Here you will find out:

- What is a collector and the purpose of solar collectors

- Working principle of a vacuum solar collector

- Advantages and disadvantages

- Varieties of vacuum collectors

- Comparison of various modifications

- Making a vacuum manifold with your own hands

- Features of the correct positioning of the vacuum solar collector

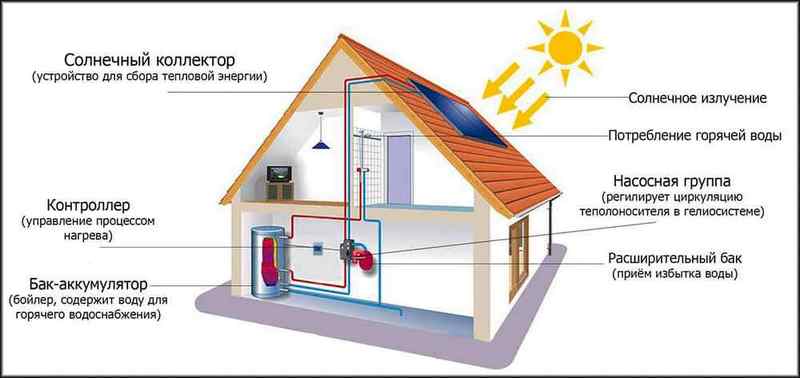

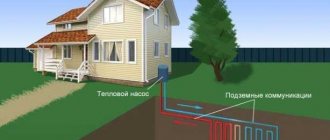

A vacuum tube solar collector is an environmentally friendly way of storing solar energy and using it to heat your home and provide hot water. Such devices are placed on the roof of private houses in the right place.

Types of vacuum tubes

There are five types of vacuum tubes for solar collectors. They differ in internal structure and design. In addition, each of them can be supplemented with a metal (usually aluminum) absorber, which is placed inside a glass bulb in the form of a tube.

Important! Most manufacturers fill the bottom gap between the glass walls with barium - it absorbs gas impurities and improves thermal insulation properties. Its absence can reduce the efficiency of the collector by up to 15%.

Thermosiphon (open) vacuum tubes

This type of solar collector tube is used in collectors with an external storage tank. they are filled with water and form one volume with the reservoir. The heated water from the flask rises into the tank, and the cooled water goes down.

Thermosiphon vacuum collectors are used in the following cases:

- For connection to a hot water supply system;

- In regions with a high level of insolation during the cold season;

- For seasonal use (spring, summer, autumn).

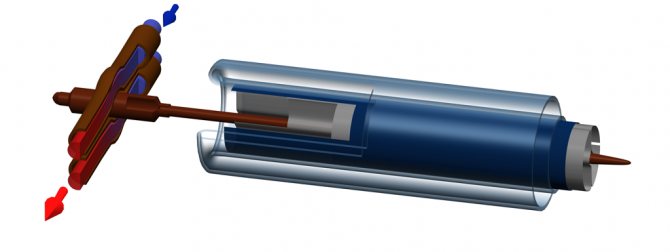

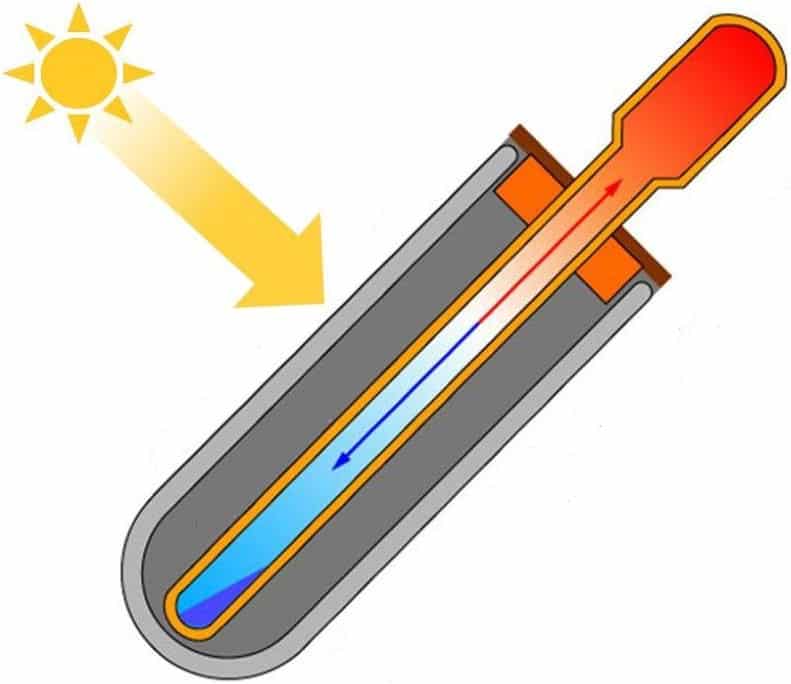

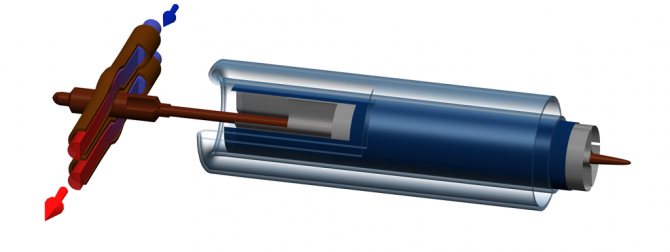

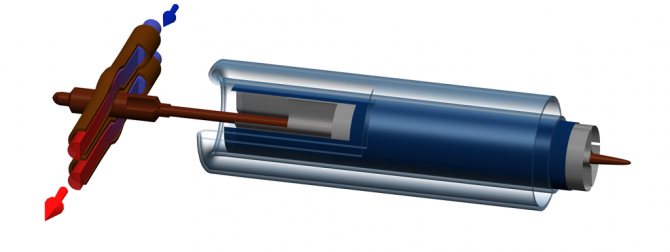

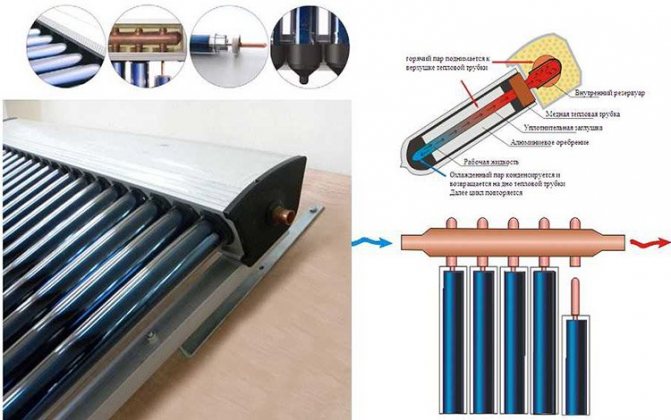

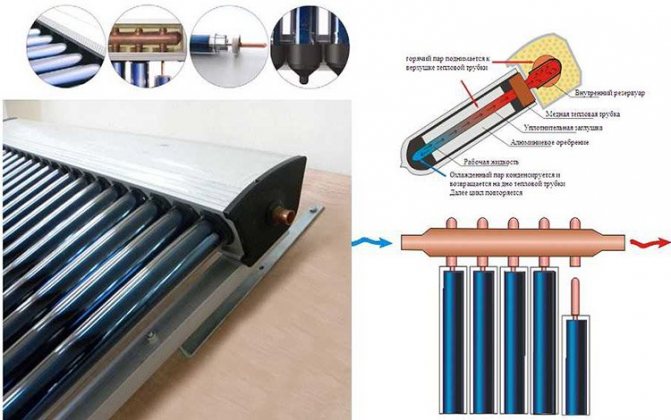

Coaxial pipe (Heat Pipe)

This is the most common type of vacuum tube. It contains a copper tube inside a glass bulb filled with a liquid with a low boiling point or low pressure water.

When heated, the liquid or water begins to boil, the steam rises, simultaneously heating up from the copper walls. At the top, it enters the heat exchanger - an expansion at the end, in which it gives off heat through the walls to the water that circulates around it.

After cooling, the steam condenses on the walls of the heat exchanger and flows down. The cycle is repeated anew.

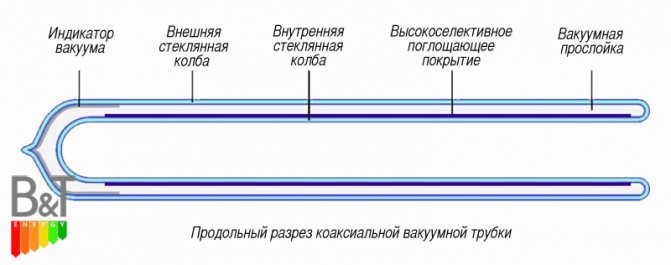

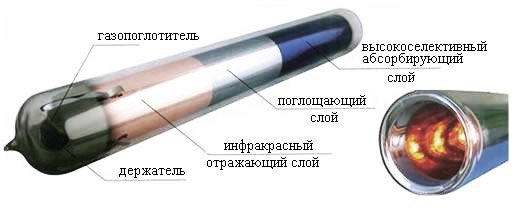

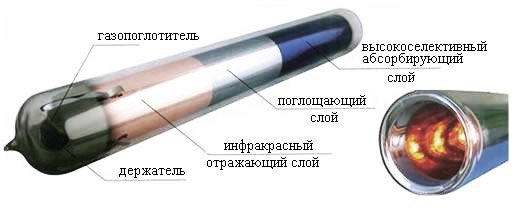

Schematic internal structure of a coaxial tube and heat exchanger.

Twin coaxial tubes

The principle of operation of such a heat sink is the same as that of the previous one, with one exception - two copper pipes with liquid are connected to one heat exchanger. The tandem system allows for more efficient heat removal, and the large capacity and wall area of the heat exchanger allows you to quickly heat the water.

The twin coaxial vacuum manifold is installed where necessary:

- Provide small heating of large volumes of water;

- There is a need for thermal energy during a sunny day;

- High average level of insolation;

- There is a rapid pumping of water through the system.

Feather vacuum tubes

In their design, there is an additional heat exchanger, which allows more efficient heat removal from the inside of the glass bulb. It is usually made in the form of two longitudinal plates located on the sides of the copper heat sink.

Otherwise, the principle of operation is exactly the same as that of a coaxial tube.

U-shaped vacuum tubes (U-type)

This system is fundamentally different from the previous ones. It uses two lines - for cold and heated water.

A heat exchanger in the form of an English letter U is installed in a glass flask, through which water flows. From the line with cold water, it enters it, heats up and returns to the pipe with heated water.

The U-type vacuum tube manifold is the most efficient, but installation is difficult. During assembly, the flow lines are welded to the copper tubes inside the glass bulb. The result is a single integral system with high energy efficiency, but low maintainability.

Installing the flask on a U-shaped copper tube.

What should be the heat collector?

The heat collector is another very important working element of the vacuum collector. Through this unit, the accumulated heat is transferred from the tubes to the coolant.

The heat collector is located at the top of the appliance. One of its components, a copper core, receives energy and transfers it to the main heat carrier circulating in a closed system "tank-collector heat exchanger".

A small pump connected to the system ensures correct circulation. The automation controlling the heating complex clearly monitors the temperature level in the channels and, if it falls below the permissible critical minimum (for example, at night), stops the pump operation.

This avoids reheating when the coolant begins to take heat from the hot water collected in the storage tank.

Pros and cons of vacuum collectors

The main advantage of the units is called the almost complete absence of heat loss during operation. This is ensured by a vacuum environment, which is one of the highest quality natural insulators. But the list of benefits doesn't end there. The devices also have other pronounced advantages, for example:

- efficiency of work at low temperature indicators (up to -30 ° С);

- ability to accumulate temperature up to 300 ° С;

- maximum possible absorption of thermal energy, including the invisible spectrum;

- operational stability;

- low susceptibility to aggressive atmospheric manifestations;

- low windage, due to the design features of tubular systems capable of passing air masses of different densities through themselves;

- high level of efficiency in regions with temperate and cool climates with few clear and sunny days;

- durability subject to the basic rules of operation;

- availability for repair and the ability to change not the entire system, but only one failed fragment.

The disadvantages include the inability of the collectors to self-cleaning from frost, ice, snow and the high price of component parts needed to assemble the unit at home.

How to place the appliance correctly

In order for the vacuum collector to work fully and effectively provide the living space with the necessary energy, it is necessary for it to find the most successful place and correctly orient the device relative to the parts of the world.

For settlements in the northern hemisphere, it is important to place the collector in the southern part of the roof of the house or on the sunny side of the site. It is desirable to provide a minimum deviation for the plane of the device.

If there is no way to direct the surface to the south, it is worth choosing the lightest perspective in open space among the west and east.

The solar energy complex should not be obstructed by chimneys, decorative fragments of roofing, spreading tree branches and tall residential or technical buildings. This will reduce the efficiency of the work and reduce the level of heating of the active elements.

If the unit is positioned correctly, it will provide almost the same heat output throughout the year, regardless of the season.

If you do not have a lot of experience in performing complex repair, installation and plumbing work, it is irrational to vacuum the tubes at home. This process is very laborious and requires special knowledge and specialized equipment.

In addition, self-made vacuum-type elements have a much lower level of efficiency than factory-made parts. Therefore, it is most reasonable to purchase products from a specialized manufacturer, and then try to assemble several sections at home.

Features of the correct positioning of the vacuum solar collector

In order for the vacuum solar collector to work with maximum efficiency, it is necessary to correctly position it in space. For the northern hemisphere, the plane of the outer block should face south. The angle of its inclination to the horizon also matters. It should be equal to the latitude of the area where the unit is being installed.

In addition to geographical features, it is necessary to take into account the geometry of the roof where it is installed. The collector must be installed in such a way that the shadow from the roof superstructures does not fall on it under any circumstances.

Thus, a vacuum-type solar collector is an effective solution for heating and supplying a house with hot water. However, its design features and dependence on the movement of the sun, which is a source of energy for it, requires compliance with a number of features during its installation.

Varieties of solar panels

The solar systems are classified according to the design features of the tubes and the type of heat channel used as a receiver:

1. The coaxial model of a vacuum solar collector for heating a house is a double flask made of glass, in the cavity of which air is evacuated. The surface is coated with an absorbent coating, so the energy is transferred from the tube itself.

2. The feather structure is single-walled, the void is located here in the space of the heat channel, part of which, together with the storage, is integrated into the flask.

4. In systems with forced circulation, a low-power pump is installed to facilitate the movement of the carrier. At the same time, the power consumption is much less than the energy received for heating a private house.

5. There is also a difference in the number of circuits. In the simplest collectors, heating water is heated and consumed from the storage tank.

6. More complex ones consist of a vacuum tube and fluid sampling elements. The device contains an anti-freeze and non-toxic media with anti-corrosion and antifoam additives. This method reliably protects the equipment from salts and scale and contributes to a longer operation during heating.

Overview of models and their characteristics

At the moment, China is the leader in the production of solar collectors. According to the reviews of the owners of private houses, domestic manufacturers also supply equipment with good characteristics for sale. European devices are quite expensive, but over time, the costs of purchasing and installing devices are fully justified. The most famous companies produce the following collectors:

Plumbers: You will pay up to 50% LESS for water with this faucet attachment

Collectors Dacha and Universal are the most famous devices of a domestic manufacturer. The SCH-18 is highly efficient with condensate temperatures up to 250 ° C. The flasks are made of red copper, the heat carrier is liquid. The absence of water in a vacuum ensures resistance to freezing. Robust case with good wind resistance. The pipeline is protected by a polyurethane manifold. Rubber anti-dust seals keep dust and precipitation out.

They work effectively at temperatures down to -35 ° C, the type of functionality is a pressure system for heating. There is a controller for controlling the heater, the size of the tubes is 1800 mm, the volume of the tank is 135-300 liters, the power of the heating element is 1.5-2 kW. The manifolds are manufactured in accordance with international certifications, which ensures their safety and reliability.

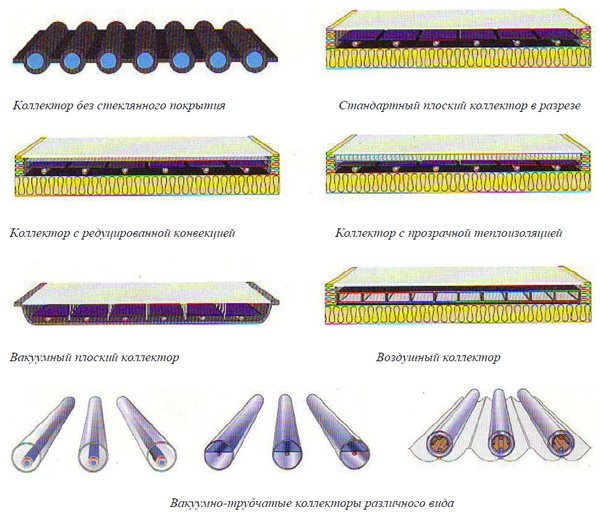

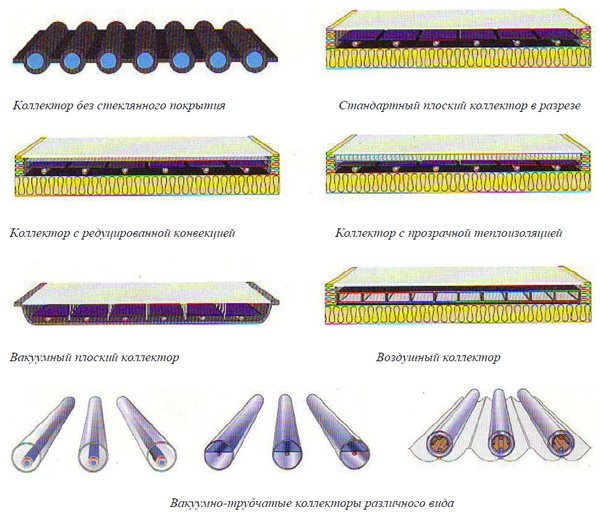

How is the collector of a vacuum type

Modern vacuum devices that provide rooms with heat and hot water due to solar energy are technologically somewhat different and are subdivided into such types as:

- tubular without glass protective coating;

- module with reduced conversion;

- standard flat version;

- device with transparent thermal insulation;

- air unit;

- flat vacuum manifold.

They all have a common constructive similarity, so they consist of:

- an outer transparent pipe, from where air is completely pumped out;

- a heated pipe located in a large pipe where a liquid or gaseous heat carrier moves;

- one or two prefabricated distributors, to which pipes of a larger caliber are connected and the circulation circuit of thin pipes placed inside enters.

The whole structure is somewhat reminiscent of a thermos with transparent walls, in which an unprecedented high level of thermal insulation is maintained. Thanks to this feature, the body of the inner tube acquires the ability to warm up qualitatively and fully give the energy resource to the coolant circulating inside.

Varieties of vacuum collectors

Varieties of vacuum collectors

There are two types of glass tubes used in the design of the collectors:

- coaxial;

- feather.

Let's take a closer look at each of them.

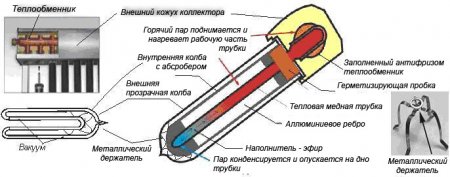

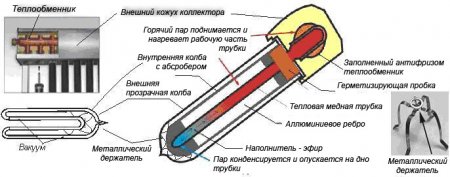

Coaxial tube

It is a kind of thermos that consists of a double flask. The outer bulb is coated with a special heat-absorbing substance. A vacuum is created between the two tubes. This made it possible to ensure that the heat during operation is transferred directly from the glass bulbs.

Inside each tube there is one more - copper (it is filled with an ethereal liquid). When the temperature rises, this liquid evaporates, transfers the stored heat and flows back as condensation. Then the cycle repeats over and over.

Feather tube

This type of tube consists of a single-walled bulb. By the way, they significantly exceed their coaxial counterparts in wall thickness. The copper tube is reinforced with a special corrugated plate treated with a moisture-absorbing substance. It turns out that air in this case is pumped out from the entire heat channel.

Such channels, by the way, are also different:

- direct-flow;

- Hit Pipe.

"Hit Pipe" type channels

Heat transfer in a vacuum solar collector type "Heat Pipe"

Their other name is heat pipes. They work as follows: when the temperature rises, the ethereal liquid in closed pipes rises up the channel, after which it condenses there in a specially equipped heat collector. In the latter, the liquid transfers heat energy and descends down the tube. From the heat collector, heat is transferred further into the system using a circulating heat carrier.

Coaxial vacuum pipe heat-pipe with 2-pipe manifold

It is characteristic that metal tubes here can be not only copper, but also aluminum.

Direct-flow channels

In each of these channels in the glass tube there are two metal pipes at once. On one of them, the liquid enters the flask, heats up there and exits through the second.

Structural nuances and classification

Vacuum-type collectors are classified by the type of glass tubes installed in the structure, or by the characteristics of the thermal channels. Tubes are usually coaxial and feather type, and heat channels are U-shaped direct flow and heat pipe types. ...

Feature of coaxial tubes

Coaxial tubes are a double glass thermos flask with an artificially created vacuum space between the walls. The inner surface of the tube has a layer of a special heat-absorbing coating, so the actual heat transfer occurs directly from the walls of the glass bulb.

Coaxial tubes are made of high-strength borosilicate-based glass with high light transmittance. Elements, depending on the manufacturer, have up to three layers of magnetron sputtering, demonstrate excellent strength and resistance to various atmospheric manifestations (rain, hail, etc.), withstand a pressure of 1 Mpa and reliably serve for 15 years.

As an absorbing element, a copper tube containing an ether composition is soldered into the glass tube. During the heating process, it evaporates, effectively gives off its heat, condenses and flows down to the bottom of the tube. The cycle then repeats, thus creating a continuous heat transfer process.

Feather Tubes Features

Vacuum fountain tubes have a greater wall thickness than coaxial ones and consist of not two, but one bulb. The internal copper absorption element is equipped along its entire length with a strong reinforcement - a corrugated plate with a high-level energy-absorbing sputtering.

Due to this design feature, the vacuum is located directly in the heat channel, part of which, together with the absorbent, is integrated directly into the flask.

The feather vacuum tube contains a plate inside, which is shaped like a feather. In terms of efficiency, it exceeds the capabilities of its coaxial counterpart, but has a significantly higher cost and is difficult to replace in case of violation of the integrity of the flask or failure of the heating element

Feather tube manifolds are considered to be the most efficient in their class, do the job well, and provide years of reliable service.

The principle of operation of the heat pipe

Heat pipes consist of closed tubes containing an easily evaporating liquid compound. Under the influence of sunlight, it warms up, goes to the upper region of the channel and concentrates there in a special heat collector (manifold).

The working fluid at this moment gives up all the accumulated heat and goes down again to resume the process.

The heat-pipe heat exchanger sleeve is connected to the manifold's heat exchanger by means of a special socket soldered into the 1-pipe heat exchanger itself, or it is bent around by the 2-pipe heat exchanger.

The working element of the heat pipe is made of copper, in more rare cases - of aluminum. Shows high resistance to operational loads, reliably serves for 15 years, has a reasonable cost and is one of the most popular elements of modern tube-type vacuum solar systems

The released energy from the heat reservoir is taken by the coolant and transported further through the system, thus providing hot water in the taps and heating in the batteries. The heat pipe system is easy to install and demonstrates high working efficiency.

Collectors equipped with heat pipe vacuum tubes have a good level of reliability and are suitable for use not only in everyday life, but also in high-pressure solar thermal systems

In the event of a breakdown or failure, without any difficulties, it is possible to replace the damaged unit with a new one, without resorting to reconstruction of the entire system.

Repair work can be easily carried out directly at the location of the collector without dismantling the unit and without applying unnecessary effort to the work.

Description of U-shaped direct flow heat exchanger

The tube of the once-through heat exchanger is U-shaped.Water or working heat carrier of the heating system circulates inside. One part of the element is intended for a cold heat carrier, and the second one correctly removes the already heated one.

When heated, the active composition expands and enters the storage tank, thus creating a natural circulation of the liquid in the system. A special selective coating applied to the inner walls increases the heat absorption capacity and increases the efficiency of the system as a whole.

Compared to heat-pipe type pipes, U-shaped products have greater hydraulic resistance, place increased demands on the coolant and are much more expensive. Collectors operating on straight-flow U-tubes cannot work under high pressure and provide high-quality heat transfer only during the warm season

U-type tubes offer high performance and solid heat dissipation, but they have one major drawback. They form one integral structure with the manifold and are always mounted together with it.

It will not work to replace a separate single tube that is out of order. For repairs, it will be necessary to dismantle the entire complex completely and put a new one in its place.

Advantages and disadvantages

Solar vacuum collectors have less heat loss compared to flat ones. The use of vacuum nanotechnology in the production of collectors has made it possible to achieve high efficiency and reliability of solar systems.

Let's consider the main advantages of using vacuum collectors:

- Performance. There is a vacuum in the collector tubes - an ideal heat insulator, which allows you to maintain an optimal level of heat even in the autumn-winter period. By keeping the efficiency at a high level, the productivity of the vacuum collector is 40% higher than that of the flat collector.

- Reliability. The service life of vacuum collectors is about 30 years. Their durability and trouble-free operation are due to modern durable materials. The vacuum tubes contain high quality copper. The outer casing of the tubes is cast from borosilicate glass, which is able to withstand high loads. The use of vacuum collectors is especially important for climatic zones where squalls, hurricanes, hail are not uncommon.

- Solar energy efficiency. The cylindrical shape of the vacuum collector absorber captures and retains even the scattered solar energy, which the flat corrector cannot convert. 40% more solar energy can be retained from one square meter of the absorber of a vacuum solar system than from a similar area of a flat-type solar installation. The roundness of the tubes allows you to receive up to 97% of solar energy from early morning until late evening.

- Ease of use. In case of damage to the vacuum tube, it is replaced without stopping the operation of the system (no need to drain the circulating fluid). If there is a lack of heat, you can add several pipes, and if there is an excess of it, temporarily remove it. After cleaning the vacuum manifold from snow or ice, it quickly becomes operational. The collector surface has low thermal inertia due to the thin glass coating.

- Disinfection of water. The temperature of water heating during the operation of the solar system reaches high levels, which ensures its disinfection and prevents the multiplication of pathogenic organisms.

- Ease of installation. When installing vacuum collectors, there are no special difficulties, the main thing that must be adhered to is to position the collector at an angle to allow the liquid inside the tubes to drain down.

The disadvantages of solar heating are reduced to extremely low efficiency at low temperatures and at night, thus the question is that this heating system cannot be the only one in the house.Also, vacuum solar collectors are more expensive than flat ones.

Vacuum solar installations are becoming increasingly popular among the population and large companies. If before many were frightened off by the price of the issue, today the cost of equipment has slightly decreased, and the functionality has improved and modified.

Modification features of devices

Heating ducts and vacuum glass tubes for solar collectors are combined in a wide variety of combinations for the production of solar power units.

The most popular among consumers are coaxial models with a heat pipe. Buyers are attracted by the loyal price of devices and very simple, affordable service throughout the entire life cycle.

The vacuum solar collector with a heat pipe working channel is excellently repairable. Replacement of damaged tubes is carried out on site and does not involve dismantling the system or moving it to another place. However, heat transfer in these models is difficult, due to which the output efficiency is no more than 65%

Vacuum devices with heat pipe channels demonstrate high reliability and have no restrictions on their use, even in high-pressure solar thermal complexes.

Devices with a coaxial bulb containing direct-flow U-shaped channels are also included in the list of demanded ones. They are characterized by such parameters as low heat loss and efficiency from 70% and higher.

For correct operation, the vacuum device with a U-channel must be installed correctly. It is desirable that the minimum tilt angle is at least 20⁰. Only in this case it will be possible to ensure the maximum return.

The situation is somewhat spoiled by a complex repair process, specific maintenance during operation and the inability to replace a separate damaged unit. If something happens to the device, it is dismantled and a completely new collector is put in place.

Feather tubes are structurally a single cylinder made of glass with thickened strong walls (depending on the manufacturer, from 2.5 mm and more). The inner insert made of feather absorbent tightly fits the working channel made of heat-conducting metal.

Almost perfect insulation is created by the vacuum space inside the glass container. The absorbent transfers the absorbed heat without loss and provides the system with an efficiency of up to 77%.

In the event of a malfunction, the collectors equipped with feather tubes must be repaired. It is not required to change the entire system, it is enough to find the damaged unit, dismantle it and put a new one in this place

Models with a feather element are slightly more expensive than coaxial ones, but due to their high efficiency, they provide full comfort in the room and quickly pay off.

The most efficient and productive are feather flasks with internal direct-flow channels. Their actual efficiency sometimes reaches record rates of 80%.

When installing feather tubes in the frame, a strong crimp nut with a ring and a heat-resistant gasket is put on the rod of each part. This ensures the tightness of the entire structure and allows the collector to function fully in any conditions.

The price of the products is quite high, and when carrying out repairs, it is imperative to drain the entire coolant from the system and only then start troubleshooting.

The principle of operation of the SKE-type vacuum tube.

The key to the solar system is the glass vacuum tube. Each vacuum tube consists of two glass bulbs.

The outer flask is made of extremely tough borosilicate glass that can withstand the impact of hailstones falling at a speed of 18 m / s and is up to 35 mm in diameter.

The inner bulb is also made of borosilicate glass and covered with a special three-layer coating with a gradual change of the ALN / AIN-SS / CU absorbing layers. Due to the use of new technologies, a high absorption coefficient and a low beating ability are achieved, which allows reaching + 380 ° С in the middle of the tube in direct sunlight, without harming the product itself.

Air is pumped out between the two glass bulbs to create a vacuum that prevents reverse heat conduction and convective heat loss. In the middle of the glass bulb there is a sealed heat pipe (HEAT PIPE), made of pure red copper, in the middle of which there is a low-boiling and evaporating liquid, which performs the function of transferring heat to the coolant. The figure below shows the working principle of the vacuum tube.

The main intensity of solar radiation under terrestrial conditions is in the spectral range 0.28 µm - 3 µm. Borosilicate glass transmits solar radiation waves in the range of 0.4 microns - 2.7 microns. Penetrating through the outer transparent flask, energy is retained on the second flask, on which a highly selective opaque absorber layer is applied.

As a result of the absorption of light by the absorber and its subsequent emission, the wavelength increases to 11 μm. Glass is an impenetrable barrier to electromagnetic waves of this length. Solar energy entering the absorber is trapped. Absorbing solar radiation, the absorber, even without an external bulb, can heat up to a temperature of + 80 ° C. The absorber heated to such a temperature emits heat energy, which, penetrating through the body of the second bulb, is transferred to the HEAT PIPE. Due to the appearance of the greenhouse effect, which is based on the accumulated energy under the glass, in the middle of the second flask the temperature rises to + 180 ° C. This heat heats up a low-boiling and evaporating liquid, which at + 25 ° C - + 30 ° C, turning into steam, rising, transfers heat to the working part of the HEAT PIPE, where heat exchange with the coolant takes place. The release of heat forces the steam to condense and flow to the bottom of the HEAT PIPE, and the cycle repeats again.

The high heat transfer coefficient of an easily boiling and evaporating liquid, its insignificant amount and the relatively small dimensions of HEAT PIPE provide effective thermal conductivity. HEAT PIPE works like a thermal diode. Thermal conductivity is very high in one direction (up) and low in the opposite direction (down).

In order to maintain a vacuum between the two glass flasks, a layer of barium is applied to the lower interior of the flask. It actively absorbs CO, CO, N, O, HO and H during tube storage and operation. The barium layer also provides a clear visual indication of the vacuum status. White color means that vacuum conditions are violated.

The ideal combination of vacuum and heat copper pipes gives us the following advantages over flat collectors:

High thermal efficiency. thanks to modern methods of heat transfer, high quality absorbing coating.

Wide range of work: due to its low thermal capacity, it is able to work in high clouds (in the infrared range of rays that pass through the clouds).

Each tube works independently of one another. Since the antifreeze does not flow into the middle of the tube, and its access is limited by the heat exchanger, in the event of physical damage, the collector continues to work.

Less collector weight with better collector efficiency.

Better work efficiency in winter thanks to the vacuum. The tube can withstand frosts at -50 ° C.

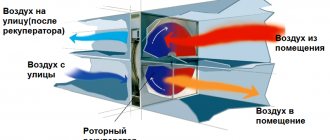

How energy is transferred

A solar collector for heating can transfer heat energy in two main ways. The first is the direct heat transfer mode.In such devices, the tank is connected directly to the vacuum tubes, and its volume, as a rule, does not exceed 200 liters. The principle of operation is as follows:

- The heat carrier heated by solar energy turns into steam and enters the copper coil. The latter serves as a heat exchanger and is located inside the storage tank.

- Further, the heated heat exchanger transfers thermal energy to the cold water that surrounds it. The liquid circulates in the radiators of the room and flows back for reheating.

The system is quite cheap and affordable, since there is no need to buy pumping equipment. The installation allows you to receive up to 300 liters of water with a temperature of +60 degrees Celsius, however, this is only a seasonal option, respectively, it is most often used in positive weather, that is, from May to September.

If you need a system with year-round use, then order a device with an indirect heat transfer mode. A distinctive feature of this type of device is the presence of a buffer tank, which is located directly in the house. The boiler volume limit is indicated in the documents. The system allows you to obtain a coolant temperature of 200-300 degrees Celsius, which makes it easy to organize a heating system. In order for the unit to function even in frosts of -50 degrees, the copper heat exchanger is filled with antifreeze.

How vacuum tubes work

The function of the evacuated solar collector tubes is to absorb solar radiation and prevent it from escaping into the environment. Thermal energy can leave the working part of the vacuum solar collector in two ways - due to direct heat transfer and in the form of infrared radiation.

The cavity between the glass walls practically completely excludes the possible direct transfer of heat in a vacuum, there are no molecules of substances that could carry it out.

The selective coating (absorbent) absorbs solar energy and prevents it from escaping. There are different types of such coatings, differing in absorption and emissivity.

Some part of solar radiation is reflected by glass, but it is insignificant - visible light makes up only a part of the absorbed spectrum. High-quality collectors are made of high strength borosilicate glass, which is resistant to mechanical damage.

Borosilicate glass is difficult to scratch or mat and will last for decades without changing the throughput.

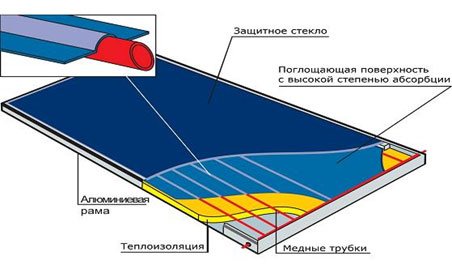

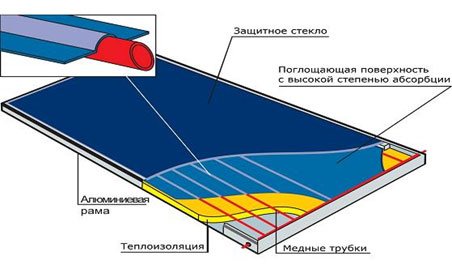

Flat collectors

A flat solar collector heats the heat carrier using a plate absorber. It is arranged quite simply. In fact, this is a plate of heat-absorbing metal, painted black on top with a special paint. A serpentine tube is tightly attached (welded) to the lower surface of the plate, through which the liquid circulates.

Selective black ink ensures maximum absorption of sunlight with virtually zero reflection. The absorbed rays heat the coolant under the absorber, which, in turn, is fed further into the system. To minimize heat loss, the absorber is insulated from the collector body and tempered glass, almost free of iron oxides. It is installed above the absorber and acts as the top cover of the housing. In addition, the use of such glass allows you to create a kind of "greenhouse effect", which further increases the heating of the absorber, and hence the temperature of the coolant.

What is a collector and the purpose of solar collectors

A solar collector is a device that collects radiation energy and then transfers the stored heat to consumers. In practice, another term is used - a solar collector.

By designation, solar installations (solar installations) use are subdivided:

- solar concentrators are devices that collect solar energy into a narrow stream.They are used to melt metal. At the Institute NPO "Physics-Sun" (Tashkent), melting furnaces were developed and manufactured, in which temperatures of more than 5000 ... 5500 ° C were achieved;

- solar panels - devices for converting radiation from the Sun into electrical energy;

- solar desalination plants - machines designed to obtain fresh water from water with a high content of mineral salts;

- solar drying installations - thermal devices in which moisture is removed from vegetables and fruits using the energy of the sun;

- solar heaters (solar air collector) are installations for transferring heat flux from infrared radiation to heat carriers.