General characteristics of polypropylene pipes

Is polypropylene so good

Today the market is overflowing with pipes made of polymer materials from various manufacturers. For example, you can find Chinese, Turkish, Czech, Russian and German pipes. Choosing any of these can be a daunting task. Before we introduce you to the advantages of polypropylene pipes from each of the manufacturers, we will consider the general characteristics of polypropylene pipes, their positive properties:

- Polypropylene is corrosion resistant. Due to this, the pipeline maintains its original quality indicators for many years.

- The service life of polypropylene pipes exceeds the service life of metal pipes by three or even four times.

- Resistant to possible biochemical aggressive influences.

- Even under extreme weather conditions, polypropylene pipes remain extremely reliable. Fittings and pipes themselves are not subject to rupture during winter.

- No vibration and noise. The noise in the pipes is not so significant as to create inconvenience to others.

- The absence of strong hydraulic resistance, as a result, the inner shell of the pipe does not affect the water pressure in any way.

- Unlike steel pipes, polypropylene pipes save the heat of hot water by 20%.

- Does not create problems during installation.

- Due to the large number of all kinds of fittings, it is possible to make a plumbing system of any configuration.

- Polypropylene does not affect human health in any way.

So, there is no point in doubting the quality of polypropylene pipes. Now let's start reviewing pipes from different world manufacturers.

Turkish quality or soap bubble?

Among the wide variety of polypropylene pipes, Turkish pipes occupy a separate place, which is justly deserved. Consider seven types of polypropylene pipes that have reliably mastered the domestic market.

Pipes and fittings TEBO

TEBO technics. TEBO technics pipes are manufactured from Ø20 to Ø160 mm. They are used for water supply and heat supply in industrial enterprises. They do an excellent job of transporting various aggressive chemical mixtures. The TEBO technics product line includes the production of PN10 and PN20 pipes. This type of polypropylene pipes is intended directly for the creation of water supply networks. The Turkish company TEBO technics produces reinforced pipes and fiberglass. According to estimates by TEBO technics, it is in the middle class of fitness. There should be no problems working with these pipes.

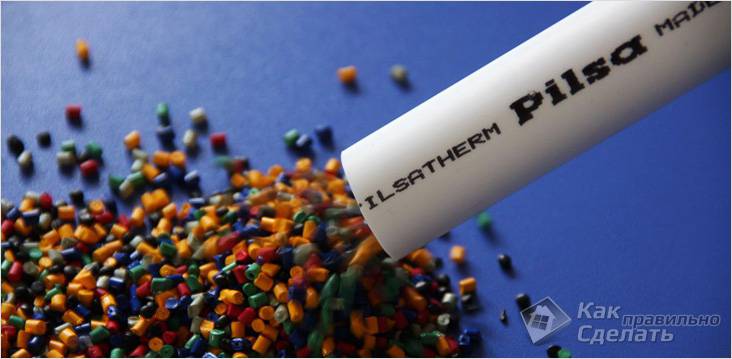

Pilsa

Pilsa. Unlike other polypropylene pipes, Pilsa is flexible, strong and durable. Due to this, these pipes are successfully used in cold / hot water supply systems and in heating systems. It is customary to use Pilsa PN20 for the heating system and hot water, and PN10 for cold water supply. For several years after their installation, you will not worry about their maintenance. The most important requirement is compliance with the installation technology.

Pilsa polypropylene pipes must not be hidden in the wall. To use these pipes in a heating system, a controlled boiler must be used, as otherwise a temperature of more than 95 ° C may be given.

For the sake of objectivity, one drawback of Pilsa pipes should be noted. After stripping pipes from aluminum, it can partially remain on the surface. This is because the pipes have a slight ovality.

Wesbo. The Turkish Novoplast plant produces polypropylene pipes, which are known as Wesbo. Although the price of these products is low, they are of high quality. However, as for the set of shaped elements, there is a big minus, since the choice is very small. But this is perhaps the only drawback, therefore, they are also very popular in our market.

Valtec

Valtec. Valtec Turkish pipes are of the best quality. PP-R 100 fittings are manufactured here, which allows the pipes to have greater reliability and strength. The pipes are perfectly round. The location of the foil in the reinforced pipes is ideal.

Firat. Fittings and pipes of the PPRC system from the Turkish company Firat are manufactured in accordance with all existing international quality standards. For many years the company has been occupying leading positions. These pipes are easy to install and maintain. They don't rust.

The only drawback of Firat pipes is their high coefficient of expansion when they are heated. If you use them in hot water supply, then Firat pipes can lead.

Kalde. Kalde pipes are often compared to Ecoplastic. But this comparison is biased, since Kalde pipes have a solid aluminum shell. Ekoplast has a perforated shell. Inside, Kalde plastic is gray. According to reviews, Kalde polypropylene pipes are softer and more pliable, and due to the lack of perforation on the aluminum layer, pipe delamination can occur.

If you do not follow the Kalde pipe installation technology, then bubbles will appear on the pipe surface. Their laying is allowed only outside the wall.

Turkish pipes

Jakko. The company produces high-quality polypropylene pipes - reinforced with fiberglass. In the process of soldering, they show their best side. Joints can only leak if the specialist who soldered them does not have experience. Although most often problems arise when soldering hot water supply and heating. For cold water, Jakko pipes are ideal. Although the manufacturer claims a minimum level of linear expansion, there is sagging on a track of more than nine meters.

Expansion joints can be installed in the pipeline to cope with the problem of sagging. On average, every four meters.

What is specific about polypropylene pipes

Polypropylene pipes have the following strengths:

- Light weight compared to a metal pipe. This greatly simplifies the installation and transport of pipes and fittings.

- They are not afraid of rusting, dirt, corrosive liquids.

- The organization of the pipeline is very fast: no complicated devices or special skills are required.

- The service life is 50 years or more.

- Many types of polypropylene pipes have good sound insulation characteristics.

- Polypropylene for heating is completely environmentally friendly.

There are also some disadvantages:

- Significant coefficient of thermal expansion. Reinforced products have them at the level of 2-3.5 mm per 1 m, solid ones are 4-5 times more pliable.

- As for the pipe with external reinforcement, then it will be necessary to process it with special devices.

- The market is replete with fakes of polypropylene pipes: the outer layer is especially prone to defects in this case.

- The high fluidity of polypropylene pipes leads to the fact that even the own weight of the products can contribute to deformation. To avoid such phenomena, the polypropylene pipeline is equipped with special fasteners, which are installed every half a meter.

- The significant stiffness of polypropylene implies the need for a large number of fittings when organizing bending sections.

Chinese pipes - cheap fake or good quality?

Although products from China do not always enjoy a positive reputation, good quality can be found among Chinese PP pipes. We present to your attention well-known pipe brands that can be found on the Russian market:

Blue ocean

Blue Ocean. The Chinese company Blue Ocean produces quality polyethylene fittings and pipes. As practice has shown, pipes from the manufacturer Blue Ocean are excellently soldered. For these pipes, it is customary to use soldering iron nozzles, which have small roundings that are located inside the nozzle. Thanks to this innovation, aluminum is better sealed with a polypropylene layer. One of the disadvantages of pipes is the diameter error, which can fluctuate within small limits. Moreover, as the installers say, Blue Ocean pipes are tautly inserted into the soldering iron. And you have to solder by eye, since the red line is drawn in a spiral.

Dizayn. Dizayn pipes are available in reinforced form. There is no need to strip the aluminum before soldering. Thanks to this, their installation for both cold and hot water supply is accelerated and simplified. As a result, the soldering joints have an aesthetic appearance. Chinese Dizayn pipes occupy a worthy place in the Russian market. Even non-specialists can work with them. According to some indicators, they are not inferior to the leading European brands of polypropylene pipes.

So, although China is famous for producing cheap building material, you can find quality polypropylene pipes.

Are Czech pipes a quality standard?

On the market for polypropylene pipes, Czech pipes also take their place. And to be convinced of this, we propose to consider the features of well-known brands of Czech polypropylene pipes.

Wawin

WAWIN Ecoplastik. Czech WAWIN Ecoplastik pipes are considered a quality standard in Europe and the world. From the first batch, WAWIN Ecoplastik polypropylene pipes have proven themselves only on the positive side. Due to the good quality and selection of fittings and pipes, the Ecoplastik system has become popular in many countries. Czech polypropylene pipes are used:

- for hot / cold water, air, underfloor / central heating;

- PN 10 - for underfloor heating and cold water supply;

- PN 16 - for low pressure central heating and high pressure cold water;

- PN 20 - for hot water supply and central heating.

The product range of WAWIN Ecoplastik polypropylene pipes includes:

- PP-R - all-plastic PN 10, PN 16 and PN20.

- Ecoplastik Stabi - multilayer PN 20. The pipe consists of a layer of plastic, foil and aluminum.

- Fiber polypropylene pipe.

- All-plastic and combined fittings.

WAWIN Ecoplastik manufactures fiberglass reinforced Fiber pipes. They are used in various directions: heat supply, water supply systems for any purpose. Before soldering, there is no need to strip the aluminum from the surface. Fiber pipes have high strength with 3 times linear expansion.

FV-Plast

FV-Plast. Czech FV-Plast pipes are used for heating and water supply systems. A layer of aluminum is included in the structure of the pipe. Thanks to this, the design of the pipes is more resistant to temperature extremes. Due to the presence of a large number of fittings, all kinds of water supply and heating structures can be soldered. FV-Plast is used not only for the manufacture of plumbing and heating systems. They are used in agriculture and industry. Also used for air duct wiring.

The low weight of the FV-Plast pipe makes installation simple and safe. There is a slight roughness on the inner wall of the pipe, which does not affect the water pressure in the system.

Types and types of connection of fittings

The English word "fit" means to collect. It is thanks to him that the fitting got its name. With the help of such connecting elements, pipes are joined in the same and different planes.

They allow you to create ramified systems and avoid obstacles. When using fittings, pipes of the same or different diameters are joined.

Manufacturers produce threaded and soldered connectors. The first type allows you to dock communications made of polypropylene with steel pipes and fittings in the form of taps and valves.

The second type is designed to connect polymer elements to each other by soldering. First of all, when using special welding equipment. It heats up the parts, so their structure softens. Only then can the fitting be pushed onto the pipe.

Couplings and adapters

The simplest fitting for polypropylene pipes is a coupling. It is manufactured in the form of a barrel, in which the inner diameter corresponds to the size of the pipe section along the outer edge.

Clutch pp

The couplings are characterized by thickened walls. They are used to connect pipes of the same diameter, inserted into the so-called barrel from both sides, if it is completely made of polypropylene. When there is a thread on the sleeve, soldering is done from one edge only.

Combined coupling pp

Adapter - an element that allows you to connect pipes of different diameters. It is used for branched systems with several consumers.

PP adapter

With the help of adapters, it is possible to narrow the diameter of the communication and create excess pressure in the circuit.

Elbow, tee and cross

In most cases, engineering communications have a branched design. Angles are used to rotate the system 90 ° and 45 °. They form a system of the required configuration. After all, polypropylene is a tough and resilient material that bends only after heating.

However, this method is not used when laying communications. As a result, bending changes the size of the section and the thickness of the pipe walls. This reduces the strength characteristics of the system. Consequently, it often leads to the appearance of a leak with an increase in the pressure and temperature of the transported medium.

Corner pp

Angles are also available with a 3/4 female thread at one end. They are used during the installation of mixers.

Tee PP

Tees and crosses are used for branching engineering communications. They allow two or three taps to be brought together. The sizes of fittings for polyethylene pipes are selected depending on the scheme.

Crosspiece PP

Tees and crosses allow you to create bends at right angles or sharp angles. This type of fittings is also available with a thread at one end. In this case, they are used when installing valves.

Bypass and expansion joints

To bypass obstacles on the way of laying systems, contours are used. With their help, a more round bend is created than when using corners. Bypasses allow you to smoothly change the direction of pipelines Therefore, it is possible to lay communications that are distinguished by a more attractive and neat appearance.

PP bypass

Compensators are parts of engineering systems capable of absorbing pressure and temperature differences in hot water supply and heating pipelines. They increase the reliability and maintain the integrity of the networks. Several ready-made solutions are available. Polypropylene expansion joints are made in the form of a loop.

Fitting American

The assembly process of PP systems is facilitated by an American woman. It is a metal and plastic element with a rubber insert. Parts are used for detachable hermetic joints.

American pp

Such fittings with an internal or external thread on one side are used when installing shut-off valves, hydraulic accumulators, circulation pumps, heating radiators, and so on.

Taps, valves and plugs

During the operation of utilities, it is often necessary to shut off the water. This is achieved by installing taps and valves. They can be made from PP or brass.

Valve pp

In the first case, the parts are soldered into the systems. In the second, adapters are additionally used. Therefore, allowing to make threaded connection of parts of networks from different materials.

PP crane

Plugs are used in places where polypropylene pipelines end.

PP plug

Such parts can be soldered to permanently close off the outlet or temporarily installed by means of a threaded connection.

Domestic manufacturer keeps the brand

Although our market is filled with imported materials from different countries, Russia also produces polypropylene pipes. There are several well-known manufacturers of Russian polypropylene pipes.

PRO AQVA. Polypropylene pipes PRO AQVA are used in a wide variety of areas: water supply, heating, pneumatic pipelines and process pipelines. These pipes are capable of withstanding operating temperatures up to + 95 ° C. They are resistant to corrosion. Easy to install. They are distinguished by high chemical resistance. They are harmless to the environment and to humans. Unlike Chinese pipes, PRO AQVA is 1.6 times stronger.

Only PRO AQVA can withstand a pressure of 79.5 atm, so their service life exceeds the service life of all its analogues.

RBK. Since 2007 RBK has been producing multilayer polypropylene pipes PN 25. PP-R / AI / PP-R polypropylene is used for their production. There is an aluminum reinforcement in the middle of the pipe. In reinforced pipes, the aluminum layer is located outside the walls. For objectivity, negative customer reviews should also be noted, which agree that the diameter of the pipes is walking.

Heissekraft

Heisskraft. Reinforcement of pipes takes place in Germany. Heisskraft pipes are of high quality. They have a characteristic gray color. This is due to the fact that technical soot is added to the polypropylene composition. This substance serves as a stabilizer for polypropylene pipes.

Polytec. Polytek pipes are little known in our market. Although, according to reviews, it can be concluded that these pipes have an above average rating. But, according to the installers, the walls are subject to deformation during the compression process. Soldering Polytec pipes does not create any difficulties. The only downside is that fittings are not always commercially available, so they should be bought at the same time when buying the pipes themselves.

An example to follow

Polypropylene pipes made in Germany are of the highest quality. To verify this, you can view the characteristics below from well-known manufacturers.

Wefatherm

WEFATHERM. German WEFATHERM pipes are used for laying heating and plumbing systems. The company produces not only polypropylene pipes, but fittings and fittings. Pipes are made both with aluminum and reinforced. These pipes have a number of clear advantages over their competitors:

- The inner surface of the pipe walls is smooth. As a result, the water pressure does not drop.

- A wide range of fittings that allows you to combine WEFATHERM pipes with each other and with other systems.

- A perfectly sealed joint is formed by diffusion welding. It does not take much time to cool and process the compound.

Aquatherm GMBH. The German company Aquatherm GMBH is a leader in the production of polymer pipe materials. The products are used for underfloor heating, heating, water supply, air conditioning and fire extinguishing. Pipes Aquatherm GMBH are produced in different series and versions.

Fusiotherm

For example, Fusiotherm universal polypropylene pipes. They are made of PP-R 80 polypropylene. This pipe has found its wide application:

- Compressed air.

- Cold water.

- Hot water.

- Conditioning.

- Heating mains.

- Heat supply.

- Heating of stadiums.

- Shipbuilding.

- Cooling of ice rinks.

Fusiotherm pipes are also used for pumping more than three hundred types of chemicals.

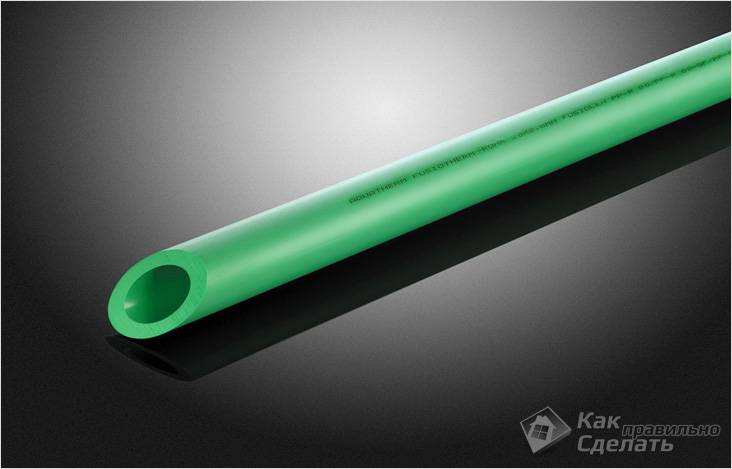

It is customary to use Faser for heat supply. The diameter of pipes and fittings ranges from 20 to 250 mm. The pipe is composed of fiberglass and reinforcement. Faser polypropylene pipes withstand operating temperatures up to + 95 ° С with pressures up to 20 atm. The color of the product is green. Pipes are also produced in white, but Ø20–40 mm.

Stabi pipes have also proven themselves positively. These are perforated pipes with a layer of aluminum. They are recommended for heating systems. Stabi diameter ranges from 16mm to 110mm. The peak operating temperature is considered to be + 130 ° C with a pressure of up to 20 atm. The pipes are distinguished by the presence of perforations.

Climatherm products are used for cold water supply and air conditioning. The diameter of the pipes is 20–630 mm. The composition of polypropylene includes fiberglass and a reinforcement layer.

Banninger

BANNINGER. German BANNINGER pipes and fittings are also distinguished by their high quality and reliability. BANNINGER pipes have found their wide application in the field of heat supply, water supply systems, and various industries. BANNINGER pipes are available in different series:

BANNINGER series PN 20 and PN 16. These pipes are used for cold and hot water supply. They are made of PP-RCT polypropylene. This is a new generation material. Its structure resembles a crystal. Its technical characteristics are improved by 50% in comparison with all analogues. Numerous crystals in the structure of polypropylene are formed due to a special cooling technology. The result is a very flexible and dense product. These features make it possible to withstand pressures up to 20 bar at a temperature of + 95 ° C for a long time.

BANNINGER Stabi. The Stabi pipe series is made of multilayer composite material. They are mainly used for heating and water supply for hot and cold purposes. These pipes are made from crystal structure PP-RCT copolymer. BANNINGER Stabi are distinguished by many positive characteristics, for example: minimal thermal expansion and high mechanical strength. Before welding the pipes, it is necessary to remove the layer of polypropylene and aluminum.

BANNINGER Faser. They are similarly used for water supply and heating. The structure of the plastic resembles that of a crystal. The pipes are fiberglass reinforced. Unlike conventional polypropylene pipes, BANNINGER Faser is characterized by high strength, resistance to temperature changes and a low coefficient of linear expansion.

BANNINGER Faser pipes do not require pre-stripping of aluminum. This greatly speeds up and simplifies the installation process.

BANNINGER Climatec. The BANNINGER Climatec pipe is made of composite laminates. Used primarily for air conditioning, ventilation and industry. The inner plastic layer is reinforced with PP-fiberglass. BANNINGER Climatec, unlike Stabi, does not delaminate. They do not require preliminary stripping.

Rehau. In Russia, the most famous German polypropylene pipes from Rehau. They are used for various engineering structures in residential and public premises. The duration of operation directly depends on the skill level of the specialist.

So, we examined with you the features of the famous German polypropylene pipes. As you can see, their assortment is diverse, and the scope is wide.

Major manufacturers of polypropylene products

The popularity of plastic products made from this material has increased significantly in recent years. As a result, domestic production of these products in Russia is also growing. Today, hundreds of enterprises produce polypropylene products. The most significant are:

- The Sinikon enterprise is a large manufacturer from Moscow, supplying the market with polypropylene products for cold and hot water supply, as well as for gravity sewer systems.

- "Ikaplast" - the company started its activity more than ten years ago. Its products are of high quality, which is ensured by a multi-stage control system.The main specialization is reinforced pipes for pipelines, including for the transportation of aggressive media.

- has two factories for the production of reinforced plastic pipes, the head one is located in Yaroslavl. The main product is reinforced products, as well as pressure and non-pressure water pipe fittings.

- One of the largest manufacturers of polypropylene products is the Politron enterprise. Applying modern equipment, the company produces a significant amount of pipes for construction assortment, as well as fittings for them.

- "Cosmoplast" is a specialized enterprise for the production of a variety of polypropylene fittings.

- OJSC Almetyevsk Pipe Plant. He began his production activity during the Soviet era, making products from steel. Today it produces a significant number of polypropylene products for plumbing.

Of course, this list is only a small part of the hundreds of enterprises that manufacture pipe products for construction purposes from plastics.

If you want to organize your own production of such products, it should be noted that a full set of equipment for its production will cost approximately from 700 thousand to 2 million rubles.

Watch the video

Russia produces raw materials only for the production of free-flow. Pipes and fittings for such systems are made from polypropylene copolymer. The raw material for the production of pressure water pipelines - random copolymer of polypropylene - is completely imported from abroad.

Advantages and disadvantages of polypropylene

This type of product for plumbing has a number of advantages over steel counterparts:

- The material is chemically inert and is not exposed to aggressive media.

- Manufacturers declare the service life of polypropylene pipes for water supply at least 50 years. For a low-pressure pipeline, it can be increased to 100 years. On heating systems, such products can work for up to 25 years. In any case, this limitation is many times higher than similar characteristics for steel products, or even an order of magnitude.

- The materials are not electrically conductive.

- The product is environmentally friendly, does not release substances harmful to humans and animals into the water and the surrounding space.

- Products made of polypropylene are distinguished by their manufacturability when installing the pipeline by the soldering method. The process is accessible even to untrained personnel.

- During operation, a pipeline made of this material does not need additional maintenance to protect it from corrosion.

The disadvantages include the following points:

- Pipes do not withstand the temperature of the coolant above + 95-100 degrees, especially at a pressure of more than 10 atmospheres.

- Difficulties in the repair associated with the use of permanent connections during installation.

What pipes to choose for water supply

The question is natural - polypropylene or metal-plastic, which is better for water supply?

In terms of price-quality ratio, you should definitely choose polypropylene. For low-pressure systems, you can take a product made of pure plastic, and for a pressure of more than 10 atmospheres - reinforced with fiberglass. In any case, from the variety of these materials, you can always choose a suitable option for a water supply device.

Watch the video

With regard to materials for the installation of heating systems, it is preferable to use polypropylene, reinforced with aluminum.

Installation features

Having a water supply project on hand, you need to purchase the required number of basic and component products. The connection of various elements is made by soldering using a soldering iron of a special design.

It comes complete with special mandrels and couplings for heating parts in sizes from 16 to 53 millimeters. For more information on installing a polypropylene water supply system, see this article.

Large tooling sold separately.

The parts to be joined are heated in a few seconds, removed from the soldering iron, and then joined manually.