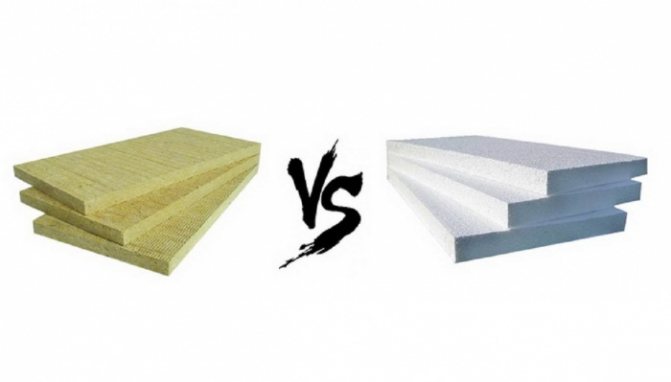

Today we will figure out what is better for foam or mineral wool for home insulation. We will look at the defining characteristics of materials and draw conclusions based only on facts. Looking ahead, we will say that as a result, mineral wool is much superior to polystyrene in a number of characteristics and cost. EPPS is a material with a narrow focus, it is out of competition when it comes to warming the foundation or laying in the ground.

What is better than polystyrene or mineral wool for thermal conductivity

EPS is the warmest.

Oddly enough, but the seemingly obvious choice of thermal insulation drives many into a stupor. Let's start with what is warmer: foam or mineral wool. What better retains heat can be determined by the coefficient of thermal conductivity. Thermal conductivity is the ability of a material to conduct heat. This value is expressed by a coefficient that shows how much heat passes through a unit of length and area of the insulation, per unit of time when the temperature drops by one degree. The coefficient of thermal conductivity is expressed in watts per meter-Kelvin (W / m * K). The lower the value, the worse the material conducts heat. Accordingly, it is more effective as a heater.

To figure out what is warmer than polystyrene or mineral wool, let's look at the data declared by the manufacturer:

- ordinary foam 0.033-0.037 W / m * K;

- extruded polystyrene foam 0.029-0.034 W / m * K;

- mineral wool 0.036-0.045 W / m * K.

The thermal conductivity of foam and mineral wool is affected by the density of the material. The higher the density, the worse the thermal insulation qualities. This is especially noticeable in the example of fibrous insulation.

If you choose exclusively for thermal conductivity penoplex or mineral wool, then, of course, EPS is better, but it is not suitable in all cases. Even ordinary foam is more effective than mineral wool, since the average lambda of fiber insulation is about 0.04 W / m * K.

Comparison of applications

Floor insulation with penoplex

Each of the thermal insulation materials we are considering has its own field of application. Penoplex is versatile, it can insulate any elements of buildings: foundation, basement, walls, roofs, floors.

Penoplex is also used as insulation for the blind area. You can read more about the insulated blind area around the house here.

Even indoors, you can use this material, but with certain caveats. Penoplex is especially effective and practical for insulating floors in a private house, a bathhouse and insulating balconies.

You may be interested in learning how to make a floor in a bath with your own hands. What type of insulation to choose: technoples or penoplex, and what are the characteristics of each of them is described in the next article.

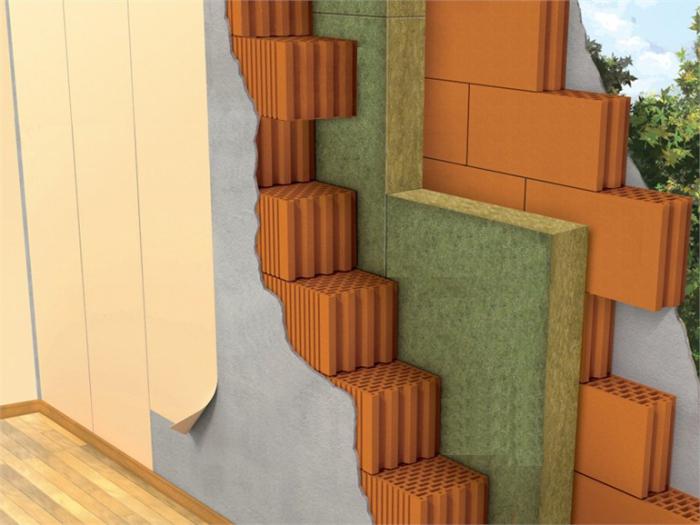

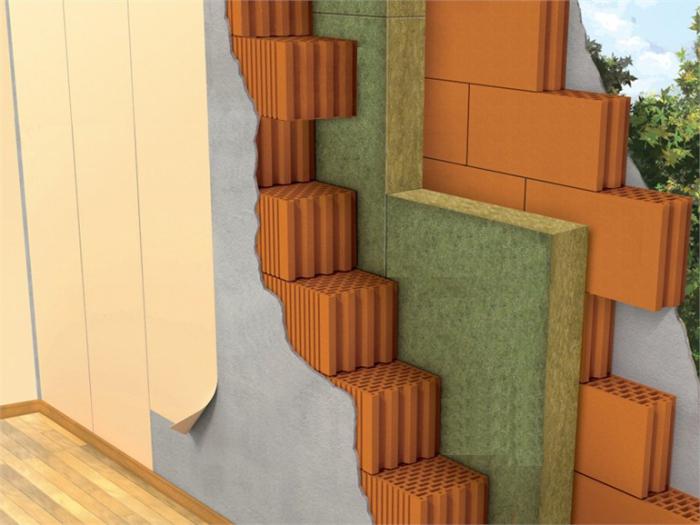

Minvata is most suitable for insulating external walls with additional processing or inside the walls, as well as insulating attics and roofs.

It is important: mineral wool is absolutely not suitable for indoor insulation of premises and insulation of foundations.

Hygroscopicity of mineral wool and polystyrene

This is where editing errors lead.

The second no less significant factor that will help determine what is better for foam or mineral wool for insulation is hygroscopicity (the ability of the material to absorb moisture). Moisture absorption is measured as a percentage of the weight of the material per day. That is, how much moisture as a percentage of its own weight is absorbed by the insulation when immersed in water for 24 hours. Declared characteristics:

- polystyrene not more than 1%;

- extruded polystyrene foam 0.04%;

- mineral wool 1.5%.

The degree of water absorption of the insulation determines the possible areas of its application.For example, EPSP practically does not absorb moisture, therefore it is used for laying in the ground. The foam from moisture begins to crumble, and the mineral wool, when it gets wet, does not hold heat at all, so there is not much sense from it either. At the same time, starting only from the hygroscopicity of materials, it is impossible to determine the best way to insulate a house with foam or mineral wool. The question must be considered in a complex and the following characteristic is important.

There are stoves for a house on a long-burning coal that are heated by convection, and there are ones with a built-in heat exchanger for water heating.

You can read about how the Buleryan oven works here.

How do penoplex and mineral wool differ from each other?

First of all, it is worth noting the ability to ignite, which, unlike foam, is absent in mineral wool. On the other hand, the latter does not resist moisture so well, therefore, it is more susceptible to loss of its qualities and requires additional installation of waterproofing.

It is difficult to say which insulation is more convenient for installation, most of all it depends on which surface needs to be insulated. Penoplex weighs slightly less and is ideal for working with flat surfaces. When working with mineral wool, you must have special clothing, a respirator and goggles.

Water vapor permeability of mineral wool and foam

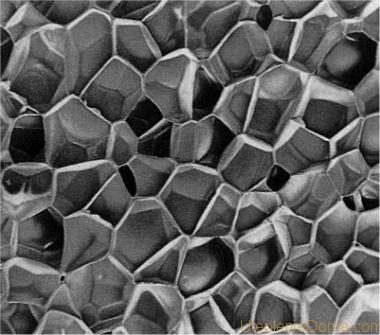

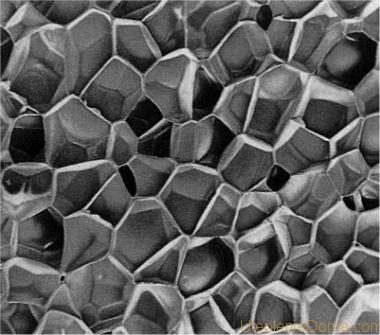

Closed-cell structure of the foam due to which it does not allow steam to pass through.

Vapor permeability is the ability of a material to conduct steam, as people say - to breathe. Water vapor permeability is expressed in mg / m * h * Pa. This is a pair in mg, which passes in an hour through 1 square meter of insulation with a thickness of one meter. In this case, the condition must be observed that the temperature on both sides of the insulation is the same and the water vapor pressure is 1 Pa. The value of vapor permeability is especially important when you decide what is the best way to insulate a wooden house with foam or mineral wool. Although this indicator is also relevant for bricks with concrete. The accumulation of moisture leads to negative consequences - the formation of fungus, a decrease in the thermal resistance of the enclosing structure, and a reduction in the service life.

Let's look at the values declared by the manufacturer:

- foam 0.05 mg / m * h * Pa;

- extruded polystyrene foam 0.013 mg / m * h * Pa;

- mineral wool 0.3-0.5 mg / m * h * Pa.

Foam plastics are materials with a closed cell structure, so they practically do not allow steam, especially EPS.

You can make a Bubafonya stove with your own hands from a barrel or a gas cylinder in just one day.

It turns out that you need to know how to properly heat a stove with wood. Details here.

Features and characteristics of foam

For thermal insulation inside and outside the premises, foam is very often used. It belongs to the class of plastics. It consists of the smallest cells, inside of which there are air bubbles. This structure gives it thermal insulation properties. The positive characteristics include:

- ease of use;

- durability;

- health safety;

- non-toxic;

- does not allow moisture to pass through;

- light weight:

- affordable price;

- high thermal insulation qualities.

The low weight of the foam allows it to be used for insulating any buildings. This has a positive effect on the building, since the low weight will not have an additional load on the load-bearing walls of the structure.

Insulating material there are also negative sides:

- not resistant to ultraviolet light, so there is a need for additional protection;

- subject to destruction in contact with technical fluids;

- is subject to combustion, but emits a minimum amount of toxic substances;

- fragile in work requires some experience in handling.

In terms of its thermal insulation properties, it is many times superior to other materials. Its main disadvantage is the flammability of the material.

Which material is better in operation

Polystyrene burns, a house can catch fire like a match.

In principle, the installation is almost identical, so there is no particular difference that mineral wool or foam is used. What shows itself better during operation is another question. Here we will look at several aspects:

- shrinkage;

- fire safety;

- toxicity;

- mouse.

Polyfoam and its derivatives do not shrink at all. Mineral wool of low density can settle, but at a density higher than 85 kg / m3. cube and wall heights up to 3 meters is unlikely. If you select thermal insulation according to the recommendations of the manufacturers and adhere to the correct installation technology, then this problem is completely removed.

Polyfoam and EPS cannot boast of fire safety. Both materials support combustion while emitting toxic fumes. With this material, you need to be extremely careful, if a fire source occurs, the insulation will burn out very quickly. Minvata does not burn at all, it can withstand temperatures of 750 degrees. It is even used to insulate chimneys. Foam plastics are toxic and full of carcinogens, so that marketers do not say there about its environmental friendliness. Many types of mineral wool are also harmful, as they contain phenol-formaldehyde, while there are acrylic-based materials that are absolutely safe.

Another problem is mice. They successfully live both in polystyrene and in mineral wool, although they like polystyrene more. In the book "10 thousand tips and teachings for all occasions" from the cartoon "The Enchanted Boy" of 1955, little Niels read: "To get rid of rats and mice once and for all, it is best to get a young and healthy cat." The advice is still relevant.

Let's summarize

The selected insulation must correspond to the climatic conditions of the area. Much in the choice will depend on which surface the heat-insulating material is intended for. For example, for buildings made of natural wood, polystyrene or penoplex will not work. It will provoke rotting wood. For houses made of timber, mineral wool with waterproofing is better suited.

For insulation of a balcony or loggia, the most suitable insulation option - penoplex... It is denser and can be glued without lathing, which saves space.

For the insulation of private houses, experts recommend using mineral wool. It does not allow cold air to pass through, it is easy to install and does not burn. In the process of working with glass wool, protective equipment (gloves, goggles, respirator) must be used.

The indicators of all thermal insulation materials differ. The choice of each of them will depend on the conditions of use.

The difference in the cost of foam and mineral wool

Cost in Moscow for 2020.

The last aspect is selfish, it lies in the fact that foam or mineral wool is cheaper? Consider the prices in Moscow for 2020:

- polystyrene 50 mm costs 145 rubles. for 1 sq.m .;

- extruded polystyrene foam 50 mm costs 238 rubles. for 1 sq.m .;

- mineral wool (universal) 50 mm costs 70 rubles. for 1 sq. m.

As you can see, mineral wool is 2 times cheaper than conventional foam and 3.5 times cheaper than EPS. The installation of mineral wool involves the use of steam and waterproofing, but even in a complex it will be cheaper.

Based on all the characteristics we have considered, we can say for sure that foam or mineral wool is better for insulation. In our opinion, mineral wool won this competition. It is practically not inferior to foam in terms of thermal conductivity. At the same time, the fibrous thermal insulation allows steam to pass through, does not burn, and is environmentally friendly. The high degree of water absorption is compensated by the installation of steam and waterproofing films. And most importantly, mineral wool is twice as cheap as polystyrene and three times as cheap as EPS.

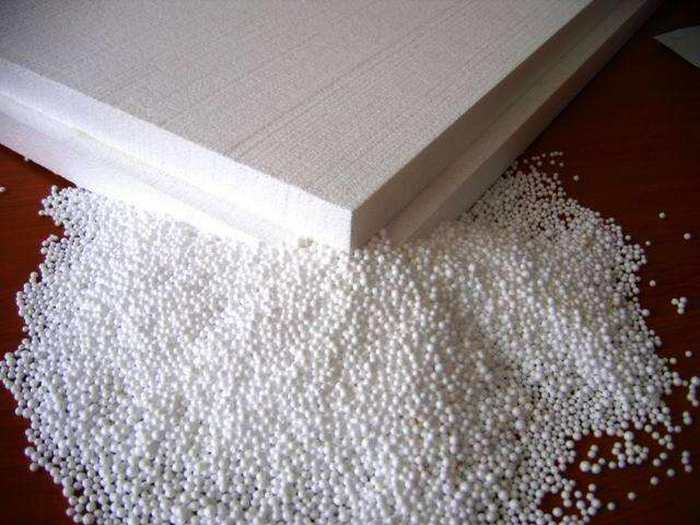

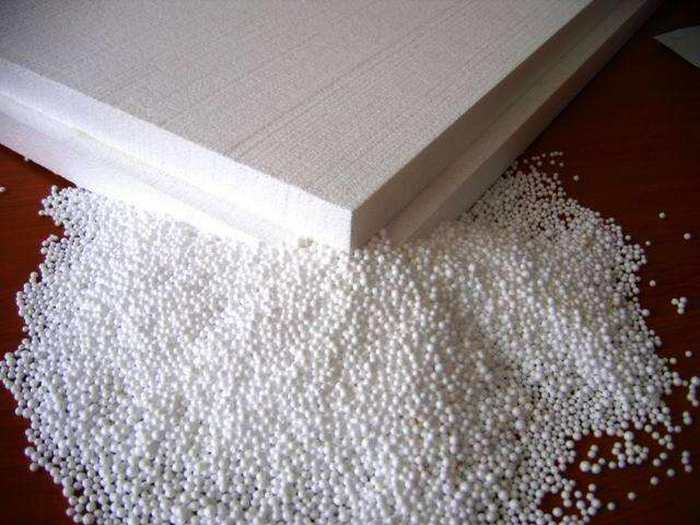

Extruded polystyrene foam

This material is also called penoplex.It is a more modern version of foam made from expanded polystyrene foam. It differs from polystyrene in its structure, it is produced in the form of plates. Penoplex has a higher density and strength than conventional foam.

Extruded polystyrene foam produced in different types depending on the area of application. Its main advantages include:

- low thermal conductivity;

- high bending and compressive strength;

- low water absorption and vapor permeability;

- combustion resistance;

- withstands a wide temperature range.

If we talk about the disadvantages of extruded polystyrene foam, then he also has them. It is a synthetic material. According to many scientists, it can be harmful to health if you use expanded polystyrene for indoor insulation... If they insulate the inside of the housing, then it is necessary to cover it with other materials, for example, drywall or plaster, so that no gaps remain.

What is better to insulate with penoplex

There will be no categorical answer, however, based on the opinion of experts, penoplex is very good for private houses. But there is an essential point. "Non-breathing" penoplex clogs the walls, and moisture in the form of steam will accumulate in the enclosing structures without leaving the premises. Excess moisture inside the house can be removed using mechanical ventilation or regular ventilation. Unless, of course, you have dilapidated wooden frames. Then the airing is always there.

But with regard to the insulation of foundations, blind areas, basements and for the floor (which is not always), everything is in order. Penoplex is often used for multi-layer foundations, installing as a middle layer. A very rational solution. By the way, you can read about how to insulate the foundation with this polymer in this article.

Floors and interfloor floors are also perfectly insulated (under a cement screed, of course).

Let me remind you that for buildings with a certain fire category, as well as with increased internal humidity (for a bath, gym, car wash, etc.), this material is undesirable.

Comparative characteristics of both types of heaters

Fire resistance

One of the most important criteria that a developer or master pays attention to. In this case, the advantage is on the side of stone wool. So, the stone insulation is absolutely non-combustible, which is confirmed by certificates and markings on the packaging "NG". Moreover, stone wool is considered a self-extinguishing insulation that prevents combustion. That is why basalt slabs are often used at the points of interface with flammable devices and objects. Stone mineral wool begins to melt only at a temperature of 1114 degrees Celsius. At the same time, the foam burns well under direct fire. And even the use of fire retardants, which, as the manufacturer assures, prevent combustion, is not entirely reliable. As these substances evaporate over time and the foam plates are prone to burning again.

Thermal conductivity

It is known here that house insulation using stone wool and expanded polystyrene is almost equally effective. However, experts by the method of trials and testing have all found out that the foam plates will be warmer and better. Since this material has a closed-cell structure, unlike stone wool. Thus, foam insulation definitely works better. In terms of thermal insulation qualities, only basalt wool is identical to expanded polystyrene, having a high density and high rigidity. Other types of stone wool (soft mats and semi-rigid slabs) are inferior to expanded polystyrene.

Vapor barrier

An equally important factor that will regulate the formation of condensation on the wall material under the insulated facade.So, for polystyrene, the vapor permeability is 0.03 mg / (m · h · Pa), while stone wool can pass moisture / evaporation in 10 times. That is why basalt insulation definitely wins if you do not know what is better to choose as insulation.

It is worth knowing that when installing a multilayer insulation system for the facade, the insulation materials must be positioned in such a way that the vapor permeability of the insulation decreases in the direction from the walls of the house. However, if the insulation system contains plastic / polymer materials that do not allow moisture to pass through or accumulate, then it is not recommended to use stone wool in tandem. Therefore, if there is a desire to glue the mineral wool slabs on the foam, then you take all the risk on yourself. Condensation can accumulate on polystyrene walls and gradually destroy the structure of the cotton wool. Although if you correctly mount the foam with the device of technical gaps for evacuation of fumes, then it is quite possible that the answer to the question "is it possible to stick basalt wool on the foam" will be "yes". But everything is strictly individual and depends on the original wall material of the house. So, for brickwork, this can be done by precisely adhering to the technology and recommendations of professionals. It is forbidden to use polystyrene foam, and on top of stone wool on a wooden facade is prohibited. Because wood breathes and styrofoam does not. Over time, moisture from condensation will simply "eat" the tree.

Advice: when installing insulation, in any case, a layer of vapor barrier material should be laid. At the same time, a lower level of vapor barrier should be located closer to the walls, and a larger vapor barrier should be closer to the facade finish. This will allow condensation and vapors to escape.

Material structure and strength

Expanded polystyrene has a structure of many closed cells filled with air. Hence the low weight of the insulation and its low thermal conductivity. In addition, it is precisely this structure that does not allow the foam to deform for many decades. In turn, the stone insulation has a fibrous structure, connected by air and phenolic resins. That is, air can circulate freely through the stone slabs. That is why even with the greatest rigidity, basalt wool slabs can sag over time. Of course, this will not happen very soon, but still. So here the answer to the question "which is better" is unambiguous - polystyrene.

Similar properties of two heaters

Both materials are made from natural ingredients, which reduces the risk of harm to health. Also, mineral wool and penoplex, with the correct installation technique and storage conditions, can last for quite a long time.

Probably which of the two materials is warmer can be considered the most important question. If, for example, in the case of wall insulation, you need to use penoplex with a thickness of 50 mm, then mineral wool for the same effect will be needed 60 mm... The cost of both building materials is almost the same, the price most often depends on the manufacturer.