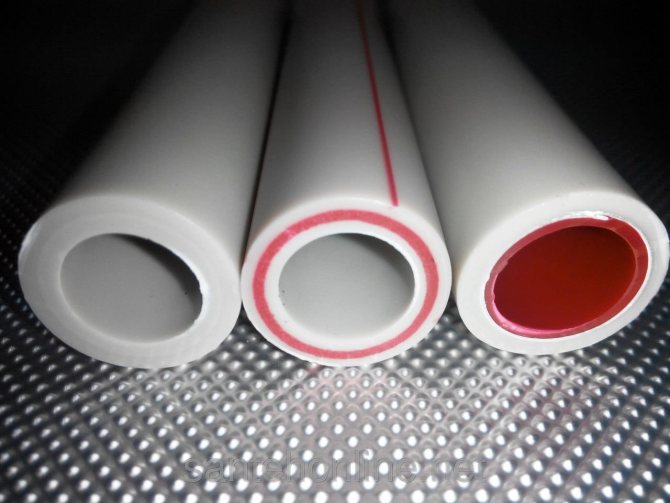

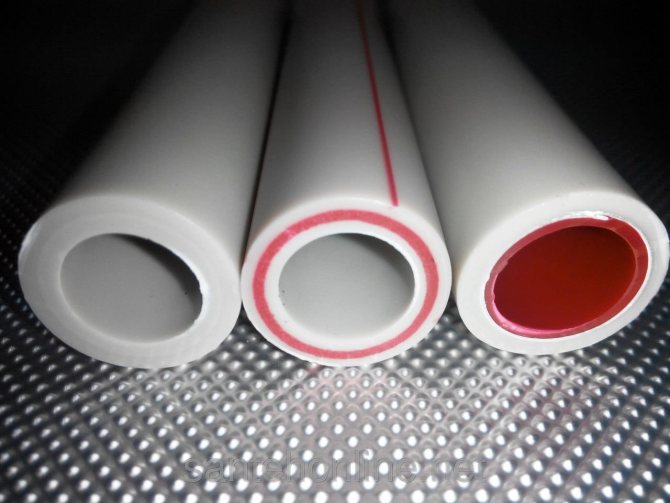

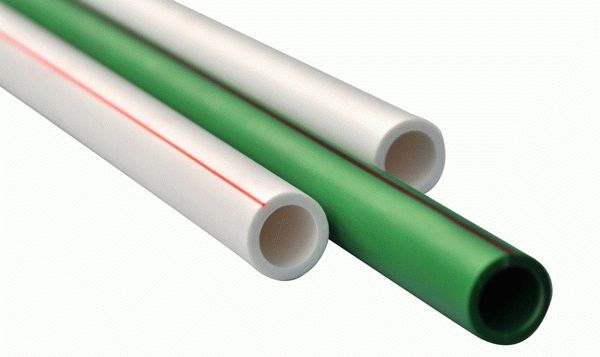

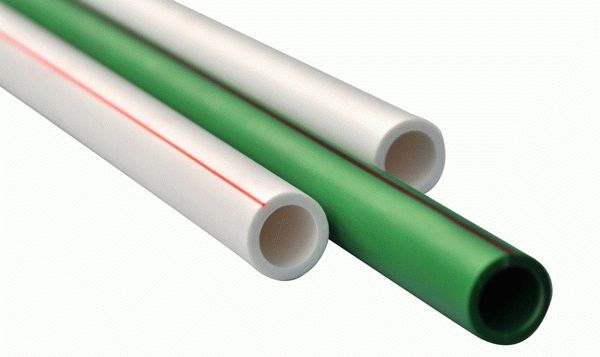

Pipes are produced for various applications, for example, solid polypropylene products with a small inner diameter are successfully used for underfloor heating, and materials with additional reinforcement show themselves perfectly when laying a heating circuit.

Fiberglass

Glass fiber-reinforced polypropylene is made by coextrusion, where the fiber is embedded between two layers of applied plastic.

Features of products with fiberglass:

- less susceptible to stretching when heated;

- keep their shape well;

- withstand pressure changes in the network;

- do not delaminate during operation;

- considered the most durable of all varieties;

- during installation, they do not require additional cleaning at the soldering points.

With aluminum

Materials with an aluminum layer withstand temperature fluctuations well, have minimal thermal expansion and practically do not lose their original shape at high temperatures, which is an indisputable advantage.

A feature of reinforced products during installation is the correct cleaning at the joints with the fittings. If you abandon this procedure, then the heating system will quickly fail, and you will have to redo everything during operation.

Solid plastic

Solid plastic products are good for underfloor heating and for use in hidden wiring. The concrete base serves as an excellent reinforcing material, protecting the pipeline from external influences, helping to reduce thermal expansion. Ease of installation and reliability of soldering allow you to forget about the problem of leaking joints for the entire service life.

The positive aspects of using pipes include:

- flexibility;

- length reaching 200 meters;

- special molecular memory that helps to return to its original form during cooling.

Reinforced plastic

The heating system made of metal-plastic is advantageously used in houses where the temperature fluctuations of the coolant exceed 90 ° C. The pipes do not sag under high temperatures, keeping their original appearance. The weak point in the system is the connecting fittings, which can leak when the coolant cools down and therefore require constant additional maintenance.

It is not recommended to use this material for hidden wiring devices, for example, for underfloor heating and a water intake device without access to the connection points.

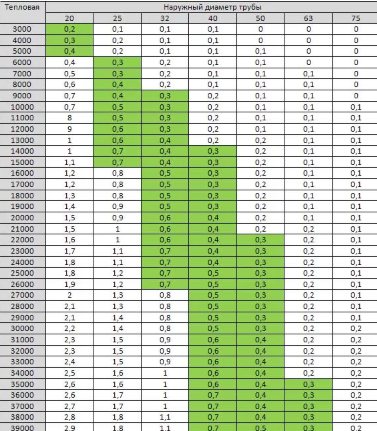

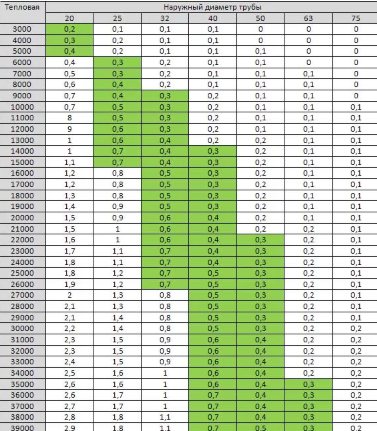

Formula for calculating the diameter of the line

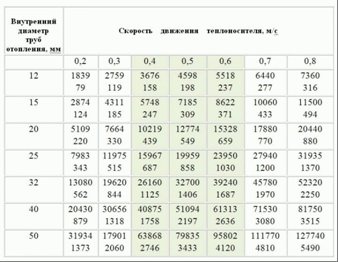

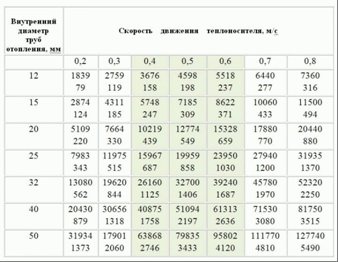

The correct determination of the diameter of the pipe used for the heating main of an apartment or private house is made on the basis of the table and formula. When working with the table, you need to focus on the green cells - they indicate the optimal speed of the coolant pressure.

The calculation is made according to the formula D = √ (354 * (0.86 * Q / ∆t) / V), where:

- V is the velocity of the liquid in the pipe (m / s);

- Q is the required amount of heat for heating (kW);

- ∆t is the difference between reverse and direct feed (C);

- D - pipe diameter (mm).

In a system with natural circulation, the pipe diameter is chosen larger

As an example, we can consider a two-story house with four wings (2 per floor) connected to a two-pipe system with a total heat loss of 36 kW, 20 kW of which is for heating the 1st floor, 16 kW for the second. For communications, polypropylene was used, they operate in 80/60 mode at a temperature of 10 degrees.

Counting Algorithm:

- The entire volume of water falls on the section where the first branch is connected to the boiler. This is a total heat quantity of 38 kW.

- In the table, you need to find this line and the corresponding green cells. With these parameters, the required diameter is 40 and 50 mm. The choice is made in favor of less.

- The fork shows the amount of heat on the first (20 kW) and second (16 kW) floors. The section of pipe fittings according to the table is 32 mm.

- Since there are 2 wings on each floor, the circuit is divided into two branches. For the first floor 20/2 = 10 kW per wing, for the second - 16/2 = 8 kW per wing.

- According to the table, the diameter is determined - 25 mm, used until the load drops to 5 kW, then - 20 mm.

Calculations for the return are not needed - pipes with similar parameters are used.

Specifications

The production of polypropylene pipes (PP) is regulated by the standards GOST 21553 and GOST 15139.

Pressure resistant

In heating systems, it is not always possible to maintain a constant pressure, its indicators may vary depending on the temperature regime and the throughput of the collector. Therefore, when using PP in the heating circuit, it is necessary to take into account the margin of the internal diameter of the pipe, which will have a positive effect when the pressure changes and save the system from ruptures.

Paying attention to the marking, you can easily select the required bore, taking into account the stock. So, with a calculated diameter of 20 mm, a collector with a bore diameter of 25 mm is selected, where the margin for expansion is taken into account when the pressure in the system changes. The letters PN and two numbers on the marking indicate the pressure for which the materials used are designed.

Installation of a heating system using polypropylene pipes

Installation of a heating system involves the correct choice of the scheme of work. For example, the use of polypropylene pipes provides several options for work:

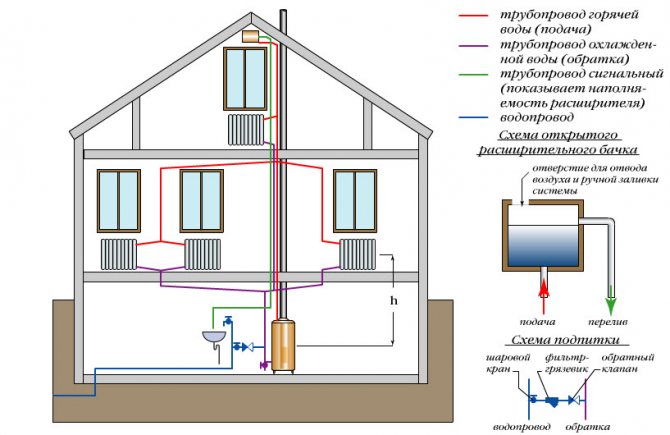

Hot water pipes installation diagram.

- Gravity circulation of water in the system. In this case, there is no need to install a circulation pump, since the movement of water will be independent. This option is suitable for rooms where the likelihood of problems with interruptions in the operation of electricity is frequent, which will lead to the impossibility of using the pump.

- Lower heating spill system. This system has a beam wiring, which assumes the presence of a pump used to increase the water pressure, which requires a smaller diameter.

- It is possible to use one- and two-pipe systems with connection to a radiator using a side or bottom connection type.

What to look for when choosing

For a heating circuit with unstable input parameters, it is more correct to use reinforced materials.

Pay attention to the following characteristics:

- pressure;

- wall thickness;

- reinforcement;

- temperature regime;

- bore diameter.

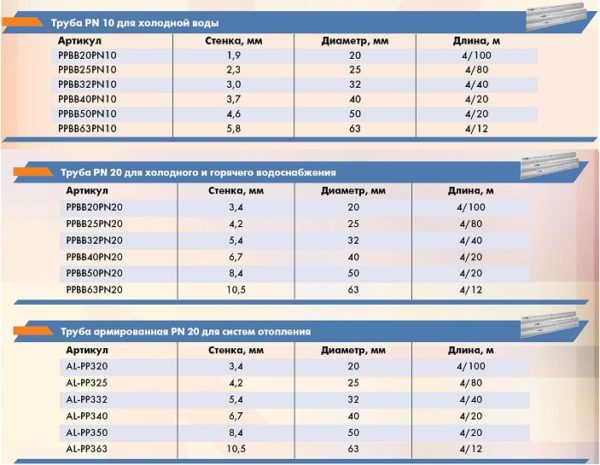

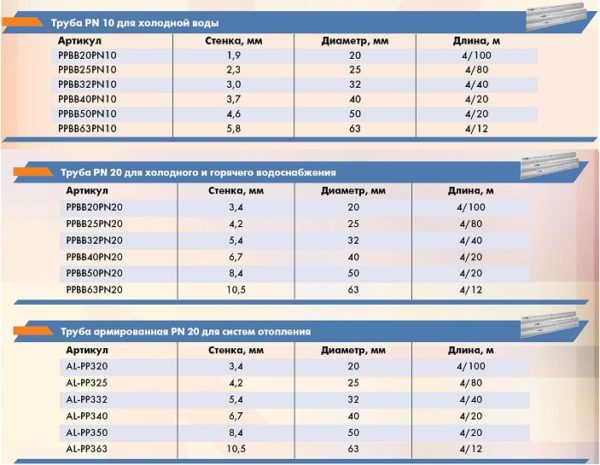

Types of pipes according to the maximum permissible pressure value

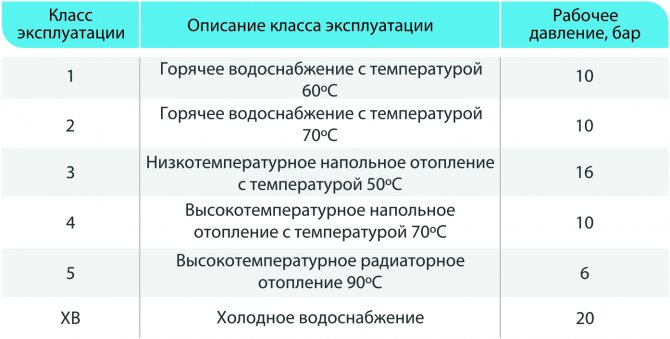

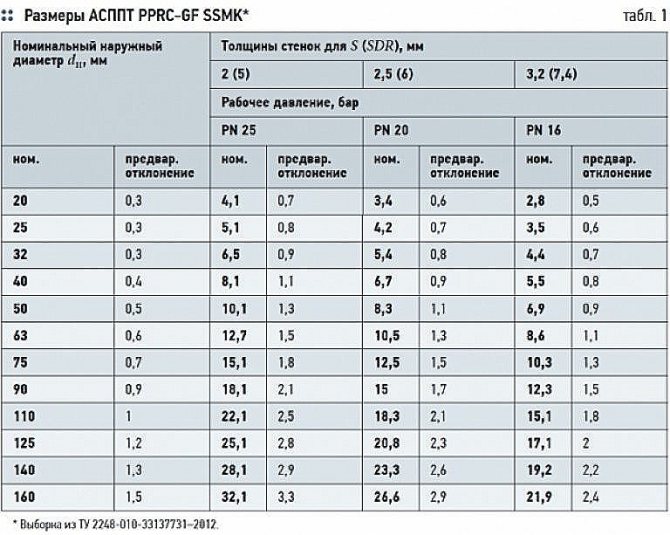

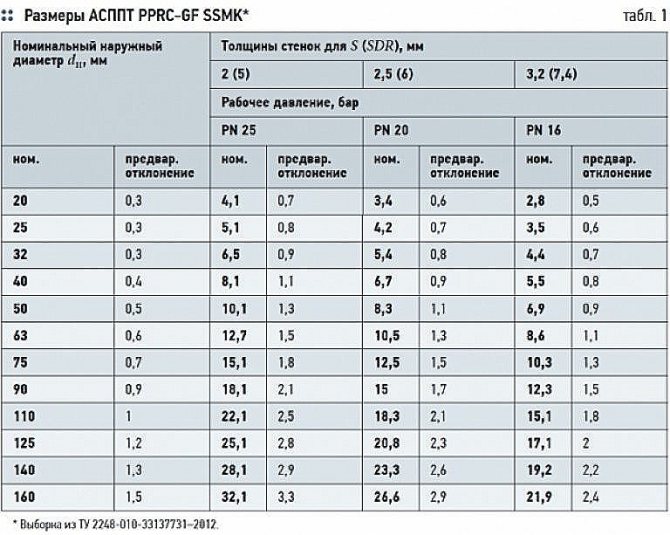

For the correct selection, they are guided by the standard TU 2248-010-33137731-2012:

- PN 10 are designed for a pressure of 10 bar at a heating medium temperature not exceeding 40 ° C.

- PN 16 - 16 bar at a water temperature of 60 ° C, and with significant changes in temperature, performance decreases sharply.

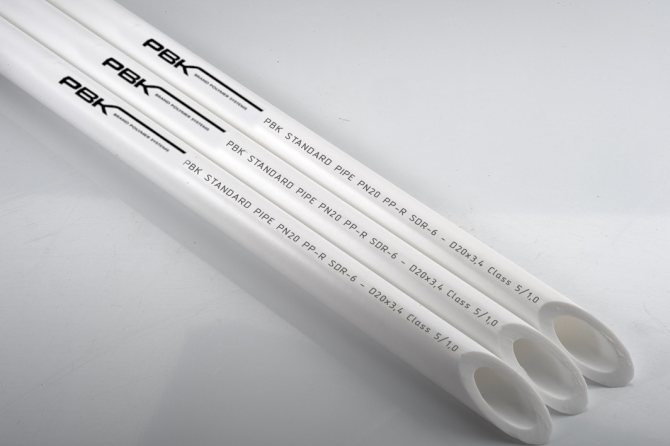

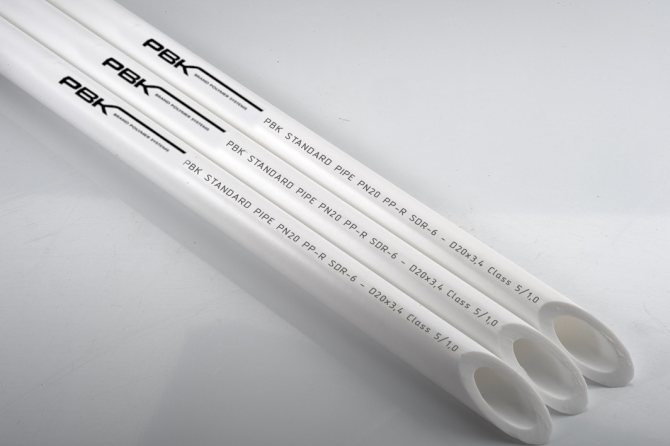

- PN 20 - 20 bar, designed for temperatures up to 80 ° C and recommended for hot water supply.

- PN 25 - 25 bar - these are only reinforced products with a temperature regime not exceeding 95 ° C, suitable for heating systems in private houses.

Prices for polypropylene pipes of PN10 class

Polypropylene pipes PN 10

Resistant to high temperatures

When marking pipes, the manufacturer indicates the temperature regime for which the products are designed. So, on reinforced, this parameter is equal to - 90-95 ° С, on ordinary polypropylene - 60 ° С.

Rust is excluded

The main positive characteristic of polypropylene is corrosion resistance. Even with the most low-quality coolant, the collectors are not overgrown with dirt. Due to the perfectly smooth walls, a reaction that promotes the destruction of the material is excluded. At the same time, one should not forget about the radiators, which it is advisable to rinse from accumulated dirt before winter operation.

Low coefficient of thermal conductivity

Plastic has poor thermal conductivity, so this fact is taken into account when installing heating. The same temperature regime of the coolant and the wall has a positive effect on the absence of condensate on the surface of the circuit, which led to its use for the installation of warm floors. The calculation of the power of the heating system is carried out exclusively for radiators.

Long service life

Manufacturers have endowed the plastic with characteristics that allow it to retain its original qualities for a long time, of course, subject to the operational rules. The warranty period is over 25 years.

Types, marking, scope

A wide range of polypropylene pipes has arisen due to the variety of types of this polymer. In order to make it easier for the consumer to navigate, international marking of polypropylene pipes for heating has been introduced. According to it, you can determine the main technical characteristics of polypropylene pipes.

The main types of markings and technical data are presented in the table below.

| Marking | Pipe pressure designation (maximum) | Polymer type | Appointment | Working temperature | Pressure parameters |

| PN (PPH) | Polypropylene pipes PN 10 | Homopolypropylene, thin-walled pipes | Cold water, ventilation systems, industrial pipelines (large diameter). | +20 ° С ... 45 ° С (depending on the type) | 1 MPa (10.2 kg / cm²) - 10 atmospheres |

| PPB | PN 16 | Block copolymer, high deformation | Cold water, ventilation, warm floor. Fittings and connections for polypropylene pipes are made. | +60 ° C | 1.6 MPa (16.32 kg / cm²) - 16 atmospheres |

| PPR | PN 20 (PPRC RS 20) | Random copolymer | Hot and cold water supply, heating with a radiator system. | + 80 ... +95 ° С | 2 MPa (20.4 kg / cm²) - 20 atmospheres |

| PPs, (PPRS) | PN 25 | Random copolymer, reinforced with a layer of aluminum, fiberglass, nylon. | For all types of water supply, for central heating systems, underfloor heating. | +/– 95 ° C | 2.5 MPa (25.49 kg / cm²) -25 atmospheres |

It is necessary to choose products made of polypropylene for heating and water supply, starting from the parameters indicated above

.

Table: diameter, wall thickness, weight.

| Outside diameter (mm) | Wall thickness (mm) | Weight, mass (gram) | ||||||

| PN 10 | PN 20 | PN 25 | PN 10 | PN 20 | PN 25 | PN 10 | PN 20 | PN 25 |

| 20 | 20 | 20 | 1,9 | 3,4 | 3,0 | 110 | 167 | 172 |

| 25 | 25 | 25 | 2,3 | 4,2 | 3,3 | 159 | 261 | 242 |

| 32 | 32 | 32 | 2,9 | 5,4 | 4,0 | 253 | 424 | 381 |

| 40 | 40 | 40 | 3,7 | 6,7 | 5,0 | 398 | 653 | 587 |

| 50 | 50 | 50 | 4,6 | 8,3 | 6,5 | 625 | 1020 | 825 |

| 63 | 63 | 5,8 | 10,5 | 981 | 1620 | |||

| 75 | 75 | 6,8 | 12,5 | 1380 | 2300 | |||

| 90 | 8,2 | 1980 | ||||||

| 110 | 10,0 | 2950 | ||||||

Thus, pipes bearing the designation PPs (PPRS) have the highest performance.

All polypropylene is divided into types:

- Consisting of monolayer polymers of different types: PPH, PPB, PPR, PPs. Depending on the type of polymer, they have different technical parameters. Each of these types of pipes has its own class.

- Pipes consisting of several layers (reinforced) are mainly copolymers.

They are reinforced:

- aluminum foil: perforated and solid;

- polyethylene;

- fiberglass.

The second type is used for all types of communication. They have increased strength and are resistant to deformation.Polypropylene pipes for heating of this type have a rather long service life. They are not afraid of high temperatures up to +95 ° C, but at maximum loads, the service life is reduced. To check the system after installation, it should be noted that setting the temperature close to +120 ° C (steam t) is very risky.

The strength of the reinforced polymer itself has created the prerequisites for its use in the heating system of multi-storey buildings. It finds application not only in the piping of central heating systems. Due to the low linear expansion of PPs, polypropylene hot water pipes have proven themselves well for laying routes, therefore, they are in demand among consumers.

Reinforced pipes

Pipes reinforced with polyethylene and fiberglass are equated in class with metal-plastic. Their peculiarity is that the strength of the products is not inferior to pipes with an aluminum layer. The advantage is that there is no need to strip, chamfer before mounting, so they form a tighter joint when soldered. Some experts question whether they can be used for flush-mounted systems.

Reinforced PPs (random copolymer) pipes are made from propylene with the addition of ethylene molecules using a high-temperature regime, by means of punching and mixing (extrusion). They can be used for hidden distribution of warm floors. Experts recommend specifically polypropylene, reinforced with polyethylene and fiberglass

.

Values of markings on pipes:

- the first word denotes the name of the manufacturer;

- the second - means marking by the type of polymer from which the pipe is made (PN, PPB, PPR, PPs);

- the third value will indicate the nominal pressure properties of the pipe (designation: PN 10, PN 16, PN 20, PN 25);

- the next is a series of numbers indicating the diameter and thickness of the walls;

- then comes the class - it means the degree of operational reliability;

- then follows a description of the permissible working pressure in figures (how much the pipe will withstand);

- at the end of the marking indicate TU and GOST, which depend on the grades of the polypropylene pipe.

Of course, not all properties of the product are indicated in the marking. But enough to get an idea of the general purpose.

Meaning of markings on pipes

An important selection criterion is the marking applied to the surface of the manufactured product, where, in addition to the operating parameters of pressure and temperature, the pipe diameter is indicated. This is the main indicator for the heating system of a private house.

Product diameters:

- 16-20 mm - designed for underfloor heating and water supply;

- 20-25 mm - for the heating system in private houses;

- 25-32 mm - for centralized highways;

- 200 mm and more are used for heating administrative facilities.

Particular attention should be paid to the diameter of polypropylene pipes used for heating a private house, where one type cannot be dispensed with.

The correct combination and selection of materials with different markings contributes to an increase in heating efficiency several times. So, the transition from a larger diameter of pipes to a smaller one increases the pressure in the system, contributing to excellent circulation of the coolant and increased heat transfer.

Polypropylene pipes for heating technical characteristics

How to choose the right pipes of the required diameter

In cases where heating is carried out in a private house or cottage, the pipes must be selected taking into account the fact that the diameter will not change only when there is a direct connection to the central heating system. In the case of an autonomous pipe system, any size (different diameter and length) can be used, depending on the preferences of the owner of the house.

When choosing the necessary blanks, you need to take into account all the features, especially when it comes to a natural heating system, where the ratio of the cross section to the pump power will not be a primary feature. This fact is attributed to the advantages of this heating system.

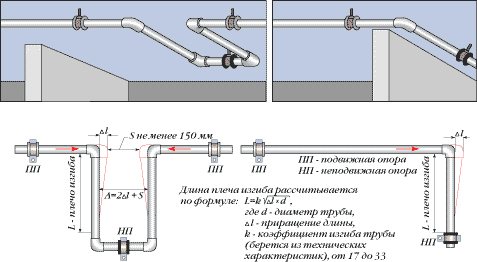

Pipe installation diagram.

The disadvantage of such a system is the small radius of action and the high cost of large elements used in this case.

To ensure the efficiency of the system, it is necessary to maintain a certain level of pressure in it, which allows the water moving inside to overcome all obstacles in its path. Resistances (obstacles) can be in the form of friction of water against the walls, a drain or a tap and a heating device. The most interesting thing is that the resistance and the speed with which water will flow depends on the length and diameter of the pipeline. With a high water velocity, a small cross-section and a long pipeline, the level of resistance on the path of the water increases.

Selection recommendations

It is worth giving preference to reinforced products that allow high-quality installation of the heating circuit and forget about the problems associated with leaks for a long time.

Experts recommend:

- purchase materials from trusted suppliers, products must have a quality certificate;

- pay attention to the marking containing complete information;

- make a choice in favor of reinforced products;

- choose pipes with fiberglass reinforcement for the heating system. Long-burning stoves for wood-fired heating can be found on our website.

Fiberglass Reinforced Pipes Prices

Fiberglass Reinforced Pipes

DIY heating installation

The heating system can be installed independently. The main thing is to choose the right materials, correctly match them and seal them together. The design itself is fairly simple to assemble and operate.

Which connectors to use

In order to attach one pipe to another, pipes to risers and radiators, pressure gauges and other devices, special connectors are needed. There are the following types:

- Straight (conventional couplings). They are necessary in those places where one pipe is connected to another of the same diameter, but not at an angle;

- Curved. Used in places where the system bends and turns;

- Triple. They are necessary if you need to make two from one pipe or one from two. For example, in the places where the branches from the main pipe to the radiator;

- Blind (stubs). They are installed in dead-end zones, for example, on extreme radiators;

- With a change in the inner section. They are used when changing from a pipe of a larger diameter to a pipe of a smaller diameter. For example, when connecting pipes to risers;

- With plastic and metal. Such connectors are necessary in a place where there is a transition from plastic products (pipes) to metal ones (radiators, pressure gauges, tanks).

Before starting the installation work, it is necessary to recreate the exact diagram of the proposed system on paper and calculate the number of connectors of each type. In addition, it is important to select connectors whose internal cross-sectional diameters will match the pipe diameters.

We recommend that you familiarize yourself with: Using paint for the surface of galvanized pipes

Algorithm of installation work

After drawing up a heating scheme and purchasing all the necessary elements, you can proceed to the installation work.

To do this, you need a special set consisting of a soldering iron with nozzles (couplings and drones) and shaders.

It is not necessary to purchase it to install one heating system, you can rent it.

It is important! When carrying out work for the first time, it is recommended to buy more parts than necessary. After incorrect welding, the detached parts are no longer usable, therefore you will have to take new ones.

The installation work algorithm is as follows:

- Cutting pipes and unfolding connectors. This is a preparatory stage, which is important to follow strictly according to the instructions. The pipe is cut using special scissors.

- Shaver pipe cleaning. This step is only necessary when installing pipes with aluminum reinforcement. To do this, take a shaver and put it on the pipe, rotations are done manually or with a screwdriver.

- Soldering iron assembly.Couplings and mandrels of the corresponding diameter are put on the apparatus, after which it is turned on and waiting for heating up to 260 ͒С. At this time, a depth mark is made on the pipe corresponding to the connecting element.

- Compound. A pipe is inserted into the sleeve of a heated soldering iron to a certain depth, and a connecting element is inserted into the mandrel on the other side, after which the elements are soldered to each other for a certain time. Time is calculated as follows: with a pipe diameter of 1.6 cm - 5 seconds, 2.0 cm - 7 seconds, 3.2 cm - 8 seconds.

- All other sections of the pipe are collected in a similar way, after which the structure is attached to the heating system.

Features of installation in an apartment and a private house

It is easier to install a heating system in an apartment. As a rule, one radiator is installed in each room, which departs from the common riser. The pipes are connected according to the proposed scheme, and then they are connected to the riser and the radiator.

In the case of installing several radiators, you can choose two-pipe and one-pipe heating systems. In the first case, from each previous radiator, the coolant goes to the next. Accordingly, in all subsequent radiators, the temperature will be lower than in the previous ones. In the second case, there are two pipes: one for the inlet of the liquid, the other for the outlet.

Before carrying out work in the apartment, it is necessary to agree on the repair of heating with the housing office and the nearest neighbors. Replacement of risers, as a rule, is done centrally.

When installing a heating system in a private house, there will be more work... It is necessary to select the type of coolant, the type of boiler and the system for removing the coolant from the boiler and in the reverse order.

Installing the boiler itself in the absence of experience can also be difficult. A heat pipe is installed, as a rule, in the basement of the house. Then the boiler is connected with pipes to radiators in each of the rooms. Such systems are quite complex, but they also have advantages - the temperature and pressure in the pipes can be adjusted independently.

Types of pipes for heating

Reinforced polypropylene pipe, regardless of the type of additional material, can be used to supply hot water through the system. Fiberglass and basalt thread are melted with polymer during the production process. Aluminum is fixed on the polypropylene wall with a special glue. The metal is perforated. This allows the bond between the inner and outer polymer layers to be maintained.

Reinforced polypropylene pipes, regardless of the material chosen to strengthen the structure, have a certain structure. The inner and outer layers are made of polymer. In the center between them is a certain material for reinforcement.

When heated, all-polymer pipes elongate and sag. The reinforced polypropylene pipe is distinguished by its special design and increased rigidity. The most effective in this case are aluminum and basalt fiber. They reduce the coefficient of deformation of the product by 3 times. Their price will be higher than that of fiberglass pipes.

disadvantages

How to choose a machine for welding polypropylene pipes

There are several disadvantages to polypropylene pipes reinforced with aluminum. However, one of them is more pronounced than all the others: they need high-quality cleaning before welding.

Despite this drawback, some companies are actively using pipes with perforated aluminum reinforcement. Perforation has a rather strong effect on the level of oxygen penetration into the heating system. Due to such penetrations, the heating boiler and other parts of the heating can fail.

Fiberglass-reinforced stripped pipes do not have the above-described disadvantages.

What pipes are installed in the house

What is needed for the coolant to circulate at an optimal speed? A little, just take into account the recommendations of heating engineers when connecting radiators and piping.

So, given the fact that most systems are mounted using polypropylene pipes, and their marking indicates the outer diameter, it is worth considering:

- The connection of one separate or maximum of two separate radiators is done with a 16 mm pipe;

- Branches of one powerful, up to 7 kW or several small-power devices of 1.2-2.0 kW each, but no more than 5 pieces in the wing, you can use a 20 mm plastic pipe;

- The 25 mm pipe is applicable both for group connection of batteries and for laying a line. It can connect one or two powerful radiators up to 15 kW or up to 7-8 small ones with a total power of 11-12 kW. It is used for individual branches or directions;

- Pipes 32 mm are used as the main line for a separate object - a building or a floor. Up to 12 pieces of batteries with a capacity of 19-20 kW are connected to it.

- Up to 20 heating devices with a total power of 30 kW are connected to pipes with a diameter of 40 mm.

Another indicator that needs to be remembered in the calculations is hydraulic resistance. For a one-story house, these will not necessarily be turns and bends, even with a straight pipe laying, the pressure inside it may vary in different sections. In addition, air pockets can form in the radiators. Because, they simply will not be pushed by the pressure of the liquid. Therefore, when selecting the diameter of the pipelines, the installation of injection pumps is also taken into account. They will maintain the required speed of movement of the coolant and compensate for hydraulic resistance.

So, for a building with a heated area of 150-180 sq. meters to overcome hydraulic resistance and maintain normal pressure, a pump with a capacity of 25-40 W is suitable. It will provide a pressure of up to 0.4 atmospheres. For an area up to 300 meters, a pump with a power of 45-60 W is installed, providing a pressure of up to 0.6 atmospheres.

Product advantages and disadvantages

The technical characteristics of polypropylene pipes have their own advantages and disadvantages. However, like any other material.

Let's start with the positives:

- The price for this type of material is quite affordable for an ordinary consumer.

- The coefficient of thermal conductivity is low, which ensures minimal heat loss. There is no need to equip additional thermal insulation, which also leads to the absence of condensation.

- If the soldering technology was followed, then such joints will have a very high strength and reliability, which will significantly affect the service life of the products.

Polypropylene pipes and fittings

- Such pipes are light enough, which has a positive effect on the installation process itself. There is no need to invite a whole team and special equipment. This characteristic also has a positive effect on the fact that during the construction of a private house, the load exerted on the reference points will be significantly lower than when using metal or cast-iron counterparts.

- These products are good for the construction of private houses, as they have good resistance to low temperature indicators. Even if the building will not be used in winter, the system will remain intact, since the material has good elasticity. Therefore, even if the water inside the pipeline freezes, this will not affect the integrity of the material in any way.

- A polypropylene pipe for heating has such characteristics as resistance to "overgrowth". On the inside, such products have polished surfaces that do not allow salts to settle, which means that all gaps remain the same as when the system was first turned on.

- Since this material is intended for arranging heating, then, accordingly, high-temperature water will flow through such a pipeline. But polypropylene is not afraid of such influences, it easily withstands liquid at 100 degrees.

- The installation itself has a fairly simple technology, so even if you tackle it yourself, the work will be 2 times faster than when creating a system of metal pipes.

- Despite the fact that such products at first glance have thin walls, they have excellent sound insulation. Therefore, even if the entire system is located near the surface of the floor and walls, the noise from the running water will not bother the owners of the house.

- The appearance of such material is quite aesthetic, so even if some areas are not covered, the interior will not spoil it. In addition, polypropylene does not require regular painting, and if the material was purchased of high quality, then even after many years of intensive use, the pipes will not change their color.

Polypropylene pipes

Of course, this option has a huge number of advantages, but for the sake of fairness, you should also go through the negative points:

- Despite their elasticity, such pipes are quite elastic, so if it becomes necessary to create complex systems, you will have to use a large number of fittings.

- In order to connect the entire pipeline together, you will need a special soldering iron. For the sake of fairness, it is worth noting, of course, that this tool is quite simple to work with, but it is far from cheap. To resolve this issue, you might consider renting a tool.

- When the material is exposed to high temperatures, it expands, and this already leads to the fact that the pipe itself increases its length. Accordingly, the installation itself inside the walls becomes somewhat difficult.

general characteristics

Various plastic products gradually replaced metal communications. Modern production offers several options for pipes made of this material, each of which has its own characteristics.

In the process of planning a renovation or building a new house, the question arises: which polypropylene pipe to use for heating? Such products are marked with the letters PPR. They include several varieties. In addition to polypropylene, the category of plastic products includes pipes made of polyethylene (PERT) and metal-plastic (PEX-AL-PEX).

Polypropylene differs in technical characteristics, installation features. It is one of the best, durable materials. There are several groups of polypropylene communications. Today it has become possible to install heating from polypropylene pipes. New technologies have made it possible to use various methods of reinforcement in the production of such products. This greatly expands the scope of the material.