Examples of installing deflectors on ventilation ducts

Detailed description, application and advantages of Deflectors

| Model | Diameter | Description |

| TD-110 | Ø110 | It is most advisable to use for ventilation of rooms, lavatories, cellars, private garages. A wide range of standard sizes allows you to choose the Deflector for installation on an already laid air duct. |

| TD-120 | Ø120 | |

| TD-150 | Ø150 | |

| TD-160 | Ø160 | |

| TD-200 | Ø200 | A good solution for ventilation of living rooms with an area of up to 40m2 and with the number of people permanently staying there up to 4 people. At a wind speed of 3-4 m / s, it can draw from the room up to 200 m3 of air per hour. |

| TD-250 | Ø250 | |

| TD-300 | Ø300 | |

| TD-315 | Ø315 | |

| TD-350 | Ø350 | |

| TD-400 | Ø400 | They are used for ventilation of apartment buildings, premises with a large area, livestock farms, hangars, warehouses, etc. The required air volume is achieved by installing several deflectors. The quantity is determined by calculation. |

| TD-500 | Ø500 | |

| TD-600 | Ø600 | |

| TD-680 | Ø680 | |

| TD-800 | Ø800 | |

| TD-1000 | Ø1000 |

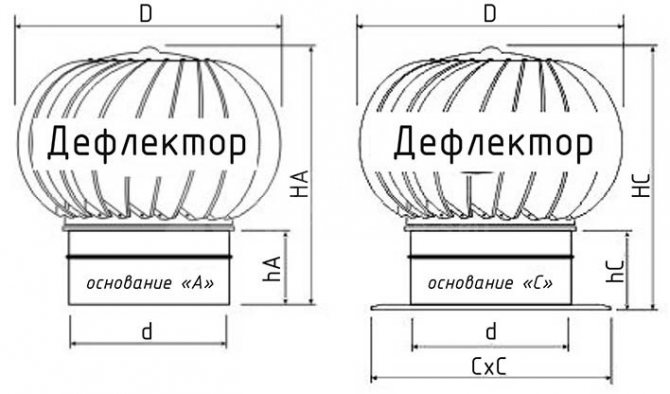

Overall dimensions of TurboDeflectors

Material: Deflectors are made of stainless steel 0.5-1.0mm. Dimensions: Deflectors are available with two types of bases: BUT - nozzle for a round pipe FROM - flat base

| d | D | HA | hA | C | HC | hC | |

| TD-160 | 160 | 270 | 260 | 70 | 295 | 280 | 90 |

| TD-200 | 200 | 290 | 290 | 70 | 295 | 310 | 90 |

| TD-250 | 250 | 350 | 345 | 110 | 350 | 345 | 110 |

| TD-300 | 302 | 400 | 365 | 110 | 390 | 385 | 130 |

| TD-315 | 317 | 400 | 365 | 110 | 390 | 385 | 130 |

| TD-355 | 360 | 450 | 385 | 110 | 490 | 435 | 160 |

| TD-400 | 400 | 495 | 465 | 140 | 490 | 485 | 160 |

| TD-500 | 500 | 615 | 635 | 225 | 615 | 635 | 225 |

The device of a turbo deflector for ventilation and where it is used

The issue of organizing effective ventilation of premises is much broader than it might seem. So, if the object is located at a site remote from the main power grids, it is impractical to use the usual supply and exhaust system with electric fans. The best option in this situation would be to install a turbo deflector for ventilation.

What is it and what is a turbo deflector for ventilation for?

Principle of operation

A turbo deflector is a natural ventilation element that is used to create traction in ventilation ducts. The turbo deflector works due to the force of the wind.

Such a device is used in systems with natural ventilation and consists of an active head with blades mounted on a base using bearings with zero resistance. Thanks to the bearings, the turbine rotates at a constant speed even in gusty winds.

Thus, the wind entering the blades makes the head of the device move, thereby discharging air in the system and improving traction. For the operation of the turbo deflector, wind at a speed of 0.5 meters per second is sufficient, since all parts are made of lightweight materials. Accordingly, the stronger the wind, the higher the power of the device. Compared to conventional deflectors, the efficiency of this device is twice as high.

Important: Regardless of the direction of the wind, the turbo deflector head always rotates in one direction only, which is extremely important for systems connected to gas columns - in a strong gust of wind, the flame will not go out.

Reviews: pros and cons

Compared to other similar devices, the turbo deflector has a number of the following advantages:

- non-volatility - the rotary turbine works only due to the wind power;

- protection of the ventilation and chimney system from atmospheric precipitation, debris and birds;

- resistance to corrosion - turbine elements are made of stainless and galvanized steel or high quality aluminum;

- reduction of energy consumption by air conditioning - the moving turbine head discharges air much more efficiently than stationary devices, preventing the room from overheating in hot weather and thereby reducing electricity costs for the air conditioning system;

- removal of excess moisture - the device prevents condensation from forming under the roof of the building and on its walls, as well as accumulating in insulation and other materials;

- reduction of ice formation in ventilation ducts;

- high-quality fastening of all parts of the device - even with a strong gusty wind, the unit will not be ripped off the pipe or skewed;

- aesthetic appearance, allowing the use of a turbo deflector even on residential buildings;

- safety of use;

- ease of maintenance;

- long service life - 15 years.

At the same time, the following point can be attributed to the disadvantages of using a turbo deflector: in the event of a complete absence of wind, the movable head of the rotary turbine will stop moving. If it stops during a period of frost with a high amount of atmospheric precipitation, there is a high probability of freezing, because of which the head will subsequently not be able to start rotating again.

What does his device look like

As already mentioned, the turbo deflector consists of an active head with blades mounted on a base using bearings with zero resistance.

The upper part of the device (turbine head) rotates around its axis due to the force of the wind, creating the necessary vacuum inside the ventilation shaft. In this case, the lower part is attached to the channel itself using self-tapping screws.

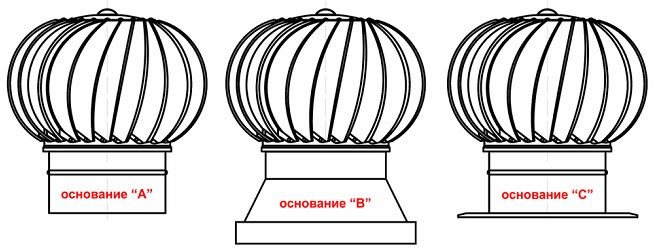

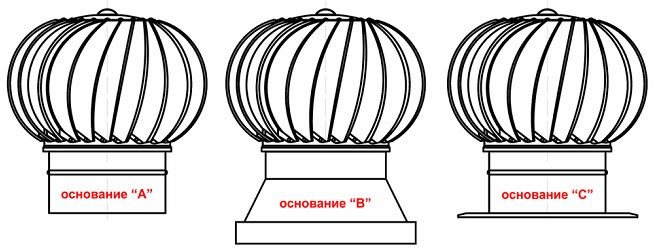

Turbo deflectors are produced with three types of bases:

- round;

- square;

- flat square.

In this case, the sizes of the nozzles can vary from 10 to 68 centimeters.

At the request of the customer, the turbo deflector is completed with roof passages designed for a skaz angle from 15 to 35 degrees. The actual sizes of the transitions can vary greatly.

The device can be installed both on standard pipes and on non-standard ventilation ducts. That is why transitions are often made to order.

Turbo deflector drawings

Price

The cost of a turbo deflector directly depends on the material from which it is made and the size of the connecting channel. Devices made of galvanized steel are somewhat cheaper than models made of stainless steel. The average cost of a galvanized rotary turbine starts from 2 thousand rubles, and a stainless one starts from 3 thousand rubles.

Where to buy a turbo deflector for ventilation?

In Moscow

In Moscow, you can buy a turbo deflector for ventilation in organizations such as:

- "Ventar-S": website: https://ventar-s.ru;

- address: Moscow, Entuziastov highway, 56;

- telephone.

- website: https://www.teplomost.ru;

- website: https://www.roofmaster.ru;

- website: https://msk.ecovita.ru;

- website: https://ventdeflektor.ru;

In St. Petersburg

In St. Petersburg, the following companies are engaged in the sale of turbo deflectors for ventilation:

- "Vendeflektor": website: https://ventdeflektor.ru;

- address: the city of St. Petersburg, Zvenigorodskaya street, house 22;

- telephone.

- "AEROSHOP": website: https://aeroshop-spb.ru/;

- address: the city of St. Petersburg, street Latvian shooters, house 31;

- telephone.

- website: https://cyclonespb.ru;

- website: https://vimso.ru;

- website: https://www.ecovita.ru;

In conclusion, I would like to note that the turbo deflector significantly saves energy consumption and helps maintain a comfortable temperature in the rooms being serviced. In addition, the device solves the problem of excessive humidity and musty air even in large buildings, and also removes dust and toxic fumes. That is why installing a turbo deflector is not only useful, but also profitable - due to energy savings, the turbo deflector pays for itself already in the first year of use.

Aug 23, 2017ventsyst

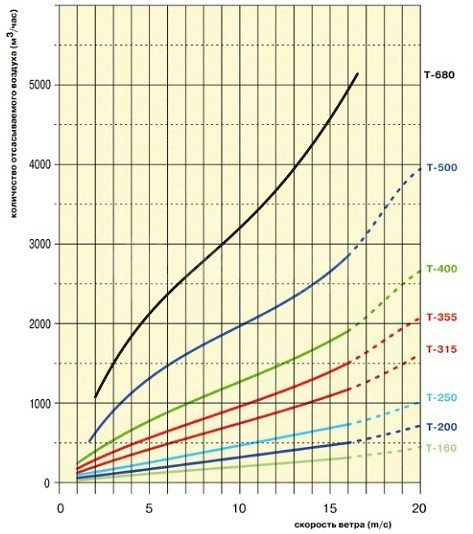

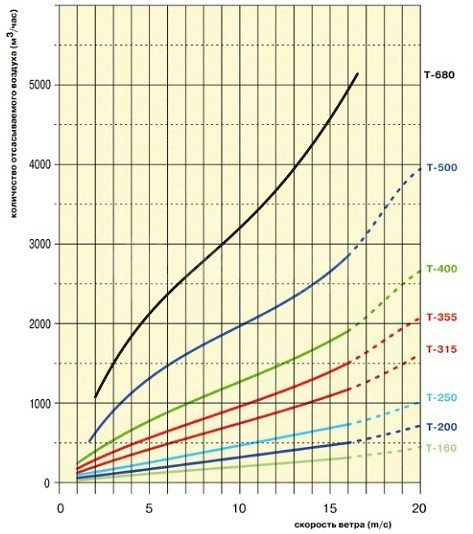

Calculating the number of Turbo Deflectors

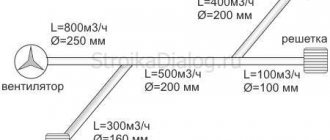

Calculation of the number of deflectors during installation Ventilated volume = room volume X air exchange per hour (note: air exchange per hour is different for different rooms)

For example: The room is 20m long, 12m wide and 4.4m high.The average wind force is 3.5 m / s. Air exchange for the room should be 3 times per hour. Thus, we get: Ventilated volume = (20 * 15 * 4.4) * 3 (air exchange) = 3168 m3 / h Thus, we must install 4 Deflectors TD-400 The cross-sectional area of the duct shaft must correspond to the cross-sectional area of the diameter of the Deflector within 20%

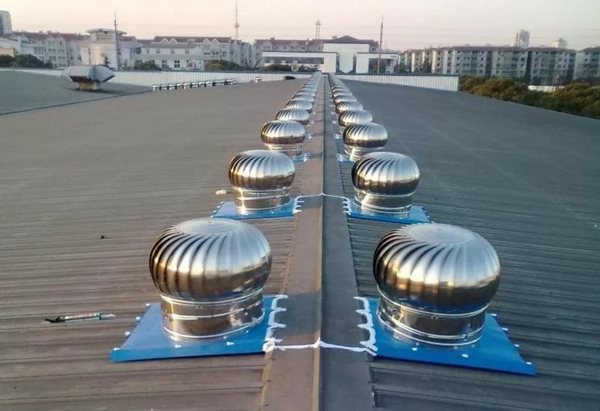

Do-it-yourself selection rules and installation

To install a turbo deflector, you do not need to have special skills and techniques. Due to its low weight and robust design, it can be easily installed by one person. The average installation time is no more than two hours. The device is installed at the highest point of the roof and along the ridge (at a distance of 4 to 6 m to the next deflector). If the turbine is placed high, it will exclude the possibility of snow getting inside the ventilation duct, if sediments are formed near it. In air ducts, valves can be used to regulate ventilation.

When installing a rotary turbine on a chimney, it should be taken into account that the temperature in it should not exceed + 100 ° C. For systems with high temperatures, high temperature packing must be used.

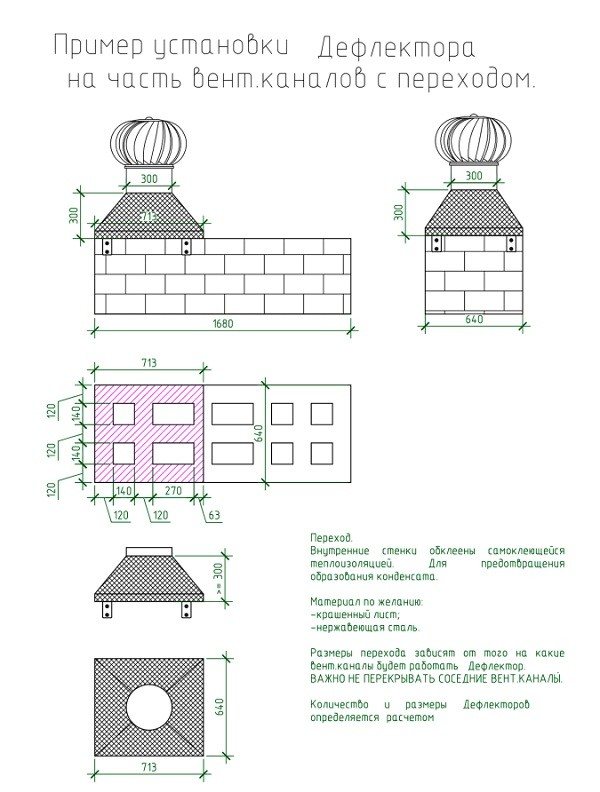

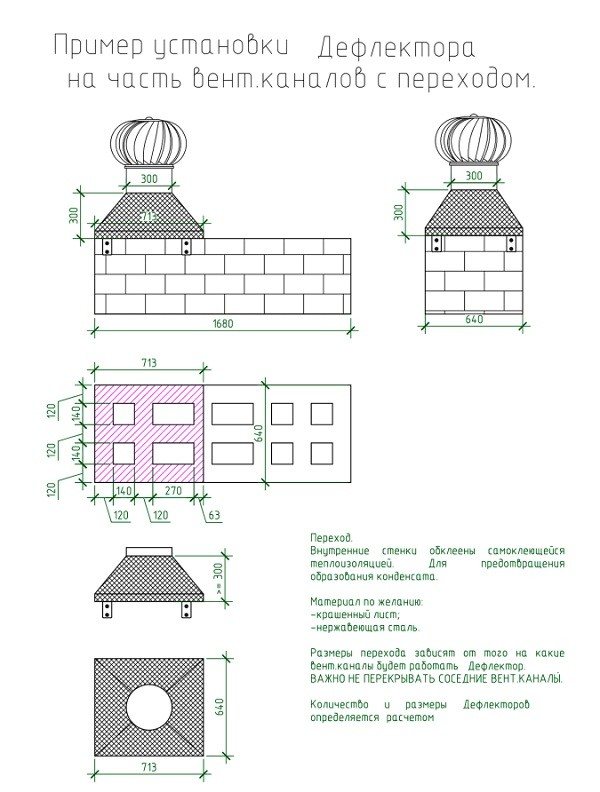

Installation diagram of a deflector on a part of ventilation ducts with a transition

Recommendation! There are a lot of manufacturers who claim that their products are the best. But before you buy a turbo deflector, you should carefully study the market and choose the device that has certificates of quality and safety checks, as well as a warranty period and a long service life.

You can make a turbo deflector with your own hands, but compared to simpler fixed models, this one will take longer, and you will need to cut out many identical petals. Accurate calculations and drawing are also important. Before you start cutting metal, it is recommended to make patterns from cardboard.

Varieties of deflectors

To improve the performance of the ventilation system, there are many types of deflectors on the market. Some of them are static, others are rotational. The latter include turbines, in which the impeller head rotates, operating due to the force of the wind.

Note! Regardless of whether the deflector is static or rotary, they are all made to improve draft in a chimney or ventilation duct. They protect the system from precipitation and debris. However, the most effective device can be safely called a turbo deflector.

Rotary turbines can be classified according to the following parameters:

- Manufacturing material. Deflectors are made of stainless steel, galvanized or painted metal, aluminum.

- The diameter of the nozzle or the connecting ring is at least 110 mm and maximum 680 mm. It is clear that the dimensions are identical to the diameter of the sewer pipes.

Despite the fact that manufacturers produce modifications of turbo deflectors, which outwardly practically do not differ from each other, their characteristics are different. Below is some information about these products:

- Turbovent. The company of the same name is engaged in the production of rotary ventilation products made of aluminum. Products have a thickness of 0.5 to 1 mm. The base is made of galvanized steel, with a thickness of 0.7 to 0.9 mm. The turbo deflector can be painted in any of the RAL colors;

- Turbomax. Manufacturers are selling, calling the product a natural thrust blower. To create the deflector you need steel, grade AISI 321, which is 0.5 mm thick. Scope of use: both for a natural ventilation system, as well as for stove and fireplace chimneys. And this is not in vain, since the turbo deflector is able to withstand temperatures up to +250 ℃. Products are made of high quality stainless steel.

You can also find products from unknown brands on store shelves. Such products must be bought carefully, paying attention to the certificate. Better yet, make a turbo deflector for ventilation with your own hands. We need drawings and related instructions.

What shape can a turbo deflector be

In order to understand what work will have to be done when installing a turbo deflector for ventilation with your own hands, it is worthwhile at the design stage of the system to determine what the base of the structure will be:

- in the form of a nozzle on a pipe with a circular cross section;

- in the form of a nozzle on a square pipe;

- in the form of a flat square base.

Important! An optional solution for the basic configuration of the product is also possible - the turbines are equipped with roof passages for roofs with slopes of 15-35 degrees. At the same time, you should not be afraid of snow or other precipitation getting inside the ventilation - this is excluded.

The lower part of the deflector can be round, square, rectangular

Turbines are installed at the highest point of the roof structure. They are located along the ridge with a certain step - 4-6 m. If we are talking only about ventilation of the attic space, then it is optimal to use turbines of the TA-315 type. This particular model in terms of performance is ready to serve roof space from 50 to 80 m2. Here, it is important to consider the angle of inclination of the ramp. For steep roofs, the number of turbines will be less, and for shallow roofs, more.

When equipping ventilation systems of residential buildings, the installation is carried out at the exit of the ventilation shaft or chimney. Alternatively, installation can be performed on air duct dampers. When arranging industrial buildings, the use of adjustable air intake devices is shown. In this case, such a problem as heat loss in winter is leveled.

How to maintain a turbo deflector and how to fix its breakdown

The fault of this device, in fact, is only one - the lack of rotation of the turbine. This can be caused by the following factors:

- Lack of wind. Action: Make sure there is really no wind. In this case, the decision can only consist in waiting for its appearance.

- Seized bearings. What to do: Check the bearings for lubrication and foreign objects that impede rotation. Replace bearings if necessary.

- Freezing of the turbine part of the deflector. What to do: Knock off the ice cover or wait for it to thaw.

User reviews of the turbo deflector are mostly positive. It simply cannot be expected otherwise due to the simplicity of its design and high efficiency. Maintenance is extremely simple and consists of greasing the bearings annually. The turbo deflector is attractive for the comfort it brings to people's lives through improved ventilation. Its other undoubted trump card is the lack of energy consumption and, therefore, any operating costs.

The value of the turbocharged deflector

Ventilation without electricity using a turbo deflector is 4 times more efficient than other models of this device. In this case, the system works according to a simple principle: the active head rotates under the influence of the wind, providing dynamic air circulation.

Option for a homemade deflector for garage ventilation

The turbine rotates in one direction only, ensuring the intensity of the air flow and preventing the formation of reverse thrust. The air in the ventilation duct is diluted and gases, steam, moisture, excess heat, dust are extracted from the under-roof space, as well as from the interior of the building.

Important! The use of a turbocharged design will allow the homeowner to avoid unpleasant moments when a conventional deflector tilts to the side over time and, disrupted by gusts of wind, flies down.For the manufacture of a pipe deflector, thin sheet aluminum or stainless steel is used. And the elements are fixed on metal bearings. All of this as a whole is a stable knot.

Competitive advantages of our turbo deflectors:

Debugged production and significant design improvements:

We work with a manufacturer with more than 10 years of production experience! During this time, the manufacturer took into account many wishes of customers, made improvements and improved operational parameters, optimized requirements for the quality of materials while maintaining affordable prices. Constant quality control of finished products, the use of only high-quality components from trusted suppliers, allowed us to increase the warranty for turbo deflectors up to 2 years! A wide range of turbo deflectors with a diameter from 100 to 200mm., As well as up to 1000mm (on request) and various versions: galvanized, stainless steel, aviation aluminum, painted in colors, provide almost all the needs and wishes of our customers!

Quality components:

Our product uses mainly European components: stainless steel and bearings, all-metal rivets, high-quality anti-freeze grease.

All parts are manufactured on high-precision CNC machines.

Why is it important to focus on the quality of the turbo deflectors, as well as on the reliability and durability of the components?

1.Turbo deflector sometimes works in an aggressive environment dust, CO2, moisture, temperature drops, etc. Neither aluminum nor ordinary steel (tin or even galvanized) can withstand such operating conditions for a long time, the service life of such products is extremely limited.

Our turbo deflectors have European stainless steel parts, full metal hemispherical rivets, European bearings and a special grease that does not freeze even at very low temperatures. The bearing unit is reliably protected by a special dust-moisture protective stainless steel washer. The axle is made of calibrated stainless steel. The rods are made of durable and tough 2mm aircraft grade aluminum. The blades are stamped from high-quality stainless steel with a thickness of only 0.4 mm, which makes it lightweight and reduces the load on the bearing assembly. In the case of purchasing a turbo deflector, in the production of which cheap materials and technologies are used (Chinese blind rivets, cheap bearings and rubber seals, lithol as a lubricant, the absence of stiffeners in the impeller and housing, etc.), you get an unreliable and short-lived product, and in a sense, you are just losing your money!

2. Accuracy and quality of processing is no less important factor in serial production. It is not possible to make 20,000 pieces. turbo deflectors in the garage "on the knee".

Therefore, in the manufacture of parts for our turbo deflectors, specialized numerical control (CNC) machines, hydraulic presses with specially manufactured forms, and rolling mills are used. All parts are made on dies and have 100% repeatability, there is not a single part that would be drilled with a drill or cut with scissors!

In addition to stainless steel turbo deflectors, we also offer galvanized steel turbo deflectors and aircraft aluminum turbo deflectors. These products can be painted in any color according to the RAL color palette. The cost of a colored turbo deflector made of galvanized steel or aluminum will be equal to the cost of a stainless steel turbo deflector.

Different turbo deflectors can be used depending on the place of use:

So, for example, if the turbo deflector will be exposed to high temperatures and corrosive gases, then a stainless steel turbo deflector is best suited. If you purchase a turbo deflector for ventilation without aggressive factors. Then you can purchase an aluminum turbo deflector. Due to the lightness and strength of aircraft grade aluminum, this turbo deflector is easier to wind and transfers less load to the bearings. Painted turbo deflectors, like aluminum ones, cannot be used in an aggressive environment, since this will not contribute to their long-term operation, therefore, their use is optimal only on ventilation pipes. In addition, painted options are suitable where it is required to maintain the color balance of roofs or ventilation systems.

Note:

the indicated diameters of the durbine deflectors mean its inner bore diameter, so when choosing it must match the outer diameters of your pipes. That is, the turbo deflector is pushed onto the pipe!

To buy a turbo deflector in Crimea or with delivery across Russia, contact us in a convenient way. Or place an order for a turbo deflector through the basket.

How do they work?

As with everything ingenious, the principle of operation of the wind hoods is very simple. The wind, hitting its body, is dissected by a diffuser, after which the pressure indicators inside the cylinder decrease, and the draft in the exhaust pipe itself, on the contrary, increases.

Principle of operation

Therefore, it is logical that there is a direct relationship between the resistance of the device and the thrust inside the channels.

The efficiency of the deflectors is influenced by: design features and shape, overall dimensions, height at which the device is mounted.

However, with all their positive aspects, the deflectors are not without certain disadvantages: with the vertical direction of the wind, the air mass comes into contact with the upper section of the device, while the mining cannot be fully thrown into the external environment. To eliminate such phenomena, it is customary to use variations with two cones.

Practical examples of the positive use of turbo deflectors

Situation # 1 Reverse thrust

- Problem. In a high-rise 9-storey building in the apartments on the upper floors, the effect of reverse thrust was observed - air flows flowed from one channel to another.

- Decision. Concrete canopies of ventilation ducts brought to the roof have been dismantled. In their place, a TD-500 turbo deflector with a transition was installed. Self-adhesive insulation is used to avoid the formation of condensation on the transitions.

- Bottom line. All air exchange problems disappeared. The thrust became stable, the blowing and overflow of air masses disappeared.