Causes of leaks in the heating system

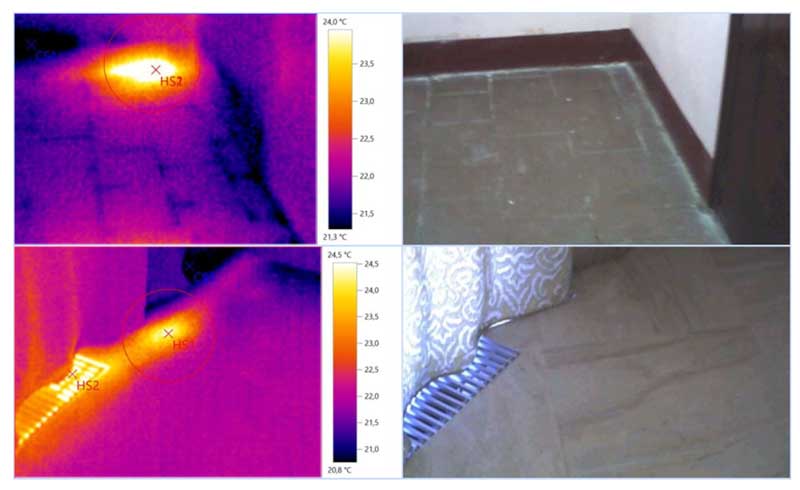

When solving the problem of how to find a leak in the heating system, it is useful to know the causes of its occurrence - this will help to quickly and effectively eliminate the malfunction. There are quite a few reasons for the depressurization of the heating main, the main ones are:

Violation of the tightness of the connections. This is the main cause of leaks that all conventional hot water heating pipes are exposed to. They arise as a result of corrosion when using metal pipes, aging of sealing gaskets, spontaneous unscrewing of threaded connections.

One of the common causes of leaks at the joints is the thermal expansion of metals, while during the operation of the heating system in a high-temperature operating mode, water does not leak, and after the coolant cools down, the metal of the fittings at the joints narrows and may leak.

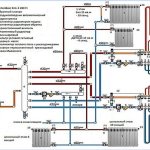

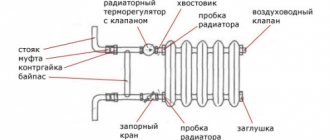

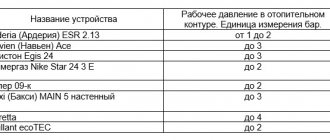

Fig. 2 Connection diagram for boilers, radiators and underfloor heating

Causes of leaks

Among the reasons for the leakage of the coolant (any, and not only water), there are three main ones:

1 Corrosion; 2 Violations in the technology of installation of the system; 3 Illiterate exploitation.

Corrosion of a metal is caused by two types of chemical reactions: oxidation under the influence of oxygen and an electrochemical reaction that occurs when metals dock with different numbers of negative and positive ions in the atomic structure of a substance.

Technological irregularities during the installation of the system, which lead to leakage of the coolant, include, for example, the use of inappropriate electrodes and the occurrence of local foci of electrochemical corrosion in the places of welds. The most sensitive to violations in the installation technology are metal-plastic pipes connected by threaded fittings. Such a leak is practically unavoidable and requires a complete replacement of the pipeline section together with the fitting.

Incorrect work and selection of materials

The illiterate operation of the heating system also leads to water leaks from the pipes. For example, boiling of the coolant and the accompanying hydrodynamic shock lead to damage to the gaskets and even destruction of threaded connections. If it is decided to change the type of coolant by replacing the water with antifreeze, then you need to be prepared for the threaded connections to flow. This is especially true for those devices that were mounted twenty years ago and were used to seal them with tow, oil paint, rubber and other inexpensive auxiliary materials.

An unnecessarily high pressure in the system also leads to water leakage from the pipes. It does not affect the efficiency of its work in any way and even harms, leading to boiling of water at temperatures below 100 ° C. Pressure is needed to pump the coolant to the upper tiers of multi-storey buildings or to activate sluggish thermal convection in single-pipe systems with lower wiring. In one-story houses, it is better to use circulation pumps with a working pressure of no more than 1.5 atmospheres.

Reinforced-plastic pipes, which have become popular recently, are very sensitive to the operating mode. They cannot withstand sudden temperature changes, overheating and water hammer. Their structure delaminates, as a result of which the pipes lose strength, cracks and fistulas appear in them.

How to detect a water leak in a heating system

Any heating main in a private house is equipped with a pressure tester - a pressure gauge, which is used for adjustment and control.Its readings correspond to the pressure in the system and should be stable - any deviation in the direction of decrease indicates depressurization and possible leakage of the coolant.

Typically, heating consists of several circuits (heating radiators, underfloor heating), and installing a pressure gauge in each of them allows you to determine a depressurized area.

If a leak occurs in an open pipeline located in a house, it can be detected by wet marks on the floor or walls; when using antifreeze, the spots will have the corresponding color.

How to find a leak underground or in a screed

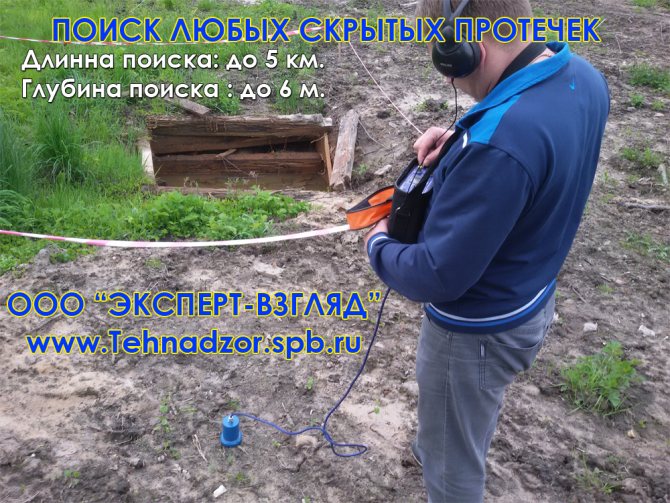

As mentioned above, a pressure gauge allows you to detect a leaking circuit, finding a leak under a layer of earth or a screed without special devices is a rather difficult task. Since most problems arise at pipe joints, the first step is to open the screed or dig the ground in these places. The second option is to use special devices (for this you can hire specialists or rent equipment), to detect breakthroughs they use:

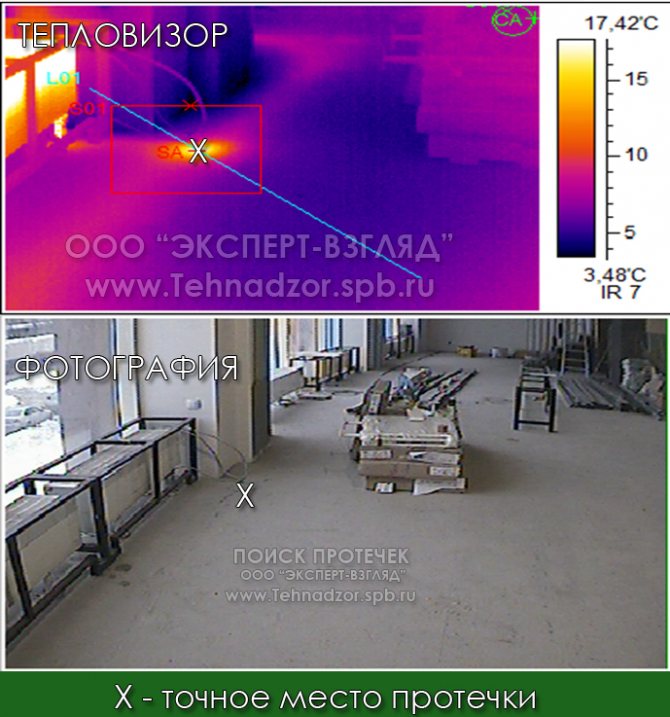

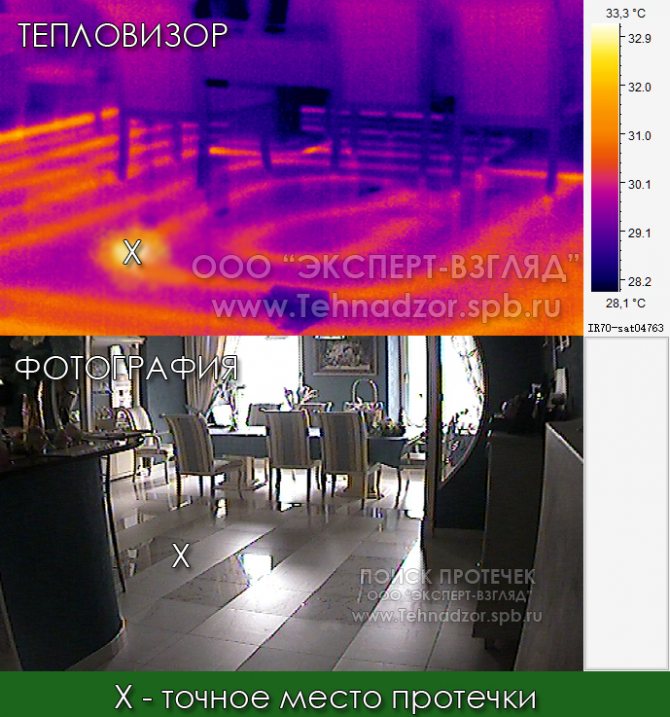

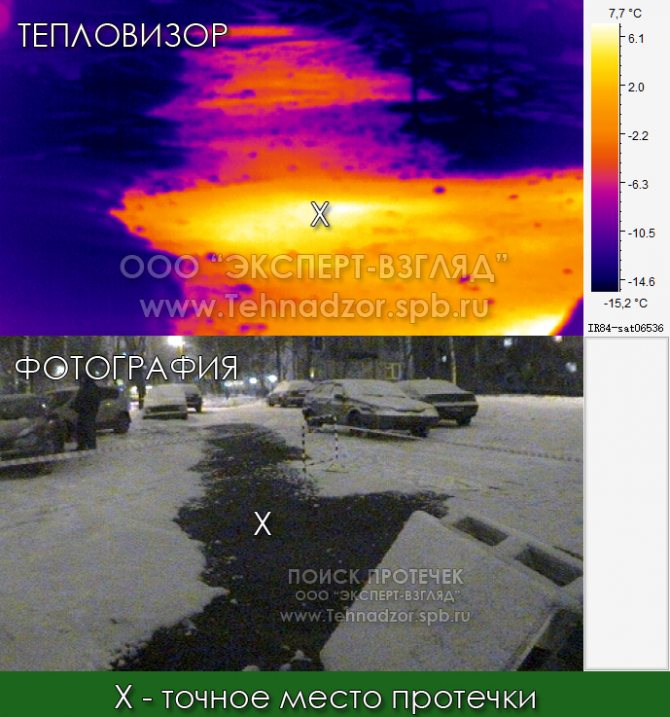

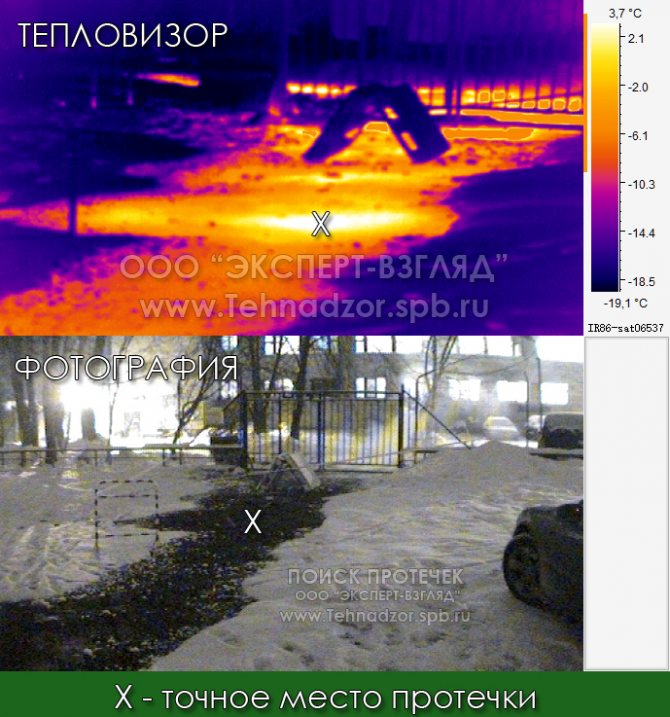

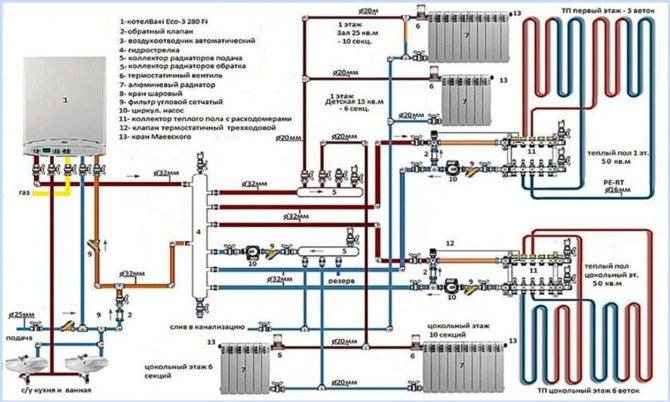

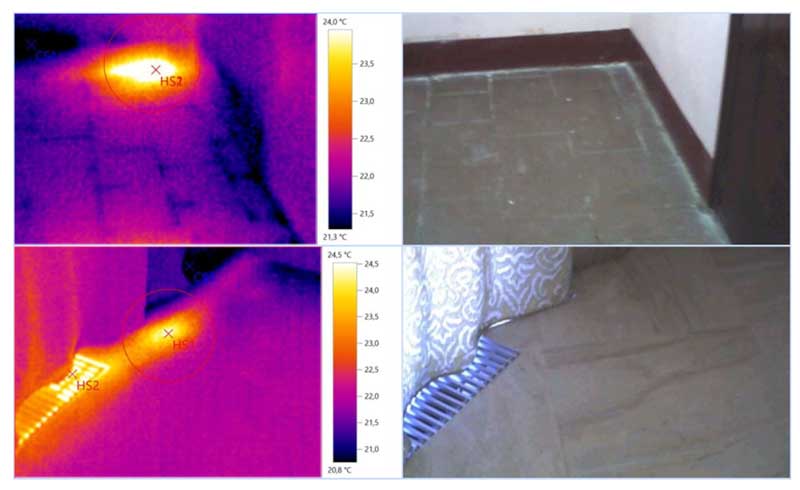

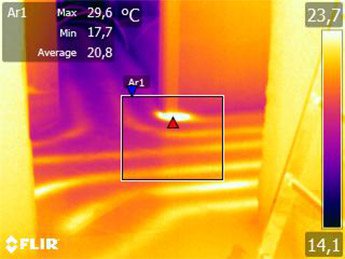

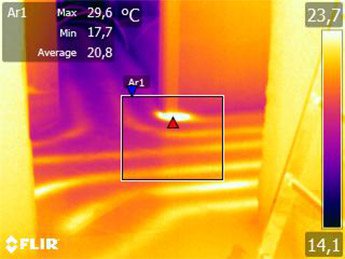

- Thermal imagers. With the help of compact devices, you can immediately find water leaks in the house or underground when the pipeline is shallow. The unsealed section will look like a thermal blurred spot with an elevated temperature at the point where the coolant flows out.

- Moisture meters. High humidity signals that a leak has occurred in a given location. The method is used only indoors, its effectiveness is low - it can only detect a room with high humidity, and not a specific area.

- Phonendoscope. Acoustic devices that pick up sounds are more suitable for outdoor identification of sources of noise, with their help it is very difficult to find a leaking area in the walls or screed.

Fig. 4 Leak detection with thermal imagers

How to find a leak in a heating system and remove it with your own hands

The very first leak of the heating system is a signal for action for the homeowner. If you don't tackle it in time, bigger problems will begin. You cannot leave the heat supply without repair, even if the leak is very tiny and does not inconvenience you. After some period of time, it will increase and it will be necessary to change the system - in whole or in part. Where can a leak occur and why? How to find and remove it with your own hands?

Where do the leaks in the heating system come from?

A very popular cause of leaks in iron pipes is corrosion. Steel, even finished with specialized coatings, rusts. Only the speed of the process differs. It is subject to the operating conditions of each specific system.

Heating pipes rupture

The metal is affected by temperature extremes, moisture, hydraulic shocks. Impurities in the thermal carrier contain aggressive chemical substances, abrasive materials that accelerate corrosion. Areas where parts of the system become rusty are likely to leak. Basically, these are connections, joints, seams.

Polymers do not rust, but this does not mean at all that they do not leak. Over time, pipes made of metal-plastic may also leak. Very often the same happens if they are incorrectly selected. Certain homeowners save money and buy cold water pipes. This is a serious error. leads to deformations, breaks in the system.

Often the owners of houses suffer, who select bad products for heating. Inexpensive polypropylene pipes swell, burst, and flow. If this happens, the damaged sections must be replaced. Imaginary savings turn into extraordinary expenses of cash, energy and nerves.

The least prone to the risk of leaks are pipes made of metal-plastic, which are specifically intended for heating systems.They are designed for a high temperature of the heat carrier, do not change and, as a rule, will last a couple of decades.

Repair of metal-plastic pipes

What details can leak

There are several options for eliminating leaks. The choice of the correct methods depends on the type of system element in which the leak has occurred. This could be:

- Integral pipe. Here the holes are tightened with clamps, self-tapping screws, sealed with specialized compounds or cemented. If the pipe is plastic, it is most advisable to change the entire length. If this is not possible, use artisanal welding.

- Connecting places. There are many different connections in the heating system - places for fastening pipes, adapters, etc. Leaks appear either due to loose fasteners, or due to rust. Polymer parts are easier to fix, but with steel and cast iron it is more difficult: you will need to apply force or apply cold welding.

- Between battery sections. The reason is the same - leakage. Sometimes it flows due to mechanical damage. If water seeps between sections, remove the heater and tighten the connections.

- On the heater plate. In such a case, it is best to immediately replace the heater, because A very popular cause of problems is thin walls and low quality material from which the radiator design is made. If it does not come out to change immediately, then cold welding will save, but this is only a short-term measure. In the next season, new unpleasant moments may appear.

Leakage: what to do immediately

What to do immediately after finding a leak in the heating system depends on 2 factors: the type of house and the type of the leak itself. If the heat supply has flowed in a private house, then the owner can remove even a serious malfunction himself. But in the apartment you have to act more carefully and quickly. The very first, you can flood the neighbors who live below. Second, you have to turn off the heating riser, which means that all apartments will cool down.

If the leak is small (the pipe or heating device only gets a little wet), you can try to remove it on your own with the help of improvised means. If it flows heavily, then immediately close the supply of the heat carrier and call the emergency team. Until the heat supply is turned off, it is necessary to throw a blanket over the heater or pipe so that no one gets burned by hot water.

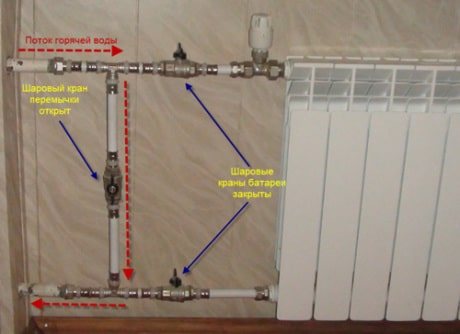

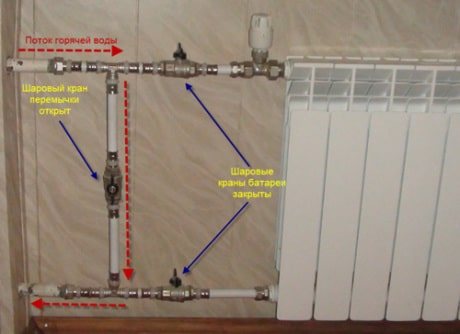

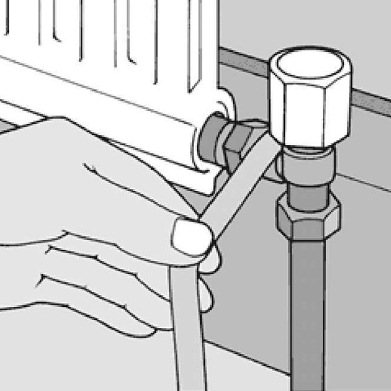

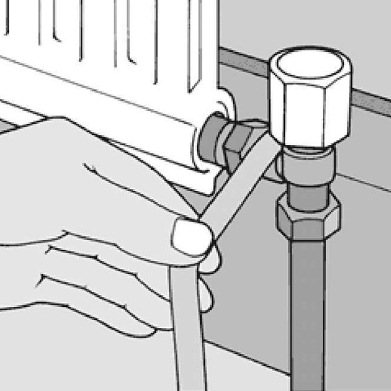

In certain apartments, specialized valves or taps are installed, thanks to which it is possible to close the supply of the heat carrier. But as a rule, these cranes are placed on the entire staircase and placed in basements. You need to go down there and close the riser on the main pipe. Then you should immediately start to eliminate the leak.

Cocks that shut off the supply of the heat carrier

How to identify the damaged area

If it leaks slightly, and the place of the leak in the heating system is not clear at first glance, then it can be determined after turning off the supply of the heat carrier. Only the cold system is verified, because water quickly disappears from heated surfaces. A piece of ordinary toilet paper or a dry whitish napkin will help in this.

When the system has cooled down, a piece of paper should be slowly swept over the suspected leak. Very carefully examine the connections, joints. The place where the paper gets wet, you need to inspect and find a hole. The task is complicated if the pipes are disguised as finishing materials, under the floor or in the ground.

Turning off the heat supply with a circular pump

How to find water leaks underground or in a screed

If pipes have leaked underground, in the walls or in the floor contour with underfloor heating, it is rather difficult to manage without calling specialists. To find such breakthroughs, devices are used:

- Thermal imagers.The temperature of the surface under which the heating system is hidden is very high to use a thermal imager. If the pipes are shallow, then with the help of this device it will be very difficult to find a leak. Problems can appear only in the case of a large depth of pipes or a low temperature of the heat carrier.

How to find where the water goes from the heating system

- Moisture meters. This is a less excellent way to find leaks than with thermal imagers, but a moisture meter can still be useful when counting leaking pipes in walls or in heated floors. For the purpose of searching for communications located underground, it is not used.

- Sound devices. Sometimes a leak can be determined using a specialized device that captures sounds. By its own design, it resembles a phonendoscope. However, the benefits from it are not always at all.

Latent leak designation

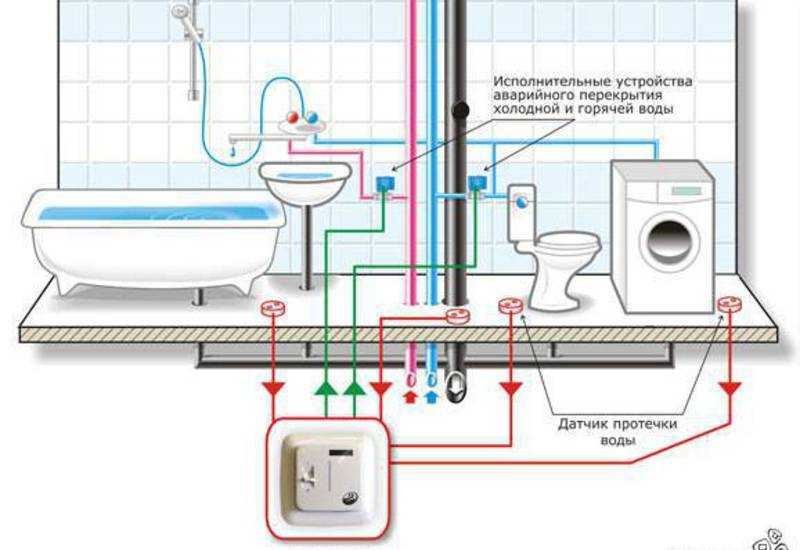

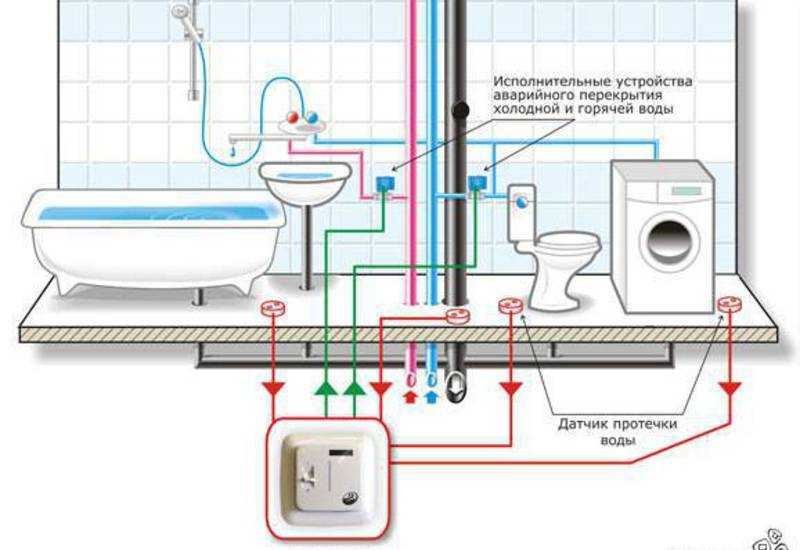

System "Neptune" - instant detection of leaks

There are specialized systems that quickly determine the locations of leaks in water supply and heating systems. You will need to spend money and time on their installation, but the costs will pay off in abundance: thanks to such devices, it will be possible to avoid problems in case of significant accidents. Our Neptune system is very popular. It will not be very expensive for analogs and has shown itself perfectly.

"Neptune" not only quickly finds a leak, but also blocks the water supply. The system consists of a control unit, sensors and valves. It is fully automated, and after the installation has occurred, the owner of the premises will no longer have to worry about breakouts. As soon as the meter sends a signal that a leak has occurred to the main unit, the valves are activated and shut off the water. Further, the owner can deal with getting rid of the problem without thinking about what will flood his neighbors or his house.

Scheme: "Neptune" in an ordinary apartment in the city

How to find a leak in a heated floor circuit yourself

Underfloor heating leaks can be a real problem. If it is possible to remove the coating with little effort, this greatly facilitates its solution. Difficulties appear if the contour is placed under the screed. Sometimes the breakout point gives out a wet spot on the floor, but this only happens in cases of large damage. When the pipe just leaks a little, it is harder to find the breakage. Let's consider how to act in a similar situation.

You can try to find a leak on your own, but first you have to determine where the pipes are generally located. To do this, turn on the heated floor at the highest heating, and the screed above it is well moistened with water. Moisture is likely to erode above the loops of the contour. This will show in the lighter and drier areas of the floor.

The brightened areas are outlined with a pencil, while tracking how fast they dry. Where a wet spot remains for the longest time, it is necessary to look for a pipe break. This option does not always work 100%. He shows the location of the pipes first of all, but the broken section is visible if the leak is strong. In order to find and eliminate the leak, you will have to break the screed over the heated floor.

Inspecting the floor with a thermal imager

Removing a leak in the heating system with your own hands

If the leak is strong, shut off the heat supply in the riser. In the event of a small breakdown (if the water barely drips), you can immediately begin to eliminate it. Consider how best to repair the heating system.

Clamp on steel pipe

Option # 1: when the pipe is leaking

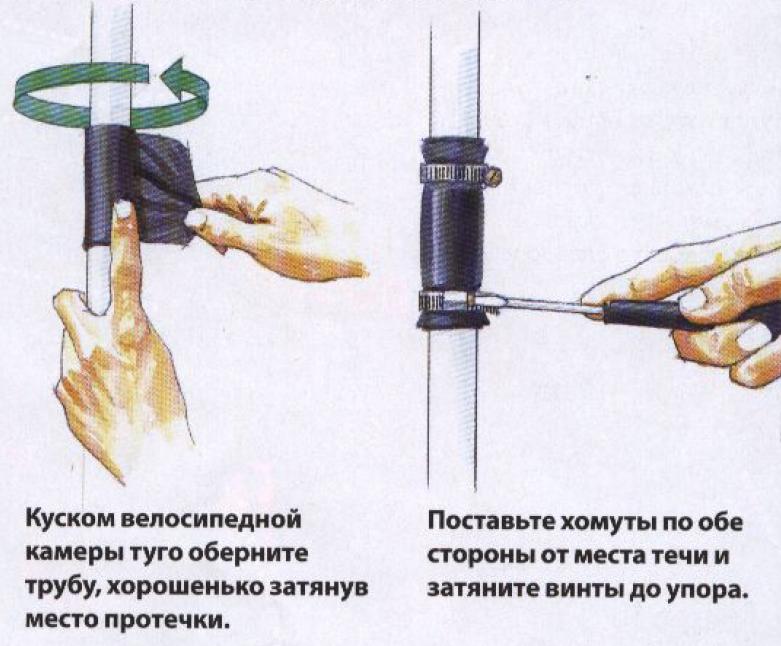

If a section of a pipe is profiled without a thread, then the problem is in a bad weld. A clamp is required to repair the damage. It can be purchased at a store selling building materials and tools, or made with your own hands from a strip of metal. A gasket or a piece of a bicycle tube is used as a seal.

The pipe is cleaned of paint drips, a dense rubber gasket is applied on top, then a clamp. Bolts are included for fastening the clamp. They are tightened as tightly as possible. Sometimes the damage is additionally treated with a sealant. This is a great way to securely seal a hole in a pipe. There will be no more leaks.

Factory made clamps

Option # 2: Leaking under the extra nut

If the accessory nut is properly secured from the outset, leakage may result from mechanical damage or rust. It is necessary to close the riser and throw off the water. Then the nut is unscrewed, sealed with flax, paint or a specialized compound and tightened again. Plumbing flax and other seals are wound clockwise.

When the work is completed, it is necessary to open the riser valve again and check the connection tightness. If water still seeps out, repeat the procedure over and over again adding 5-6 new threads to the pipe.

Removing the leak under the additional nut

Option # 3: if the heater is dripping

The radiator plate or the joint between the sections can leak. In the first option, it is best to immediately replace the damaged component. If this is not possible, then a small leak is dealt with using cold welding. It can be purchased at every store that sells building materials and tools. Instructions for use should be on the packaging.

For repair work on the heater, the riser is blocked, cleaned, degreased the damaged area, after which a sealing compound is applied to the hole itself and the area around it. Welding should close approximately 3-4 cm of pipe around the fistula. The composition quickly solidifies. After complete drying, you can start the heat supply.

If it flows between the sections, then the heater is disassembled and the nipple connection is tightly tightened. A lot of effort is needed to secure the nipple. As a rule, it is impossible to break it, thanks to this you should not be afraid. After the work is completed, the heater is placed in its old place and the supply of the heat carrier is turned on.

Leakage between cast iron battery sections

Heating pipe repair instruction

Among modern compounds for eliminating leaks in the heating system, sealants deserve great attention. These are specialized moisture resistant products. They will not protect in case of a large fistula, but they will fit perfectly for repairing small damages in water supply and heating systems. Silicone-based sanitary sealant can last for years. It is best to purchase it and cold welding just in case of a fire in case of a fire at the beginning of the heating season. Such funds will come in handy in any home.

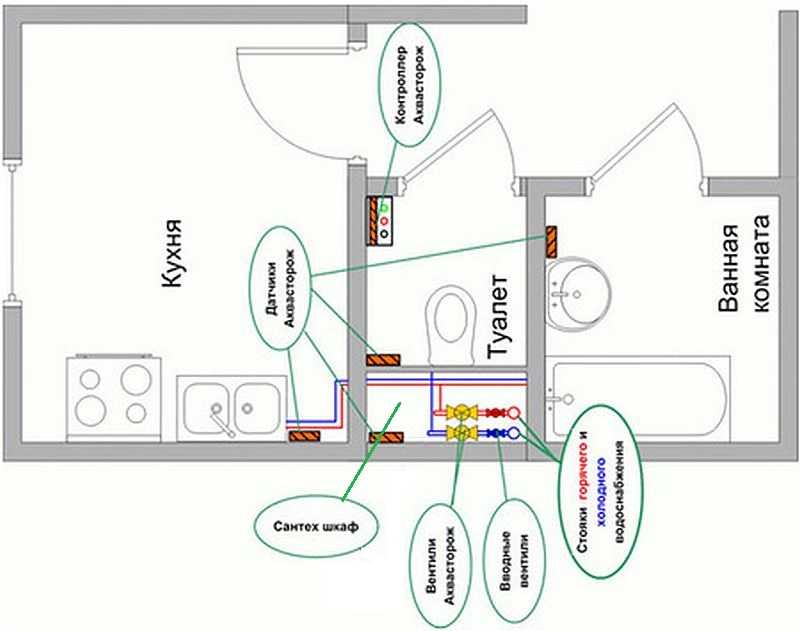

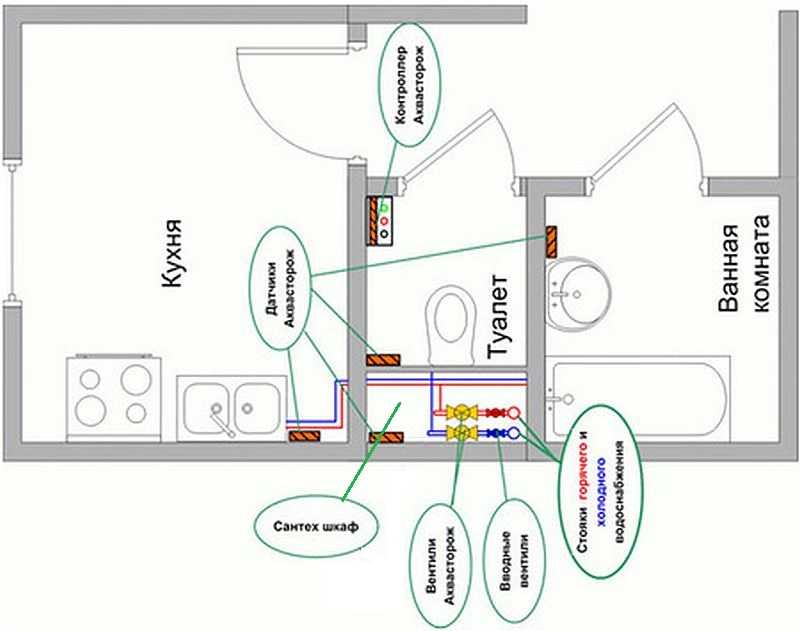

Where to install motorized valves

With the installation of cranes, not everything is easy. The specific installation locations depend on the system design. If it is a small apartment with one or two risers - cold and hot water - everything is simple. We overlap the bends and that's it. In more complex systems, it is necessary to think over the place of installation of electric cranes.

The location of the shut-off valves depends on the design of the system

In apartments

If the water supply is centralized, the taps of the system from leaks are placed at the entrance to the apartment / house. It is much better if the taps are located before the meter and filter. But with such an arrangement, operational services may disagree. They usually require the electric crane to be positioned after the meter. In this case, in the event of a leak, the connection between the meter and the filter remains under pressure at all times. It will be impossible to eliminate the leak at these points. You can insist on your own, but you need to prove your point of view.

In some layouts, the apartment may have four risers - two cold and two warm water. In this case, there are two solutions - more correct and more economical.That's right - put two modules, each of which will serve its own zone. This is more convenient, since an accident will happen only on one of the risers / devices and it is unreasonable to disconnect the opposite part. But two modules are double the cost. To save money, you can put one control unit that will shut off the taps by 4 risers. But in this case, do not forget that you will have to pull the wires through the entire apartment.

We need to think about where to install the system elements

In the case of heating, not everything is simple either. Most of the high-rise buildings have vertical wiring. This is when in every (or almost every) room there is a riser and one or two radiators are powered from it. It turns out that at least one crane must be installed for each bend - for the supply. But then the water that is contained in the radiator and pipes will flow out. Of course, this is not so much, but a couple of liters is sometimes enough for the neighbors below to have a stain on the ceiling. On the other hand, it is too expensive to put two taps on each radiator.

In a private house

To prevent the pump from pumping water in an emergency, it is necessary to use a water leakage protection controller with a power relay. If power is applied to the pump through the contacts of this relay, simultaneously with the signal to close the ball valves or valves, the power supply to the pump will be cut off. Why not just turn off the power to the pump? Because in this case, all the water that is in the system can pour out into the resulting gap. And this is usually a lot.

In order to understand in which places of the water supply system of a private house it is necessary to install taps to prevent water leaks, it is necessary to study the diagram. Most often, shut-off valves with electric drives are installed after the pumping station and on the boiler.

Protection against water leakage can be included, or you can assemble your configuration from components

Heating is a little more complicated. It is not necessary to block the movement of the coolant if it is impossible to immediately extinguish the boiler. That is, in systems with solid fuel boilers, water leakage control can be set only if it does not block the circulation of the coolant. If there is a small circuit, taps can be installed so that this small circuit works and the rest of the system is shut down. If a heat accumulator is installed in the system, taps must be installed so that water does not pour out of it. These are large-volume containers - at least 500 liters, and usually many times more. If all the liquid spills out, it won't seem a little.

In heating systems with automated boilers, taps can shut off the circulation. If the protection against water leaks works and cuts off the circulation, the boiler will stop due to overheating. This is not a completely normal situation, but it is not an emergency either.

What urgent measures are taken if a leak occurs

The appearance of a leak in the heating system requires an immediate response. The first steps to take depend on the nature of the problem and the location in which it occurred.

A leak in a private house can be eliminated on your own, but in an apartment you should be careful not to flood the neighbors living below. Another nuance is that during the renovation, the entire riser will have to be blocked, which means that all the apartments that it connects will be without heat.

You can try to fix a small leak yourself with the help of available tools. If the problem is serious, then they block the access to the coolant and call in specialists.

Hot water sprayed in all directions can cause injury, therefore, before shutting off the water supply, a thick blanket must be thrown over the pipe or radiator. Valves for shutting off hot water can be located directly in the apartment, but most often they are located in the basement of the entrance. We'll have to go down there, find the right tap and turn it off.

The reasons for the leakage of the toilet at the junction with the sewer

There are only a few reasons why a leak can form at the points of connection to the sewer:

- A skewed or damaged gasket is the most common cause of toilet joint leakage. If it is new, and the joint is leaking, most likely, you assembled it incorrectly or there is a defect in the gasket.

- The corrugation of the toilet can often leak. This nuisance can be easily eliminated on its own. The reason for this is a cracked seal. From time to time, the rubber from which it is made ceases to be elastic and cracks. The result is gaps that open up water access.

- Loose cistern fixing bolts. They are usually made of metal or plastic. Metal rusts from time to time, and plastic can burst.

- Another reason for the leak is the drain pipe.

How to find a leak in a wall?

You can understand that there is a leak in the wall by the following signs:

- wet spots

- damp walls

- bloated wallpaper

- peeling putty

- fungus or mold

Traces of leaks are very often hidden by tiles or waterproof wallpaper, so it takes a long time from the moment a leak begins to be discovered. A small spot may indicate a serious problem. Better not to put it off and immediately find out how to find a leak in the wall.

Disassembling tiles, tiles, removing wallpaper is not an option. We offer a non-contact method for localizing the problem, and we know how to find a leak in a pipe without dismantling. Our secret is in choosing not one device, but a whole complex.

Where leaks can occur

Pipes, plumbing fixtures and appliances (boilers, radiators, expansion tanks) leak as a result of corrosion, aging of gaskets or mechanical damage.

When using steel heating pipes, unsealed joints lead to leaks in couplings, squeegees (battery connection areas), taps, connection points of shut-off valves, heating and measuring devices, pumping and water heating equipment. Similar problems arise when using a metal-plastic pipeline, in addition to the above, water can flow out after a while through the threaded connections of the compression couplings as a result of their self-unscrewing.

Fig. 3 Search devices for detecting leaks in hidden pipelines

Examples of leaks we found

- in a residential building

- warm floor

- heating pipes

- DHW

- Violation of waterproofing

- HVS

- Sewerage

- heating

Heating leaks in the facade

A strong leak in the heating pipe was detected. The depth of the pipes is 0.6 meters below the floor level. Found from the front of the house.

Underfloor heating leaks

An autopsy of the place made it possible to understand the reason. At the time of pouring the screed, the pipes were repeatedly damaged with shovels.

Heating pipes leaking

The customer complained about the pressure drop in the boiler and the leak from the second floor. We used a thermal imager to find the leak. An autopsy indicated mechanical damage.

Hot water leak

The exact location of the defect has been identified.

Violation of waterproofing

Violations of the waterproofing of the balcony, the wall is damp. An autopsy of the site confirmed a violation of the waterproofing technology.

Cold water flow

The leaks were invisible to the eye, but moisture was already appearing on the walls. Without our intervention, the leak would have ruined the finish.

Leaking sewer

Revealed using an endoscope.

Leaking in a warm floor

A temperature anomaly caused by a leak has been identified. Gave recommendations for revision and elimination of the leak.

Heating leak

A temperature anomaly was detected, suggesting the location of the leak. Disassembly confirmed the assumption.

Some technical points

Wired sensors are usually supplied with 2 meter cables. Electric ball valves are sold with the same cable length. This is not always enough.You can extend the length using the manufacturer's recommended cable. The brands are usually indicated in the instruction manual. Only when buying, check the cross-section of the cores. Unfortunately, very often the actual diameter is much smaller than the stated one.

Generally speaking, the following extension cables can be recommended:

- for wired sensors, a shielded twisted pair with a conductor cross-section of at least 0.35 mm² is suitable;

- for cranes - a power cable in two-layer insulation with a conductor cross-section of at least 0.75 mm².

The correct arrangement of elements is not always obvious

It is desirable to make the connection maintainable. That is, if you are laying wires in the wall or in the floor, the connection must be made in the junction box. Connection method - any, reliable (soldering, contactors of any type, since the equipment is low-current). It is better to lay wires in walls or in the floor in cable ducts or pipes. In this case, it will be possible to replace the damaged cable without opening the strobe.

How to identify the damaged area

If it leaks slightly, and the place of the leak in the heating system is not obvious at first glance, then it can be determined after turning off the coolant supply. Check only the cold system, because water evaporates quickly from heated surfaces. A piece of ordinary toilet paper or a dry white napkin will help in this.

When the system has cooled down, slowly slide a piece of paper over the suspected leak. Connections and joints are especially carefully examined. The place where the paper gets wet, you need to examine and find a hole. The task is complicated if the pipes are disguised as finishing materials, are under the floor or in the ground.

First steps to take

As soon as you notice that the washing machine is leaking, you need to immediately take measures to protect yourself and the apartment from unpleasant consequences. To get started, follow these steps:

- Unplug the machine from the mains, never stepping on a puddle to avoid electric shock. If you cannot reach the outlet from a dry area, turn off the electricity in the entire apartment (house).

- Shut off the water supply to the household appliance by closing the intake tap or completely shutting off the water supply in the apartment.

- Drain the washing machine tank using the emergency hose or drain filter (located below the loading door).

- Take the laundry out of the drum and start inspecting the equipment.

Having eliminated local flooding around the machine, do not forget to drain the water from the device itself

Most washing machine manufacturers (LG, Beko, Samsung, Bosch, etc.) equip their appliances with a leakage protection system. What does it mean? If any of the components leaks, the Aquastop function blocks further water supply and distribution to vital parts of the machine, such as the control panel. Thus, flooding of the apartment and related troubles is prevented.

What is an anti-flood and how does protection against water leaks work?

The anti-flood system consists of several elements: water availability sensors, electrically controlled taps or valves, and a control unit. Sensors for monitoring the presence of water are placed in places where leaks are most likely. Electric cranes are placed on risers with water, in key places of the water supply and heating systems - in order to minimize the amount of spilled water in the event of an accident. Crane drives and sensors are connected to the control and management unit (controller). It processes signals from sensors and, in the event of an alarm signal, supplies power to the taps. Those are triggered by blocking the flow of water / heat carrier. This is, in a nutshell, how water leakage protection works.

Protection against water leakage consists of three components: water presence sensors, electric taps and a controller that controls it all.

These systems are used both for water supply - hot and cold, and for heating.After all, an accident in the heating system is probably even worse than on the water supply - hotter water causes more damage, and can also cause serious burns. In general, for flood protection to be effective, you need to think carefully about the installation locations of sensors and taps.

What areas and elements can leak

The most common leak is in metal pipes. The elements that can be destroyed are as follows:

- joints of pipes, adapters and seams;

- one-piece pipe;

- radiator;

- under the lock nut;

- in the underfloor heating circuit;

- space between battery sections.

Heating system leaks are often found in radiators

Most often, cheap polymer pipes are prone to violation of integrity. They break, flow, swell. Reinforced-plastic pipes are also susceptible to leaks if they were incorrectly selected. There are special products for the heating system. If pipes for cold water are installed in it, then under the influence of high temperatures they are deformed and burst.

Where to place sensors

Since the protection against water leaks is designed to protect against floods, sensors should be placed in all places where the appearance of water is most likely. It often happens that the system triggered with a delay precisely because of the wrong location of the sensors. Until the water reached the sensor, a lot of it poured out. Based on the experience of the owners, the following locations can be recommended for installing the water leakage sensors:

Under each flexible hose. It is here that emergencies most often arise. Under household appliances that use water during operation: dishwasher, washing machine

Please note: you need to slip the sensor under the device. Those

install not next to it, but under it. The catchment points are the lowest points where water will enter first.

Under the boiler, heating boiler, next to the pumping station, in the pit where the pump is installed. Under the radiator, heated towel rail. Near (under) a bath, shower, sink, toilet.

When installing water leakage sensors, try to position them so that water gets on them first. For example, to control the faucet in the kitchen, the sensor should not be placed under the cabinet, but in the cabinet - under the siphon or somewhere in the area. If something happens to the piping to the tap, the water will first be in the cabinet and only then will it flow under it.

If you need to monitor leaks in household appliances - washing machines, dishwashers - place the sensors under the appliances. Not near, but directly near the connection of the drain hose.

How to fix a battery leak

I would like to immediately note that the proposed methods of eliminating the leak are suitable in the case when it is small and the water just leaks, and does not hit with a stream. There are 2 types of heating radiator defects:

- leaks at the joints of sections and threaded connections with pipes;

- cracks in the case.

It is very convenient when the battery is installed according to all the rules and is equipped with shut-off valves. They must be closed, the American women must be unscrewed and the heating device must be carefully removed. The coolant must be immediately drained into a previously prepared bucket. After that, the leak between the sections is eliminated by disassembling the radiator and replacing the gaskets. Moreover, it is recommended to change all the gaskets, and not only in the place where there is a water leak.

In the same way, the cracked section of the aluminum or cast iron battery is replaced without any problems, and the remaining ones are checked for leaks. But what if there are no taps, and it is not possible to turn off the entire riser in an apartment building? First, it is necessary to take measures to localize the accident; with a small defect, it is enough just to substitute the container.

When the battery is leaking heavily, it is recommended to throw an old blanket or cloth over the area that will absorb water well. Then immediately call the emergency service. While the specialists arrive, we must try to block the riser in the basement of the house.

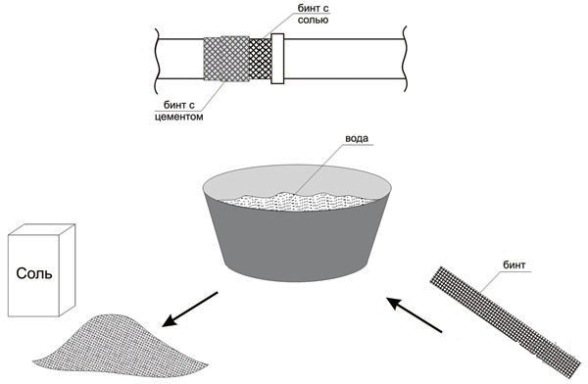

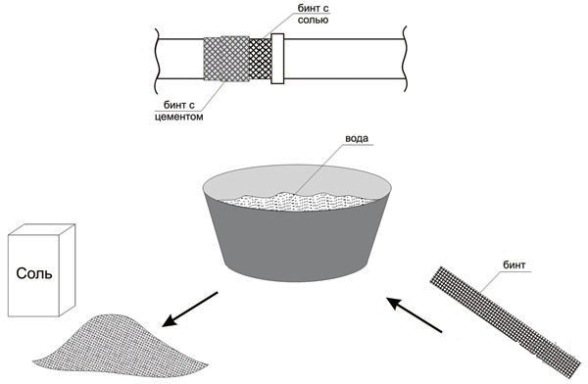

It is possible to eliminate the radiator leakage by applying a "bandage" to this place. A small crack is repaired by artificial rusting using ordinary kitchen salt. The defect is cleaned to metal, after which a thick cloth with salt is applied to it. To fix it, a bandage soaked in cement or tape is used. The method works only on steel or cast-iron heating radiators; leaks in aluminum batteries cannot be eliminated in this way.

You can try to seal bimetallic and aluminum radiators with a cloth impregnated with epoxy glue. It is also used in a situation when a tap on a battery is flowing. Another way is to use a compound called "cold" welding, but it must also be tied tightly to the leak and fixed. In practice, all of these options work well when the device is not under pressure. Otherwise, it is very difficult to close up the crack from which the hot coolant is constantly flowing.

Advice. Sometimes a simple self-tapping screw of a suitable diameter helps out, which is screwed directly into the hole.

Repair of plastic and polypropylene pipes

Most modern sewerage, water supply and heating systems are made from PVC pipes. Water leaks in them do not occur so often and, as a rule, due to mechanical damage or due to improper installation.

If a leak develops in the fitting connection, it is enough to tighten it - this is easy to do even without shutting off the supply. If the reason is a burst pipe, then almost any of the above methods will do for DIY repair.

Taking into account the characteristics of the material, it is possible to eliminate minor water leakage in PVC pipelines using soldering. To do this, gently heat the burst area to a soft state, and also bring a small piece of pipe made of the same material to the melting point. Immediately after that, you need to apply molten plastic to the breakout site. Make sure that the pipe section does not deform due to heating.

In case of serious damage, you can cut the pipeline at the leak and apply polyurethane, epoxy or hot melt adhesive to both ends. Then both pipes should be aligned, after putting a cut plastic bottle on them. Next, a hairdryer is taken and the area to be repaired is warmed up until the homemade "sleeve", squeezing and welded to the water supply, does not form an airtight connection.

Before you repair polypropylene pipes with your own hands using improvised means, think about whether it makes sense to expose your home to the risk of flooding, or is it better to immediately replace the damaged area. If you have a welding machine and experience working with it, this process will take no more time.

Recently, special nozzles for this kind of equipment have appeared on the market, allowing you to reliably seal through holes in polypropylene pipes. How this is done is clearly shown in the video below.

Remember: almost all of the above methods of eliminating water leaks are only a temporary measure. Depending on the condition, it is necessary to replace all pipes or only the damaged section with a new one as soon as possible. In the absence of the appropriate skills and tools, you can always turn to professionals for help.

A flood in an apartment is always easier to prevent than eliminate its consequences. By installing the Neptune automatic leakage protection system, you will be reliably protected from unforeseen costs for the restoration of your apartment, as well as for compensation for damage to the injured neighbors below,

(1 rating, average 5 out of 5)

Leak elimination methods

When the leak is found and the necessary tools are available to fix it, it's time to fix the water leak in the heating system.

When the pipe flows

Leakage in the pipe most often occurs due to poor-quality welds. Solves the problem with a rubber gasket and a clamp. The pipe is well cleaned of paint, a sealant is applied to the hole, a gasket and a clamp are applied on top. The bolts are tightened as tightly as possible to prevent future leakage.

On a curved pipe section, the leak is repaired with epoxy or repair tape. The resin is applied only to a dry surface, so you will have to drain the water and systems. If there is no desire to free the batteries from the coolant, it is better to choose a tape.

- Before gluing, the pipe at the point of leakage and around it about 8 cm is well cleaned and degreased.

- The tape is soaked in water for 20 seconds.

- The hole in the pipe is wrapped with an acrylic gasket from a repair kit.

- The tape is wound diagonally, starting from the edge of the spacer, forming turns up to the middle of the hole.

- At the time of winding, the tape is well pressed to the surface for about 7 minutes.

- When the material begins to stick to the gloves, it is left to dry completely.

A rubber gasket and a clamp will help solve a leak in the heating pipe.

The complete solidification time depends on the temperature of the pipe. At 20 degrees, that's about half an hour.

When the radiator has leaked

The joint between the battery sections or the radiator plate can leak. In this case, cold welding will be required. The water supply is shut off, the damaged area is first cleaned, degreased and only then the sealant is applied to the hole and an area of 3-5 cm around it. Welding freezes quickly. After it is completely dry, the heating is turned on.

It is more difficult to eliminate leakage between sections. To do this, the radiator is dismantled, and the nipple connection is tightly tightened, applying maximum effort to this. At the end of the work, the battery is mounted in place and water is supplied to the system.

Leak remediation materials

The heating medium of the heating line of private houses is under a pressure of 1.5 - 2 atmospheres, its maximum temperature rarely exceeds 80 ° C. The materials used to eliminate leaks must withstand these physical and temperature stresses. To eliminate leaks, use:

- Clamps. The most common effective way to repair any pipes, metal brackets can withstand pressure in the system up to 70 atmospheres with a coolant with a temperature of 100 ° C or more (depending on the material of the gaskets). They consist of two parts or one horseshoe-shaped plate, tightened with bolts, designed for a standard pipe diameter (you can always find the right size on sale), are used only on straight sections of the pipeline.

- Elastic bandages. Rubber elastic bandages are used to seal curved areas or where fittings are located if they are leaking. The bandage does not withstand the supply of coolant under high pressure, therefore, after screwing it in, it will have to be reinforced with wire or a steel clamp.

Fig. 5 Materials for eliminating leaks in the heating system

- Repair tapes. On the construction market, you can buy a wide range of special tapes for pipe repair (Siloplast). Before carrying out the repair, the tape is poured with water and then wound onto the damaged section of the pipeline. After polarization, the coating can withstand pressure up to 40 atmospheres, temperature range from -70 to +370 C., its service life is 50 years.

- Two-component formulations. Repairing leaks with special compounds, the most popular of which are epoxy and cold welding, are an effective method of dealing with leaks in curved or hard to reach areas. For better adhesion, the place of sealing should be dry, free from dirt, paint and grease, epoxy resin is best used in combination with strapping materials - cloth, bandage, nylon tights, fiberglass.

Fig. 6 Installation of repair clamps in the heating system - examples

Light-curing plastic B.The kit includes liquid plastic and an ultraviolet lamp, under the radiation of which the material poured into the fistula solidifies, the working temperature range of Bondic is from -40º to + 150º С.

The listed methods of eliminating leaks are the main ones; for short-term sealing of the fistula, chopiks (wooden wedges), bolts, cement coatings, various adhesives, individually and in combination with soda, are used. These options are ineffective even for a short time and cannot be the main methods for eliminating leaks in a heating main with a high temperature and pressure up to 2 atmospheres.

Finding and removing leaks in the heating system

Water leakage is a phenomenon that, over time, is faced by any home owner in whose housing a steam heating system is functioning. It is very easy to find it if the pipes are not laid in the thickness of the floor or walls. But removing a leak in a heating system is not an easy task and even critically dangerous if boiling water gushes from a broken pipe. It is better not to lead to such a situation and take measures to eliminate leaks of the heat carrier at the first sign.

Causes of leaks

Among the reasons for the leakage of a heat carrier (any, and not only water), there are three main ones:

- Corrosion;

- Violation in the installation technology of the system;

- Illiterate work.

Metal corrosion is caused by two types of chemical. reactions: oxidation under the influence of oxygen and an electrochemical reaction that appears when metals are combined with a wide variety of positive and negative ions in the atomic structure of a substance.

Innovative violations during the installation of the system, which lead to leakage of the heat carrier, include, for example, the use of inappropriate electrodes and the appearance of local foci of electrochemical corrosion in the places of welding seams. The most susceptible to violations in the installation technology are metal-plastic pipes connected by threaded connectors. Such a leak is almost irreparable and requires a complete replacement of the pipeline section at the same time as the fitting.

Advice! It is not necessary to drain the water from the system at the end of the heating season, unless this is required for repair work. When installing the system, it is best to use steel pipes of the same brand, it is absolutely impossible to join ferrous and multi-colored metals (plus pipes with zinc or other coating), and also those with alloying additives.

Wrong work and choice of materials

The illiterate operation of the heating system also leads to water leaks from the pipes. For example, boiling up of a heat carrier and an additional hydrodynamic shock result in damage to the gaskets and even destruction of threaded connections. If it is decided to change the type of heat carrier by replacing the water with antifreeze, then be prepared for the threaded fasteners to flow. This is all the more important for those devices that were mounted twenty years ago and were used to seal them with tow, oil-based paint, rubber and other cheap auxiliary materials.

An unnecessarily high pressure in the system also leads to water leakage from the pipes. It does not affect the performance of its work at all and even harms, leading to boiling of water at temperatures below 100 ° C. Pressure is needed to pump a heat carrier to the upper tiers of high-rise buildings or to activate sluggish thermal convection in single-pipe systems with lower wiring. In houses on one floor, it is better to use circular pumps with a working pressure of no more than 1.5 atmospheres.

Metal-plastic pipes, which have become common in our time, are very susceptible to the mode of operation. They do not withstand large temperature changes, overheating and water hammer. Their structure delaminates, due to which the pipes lose their strength, cracks and fistulas appear in them.

Search and removal of heat carrier leaks

It is easy to determine the place of water leakage through puddles on the floor.However, if you inadvertently brought the matter to this, then you can consider yourself on the verge of a communal catastrophe of a local nature. Due to this, it is necessary to look at the details - the appearance of rusty streaks at the joints with threads, swelling on the surface of pipes made of metal-plastic, their loss of shape and strength. If the heating pipes are laid in the thickness of the walls or a "heated floor" system in a concrete screed is arranged on an individual circuit, then it is possible to find leaks only with the help of specialized devices.

Weak (drip) leaks can be removed without draining water or stopping home heating. Elimination of flows of various intensities is possible exclusively on dry and cooled pipes. Thanks to this, it will be useful to install bypass lines (circular pumps), crushing the system into several circuits and independent sections using installed cranes with a round hole.

Repair of pipes made of metal and their joints

Even pipes made of metal that are very damaged by corrosion have a large residual strength, due to this, during repairs, significant compressive forces can be applied to them and clamps tightened with bolts can be used. For their urgent repair, you may need:

- Heat resistant (red) silicone based sealant;

- Plastic rubber bandage (sold in pharmacies);

- Two-component iron-filled epoxies (cold welded);

- Bolted iron clamps;

- Thin fiberglass or old ladies' tights.

In case of an insignificant leak in the fasteners in the form of a thread, it is enough to unscrew the lock nut (if any) by a quarter of a turn so that a gap of 0.5 mm appears. A silicone-based sealant is squeezed into it and divided equally around the entire circumference. After 30 seconds, when the sealant begins to cure, the nut is tightened.

If there is no lock nut, then you need to clean the joint from obsolete paint, scale, rust and degrease it. In case of a weak leak, it is necessary to break a piece of "cold welding", as described in the instructions for it, and equally divide it along the entire circumference of the joint, very carefully smearing the edges of the joints. For a higher flow, you can put a silicone-based sealant or a two-component metal-filled compound over the joint and press it down with a tape of fiberglass or a piece of women's tights.

A crack or fistula on the pipe can be wrapped with a rubber elastic bandage, closing with each further turn half of the previous one. The length of the winding should be twice as long as the damaged section. It is necessary to make 2-3 layers of winding and fix it with clamps. A positive result is obtained by winding with a hemostatic tourniquet from a car first-aid kit, which can be fixed with a standard latch. A crack in a pipe can also be repaired with an epoxy compound in combination with a reinforcing material - elastane or fiberglass. However, in this case, you will have to clean it to metal and degrease the entire area on which the bandage will be applied.

Advice! In our time, the polymerizing tape "Boa constrictor" appeared on sale, which is sintered into a monolith upon contact with air. It is quite convenient to use it to seal leaks of heating systems with sealant.

Repair of pipes made of metal-plastic

With all the positive qualities, these pipes have an irreparable minus generated by their system - a high coefficient of linear increase. It leads to the fact that threaded fittings are constantly weakened and they must be tightened to eliminate the leak. In most cases, up to 3 threads are left on the fitting when installed. Each drip from it, if the connector is installed correctly, is removed by a tightening 1/8 turn. If this cannot be done, then the leak can be removed only with a silicone-based sealant in combination with a reinforcing material.And you need to understand - this is a short-term measure, and the connector and pipe are replaced.

Do not use clamping clamps and bandages for repairing pipes made of metal-plastic because of the reason for their low strength. With two components, metal-filled epoxies are also ineffective, as they have poor adhesion to plastic, and ferrous metal from the filler in contact with the inner aluminum pipe provokes electrochemical corrosion.

Advice! If the metal-plastic pipe is damaged, then it is better to remove water from the system and find a replacement for it.

What to do if the toilet is leaking at the junction with the sewer

The procedure depends on the zone and the cause of the leak.

The junction of the bowl and the cistern is leaking

If the plumbing parting has worked for you for some time, then, most likely, a leak was formed due to the fact that the gasket cracked or the drain tank was warped. What to do if water oozes due to the fact that the gasket has served its purpose is clear without long explanations. It needs to be replaced. We do everything according to the instructions:

- we shut off the water and empty the drain tank;

- wipe the inside of the tank dry so that not a drop of moisture remains there;

- disconnect the supply hose;

- unscrew the fastening screws holding the tank and remove it;

- remove the lock nut on the drain;

- remove the old gasket and replace it with a new one - it is better to put the gasket on the sealant immediately, it should not differ in shape and size from the old one;

- we assemble in the reverse order.

We supply water to the tank and admire the result of our labors.

Corrugation leaks

To troubleshoot, ideally, it is better to remove the toilet in order to have more room to work, but you can do without this. What is needed is to remove the corrugation, which has worked its way out, and clean up the landing sites.

The surface of the corrugation and the seats must be treated with silicone sealant. The fit should be snug. After two hours, when the sealant has set, you can check for leaks.

In cases where dismantling the toilet is impossible or there are difficulties, and the corrugation cannot be removed, there is one trick:

- the toilet must not be used for at least a day;

- climbing under the device, use a stick made of wood or plastic;

- at the place where the corrugation connects to the toilet, pry it off;

- wringing out the corrugation, apply silicone sealant inside;

- gradually passing along the entire perimeter, treat with a sealant.

Loose bolts

Loose bolts simply need to be replaced with new ones. Everything is done very simply:

The water is shut off and the drain tank is emptied. The supply hose is unscrewed. The bolts are dismantled - you need to act with extreme caution, since they have corroded from time to time and it is difficult to move them. New bolts are installed, the main thing is not to forget about the gaskets - the bolts must be tightened tightly, but not particularly zealous.

Heating pipe repair training

Among modern compounds for eliminating leaks in the heating system, sealants deserve special attention. These are special waterproof products. They will not save in the event of a large fistula, but they are quite suitable for eliminating small damage in heating and water supply systems. Plumbing silicone sealant can last for years. It is advisable to buy it and cold welding just in case before the start of the heating season. Such funds will come in handy in every home.

Describe your question in as much detail as possible and our expert will answer it

Many homeowners have at least once in their lives faced a situation where a fistula appears in a heating pipe or a battery leaks. Having gained such experience, these people already know what tools should always be at hand to solve a problem. The ways in which leaks can be eliminated in different places of the heating system will be discussed in this article.