The characteristics of physical bodies make it possible to determine their functionality, predict the duration of the operational period, and indicate the features. With regard to materials for thermal insulation based on mineral wool, one of the main quality indicators is density, which is also the specific gravity of the insulator.

The unit of measurement for density (volumetric weight) is kg / m3. The scope and performance of the material directly depends on this indicator.

Application

1. Installation of heat-insulating coatings in flat roofs and multi-level layers.

2. Thermal insulation of pipelines, tanks, gas pipelines and technical equipment in many industrial sectors.

3. Insulation in 3 - layer sandwich panels, as well as concrete or reinforced concrete materials.

4. Unloaded insulation in building envelopes.

5. External insulation of wet type.

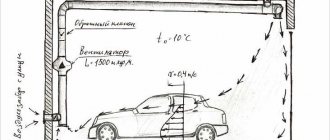

6. Thermal insulation of ventilated facade structures.

7. Entrance door filler.

Types of mineral wool

1. Stone.

2. Slag.

3. Ceramic.

4. Glass.

All types have good fire resistance. The most popular are glass and mineral wool. The stone mineral wool is based on rocks of basalt groups with an admixture of metallurgical substances. The glass wool structure is filled with fiberglass, silica sand and old glass materials.

Phenol-formaldehyde resin is used as binding components in 2 cases. According to research, this substance can harm human health. But in comparison with the popular chipboard material, which has the same resins in its composition, its amount is 20 times less.

Types of mineral wool

1. Spatial.

2. Corrugated.

3. Vertically layered.

4. Horizontally layered.

Basalt is the main component of the material. It acts as a binder, which can be urea resins, bitumen, phenolic alcohols, clay and starch.

In the process of manufacturing mineral wool on the basis of rocks of molten mineral materials, thin fibers of 1-3 microns with a thickness of 50 mm are obtained. To improve the strength, melt mixture or limestone can be added to the molten basalt fibers. Mineral wool substances repel moisture, thereby protecting the thermal insulation properties.

Features of the

The density of a material means the weight of a given substance, in one cubic meter of material. The unit of measurement is kg / m3 (kilogram per cubic meter). Another name for the density parameter is the specific gravity of the material.

Density indicators are due to the quality of the bond between the molecules of the material. The stronger the elements of the insulation are connected, the higher its strength.

The easiest way to understand what density is by considering mineral wool insulation. It can be loose and perceptibly soft, disassembling into fibers (a material with a low density, the molecules of which have weak bonds). You experience completely different sensations when touching mineral wool mats - their fibers are tougher, but most importantly, they seem to be pressed together (higher density of insulation).

Thermal conductivity coefficients

All durable components are gradually heated, and after cooling, in compliance with the intervals, the temperature regime of the internal structure and the surface of the material. The thermal insulation qualities of mineral wool are demonstrated by the coefficient of thermal conductivity.Its lowest value ensures maximum retention of thermal conductivity. Often the values of the coefficient are pre-specified by the manufacturer. The value of the coefficient is determined in laboratory conditions.

Thermal conductivity values vary around 0.032 W / (m * K). The latter indicator is found only in high quality insulation.

Indicator of thermal insulation and noise absorption

The main characteristic of any insulation is the thermal conductivity coefficient. If we take all types of mineral wool, this indicator will be in the range of 0.04 Wm * K. This is exactly what is the defining parameter for insulation. So, for example, 10 cm of mineral wool is insulated as well as 25 cm of wood or 120 cm of brick.

The reason for the low coefficient of thermal conductivity is the structure of the mineral wool slab. The fiberglass in it makes it look like a duvet. This allows, with a small thickness, to have high thermal protection rates.

Density

The density value is determined by the number of fibers involved. The high density of the mineral wool is achieved by increasing the consumable. Indicators are determined by the weight of 1-m3 product. Various manufacturers show products of varying density. Different technical processes are used for each level.

For the insulation of multi-storey residential buildings, mineral wool is used with indicators of 35 to 40 kg / m3. It is customary to use materials with higher rates for finishing objects of industrial importance.

Special formulas have been developed thanks to which professionals correctly deduct the density of the material, which is necessary for the installation of high-quality thermal insulation of a particular structure. There are various types of mineral wool with different strength indicators, each of which is designed to solve a specific task.

The characteristics make it possible to successfully use the material for thermal insulation of walls, refrigeration structures, floor systems in industrial and residential buildings. The density of the layers is about 100 to 200 kg / m3, the density of mineral fibers is about 100–150 kg / m3, the level of medium hardness slabs varies in the range of 70–300 kg / m3.

The distributed load that the material can handle depends on the density of the product. For the installation of waterproofing of horizontal planes, mineral wool in rolls with a density of 30-50 kg / m3 is used. For the purpose of waterproofing technical buildings, medium-hard slabs with a density of 75 kg / m3 should be used, while mineral wool with a density of 175-200 kg / m3 is ideal for waterproofing attics.

Density of insulation for walls, roofs, ceilings, manufacturer's choice

The main characteristic of any thermal insulator is the density of the insulation. It is she who determines the insulating properties and makes it more or less effective. For a simple understanding, you can remember the rule - the less this indicator, the better the material performs its function. However, mineral wool with a low specific gravity has a number of its disadvantages.

Influence

- Soundproofing. The lower the air permeability, the higher the sound insulation properties. However, there are specially designed basalt wool, which have good shielding properties with a low weight. Thus, the density of Rockwool Acoustic Butts at the level of 45-60 kg / m3 provides excellent sound insulation.

- Thermal insulation. The principle of operation of any product is the use of air as an insulating barrier, the thermal conductivity of which is only 0.026 W / m. With a low mass of basalt wool, it begins to freely pass through, carrying the cold with it. It is important to find a "middle ground", and for this you need to follow the manufacturer's advice.

- Carrying capacity. Basalt wool is widely used to insulate various concrete surfaces. The density of mineral wool insulation plays an important role when used in places that are subject to stress. After all, it can collapse, undergo deformation, which will lead to the formation of cracks and the loss of withered insulating qualities. In order to avoid such situations, mineral wool with an extra-high specific gravity (from 150 kg / m3) is produced.

- Ease of installation. Lightweight roll materials are widely used for roof thermal insulation. However, if these works are carried out "from below", that is, after covering the roof, laying a thermal insulator can turn into a real test. For such cases, a mineral wool with a high density and a low degree of deformation is better suited.

What kind of insulation to choose?

If you want the stone wool of your choice to perform its tasks perfectly throughout its entire service life, you need to heed the advice of the manufacturers. They recommend using different types of mineral wool in terms of specific gravity:

- Up to 35 kg / m3. They are used for unloaded surfaces: various inclined and vertical, pitched roofs;

- From 35 to 75 kg / m3. Used for thermal insulation of walls, floors, ceilings. Such mineral wool is perfect for the walls of a frame house: the density within these boundaries will provide a comfortable stay;

- From 75 to 100 kg / m3. Suitable for openings and outdoor surfaces.

- From 100 to 125 kg / m3 - for systems of ventilated facades and external walls "under plaster".

- From 125 to 150 kg / m3. Used for the bottom layer of thermal insulation of reinforced concrete surfaces.

- From 150 to 175 kg / m3. Suitable for the base layer of reinforced concrete structures.

- From 175 to 200 kg / m3. Such insulation has excellent load-bearing characteristics and can be used as a top coat "under a screed".

Manufacturer's choice

Many firms specialize in the manufacture of mineral wool with a small range of characteristics. For example, Ursa does not produce materials above 35 kg / m3. This insulation is simply not suitable for walls in terms of density. Dinosaurs like Rockwool can provide a full range of thermal insulation jobs from streams to floors.

The one thing to avoid when choosing stone wool is to rely on newbie manufacturers whose products have not been tested by time. Otherwise, there is enough knowledge about the density and thickness of the insulating layer to choose basalt wool.

termogurus.ru

Dimensions of mineral wool

Manufacturers represent 3 types of mineral wool, each of which has its own type of raw material, namely

1. Glass.

2. Slag.

3. Basalt mineral wool.

All types are successfully used for hydro and thermal insulation of various residential and industrial buildings. For a more comfortable installation, manufacturers produce products of various sizes and shapes.

Sheets

Mineral wool rolled into rolls is produced in the form of a large blank, pre-cut and completed. The dimensions of the material are indicated on the packaging, since they are different for many manufacturers. The thickness can vary from 40 to 200 mm, the width is from 565 to 610 mm, and the length is about 1170 mm. The thickness of rigid plates for hydro and thermal insulation varies from 50 to 170 mm, the width of the product is about 1190 mm, and the length is 1380 mm.

Roll material

Mineral wool in this format is ideal for thermal insulation of large areas, since the rolls contain a large amount of material. As a rule, the width of the materials varies between 50-200 mm, the length of the sheet is about 7000-14000 mm, and the width is about 1200 mm. The material is easy to cut and fit to the size of the room.

Mineral wool in cylinders

Designed for waterproofing hydraulic lines. The basis of this type of mineral wool includes: foil, fiberglass mesh and basalt. The structure can withstand high temperatures up to 250 C.The width of the product mainly varies in the range of 12–324 mm, the length is about 1200 mm, with a thickness of 20–80 mm. The exact dimensions are printed on the packaging of the material. Mineral wool in cylinders is intended for thermal insulation of heat exchange systems and heating communications. Diameter, thickness and length are selected in accordance with the size of the pipes

Optimum performance for different designs

- Up to 35 kg / m3 - pitched roofs, vertical and inclined unloaded surfaces. Insulation of objects of complex shapes.

- Up to 75 - thermal insulation of internal surfaces in residential and industrial premises: ceilings, partitions, floors, ceilings.

- 100-125 - insulation for the facade (ventilated or with subsequent plastering).

- Up to 150 - reinforced concrete floors.

- From 150 and above - supporting structures.

- From 175 - insulation for metal walls.

- 175-225 - for laying under a screed or used as a top bearing layer, this mineral wool can withstand high loads.

There are exceptions, they refer to specialized brands. For example, Isover has medium density slabs (50-80 kg / m3) suitable for installation in façade systems. Good reviews have grades with uneven rigidity, designed specifically for external work. They are softer on one side (facing the walls or the surface to be insulated) and sealed on the outside. This design provides reliable protection of the facade from the wind and allows you to apply plaster directly to the slabs. The specific gravity is important when choosing a heater for the roof, in this case, preference is given to light and resilient grades from 11 to 35 kg / m3.

Overview of manufacturers and prices

The assortment is represented by such brands as Rockwool, Ursa, Technonikol, Izover, Izorok, Knauf, Paroc. The average cost of 1 m2 with a thickness of 50 mm is 90 rubles. Some firms produce extremely low-density products (Ursa, Knauf), others specialize in the manufacture of universal brands. Basalt wool, optimal in terms of rigidity and weight, is offered by Paroc and Rockwool.

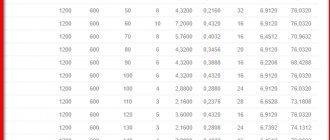

| Insulation name | Recommended field of application, brief description | Density of material, kg / m3 | Dimensions: L × W × T, mm | Number of pcs. in pack. | Price, rubles | |

| Per 1 m2 | For pack. | |||||

| Ultralight Izorok | Unloaded sound and heat insulation in frame walls, attics, interfloor ceilings | 33 | 1200×600×50 | 8 | 62,5 | 1250 |

| PP-80 Izorok | Ditto for pitched roofs, ceilings, floors, pipelines, sandwich framing structures | 80 | 1000×500×100 | 4 | 280 | 2800 |

| Rockwool Light Butts | Slabs with springy edges for thermal insulation of non-stressed vertical and inclined walls, floors along logs. Suitable for installation in rooms with high humidity | 37 | 1000×600×50 | 10 | 92,50 | 1850 |

| Rockwool Rockfacade | For insulation of facades with subsequent plastering | 115 | 1000×600×100 | 2 | 582,5 | 710 |

| TechnoNIKOL Technoblock Standard | Basalt wool with additional hydrophobization, optimal for thermal insulation of layered masonry, curtain walls, frame walls | 45 | 1200×600×50 | 12 | 102 | 885 |

| TechnoNicol Technolight Extra | Lightweight insulation with hydrophobic additives | 34 | 1200×600×100 | 6 | 134 | 580 |

| Paroc Extra | Universal heat and sound insulation material with randomly intertwined threads | 32 | 1200×600×50 | 14 | 92 | 930 |

| Isobox Teploroll | Elastic basalt wool in the form of soft mats | 30 | 5000×1200×50 | 2 | 55 | 660 |

There is a wide range of heat-insulating materials on the market, which differ from each other in raw materials for production, production method and purpose. The method of carrying out the work determines such an indicator as the density of the insulation.

The density of the insulation is a value that determines the mass of one cubic meter of material. This indicator is different for different thermal insulation materials.

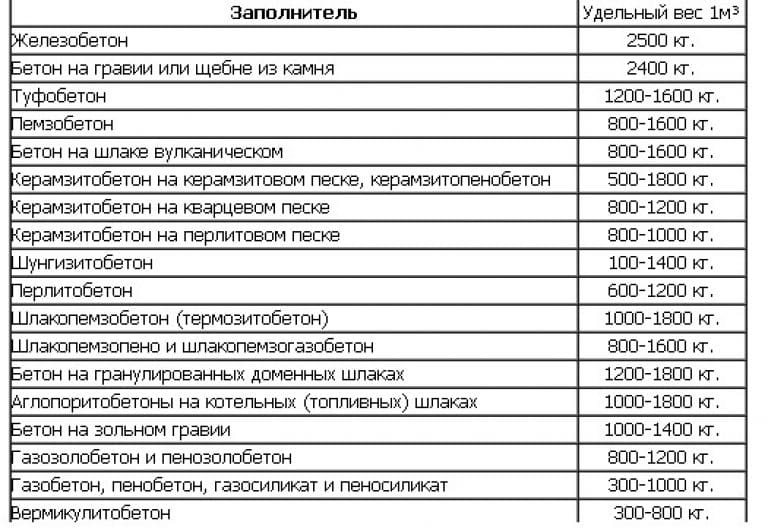

| Name | kg / m³ |

| Cellulose wool | 30-70 |

| Fiberboard | 150-230 |

| Linen mats | 30 |

| Foam glass | 100-150 |

| Cotton wool | 25-30 |

| Mineral wool | 50-200 |

| Styrofoam | 25-35 |

| Extrusion expanded polystyrene | 35-40 |

| Polyurethane foam | 30-80 |

| Expanded clay | 450-1200 |

This parameter of insulation is determined by the purpose of the insulation.

Weight

The mass of mineral wool varies depending on the substances filling it. To determine what weight the builder will be dealing with, you should pay attention to the density of the material, which can also be recognized as the mass of mineral wool at the rate of 1 cubic m. This indicator can vary from 35 to 100 kg per 1 cubic meter. The average weight of the insulation boards is 0.6 cm. In the process of performing technical operations, weight does not play a significant role.

Manufacturers' products have different weights, on average, this indicator varies from 37 to 45 kg with dimensions not exceeding 1.35 kg, and depends on the density of the thermal insulation material. Its weight changes significantly with a combined approach to insulation. In this case, the thickness of the insulation used is of decisive importance.

Effect of Density on Heat Conductivity

As a rule, the consumer often pays attention to the performance characteristics of the insulation, rather than physical properties such as density. And you should definitely take it into account, since it carries important information.

Any heat-insulating material contains air either in a rarefied state or in a normal state. There is a dependence: the less vapors there is inside the insulation and the worse it is isolated from interaction with the outside air, the higher the value of the thermal conductivity coefficient will be. And the larger the latter, the worse the material retains heat.

Wool

Wool insulation is made from lambswool fibers that are either mechanically held together or glued using 5% to 15% recycled polyester glue to form insulating rolls and rolls. Sheep are no longer raised primarily for their wool; however, they must be trimmed annually to protect the health of the animal. The wool used to make insulation is wool that has been discarded as waste from other industries because of its color or quality.

Structure

Stone wool has a fibrous structure, similar in composition to basalt. It is considered a natural natural material, 80 percent consists of the earth's crust, and the wool itself is made from molten volcanic rocks.

Balzac fiber is produced in the factory, but its composition is also similar to the chemical structure of rocks. It also contains sand, soda, limestone, borax and dolomite. In finished form, the material has impressive dimensions and is permeated with air through and through. For storage and transportation, mineral wool is compressed to a sixfold state.

Many manufacturers are trying to improve the quality of the product by making changes to the composition and production process. To increase the rigidity, the plates are pierced, impregnated with bitumen and phenols with the addition of asbestos. If the composition contains additional substances, this may change the characteristics of the product. Bitumen prevents from damage by insects and fungi, protects the product from moisture and provides additional strength.

GOST

The official standard applies to stone wool made from rocks of the gabbro-basalt group, as well as their identical substances, sedimentary rocks, volcanic, metallurgical residues, production silicate slags, alloys intended for the production of heat-insulating, sound-insulating and sound-absorbing materials.

Stone wool can be used as a heat-insulating substance in the construction industry and industrial production for finishing surfaces with temperatures ranging from -180 C to +700 C.