Carrying out insulation of the foundation and blind area, you should never skimp and save on materials, and the process itself. This can lead to unpleasant consequences in the future. In particular, cracks may appear on the walls, which will grow significantly over time. In addition, there is a risk of deformation of the house and heat leakage.

Those buildings, the foundation of which has not been insulated, and there is no blind area, will require serious overhaul in a couple of decades. And this is at best, and at worst, some sections of the foundation will have to be replaced.

Therefore, further we will try to figure out how to properly insulate the foundation and make a blind area.

What is insulation required for?

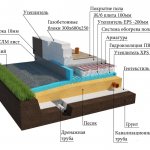

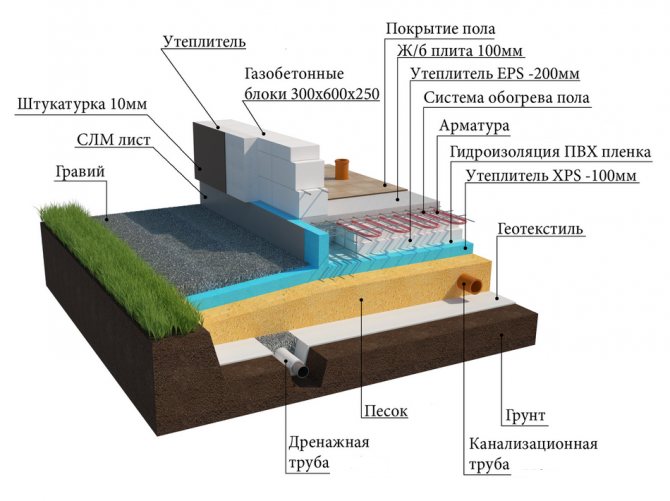

There are many types of foundations, but among them one universal one can be distinguished, which is suitable for many different buildings - this is the insulated Swedish plate foundation, which has been widely used not only among large developers, but also private builders.

The insulated slab foundation differs from the others in that the structure itself is covered on top with a special insulation. This prevents the negative influence of temperature differences on the base of the building.

A builder with vast experience will easily answer the question about the need for insulation. And it will highlight the following reasons:

- If the constructed building is located in an area with a very high level of humidity, one simply cannot do without insulation of the foundation. There is a logical explanation for this. The thing is that moisture droplets penetrate deeply into each crack, and after the air temperature drops below 0, the freezing process takes place. As a result, they expand and lead to the destruction of the concrete.

- Insulation of the foundation makes it independent of the climate and allows you to preserve the entire structure of the building.

- Thermal insulation reduces the effect of moisture on the foundation from the side of the ground.

To protect the walls from the harmful effects of the soil, in which heaving processes take place with the onset of frost, it is necessary to insulate that part of the soil that is in contact with the structure. It all depends on the soil.

For example, in dry sandy soils, there is no significant expansion during frost, while soil with a high clay content practically pushes the building to the surface of the earth.

To avoid such negative consequences, you need to make a blind area and, at the same time, lay a special thermal insulating layer with it. This layer is made on the basis of expanded clay, polyurethane foam, and expanded polystyrene. This makes it possible to keep the temperature above zero in the soil areas close to the foundation throughout the year. Thus, the risk of negative impact of soil heaving processes on the foundation is reduced.

How to insulate the basement and the blind area with penoplex or expanded polystyrene

A correctly executed scheme for insulating the basement and the blind area with penoplex or extruded polystyrene foam will ensure not only the integrity of the base, but also the structure as a whole. In what cases insulation is necessary, and when you can do without it, how to do everything correctly and without extra costs - our article will answer these questions.

The blind area has 4 functions:

- Removal of atmospheric precipitation from the base of the house;

- Performs the role of thermal insulation in the case of its insulation, protecting the soil from freezing;

- Serves as a decorative element;

- Provides more comfortable movement around the site.

If it is done according to all the rules, then it will drain water from the foundation without insulation, but it will not protect against heaving of the soil, which is observed during seasonal temperature drops. When in extreme frosts the soil water becomes ice, the volume of the soil increases and begins to put pressure on the blind area and foundation.

These structural elements are subject to destruction, which manifests itself in the form of cracks. This happens especially quickly with the blind area due to its small thickness. When it is insulated, the soil under it and near the foundation does not freeze. It is important to make a high-quality drainage system in parallel with insulation.

Advantages of the insulated blind area

We offer you to familiarize yourself with Insulating a chimney of a private house: the best ways

Each owner must decide for himself the issue of warming the basement and the blind area, but experts strongly recommend doing this in cases where the house where they live constantly stands on heaving soil on one of the following types of foundation:

- Shallow;

- Pile;

- Columnar;

- Plate.

It is better to insulate the blind area even when there is a basement floor, and if the foundation, which is below the zero mark, was not insulated during construction.

The feasibility of performing work on the insulation of the blind area is determined by the purpose of the structure. If people live in the house permanently, then thermal insulation is necessary, and if this is a dacha, where they come only in warm weather, then there is no particular point in investing a lot of money in it. It is enough just to make a good drainage from the foundation.

Many developers carry out the blind area after the completion of the construction of a house, and this is their main mistake. Ideally, everything should be done in 2 steps. The first is the device of the rough blind area after the vertical insulation of the foundation and before the final finishing of the basement.

The second stage - the device of the final blind area, is started after finishing the facade and basement. The advantages of this approach:

- The appearance of the base does not suffer;

- Such a phenomenon as winter heaving of the soil is excluded;

- Provides reliable support for the scaffolding.

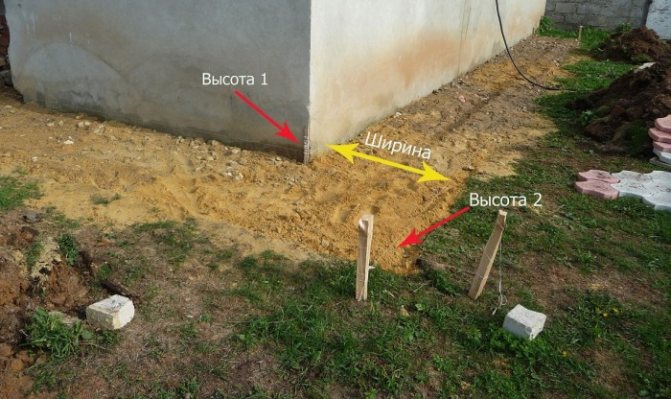

There are many guidelines for the width of the blind area. Many consider it an axiom that it should protrude at least 20 cm in relation to the overhang of the roof.But one can argue with this, because the drainage system drains water from the roof, and it practically does not get to the blind area, therefore the minimum width of the blind area should be 80 cm.

Blind area insulation scheme

The width of the structure plays a huge role in subsidence soils. The recommended value is from 1.5 to 2 m.

Such a wide blind area can cost the owner more than the structure itself, but it is impossible not to pay attention to the subsidence of the soil, because the integrity of the structure depends on it. But there is a way out - a combination of the open part of the structure with a hidden blind area.

Insulation thickness

Extruded polystyrene foam is produced in plates. They come in different brands, thicknesses and dimensions.

| Brand | Thickness, mm | Length, m | Width, m |

| PSB S-35, 20 | 20 | 1,24 | 0,64 |

| PSB S-35, 30 | 30 | 1,2 | 0,6 |

| PSB S-35, 40 | 40 | -«- | -«- |

| PSB S-35, 50 | 50 | -«- | -«- |

| PSB S-35, 60 | 60 | -«- | -«- |

| PSB S-35, 70 | 70 | -«- | -«- |

| PSB S-35, 80 | 80 | -«- | -«- |

| PSB S-35, 90 | 90 | -«- | -«- |

| PSB S-35, 100 | 100 | -«- | -«- |

| PSB S-35, 120 | 120 | -«- | -«- |

| PSB S-35, 150 | 150 | -«- | -«- |

Thermal insulation of the blind area and basement helps to reduce heat loss, protects the foundation from damage caused by temperature changes. The insulation technology of these elements is different.

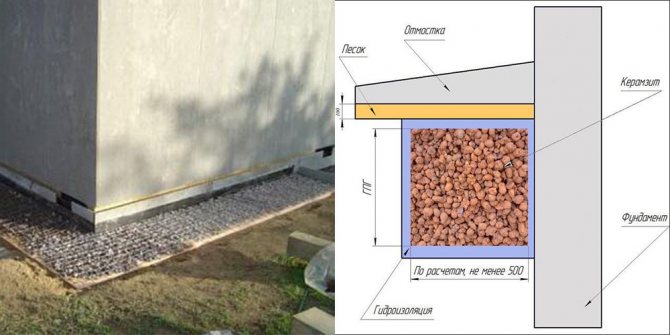

Insulation of the blind area

Penoplex is the best option for insulation

- The soil around the foundation is chosen for a width of about a meter to a depth of 0.45 m under a slight slope - from 3 to 5%;

- Lay the leveling sand layer and carefully tamp, after which the layer thickness should be at least 150 mm;

- Lay the foam or extruded polystyrene foam as tightly as possible;

- Geotextiles are spread in a trench with a minimum density of 150 mm and a width of 2 m;

- They take a drainage pipe, lay it on geotextiles along the edge of the trench with an outlet into a drainage ditch;

- Crushed stone is poured over the pipe and in the gap between it and the edge of the insulation;

- The drainage pipe is wrapped in geotextile together with crushed stone, first applying the edge lying on the insulation, and then covering it with the second edge;

- The slabs and the pipe are filled with coarse sand to a height of 300 mm and leveled, and then the surface is tamped using a rammer. They make markings for the curbs, for which a thread is pulled at a distance of 70 cm from the foundation according to the level;

- Rainwater collectors are mounted by installing a plastic receiving tray under the drainpipe and connecting a sewer pipe to it for external use with an outlet to the gutter;

- Curbs are installed and concreted from 2 sides;

- Fill the inner space with the required amount of sand and ram it again;

- Paving is carried out with paving slabs, concrete stone or other material. The height of this layer is 600 mm;

- Sprinkle soil along the outer perimeter of the curb.

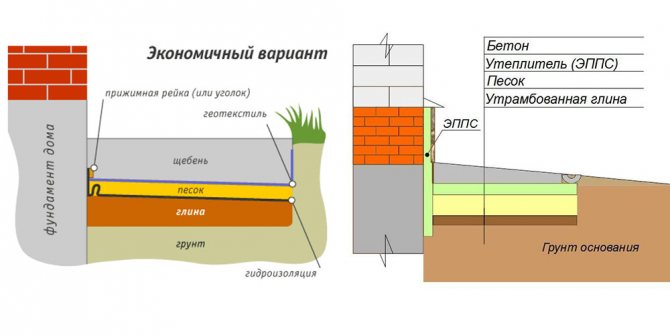

Creation of thermal insulation of the blind area

Basement insulation

It is best to insulate the basement with penoplex or extruded polystyrene foam when laying the foundation, but if this moment is missed, then you can do this during the operation of the house.

Basement insulation scheme

Consider the option when the basement and walls of the house are in the same plane. Warming is performed in 10 consecutive steps:

- Make horizontal markings around the entire perimeter, taking into account that the insulation should protrude several centimeters behind the waterproofing layer;

- They make cutting of the heat-insulating material, focusing on the marking;

- They clean the walls from dirt and dust, primed;

- A layer of special glue is applied to the base using a notched trowel, choosing an angle from the starting point;

- Apply glue to the plates and attach them to the surface of the basement, close up the joints;

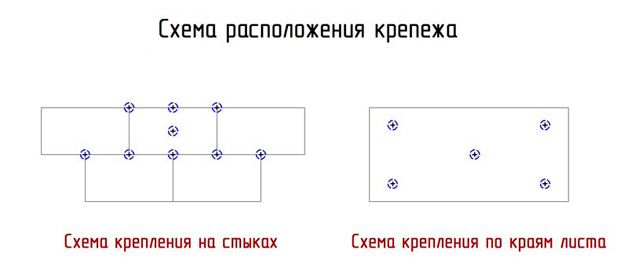

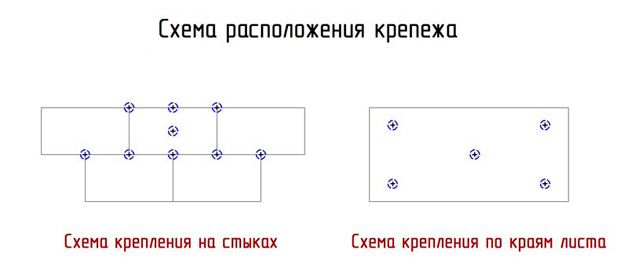

- Drill holes for dowels using a perforator, hammer in the fasteners;

- A metal corner is fixed along the perimeter of the wall using the same glue as for the slabs;

- Apply a layer of soil to the slabs;

- The reinforcing mesh is cut according to the size of the plates, greased with glue and glued to the heat insulator;

- Putty or revet the base, install the ebb.

If paving slabs are used as a finishing finish for the blind area, then it is enough to provide a slope of 3%. Lay it on a layer of cement-sand mixture, covered with a layer of 2 to 3 cm.

Final finishing with paving slabs

We offer you to familiarize yourself with the Bath with sinusitis - harm or benefit to the body?

In the process of laying, the tiles are knocked out with a rubber hammer in order to level the surface in a plane. Upon completion of the work, the DSP is scattered over the surface, then passed with a broom, sweeping away the excess. Next, pour it over with water so that the mixture from below and caught in the seams between the tiles grabs.

As you can see, only work done correctly will give a positive result.

How to insulate the foundation

There is a huge amount of materials intended for basement insulation. Among them, the most effective and common ones stand out.

It:

- glass wool;

- expanded clay raw materials;

- Styrofoam.

But the most common option, of course, is polystyrene or its analogue - expanded polystyrene. They are most often used to insulate the foundations of those buildings that are operated in a very unfavorable climate with frequent and sharp changes in temperature.

Expanded polystyrene has a low cost, but at the same time has a high quality of thermal insulation. Its structure is almost 90% small air bubbles. The application is relevant for buildings that are built on a clay type of soil.

This material, in turn, is divided into two types:

- With a foamed structure, and a sheet thickness of more than 2 cm.

- With an extruded structure and a thickness of about 5 cm.

It is best to insulate the foundation and blind area using the second option.

But there is one contraindication: it should not be used when the building has a basement and there is a very real risk of flooding it.

The slab can be 3-12 cm thick. The thickness is chosen depending on the type of premises, the way it is used, as well as on the climatic conditions that exist in the area where the building is built.

It is always recommended to use thicker slabs in the corner part of the house, since it is this part that freezes more than others.

What materials to use for insulation?

For insulation of the blind area, only extruded polystyrene foam (XPS) of high density is suitable. It is simply irrational to use more expensive materials based on polyurethane or polyisocyanurate, in turn, cheap PSB foam tends to absorb moisture and lose its thermal insulation properties.

The minimum thickness of the insulation is 30 mm for southern regions with an average temperature of a cold five-day period (CCT) not lower than -20 ° C and from 50 mm for regions with CCT to -28 ° C. In more severe climates, the insulation thickness should be close to 100 mm.

The working process

- Work on the preparation of the foundation for insulation.

To proceed directly to the work itself on the insulation of the foundation, it is necessary to remove that part of the soil that is adjacent to the wall outside the building. To do this, you need to dig a trench, the depth of which will correspond to the depth of the foundation itself, while its width should be at least 50 cm.

The part of the wall that was in the ground is cleaned, if necessary, it can even be washed, but then it is necessary to allow time for it to dry completely.

- Foundation waterproofing.

Basically, roofing material or liquid-type rubber is used for waterproofing walls. These products are applied with a spatula to the wall surface. The foundation is covered with 2 layers of roofing material. Roofing material is attached by heating a blowtorch.

- Warming with expanded polystyrene.

Everything is simple here. The insulation used for the foundation is prepared and attached to the waterproofing using mastic or a special adhesive mixture.

- Warming with expanded clay.

Expanded clay is a less known insulation material in comparison with expanded polystyrene. However, it has very good thermal insulation properties. This is due to the fact that it has a porous structure and creates a good air cushion. But its use is meaningless in a humid climate, because under the influence of moisture, expanded clay immediately loses its insulating properties.

All work is carried out in the same way as when insulating with expanded polystyrene, that is, a similar trench is dug, only a waterproofer is laid on its bottom, on which a layer of expanded clay is poured on top. After each poured layer, tamping must be carried out. Then a blind area is made on top, but do not forget to put plastic wrap so that the water from the solution does not go into expanded clay.

- Insulation with polyurethane foam.

According to its characteristics, the material is not inferior to the popular foam, but its use is much easier, since it is not required to pre-prepare the wall surface and make waterproofing. It has a liquid state and is applied to the wall with a special device.

What is the blind area and its purpose

This is the protection of the house, which is a layer of material laid out around the house along the entire perimeter and located with some slope. It helps to save the building from the accumulation of moisture after rain and melting snow. The angle of inclination based on the entire surface of the structure must be at least two degrees. To work on its arrangement, you can use a fungus to fix the insulation.This is a fastener that allows you to more reliably install the thermal insulation so as not to tear or damage it.

Previously, work to protect the foundation was carried out from clay. To do this, a trench was dug around the house, filled with clay and spilled very well with water. The clay hardened, shrank, and a waterproof film appeared on its surface, which protected the structure.

Blind area works

The blind area is a special concrete strip that is located around the perimeter of the entire building. For the construction of the blind area, materials are used that prevent moisture penetration. The width of this element must be at least 1 meter.

In the process of insulating the blind area, you must clearly follow the existing recommendations regarding this process.

As a material for insulation, materials such as are used:

- expanded polystyrene (fits under the screed);

- polyurethane foam (sprayed with a special apparatus).

The process of warming with polyurethane foam is simpler in the sense that it is not necessary to additionally process the joints of the plates, since they are simply absent here.

How to make an insulated blind area around the house

For high-quality insulation of the base of the house from moisture and cold, more often private developers choose to insulate the blind area with foam plastic with their own hands or penoplex - one of the types of extruded polystyrene foam. Penoplex, like Technoplex, has proven itself from the best side for protection against freezing of foundations and plinths. Let's consider how to insulate the blind area with expanded polystyrene plates in more detail.

Do-it-yourself insulated penoplex blind area

How to insulate the blind area with penoplex around the house

At the beginning, soil is removed along the perimeter of the house to the depth of the insulation and up to 1 meter wide. The thickness of the insulation depends on the heat-saving characteristics of the insulation. A formwork or curbstone is installed along the perimeter of the blind area to increase the level of the blind area above the ground. Geotextiles and a sand cushion are laid at the bottom, spilled with water and rammed.

If you need high-quality waterproofing, then clay is laid on the sand in a layer of 20-25 cm to create a "clay castle". You can also install roll waterproofing, which will protect the concrete blind area from moisture coming from the ground below. Next, slabs of expanded polystyrene (extruded polystyrene foam) are laid and a finishing coating of concrete, paving stones or paving slabs is arranged.

If the insulated blind area is made of concrete, then the blind area should be pre-reinforced. You should also make expansion joints from battens treated with bitumen, protecting the concrete blind area from cracking and destruction in the cold season. Concrete should be kept wet for a week, pouring water over it. Paving slabs or paving stones are laid on a sand bed mixed with cement.

How to insulate the blind area with foam around the house

Do-it-yourself insulated foam plastic blind area

As thermal insulation, you can use a variety of inorganic heaters - expanded polystyrene, polyurethane foam or expanded clay. But it is worth considering that foam plates absorb moisture, losing thermal insulation properties, in addition, the foam is defenseless against rodents. Therefore, it is recommended to make reliable waterproofing and protect the expanded polystyrene plates from rodents.

Insulation of the foundation blind area with expanded polystyrene is no different from the technology of insulation with expanded polystyrene plates, but not as effective. To obtain a degree of thermal insulation, as in EPS, you should take foam with a thickness of 10-15 cm more. It is up to you to decide whether it is worth saving by using foam plates, since they are less durable than foam and insulation can damage the soil when moving.

The joints between the foam or polystyrene plates should be sealed with polyurethane foam, and roofing material is laid for waterproofing the blind area. The top layer of the blind area to protect the insulation from mechanical damage and drain sediment from the basement can be made of different materials - asphalt, concrete, cobblestone, paving stones or polymer-sand tiles laid on a concrete or sandy base.

What not to do when insulating the foundation

If we deviate from the basic technologies, the insulation of the foundation and the blind area will not lead to the expected result. You need to watch out for the following points:

- it is necessary to store the insulation in clearly defined conditions, since improper storage leads to a loss of insulating properties;

- it is impossible to carry out insulation work in conditions of high air humidity;

- you need to select the parameters of materials as accurately as possible;

- it is necessary to process the seams correctly.

As is clear, the insulation of the foundation and the blind area is not only a prerequisite for reliable thermal insulation of the base, but also affects the duration of operation of the entire structure.

Features of the warming process

The construction of the blind area must necessarily take place at a slope from the walls. Even if the angle seems small, it allows melt or rainwater to drain confidently away from home. This provides reliable protection for the foundation and plinth.

It is advisable that no trees grow near the house, since the roots can disrupt both the structure and the foundation itself. It is also not recommended to break up near flower beds and beds.

In order for the construction technology to be fully observed, it is necessary to use only high-quality material, high-grade concrete, durable waterproofing and reliable insulation for work. When pouring concrete protection, be sure to lay a reinforcing mesh. When working, you need to take into account all three main functions performed by the finished structure:

- protection of the foundation from water;

- home decoration;

- insulation and waterproofing of the building, especially its base and basement.

The knot of insulation of the blind area is located directly under the main filler, that is, at the bottom. It is advisable to simultaneously insulate and protect the outer surface of the base. Then it will be difficult to carry out such work.

It should be borne in mind that the material that is used for the construction of the blind area should be in harmony with the general appearance of paths, sidewalks, yard covering.

Recommendations for the use of expanded polystyrene

Modern manufacturers produce extruded polystyrene foam plates with a thickness of 3 to 12 centimeters. The required thickness of the thermal insulation layer is determined at the stage of building design and depends on the following factors: the thickness of the walls and the material used and the geographical area where the building is being built. When building in the central CIS region, it is preferable to use slabs with a thickness of at least 5 cm, however, the corners, which are most susceptible to the negative effects of low temperatures, should be covered with slabs with a thickness of 6 to 10 centimeters.

When designing a building, it is best to plan what is called a building. sinking base... This form of construction will make it possible to hide hydro and thermal insulation under the overlying walls of the building. Since the basement is underground, it is exposed to the detrimental effects of groundwater and frost, which can lead to a violation of the integrity of the basement.

If the integrity of the base of the building is violated, the floor temperature may drop in the house and the appearance of drafts along it. Most often, during construction, much attention is paid to insulating only the walls of the house, but not the basement. This oversight will lead to a loss of heat in the future and an increase in fuel costs for heating the house. By insulating the basement with expanded polystyrene during the construction phase, you can avoid significant financial losses in the future.

Insulation thickness

Extruded polystyrene foam is produced in plates.They come in different brands, thicknesses and dimensions.

| Brand | Thickness, mm | Length, m | Width, m |

| PSB S-35, 20 | 20 | 1,24 | 0,64 |

| PSB S-35, 30 | 30 | 1,2 | 0,6 |

| PSB S-35, 40 | 40 | -«- | -«- |

| PSB S-35, 50 | 50 | -«- | -«- |

| PSB S-35, 60 | 60 | -«- | -«- |

| PSB S-35, 70 | 70 | -«- | -«- |

| PSB S-35, 80 | 80 | -«- | -«- |

| PSB S-35, 90 | 90 | -«- | -«- |

| PSB S-35, 100 | 100 | -«- | -«- |

| PSB S-35, 120 | 120 | -«- | -«- |

| PSB S-35, 150 | 150 | -«- | -«- |

Nuances of work

The thickness of the basement insulation with extruded polystyrene foam was mentioned above. If you want to make the insulation more effective, the layer needs to be thicker. Plates can be fixed not only with polyurethane glue, but also with cold curing bitumen-polymer mastic. It is necessary to apply the composition over the entire surface or in separate points. If you choose a mixture that contains a solvent among the ingredients, then it can destroy the structure of the expanded polystyrene. Therefore, this feature of the glue can negatively affect the thermal insulation qualities and durability.

Due to the fact that mechanical fastening can violate the integrity of the waterproofing layer and cause leakage into the basement walls, experts do not recommend fixing the plates, relying only on the strength of the glue. You can independently insulate the base with extruded polystyrene foam, the technology is described in the article. From it you can find out that almost all models of plates of the described insulation material made of expanded polystyrene contain a notch around the perimeter, this allows the canvases to be joined, forming a lock. If you purchase these canvases, you will rid the surfaces of cold bridges. When trimming, the joining of adjacent slabs should be coated with glue or mastic.

Technology of basement insulation with expanded polystyrene

Do-it-yourself insulation of the basement with expanded polystyrene can be done both in a house under construction and in an already commissioned one. It is carried out both inside and outside the building, but the outside is the most effective, since the bottom of the building together with the walls will form a single heat-insulating layer.

Tools and supplies

Insulation tools

In order to carry out work on thermal insulation of the basement with expanded polystyrene, you will need the following tools:

- solution container;

- screwdriver;

- spatula and trowel;

- buckets;

- wheelbarrow and shovel;

- brushes or roller;

- metal brush;

- assembly gun;

- hacksaw;

- stationery knife.

Consumables required for insulation outside the house:

- expanded polystyrene plates;

- roofing material;

- waterproofing material;

- reinforcing tape;

- reinforcing mesh;

- dowels;

- glue for working with expanded polystyrene;

- bituminous mixture;

- putty.

Preparatory work

The base, which we will insulate, is freed from dirt, all kinds of debris, grease stains, we cleaned of soil. If there is roll-up waterproofing, it must also be removed. When buying expanded polystyrene, you need to know the thickness and its density. As a heater, it is worth taking material with flame retardant additives or treating it with non-combustible materials. The main tools for performing insulation work are as follows: a hand saw or a hacksaw (you can use it to cut the insulator), a spatula, a comb, a working bucket, a wooden hammer, a level, a plumb line, a drill, a trowel, a sharp knife-cutter, clean rags. Materials used for fastening extruded polystyrene foam: the material itself, a reinforcing mesh 2.3 times higher than insulation, glue, foam, umbrella plugs, primer, decorative plaster, brick.

Features of installation of plates and subsequent finishing

If, after purchasing expanded polystyrene boards, you find that their thickness is not enough to provide normal thermal insulation, then the insulation can be fixed in two layers so that the required thickness is achieved. Many experts say that with good adhesion, the double layer of expanded polystyrene boards will actually be one whole.To prevent the formation of cold bridges, it is necessary to ensure that the installation of two layers of plates overlaps at the seams. However, with vertical displacements of the ground, the layers of insulation delaminate, which causes serious heat loss.

Dowel mounting options.

The question of whether to mount the insulation in two layers is very controversial, therefore, if there is such an opportunity, it is worth returning the unused material back to the store, and purchasing plates of the required thickness to replace it. As a rule, stores now accept goods back without any problems for some time.

The basement is insulated on the outside of the house. Expanded polystyrene boards are glued to the surface of the plinth using any suitable adhesive that does not contain potentially destructive solvents.

The bottom row of polystyrene foam boards must be laid with an emphasis on the base. It's great if you have a small ledge of the foundation that was made during the construction phase. Despite this, very often polystyrene is laid on the gravel backfill, where the foundation was erected. Styrofoam can also be mounted on a gravel backfill, although many experts warn against such steps. In the absence of a ledge, it is convenient to insulate with penoplex.

As a decorative finish, tiles, bricks, natural stone, facade paint, plaster are laid on top of the insulation. It is recommended not to use decorative tiles or silicate bricks, which lose many of their characteristics at subzero temperatures, and chips begin to form at the edges of the material.