Home ›Engineering systems› Integrated solutions ›Ventilation and air conditioning

You can order ventilation and air conditioning systems with installation by calling in Moscow. Design and supply of ventilation and air conditioning systems in Russia. We ask you to send a written application by email or through the form on the website.

- Air conditioning solutions

- Air conditioning services

- Air conditioners catalog

- Air conditioner manufacturers

- Ventilation services

- Ventilation types

- Ventilation solutions

- Ventilation system manufacturers

- Why is ventilation necessary?

- Air conditioning process

- SNiPs for ventilation and air conditioning

- Mechanical air evacuation method

- How ventilation differs from air conditioning

Send an application and get a quote

- Ventilation and air conditioning design

- Installation of ventilation and air conditioning

- Maintenance of ventilation and air conditioning

- Typical solutions for air conditioning and ventilation

Ventilation and air conditioning of premises provides for the arrangement of special systems, has a rather high cost and requires compliance with fire, sanitary and soundproofing requirements. Their constructive solution implies installation, laying and selection of building materials in accordance with the provisions of SNiP.

For the normal existence and life of a person, it is necessary to create and maintain certain air parameters. Changes in temperature, accumulation of harmful impurities in it significantly affect the well-being of people and their health. To maintain the required air characteristics in the room, special equipment is used.

"Standard Climate" is a professional climatic company, ready to implement solutions to any problems in climatic and other engineering equipment on a turnkey basis. We will perform a full cycle of work: selection of equipment, design, installation, delivery and maintenance. On the website airclimat.ru you can send an application. Call now: +7(499) 350-94-14

... Submit your application

- Air conditioning and ventilation systems (ACV) based on split-system air conditioners and a natural exhaust ventilation system for residential premises

- Technical ventilation system based on precise installation and an exhaust roof fan

- SCR based on a split system with supply ventilation

- SCV based on "chiller-fan coil units" combined with central heating and a natural ventilation system of an administrative building

- SCV based on "chiller-fan coil units" and a system of supply and exhaust forced ventilation of office premises

- SCV based on "chiller-fan coil units" and a system of supply and exhaust forced ventilation of the hotel building

- SCR of the cinema hall on the basis of a central supply and recirculation air conditioner

- SCR of a technological room based on a precision cabinet air conditioner

- SCR of a showroom based on a central air conditioner with exhaust air heat recovery in a cross-flow heat exchanger

- SLE operating room based on a supply and exhaust autonomous air conditioner

- Ventilation system of an administrative building based on floor-by-floor supply and exhaust ventilation units with exhaust air heat recovery

- SCV based on rooftop air conditioners and a natural exhaust ventilation system for the sales area

- SCR of a sports hall based on rooftop air conditioners with an exhaust fan section

- SCV based on the air conditioner "split systems with supply ventilation" and the natural exhaust ventilation system of the cottage

- SCV based on "chiller-fan coil units" and an air handling unit with heat recovery from the exhaust air of a cottage

Choose a wall-mounted air conditioner for one room

Ventilation solutions

- Ventilation of an apartment Ventilation of a house or cottage Ventilation of offices Ventilation of shops Ventilation of a shopping center Ventilation system in a restaurant, cafe or bar Ventilation of production Ventilation of a warehouse Ventilation of a workshop Ventilation of a server room Ventilation of a pool Ventilation of residential buildings Ventilation of an administrative building Ventilation of a gym or a fitness center Ventilation of a car service, parking lot Ventilation of a cinema or club Ventilation of a kindergarten Ventilation of a school Ventilation of clean rooms Ventilation of a hotel or hotel Ventilation of a winter garden Ventilation of a bath or sauna

Local SLE

Local air conditioning systems are developed on the basis of autonomous and non-autonomous air conditioners, which installed directly in the serviced premises... The advantage of local hard currency is ease of installation and installation... Such a system can be used in a large number of cases:

- In existing residential and office buildings to maintain a thermal microclimate in separate office spaces or living rooms

- In newly built buildings for individual rooms, the mode of cold consumption in which differs sharply from that in most other rooms, for example, in server rooms and other rooms of office buildings saturated with heat-generating equipment. In this case, fresh air supply and exhaust air removal are carried out, as a rule, by central supply and exhaust ventilation systems.

- In newly built buildings if the maintenance of optimal thermal conditions is required in a small number of roomse.g. in a limited number of suites in a small hotel

- In large rooms both existing and newly constructed buildings: cafes and restaurants, shops, project halls, auditoriums, etc.

Why is ventilation necessary?

Air renewal helps to prevent diseases of the cardiovascular and central nervous system, increased sweating, deterioration of attention, chronic diseases in people with weak immunity.

A standard ventilation system allows:

- reduce the concentration of dust and other small particles in the air;

- choose a comfortable temperature for work;

- remove exhaust gases and aggressive components that cause allergies.

Of course, you can open the vents, but then dust and dirty air will get into the room. And in the cold season, heating costs will increase. Also, drafts negatively affect human health.

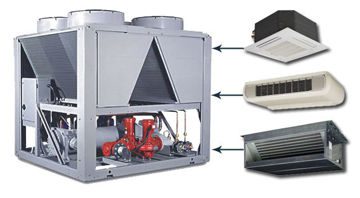

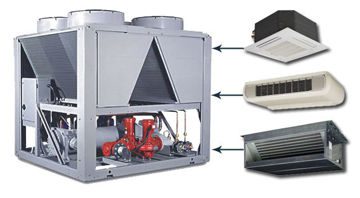

Chiller-fan coil system

Finally, the most complex, capacious and flexible is the air conditioning system built according to the “chiller-fan coil” scheme (chiller air conditioning system).

The chiller system is well suited for medium and large facilities (from 100kW) and can be designed taking into account any peculiarities, features, such as the remoteness of the refrigerated premises, the range of outdoor temperatures, environmental safety, etc.

The fundamental difference between the chiller system and all others is that it is not refrigerant that circulates in the pipelines, but cold water (or non-freezing glycol solution in case of winter operation of the system).

Note that there are several types of chillers: with a built-in or remote condenser and with an air-cooled or water-cooled condenser. Such a classification provides the necessary flexibility in configuring the system, which allowed this type of equipment to largely occupy a niche, as mentioned above, of medium and large facilities.

It is important to note that for the chiller cooling system, as a rule, its own pumping station is designed.This allows all premises of a large facility to be included in one system without dividing them into several systems, which saves capital and operating costs.

Air conditioning process

Even in the warm season, it is problematic to carry out a simple air exchange without the use of special devices. Therefore, it is advisable to use additional equipment.

In summer, the air is humid and warm. Air conditioning will keep it clean and set to a lower temperature. For example, split systems, industrial air conditioners and chiller-fan coil units are suitable.

But in the cold season, the air is frosty and less humid. Naturally, don't forget about filtering. However, it is still necessary to warm up and humidify the air, which the heater successfully copes with, guaranteeing the temperature rise to a comfortable level.

This process is often provided by mixing: cold streams are combined with warm ones. The air is cooled in special chambers due to the ingress of small drops of water.

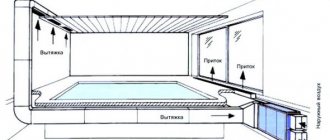

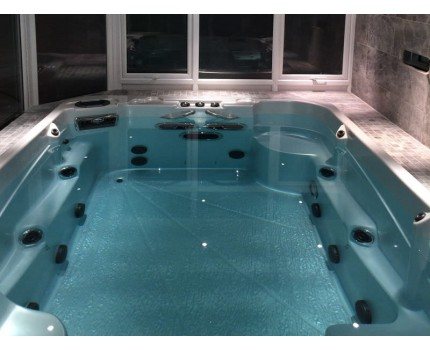

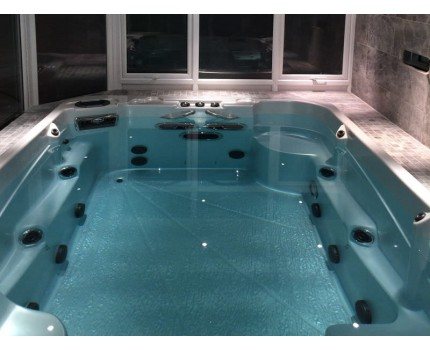

There are also premises that require a special approach to the organization of ventilation. For example, in gyms with swimming pools, water constantly evaporates, increasing the humidity level. Water evaporates from the pools and condenses on the walls and ceiling of the room.

Dehumidifiers are designed to solve such problems. The disadvantage of the latter is the lack of ventilation. The air remains in the room, but the moisture level decreases. Therefore, the concentration of oxygen decreases, which negatively affects the well-being of people.

Air conditioning system type

Experts believe that air conditioning alone in a country house is indispensable. Nevertheless, if you want to create an individual climate in each room, you still have to choose them.

All air conditioners are divided into two types. First - simple split systems, in which the condenser and the evaporator are separated into different blocks: external and internal.

Simple split air conditioning

In a country house with a large number of rooms, the second type of air conditioning system is more appropriate - multisplit system, where there is only one outdoor unit for many indoor units. At the same time, there is one caveat - all air conditioners must work either for cooling or for heating. And the number of internal devices is limited - there can be no more than four of them per external unit. Both of these types of air conditioners have one important drawback - they consume a lot of electricity (about 7 kilowatts per hour).

Multi-split air conditioning system

Energy-saving technologies are implemented in systems mini VRV - multi-zone systems... Having spent electricity to reach the desired temperature, the engine drops power and only maintains the required climate, thus saving up to 50% of electricity. At the same time, the architecture of the system provides placement of up to 9 indoor air conditioning units per 1 external one. The abbreviation VRV itself stands for Variable Refrigerant Volume, which means Variable Refrigerant Volume.

SNiPs for ventilation and air conditioning

Installation of ventilation systems is a prerequisite for modern construction design. For intelligent air circulation, standards developed over decades are taken into account. They are designed in the form of rules or SNiP standards. This abbreviation means "Building codes and regulations", the basis of which was laid by the developers of construction schemes, engineers and naturalists back in Soviet times. It is they who regulate the minimum living space per person, the obligatory presence of ventilation shafts in common houses and the minimum radius of the chimney in the private sector.

SNiPs are generally accepted standards, binding rules and building codes that cover all niches of modern construction. They describe in detail all the standards for the construction of structures of any type, as well as set out the calculation formulas and additional regulatory documentation. Everything in them is thought out for safe installation and effective functioning of air conditioning and ventilation systems in buildings, including private houses.

It is worthwhile to familiarize yourself with the regulatory documents in detail before starting the construction of a private house, that is, even at the design stage. SNiP ventilation and air conditioning regulates:

- mandatory presence in the building project of general ventilation systems;

- installation of hoods and air conditioners;

- air duct outlet through the roof or ventilation shaft;

- compulsory ventilation of bathrooms along the riser;

- installation of the hood;

- prohibits the fusion of ventilation of sewer pipes with the ventilation system of the house and the chimney.

Tip: Do all work on the installation of ventilation systems before finishing work or cosmetic repairs.

Generally accepted SNiP standards are designed to provide:

- natural air flow to all rooms;

- full air circulation during cold and warm periods;

- warming up cold air in winter; protection from drafts;

- filtration of dust and sediment suspension;

- normalization of air humidity in the house.

Attention: Competent calculation of the ventilation system in a private house under construction with a complex structure of several floors is difficult to do on your own. It's easier to entrust this to specialists who know all the SNiP coefficients!

Depending on the methods that cause air movement, the ventilation system is divided into natural, or gravitational, and artificial, or mechanical.

By natural ventilation

air exchange occurs due to the difference in the density of the outside and inside air. Since warm air is lighter than cold air, it rises, yielding to cold air. Natural ventilation is used in residential and public buildings, household and administrative premises of industrial buildings.

When artificial ventilation

the air is transported by electrically driven fans.

Natural and artificial ventilation can be exhaust, supply and supply and exhaust

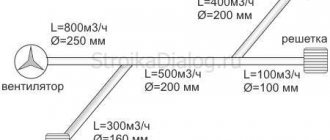

... With the help of exhaust ventilation, polluted, gas-polluted air with excess heat and moisture is removed from the premises and released into the atmosphere. Instead of the removed air, air is supplied, taking it from the outside, this will be supply ventilation. Supply and exhaust artificial ventilation schemes are shown in the figure. Supply and exhaust ventilation provides both air supply and organized air removal.

If the air is supplied with partial intake of outside air and partial mixing of air from the room, then such a system is called supply and recirculation.

Depending on the method of organizing air exchange, ventilation can be general and local.

General exchange

ventilation is designed to remove the emitted harmful substances, dust and gases, if they spread throughout the room and there is no way to catch them in the places of emission (foundries, welding shops with inconstant welding places). General ventilation, as a rule, is supply and exhaust ventilation and can be both natural and artificial.

Local ventilation can be exhaust or supply.

Local exhaust ventilation is arranged in cases where it is necessary to remove the polluted air directly from the place where it is polluted (near devices, furnaces, pickling baths). This is achieved by means of umbrellas, fume hoods, etc., at the sources of the emission of harmful substances.Harmful vapors that are released from the surface of liquids poured into baths during etching and galvanization of metal products are removed using onboard suction.

Local exhaust ventilation is widely used in the production of electric welding. At a constant welding place, a welder's table is used. Contaminated air is sucked out by a fan through an inclined panel and a grid surface of the table and is removed outside the room. The device of umbrellas over the welding places is not recommended, since gases and dust, rising upward, enter the respiratory organs of the worker.

Local supply ventilation is arranged in cases when fresh air must be supplied to certain places where the worker is most of the time (when working at open-hearth and electric smelting furnaces, in crane operators' cabins). Such systems are called air spraying.

The process of creating and maintaining certain parameters of the air environment is called air conditioning.

Typically, in air conditioning, it is mainly subjected to heat and humidity treatment. On hot summer days, the outside air is hot and humid. Such air must be cooled and sometimes dehumidified before being supplied to the room. In winter, the outside air has a low temperature and low humidity, so it must be heated and humidified before being supplied to the room.

The air is subjected to heat and moisture treatment in installations called conditioners.

Air conditioning units have special devices for certain types of air treatment. Air is usually heated in air heaters, where it receives heat from the finned or smooth surfaces of the tubes through which the coolant flows. Air cooling is carried out in surface or contact air coolers. In surface air coolers, air gives off heat to the surfaces of the tubes through which cold water or other refrigerant is passed. If these surfaces have a temperature below the dew point, then moisture from the air falls on them, and the latter is not only cooled, but also dried.

A set of technical means and devices for preparing supply air with specified parameters and maintaining the optimal or specified state of the air environment in the premises (regardless of changes in external and internal factors) is called an air conditioning system.

The air conditioning system allows you to automatically maintain the set temperature, humidity and speed of air movement, its purity, gas composition, aromatic odors, the content of light and heavy ions, and in some cases a certain barometric pressure. In most residential, public and industrial buildings, modern air conditioning systems allow maintaining only the first four of the listed parameters.

By appointment

- air conditioning is divided into comfortable and technological.

Comfort air conditioning

it is used in residential, public and industrial buildings in order to ensure optimal sanitary and hygienic conditions for people in the room.

Technological conditioning

is intended to provide the required conditions for the flow of production processes (drying processes, processing of building materials).

According to the location relative to the serviced premises, air conditioners are divided into central and local. AHUs located outside the service area can supply air to multiple rooms or areas. Typically, these air conditioners have a centralized refrigeration supply. Local air conditioners located in the serviced area or in the immediate vicinity of it are subdivided into autonomous,

which generate cold (heat) and process air with their own built-in units, and

non-autonomous

, which are supplied with cold (heat) from central sources.

At present, the industry produces central air conditioners with an air capacity of 10; twenty; 31.5; 40; 63; 80; 125; 160; 200 and 250 thousand m3 / h.

Central air conditioners consist of a number of unified sections. Air insulated valve 1

supply air prevents outside air from entering the inside of a non-operating air conditioner, thereby preventing freezing of water in the pipes of the first heating air heater. The valve opens simultaneously with the start of the fan unit

11.

Air valve

2

recirculated air serves to regulate its amount. In the air chamber

3

the supply (outdoor) and recirculated air is mixed, and in the equalization chamber

4

evenly distributed air flow rates over the entire cross-sectional area of the chamber, which is required for normal operation of the air filter

5

... Service cameras

6,

equipped with sealed doors and built-in lamps, they are mounted in sections requiring periodic inspection and maintenance during operation (filters, air heaters, irrigation chambers, heat and mass transfer units).

Air heaters first 7

and the second

9

preheaters are used to heat the air. The first heating is done only during the cold season. The heat carrier in the air heater is high-temperature (overheated) water with a temperature of 150 ... 70 ° C or steam with a pressure of up to 1.2 MPa. The second heating, carried out to reduce the relative humidity of the supplied air and reduce the temperature difference between the supply air and the air of the serviced premises, is performed both in the cold and in the warm season. Air heaters are made of bimetallic (steel-aluminum) tubes with ribbing that increases the surface in contact with the passing air. Sometimes a steel tape (spiral wound) is wound on the tubes of the air heater. In this case, the surface of pipes and tapes is galvanized.

In the irrigation chamber 8

the air is treated with water. The irrigation system of the chamber consists of two rows of nozzles that spray water. The nozzles are placed with different densities in each row: the first row in the direction of travel has a higher density, the second - a lower one. Spraying water in the chamber is reciprocal: the first row sprays water along the direction of air movement, the second row - against the movement of air. At the outlet from the irrigation chamber, there are plates of a droplet separator (separator), which prevent the entrainment of water droplets from the chamber. The sprinkler chamber body is mounted on a sump in which the water sprayed by the nozzles is collected. The pallet is equipped with pipes for water intake, drainage and overflow in case of overflow of the pallet and a ball valve.

Fan unit 11

serves to move air through the air conditioner and supply it to the air duct network for transportation to the air distribution points.

Lectures number 8

QUESTIONS:

1. Schematic diagrams of the solution of ventilation of premises in buildings for various purposes.

The efficiency of ventilation in a room depends to a large extent on the correct choice and location of devices for supplying and removing air. First of all, the distribution of air parameters in the volume of the room is determined by the constructive solution of the supply air devices. The influence of exhaust devices on the speed of movement and the air temperature in the room is usually negligible. At the same time, the overall ventilation efficiency depends on the correct organization of air extraction from the room. The basic principles of ventilation are as follows:

1) local exhaust ventilation should localize harmful emissions in the places of their formation, preventing their spread throughout the room;

2) the supply air must be supplied so that it, entering the breathing zone of people (the serviced area of the room), is clean and has a temperature and speed in accordance with the requirements of sanitary standards;

3) general ventilation must dilute and remove harmful emissions entering the room, ensuring in the serviced area the permissible values of the parameters - temperature, relative humidity, air velocity and concentration of harmful substances in it;

4) the volumes of supply and exhaust air should exclude, taking into account the air regime of the building, the overflow of contaminated air from the premises with the release of harmful substances to other premises.

The choice of air distribution devices and their location in the room depends on the purpose and overall dimensions of the room, the combination of types of harmful emissions, the requirements for the air environment, the placement of equipment and workplaces in the room and other conditions. In this case, the constructive construction solution of the building should be taken into account. The correct ventilation solution determines the ease of installation and operation of ventilation systems, the availability of the system for repair, a good appearance of the room and, most importantly, high efficiency of air exchange.

The solution to the issue of supply and removal of air depends on the specific conditions. The choice of this solution can be based on the following general recommendations:

a) the trajectory of the supply air supply should not cross the contaminated areas of the room, ensuring the supply of clean air to the serviced working area;

b) in case of significant surpluses of sensible heat in the room, supply air during the cold period of the year should be supplied with the minimum permissible temperature, meaning its heating due to excess heat;

c) in the warm season, in all cases, it is preferable to supply supply air to the serviced (working) area of the premises;

d) when solving air distribution, it is necessary to check the temperature level and air speed at work places; in this case, the mutual influence of jet streams, the constraint of the jets by fences and technological equipment, the property of jets to lay on the surface and excite circulation flows should be taken into account;

e) if there is a lack of heat in the room and the ventilation is performing the functions of the heating system, the supply air must be supplied to the serviced (working) area of the room.

Residential and public buildings.

The simplest example of organizing air exchange is ventilation of premises in

residential buildings, hostels and hotels

... According to existing standards, exhaust ventilation is arranged in these buildings from the upper zone of the kitchens, sanitary facilities, bathrooms and shower rooms, and in some cases also living rooms. Supply air enters unorganized through vents and leaks in fences. Ventilation regulation and air exchange increase is carried out by opening windows.

In hotels of a higher category, it is recommended to organize the flow of air into the upper zone of the living quarters of the rooms and the removal of air from the premises of sanitary facilities and bathrooms.

IN office buildings

with a volume of up to 1500 m3, ventilation of premises is carried out in the form of an exhaust from their upper zone with an unorganized inflow through the windows. In buildings with a larger volume, the exhaust from the upper zone of the premises is compensated by the inflow also into their upper zone ("top - up"). The flow rate of air supplied to and removed from the premises is taken in such a way as to exclude the overflow of air from one room to another.

IN public buildings

(children's institutions, general education schools, medical institutions, higher and secondary educational institutions, shops, etc.) ventilation of the main premises is also carried out according to the "top-up" scheme, that is, when

precise and exhaust openings are located in the upper zone of the room. In large rooms (halls, auditoriums), the exhaust can be partially carried out from the lower zone of the room. In high rooms with high thermal loads from the luminaires, the air outlet should be provided below the luminaires, and its removal - under the luminaires or through the design of the luminaires. In rooms with high stained-glass windows, in the absence of heating devices under them, it is advisable to supply the supply air through the longitudinal slots in the floor under the windows with overlapping jets.

Supply air can be supplied from the side of one of the end walls of the room or from the side of two end walls towards each other, which significantly reduces the speed of air movement in the serviced area. In the same rooms, with a smooth ceiling, supply air can be supplied by jets overlapping on the ceiling through the shades.

In some specific rooms, for example operating rooms, anesthesia, X-ray rooms, photo and chemical laboratories, battery rooms, etc., air supply and removal is carried out at different levels in accordance with the recommendations of special standards.

Air exchange organization diagram in auditoriums of theaters, cinemas and clubs

depends on their size, operating modes and climatic features of the area. The following ventilation solution schemes are recommended for these premises:

a) in halls without balconies with up to 400 seats, air supply to the upper or medium-high area of the room;

b) in halls without balconies with more than 400 seats, air is supplied to the upper area of the room with horizontal concentrated jets through openings in the end wall or through grilles or plafonds in the ceiling, directing air along the ceiling towards the stage or screen;

c) in the presence of a balcony, an additional air flow is provided through the holes in the rear wall under the balconies in an amount proportional to the number of seats located in the under-balcony space;

d) exhaust is carried out through holes in the ceiling or in the upper part of the walls near the stage or screen;

e) during the cold period of the year, part of the removed air is recirculated.

IN public catering buildings

the ventilation scheme is determined by the purpose of the premises. In dining and trading rooms, air is supplied to the upper zone of the premises, and is removed from the upper zone and through openings (distribution windows, doors) into the technological rooms. In hot shops (kitchens) and sinks, air is supplied to the working area, and removed through local suction and from the upper area.

Industrial building.

When organizing air exchange in industrial buildings, the following schemes can be used:

a) "bottom - up" - with the simultaneous release of heat and dust; in this case, air is supplied to the working area of the room, and removed from the upper area;

b) "from top to bottom" - when gases, vapors of volatile liquids (alcohols, acetone, toluene, etc.) or dust are released, as well as with the simultaneous release of dust and gases; in these cases, air is supplied dispersed to the upper zone, and is removed by local exhaust ventilation from the working area of the room and by the general ventilation system from its lower zone (partial ventilation of the upper zone is possible);

c) "top - up" - in production premises with simultaneous release of heat, moisture and welding aerosol, as well as in auxiliary production buildings in the fight against heat surpluses; usually in these cases, air is supplied to the upper area of the room and removed from its upper area;

d) "bottom - up and down" - in industrial premises when vapors and gases with different densities are released and their accumulation in the upper zone is unacceptable due to the danger of explosion or poisoning of people (paint shops, battery rooms, etc.)etc.); in this case, the supply air is supplied to the working area, and the general exchange exhaust is supplied from the upper and lower areas;

e) "top and bottom - up" - in rooms with a simultaneous release of heat and moisture or with the release of only moisture when steam enters the room air through leaks in production equipment and communications, from open surfaces of liquids in baths and from wetted floor surfaces; in these cases, air is supplied to two zones - working and upper, and removed from the upper zone. At the same time, to prevent fogging and droplets from the ceiling, the supply air supplied to the upper zone is somewhat overheated compared to the air supplied to the working area.

Lectures number 9

QUESTIONS:

1. Aeration of the premises of an industrial building.

Aeration

is called the organized natural air exchange in the room. It is carried out through specially provided adjustable openings in external fences using natural inducers of air movement - gravitational forces and wind. Aeration can provide very intensive ventilation of the premises.

In most cases, aeration is used in conjunction with mechanical ventilation systems, as a rule, with local ventilation units. It may be necessary to combine aeration with general ventilation systems with mechanical induction of air movement (for example, natural inflow - mechanical exhaust or mechanical inflow - natural exhaust, reinforced in this case due to backwater).

Structurally, aeration is easy to solve for rooms with external fences. The use of aeration for two- and three-span workshops is possible, although there are technical difficulties in its organization. For modern industrial buildings, which are a block of workshops, the use of aeration is possible only in extreme

spans, but even here it is limited by the growing requirements for the purity of the air emitted into the atmosphere.

Do not use aeration in workshops where there are sources of gases and vapors of harmful substances or dust due to the danger of environmental poisoning. In addition, the natural inflow in these workshops contributes to the spread of harmful emissions throughout the volume of the room. For such industries, mechanical ventilation with air purification before discharge is recommended. Aeration is also not used in rooms with artificial climate.

In rooms with a large number of workers and permanent jobs, as well as in rooms with significant moisture release, aeration is arranged only in the warm season, i.e. at tn> 10 ° C.

During the cold period of the year, in these rooms, supply ventilation with mechanical induction of air movement and its appropriate processing should be used. In rooms with significant heat emission, aeration can be carried out throughout the year. In this case, air exchange is regulated by changing the areas of openings for natural inflow and exhaust.

When calculating aeration, all three tasks of the building air regime should be considered:

external

- determination of the available pressures that provide natural air exchange; at the same time, the issues of the location of the building on the industrial site, the aerodynamics of the building and the dispersion of the removed harmful substances in the environment are resolved;

marginal

- determination of the characteristics of resistance to air permeability, drawing up an equation for the balance of air in the room and calculating the areas of aeration openings;

internal

- determination of the direction of air flows in the room, as well as the distribution of speeds and temperatures in the room with a known location of heat sources, supply and exhaust openings.

The last problem is the most difficult and little studied. At present, for the calculation of aeration, they mainly use the recommendations obtained on the basis of operating experience or in the physical modeling of aeration processes.

Given the complexity of the aeration process, practical calculations are carried out under certain assumptions. The main of these assumptions are as follows:

1) the thermal and air conditions of the room are considered to be steady in time;

2) the temperature of the working zone is understood as the average air temperature over the volume of the zone;

3) the vertical temperature change is taken according to a linear or linear-step law;

4) the constraints of convective jets over heated equipment are not taken into account;

5) the energy of the supply jets is not taken into account, considering that it is completely dissipated in the volume of the working area;

6) when determining the flow rates through the openings, their height is not taken into account, neglecting the change in the pressure difference along the vertical;

7) when compiling the air balance in the room, unorganized natural air exchange is not taken into account.

Let's give an example of aeration scheme for an industrial building.

When arranging aeration in industrial buildings, special openings are made in the walls and ventilation lanterns, in which casement bindings are installed, These openings are arranged in two tiers: the first is at a height of 1-2 m from the floor, the second is at least 4 m from the floor. In the summer (Fig. 1, a), the supply openings of the first tier are opened, and in the winter and autumn (Fig. 1, b), in order to avoid colds, the openings of the second tier are opened. In this case, cold air will enter the working area already warmed up. Air is removed from the room through an exhaust opening located in the lantern.

|

Mechanical air evacuation method

Natural ventilation often does not fulfill its direct function. Therefore, the need to use an artificial system becomes urgent. Its main difference is that it works with coercion.

The mechanical type of ventilation is used not only in industrial production, but also in residential premises. Its action is based on the operation of electric motors, air heaters, fans and filters.

Key advantages of an artificial system over a natural one:

- Efficiency. Transfer of almost any volume of air over considerable distances in the room.

- Independent of the weather. Flawless performance of direct functions by the system at any time of the year.

- Additional features. Adjustment of temperature and humidity level, cleaning the air from dust and other small particles.

Mechanical ventilation is divided into ducted and channelless. In the first, air passes along special elongated paths.

In ductless systems, the fans are placed in a special design. They provide an inflow of fresh air masses.

Depending on the type of mechanical ventilation, the systems are divided into supply, exhaust and supply and exhaust systems.

How does local ventilation work?

If air deliberately enters certain areas of the room or is removed from there, then such ventilation is qualified as local. The latter is divided into supply and exhaust.

Local fresh air ventilation requires much lower costs, provided that it is used, than general ventilation. It is popular in production facilities that require rapid gas renewal. Reduces moisture and temperature.

In most cases, there is a combination of local and general ventilation, when one type is complemented by another.

The local exhaust structure is also used in industry. It is relevant for the elimination of toxic substances, reducing the temperature in a certain small part of the room. We talked in more detail about the ventilation of industrial premises in this article.

Allows you to prevent the consequences of the mentioned and other negative factors. It has a positive effect on the comfort of employees' work, since harmful substances leave the premises almost immediately after education.

If work involving the release of toxic substances is carried out over the entire or a larger area of the room, then local ventilation will not be effective.However, it is still advisable to use it opposite the places with the highest emissions.

Autonomous SCR

Autonomous air conditioning systems are supplied from the outside with only electrical energy, for example, split air conditioners, cabinet air conditioners, etc. Such air conditioners have built-in compression refrigeration machines, usually operating on Freon-22. Autonomous systems cool and dry the air, for which the fan blows recirculated air through surface air coolers, which are the evaporators of refrigeration machines, and in the transitional or winter time they can heat the air using electric heaters or by reversing the operation of the refrigeration machine according to the so-called "thermal pump ".

The simplest option, representing decentralized provision of temperature conditions in the premises, can be considered the use of split-system air conditioners.