Foam and aerated concrete, from which foam and aerated blocks are now produced, is indeed a very interesting, convenient and relatively inexpensive building material - colossally profitable, however, only with a competent, professional approach to business. The cost of building a house from foam blocks may be an order of magnitude lower than a similar building made of traditional bricks. This is due to a number of factors:

- Low cost of the foam concrete itself as the main material for the construction of the walls of the building.

- Optimal dimensions that allow economical use of material when laying, using its minimum amount.

- Good heat and sound insulating properties of foam concrete make it possible to refuse additional expensive finishes and insulation (however, construction of a residential building from foam blocks, nevertheless, requires certain processing and finishing of the walls inside and out, since foam concrete is able to accumulate moisture over time).

Thermal insulation of a house from aerated concrete

Experts recommend making insulation from the outside of the house.

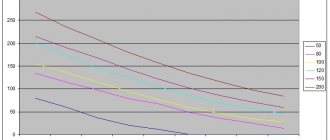

Whether it is necessary to insulate a house from aerated concrete is no longer a question, but how to do it correctly? Experts recommend making insulation from the outside of the house. This will avoid unnecessary waste of useful space, as well as provide additional protection to the outer walls of the house and the transition of the "dew point" to the outer walls. Dew point is the temperature limit at which the cooling air reaches saturation and condenses into dew. In addition, you should not experiment with the thickness of the aerated concrete wall, so the 300 millimeter option disappears right away. According to the recommendations of experts 375 millimeters - the minimum thickness of the walls of a private house made of aerated concrete! This is the minimum allowable rate, taking into account the use of insulation.

Before proceeding with the insulation, it is necessary to select the insulation material and calculate the amount of material that will be required in the production process. The choice of insulation material should be taken responsibly, because this factor will determine the final cost of the work, the method of installation, as well as the quantitative consumption of the insulation material. But before choosing an insulation material, you need to decide on the option of insulating a private house.

Options for insulating a house from aerated concrete blocks:

- From the inside. In any case, with this method, the living space will suffer, which can be used in a more efficient and rational way. In addition, you will need to install a rather expensive ventilation system, but even this will not save you from the appearance of fungi and mold in the space between the insulation and the aerated concrete wall.

- Outside. It is recommended to insulate the outside walls of the house from the outside. This method is used not only for additional protection of walls from atmospheric precipitation or the scorching sun, while this method of insulation saves time due to relatively simple installation, it does not require the creation of additional space for work. In addition, if it is necessary to change the facade of the house, this can be done without unnecessary complications. In addition, external insulation provides additional sound insulation and gives the house a more attractive appearance.

Facade foam block with facing side

When building a country house or summer cottage, each person strives to do this work quickly, efficiently and at minimal cost. One of the most important conditions for achieving these goals is the correct choice of building materials.A lot depends on this - both the construction time, and financial costs, and the safety of the building, and the level of comfort in the built house.

For example, if you choose a heavy building material that is difficult to work with (for example, brick) for the construction of a building, the work may take several months, or even years. If the material is not strong enough (due to the large number of voids inside the blocks), this will "hit" the safety of the building. Walls made of building material of insufficient density can collapse in case of accidental subsidence - for example, due to seismic vibrations or mistakes made when laying a foundation on loose soil. Too dense material, in turn, will not be able to provide high-quality thermal insulation.

To avoid these and many other problems, facade foam blocks are often used in residential and industrial construction. This material has excellent qualities - light weight, good heat and noise insulation, sufficient strength and resistance to external influences. In addition, when using a foam block with a finished facade, external wall decoration is not required, because the front surfaces of the blocks are initially covered with a decorative protective coating.

Varieties of foam blocks with a decorative coating

There are several types of facade decorative block with cladding:

- Plain. A simple wall foam block with a finished facade has become widespread in the field of country and cottage construction. Its main advantage is that after the walls have been erected, there is no need to carry out facing work. The outer surfaces of the blocks are initially covered with a layer of high-quality finishing, which makes the facade look beautiful and respectable. The facing coating applied to the front side of each block not only gives the materials excellent aesthetic qualities, but also protects it from external influences (since it has a high degree of moisture resistance).

- Angular. Unlike a conventional façade block, this material has two adjacent decorative surfaces. It is used for arranging door and window openings, finishing corners.

- Thermoblock. Structurally, such blocks consist of several layers. On the front side of the material there is a facing facade layer, which gives the foam block an aesthetic appearance. Behind it is a thick layer of heat-insulating filler designed to reduce the thermal conductivity of the blocks. On the inside, a bearing layer is provided, which gives the building material sufficient strength and resistance to mechanical stress. The thermoblock is one of the best thermal insulation materials. So, a wall made of a thermoblock with a thickness of 0.4 m is identical in thermal insulation quality to a 2.4-meter brick wall or 4.6-meter concrete one. Therefore, it is often used to fill the walls of buildings that need effective thermal insulation.

Why foam blocks are in great demand in the construction industry

Foam concrete is successfully used in many areas of construction. It is used for the construction of not only cottage and country houses, but also garages, warehouse complexes, as well as various industrial and commercial structures (workshops, workshops, etc.). The popularity of this material is due to the fact that the facade cellular block has many advantages:

- Ease. The foam block weighs much less than brick, monolithic slabs, natural stone and other materials that are often used for the construction of residential low-rise buildings. Therefore, it is much easier to work with it, it is easier to transport it by truck and deliver it directly to the construction site.

- Porous structure. The facade cellular foam block has a porous internal structure. Thanks to this, the walls of the building "breathe", thereby providing comfortable indoor air humidity.

- Effective thermal insulation.In terms of thermal insulation properties, the facade foam block is noticeably superior to brick, stone and other building materials. In buildings constructed from such material, a warm and cozy atmosphere is maintained in winter. Owners do not have to install powerful heating systems and spend a lot of money on space heating. In the summer, the foam block creates a cool microclimate for the house, which, in turn, eliminates the need to install expensive air conditioners.

- Durability. Since foam concrete does not rot and does not deteriorate due to changes in humidity or temperature, buildings made of such material remain in perfect condition for many decades. During the entire service life, the building will not need major repairs. It is enough only from time to time (as necessary) to carry out minor cosmetic repairs if any defects appear on the facade.

What materials can be used instead of a foam block

In appearance, cost and performance, the foam block is similar to materials such as:

- Arbolite blocks. Like foamed concrete, wood concrete blocks have a cellular structure and are highly air-permeable, thereby controlling the humidity inside the premises. This building material is characterized by the same advantages - a large margin of safety, unpretentiousness to climatic conditions, high-quality thermal insulation and low cost. Also, wood concrete blocks are excellent for the construction of buildings on soft and loose soils, because they are lightweight and do not exert significant stress on the soil.

- Expanded clay concrete. Expanded clay concrete blocks weigh almost 2.5 times less than ordinary bricks. This is due not only to the low density of the material itself, but also to the presence of "voids" in the structure of the blocks themselves. The material is resistant to temperature extremes, due to which it is often used for construction in regions with a harsh winter climate. The only caveat: expanded clay concrete blocks, unlike foam concrete, do not have a decorative coating. Therefore, after the completion of the masonry work, the outer surfaces of the walls must be revetted.

In order not to be mistaken with the choice, you should consult with experienced builders in advance. They will help you choose the right building materials and take into account all factors - the features of the local climate, the estimated construction costs, the bearing capacity of the soil on the site, etc.

Perhaps you will be interested in reading about the types of facing of foam blocks or the features of finishing aerated concrete blocks.

bazafasada.ru

Warming process

In order to well insulate the walls of a house made of aerated concrete from the outside, the insulation must have a vapor permeability higher than aerated concrete blocks

What type of insulation to choose, how to make insulation and what may be required for this? It is required to take into account the fact that aerated concrete has vapor-permeable properties. Therefore, in order to well insulate the walls of a house made of aerated concrete from the outside, the insulation must have a vapor permeability higher than aerated concrete blocks. Otherwise, moisture will begin to accumulate in the inner walls, which will gradually lead to their destruction or costly restoration. The most used materials as insulation for the outer walls of an aerated concrete house are mineral wool and foam.

Houses made of brick or aerated concrete: which is better to build?

Important! A necessary point that should be considered when insulating a house is the influence of rodents. Small dirty tricksters do not come close to mineral wool and simply adore polystyrene. They gnaw it, forming minks in it, so the facade needs to be covered with plaster completely to exclude the appearance of the rodent family.

External mounting of thermal insulation has a number of advantages.

- The service life of the facade is extended. A barrier appears that protects the wall from the outside from the harmful effects of the environment.

- Living space is not reduced. If the insulation is carried out from the inside, you will have to occupy part of the space with a heat-insulating structure.

- The "dew point" is shifted outside the walls into the insulation. Steam does not condense inside the walls of the house, there is no dampness, which increases the service life.

- Protection against freezing of walls. Internal thermal insulation, as opposed to protection from the outside, can lead to destructive effects of low temperatures on the facade.

How to properly insulate with foam?

Additional fixation of foam sheets is provided by the use of plastic dowels

Polyfoam does not allow steam to pass through, therefore, when choosing such a heater, you should take care of a high-quality air ventilation system. But the undoubted advantages of using foam can be attributed to its low cost (almost several times cheaper than mineral wool).

The order of work:

- External walls must be cleaned of dust and dirt. For this, aggressive detergents, a stiff brush and a metal sponge are used;

- Irregularities that arise over time or as a result of a factory defect should be leveled;

- A fiberglass mesh is required near the windows. It is fastened in such a way that under the outermost layer of insulation there is at least 10 centimeters of the mesh, and it was also possible to glue about 10 centimeters on top of it. This procedure is performed for additional reinforcement;

- A special glue is applied to the foam sheet (experts recommend using a notched trowel to uniformly apply and cover the entire surface of the foam);

- Additional fixation is provided by using plastic dowels;

- It is recommended to start plastering and painting the insulation material after the glue has dried.

Is it possible to insulate with mineral wool?

Mineral wool as an insulating material is much more practical than foam.

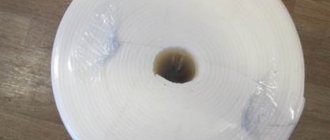

Mineral wool as an insulating material is much more practical than foam. Of course, it has a higher cost, but it also has a number of undoubted advantages: high strength and vapor permeability. This material is recommended to be used to maintain a stable level of humidity and a comfortable microclimate in a private house. The working life of the insulation material without loss of working characteristics is more than 50 years. Mineral wool insulators are produced in the following versions: some are in the form of slabs, others are produced in the form of rolls. For ease of installation, slabs are produced with dimensions of 500 * 1000 millimeters.

The order of work:

- External walls must be cleaned of dust and dirt. For this, aggressive detergents, a stiff brush and a metal sponge are used;

- Wall insulation with mineral wool will require special glue;

- Additional fixation is provided by using plastic dowels;

- After the mineral wool dries a little, a fiberglass mesh is attached to it, which will subsequently protect the walls from cracking in the paint or plaster;

- On top of the fiberglass mesh, another layer of glue is applied;

- It is recommended to start plastering and painting the insulation material after the glue has dried.

Vapor barrier and waterproofing

So that the wall insulation is not in vain, it is worth remembering all the necessary steps, one of which is - installation of vapor barrier

... Such an operation is necessary in order to provide the structure with moisture protection. It is especially relevant in damp rooms.

A procedure such as vapor barrier is a kind of barrier between water vapor and insulation.

When working with such material, you must be extremely careful not to pull the coating too much so that the film does not break.

Depending on the type of walls, the vapor barrier procedure can be different:

- if the walls are processed inside the house

... It is worth remembering that the film is applied horizontally, from bottom to top. The fastening process itself is carried out using a stapler or small nails.

The film applies an overlap, the joint of which must be at least 15 cm.

After that, the vapor barrier layer is fixed with a wooden frame. It should be understood that the quality of the procedure performed also depends on the quality of the film. It is worth buying high quality and modern materials; - vapor barrier for siding

... If you are planning to cover the house with siding, you should not neglect the vapor barrier. It is best to use foil film. The insulation itself is made with the reflective side outward. The procedure is the same as for internal work; - for

... A feature of this type of house is the absence of a rigid base, and as a result, the vapor barrier procedure is carried out between the racks. This type of house cannot be rented out without vapor barrier.

Vapor barrier and waterproofing

NOTE!

Along with vapor barrier, there is another way to protect the structure from moisture - waterproofing

... To get 100% positive effect, apply these two methods at the same time.

During this procedure, the following materials are used:

- ruberiod

... Special cardboard, which, in turn, is impregnated with petroleum bitumen, while on both sides it is coated with refractory resin; - roofing

- cardboard, which is treated with a tar composition; - glassine

which is impregnated with bitumen; - waterproofing membranes - the best option

.

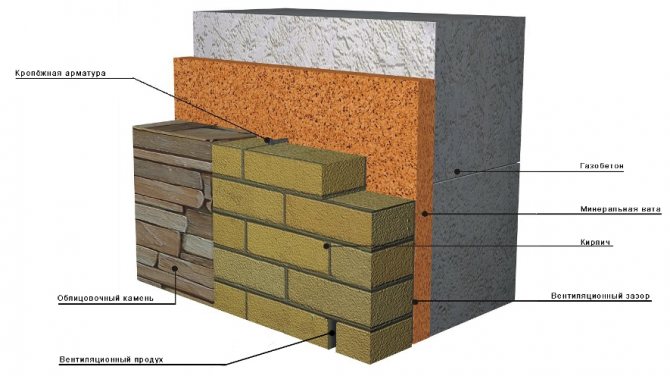

The wall, which will give your home warmth, protect it from moisture, should consist of the following layers: wall, vapor barrier layer, insulation (most often mineral wool), waterproofing film.

Other materials used for insulation

In addition to mineral wool and foam, foam (extruded polystyrene foam) and polyurethane foam can be used as insulation. Insulation of aerated concrete from the outside with penoplex significantly reduces heat loss due to the low coefficient of thermal conductivity. In addition, this material is suitable for mounting on any surface. Polyurethane foam as insulation outside the house forms foam when it begins to interact with the surface to be insulated.

Sheathing the house from aerated concrete outside

Finishing of aerated concrete blocks

Aerated concrete walls for siding are an excellent solution for the use of finishing materials

Aerated concrete blocks are several times higher than wooden materials in terms of vapor permeability. This is one of several reasons for the popularity of aerated concrete blocks. But violations made during installation or operation can affect vapor permeability. Aerated concrete walls for siding are an excellent solution for the use of finishing materials. Sometimes aerated concrete blocks can be hidden behind a brick wall, decorative tiles or plaster mixes. The job becomes easier when it turns out that an extended foundation was used when building the house. When ennobling the appearance with bricks, remember to create ventilation holes.

Finishing from the inside. The order of work:

- A primer is applied on top of the insulation;

- The plaster is applied after the primer has dried;

- It is recommended to smooth down the walls after the plaster is dry. This stage is carried out 2 times in a row (the interval between repetitions is a day);

- The wall is insulated with an internal facing material - drywall, using a special adhesive solution. A wooden frame is preliminarily prepared from slats, and plasterboard panels are mounted on them, which are subsequently painted with vapor-permeable paint.

How to veneer the foam block: types of materials and work technology

Quickly, inexpensively, warmly, for a long time.These are the goals that everyone who plans to build their own home wants to achieve. There are a lot of materials for its construction, but if foam blocks are chosen among all the variety, then another task appears - to make the finished building look aesthetically pleasing. Along with the many advantages that foam blocks have, it will be necessary to work with the facing side of the facade of the house to ensure the durability of the structure and give it an appropriate finished look, primarily from the outside. The interior decoration technology is simpler.

Material features

Foam block is a building material made from a mixture of Portland cement with sand and with the addition of a special foaming agent based on natural or synthetic substances. Among its advantages:

- durability;

- light weight, which facilitates transportation and reduces labor costs for installation;

- thermal insulation properties are much higher compared to brick.

At the same time, the house has good sound insulation, foam blocks do not burn, do not emit harmful substances. Only natural wood is more environmentally friendly. At the same time, the technology of mounting these blocks allows you to do the work yourself.

However, there are drawbacks, the main one being the tendency to darken under the influence of precipitation. This is especially evident in the cut-off points of the block.

Facing material will protect against this, which will protect the wall from the foam block, and the use of heat-insulating material will improve the microclimate in the room.

What to use for cladding

What, how to revet the foam block? Various materials are used for finishing the facade. It can be plaster, siding, decorative stone, fiber cement slabs, corrugated board, blockhouse, tile. Often, homeowners prefer to cover the building with bricks, which can be clinker or special decorative.

The technology of facing houses from foam blocks with bricks can be somewhat more complicated than when using, for example, siding, but the result is also very high quality. You just need to remember to increase the width of the foundation in advance so that there is room on it for working with bricks.

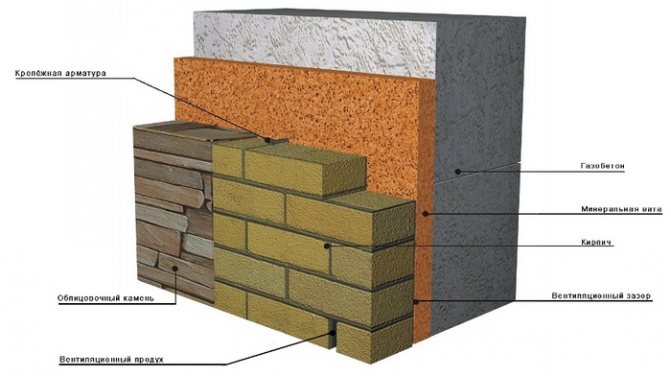

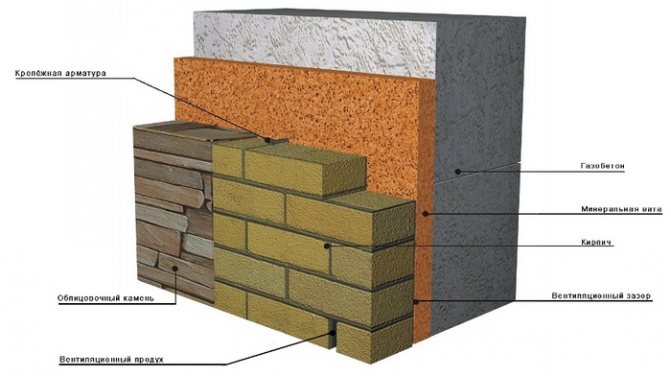

Another important point to remember: foam blocks with any facing require a ventilation gap, with its help excess moisture will be removed, therefore it is recommended to use a "breathable" heat-insulating material, for example, mineral wool.

Brick cladding of foam blocks can be carried out in two ways:

- In parallel, literally and figuratively, with the construction of walls. As the foam blocks are laid, the decorative layer is also being erected. Labor intensity increases, but the quality of the finish is excellent.

- Consistently, that is, finishing work is carried out already on a completely built building. This technology is more widespread, as it can significantly reduce construction time.

Simultaneous erection of walls from foam blocks and brick cladding

Stages of work

The technology of facing foam blocks with decorative bricks has its own characteristics. Firstly, this is a mandatory ventilation gap 20-40 mm wide, and when using thermal insulation, the gap must also be maintained. Secondly, since the masonry is made in one brick, it is advisable to use a reinforcing mesh to strengthen it, as well as to organize a bond between the brick and the wall. For this, galvanized perforated strips, flexible basalt-plastic ties, chemical anchors are used, which are installed at the rate of at least 4 pieces per 1m2 of the wall.

When installing on walls made of foam blocks, use special dowels, which will facilitate installation and securely fix the materials.

These ties are mounted in a mortar joint between foam blocks, but this is permissible if the facing brick and the foam block have seams that coincide in the same plane.Otherwise, you will have to drill a hole in the foam block itself, and in this case it is better to use chemical anchors, which will provide the required rigidity and reliability of the fastening.

The work can be divided into several stages:

- First, the first row is laid out. It is imperative that waterproofing should be arranged between the foundation and the masonry, in the capacity of which a layer of roofing material can be laid. Evenness is checked by the level.

- It is necessary to provide ventilation holes, leaving gaps between the ends of adjacent bricks. These holes should be evenly spaced along the entire length of the wall.

- After laying and leveling the first row, you can lay the second. The mortar is applied to the bottom row, and the brick to be laid is smeared from the end, after which it is laid. It should be said that the solution may contain additives such as ash, which, in the case of light-colored bricks, can create a spectacular geometric pattern.

- The technology of further cladding a wall from a foam block with a brick is similar, only it is no longer required to control the level of the horizontal masonry, which is ensured by the evenness of the first layer.

- It is necessary to ensure that the foam blocks have the same gap with the cladding, and in the last row, arrange ventilation ducts similarly to those arranged in the first row of masonry.

If a fibrous heat-insulating material is used, then it is advisable to close it, for example, with a fiberglass, protecting it from blowing and ensuring reliable ventilation of the space between the walls.

Alternative

Almost any building material used for the construction of walls requires subsequent finishing, decoration of the facade. With all its advantages, the foam block and any facing material are used in combination, and in the case of using brickwork, in fact, you have to build a second wall. Is there any way to make the process easier by combining foam blocks with finishing?

There are options with a front side, on which a texture is applied that imitates plaster, brickwork, or even having a marble-like surface, artificial stone of different colors, patterns and textures.

Foam block with textured facing side

The use of this option for construction eliminates the need to use facing tiles, bricks or other facade material.

Options for foam blocks with a facing side

Conclusion

Brick wall cladding technology may seem complicated, but the result is worth it. The combination of bricks of different colors will make the facade of the house very effective. At the same time, in addition to the aesthetic function, the facing material will protect the foam block from excess moisture, ensuring its removal, which guarantees the durability of the building and the comfort of living.

sarstroyka.ru

Alternative to using aerated concrete blocks

It is better to insulate the house at the very beginning than to carry out work later, when the labor intensity will grow several times

It is most rational and effective to provide for the insulation of aerated concrete with foam, mineral wool or foam at the stage of building a house. It is better to insulate the house at the very beginning than to carry out work later, when the labor intensity will increase several times. But the most common mistake when building a house is laying aerated concrete blocks on a concrete solution. After all, it is he who passes the cold. Outside air enters the house through the seams, increasing heating costs.

A possible option for effective installation is a special adhesive base, the thickness of which does not exceed three millimeters. The better the roof is insulated, the window openings and the foundation, the better. After all, these objects are insulated at the very beginning of construction.

Afterword

Now you will probably ask the question - is it necessary to insulate the house from aerated concrete and what materials should be used in this case? Of course you do! After all, an insulated house built of aerated concrete has a number of advantages: the relative ease of performing work, which does not require special skills, low cost and high thermal insulation of the walls provide residents of a private house with a fairly comfortable stay. But to exclude possible troubles associated with climatic features and the manifestation of the vital activity of rodents, the best solution is to insulate aerated concrete with foam, foam or mineral wool.