The technology of installing pipeline systems transporting different liquids has always taken into account the harsh conditions of most regions of Russia. These engineering networks have always been insulated. In the not so distant past, glass wool and its modifications were the main material designed to prevent freezing of pipes. And nowadays there is a tendency to use this insulation during the laying of heating systems, hot and cold water supply, sewage.

This happens, in all likelihood, from a lack of information among those who make such a decision, because there is no economic benefit from the use of mineral and other wool because of its hygroscopicity. Therefore, it is worth paying attention to modern thermal insulation materials, one of which is energy flex for pipes.

Content

- What is energy flex insulation?

- Energoflex: technical characteristics

- How is energy flex insulation applied?

- Insulation for pipes Energoflex

- Energoflex super

- Energoflex Super Protect

- Energoflex Black Star

- Energoflex Black Star Split

- Energoflex Black Star Dact and Black Star Dact Al

- Energoflex Super TP

- Additional materials required for the installation of heat insulators:

- Insulation energoflex: tips for use

- Outcome

- Watch a video about a new new type of insulation from Energoflex® Super SK

Energoflex is extremely flexible and strong

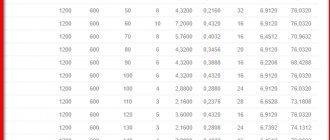

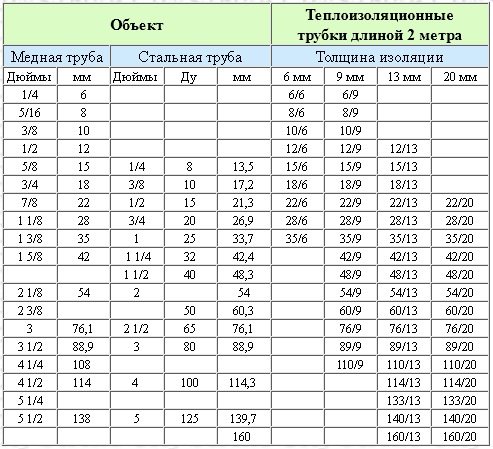

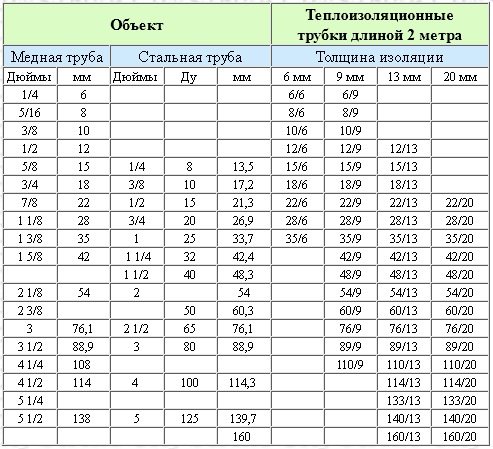

Technical characteristics of the tube made of foamed polyethylene Energoflex

Energoflex is a heat insulation material for pipes, which is a flexible thermal insulator. They use building material to insulate the pipeline and any other surfaces.

Insulation is produced from high-pressure polyethylene, which is extruded and then foamed. The structure of the initial substance is porous, the cavities are filled with air. Thanks to this, it was possible to achieve impeccable thermal insulation properties.

Thermal insulation Energoflex is produced in the following types:

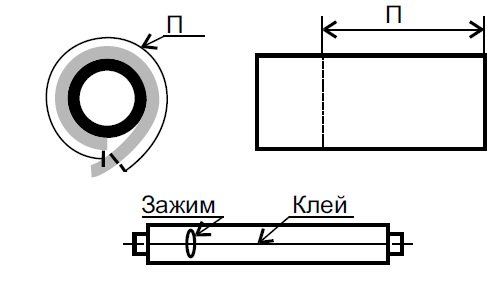

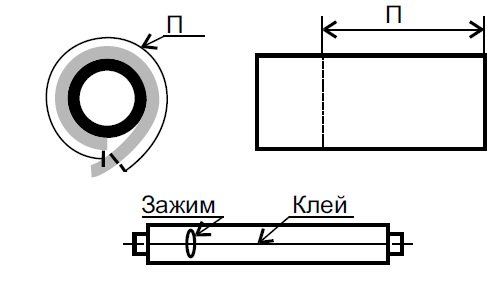

- Hollow tubes that fit over the tubes. The diameter of the products ranges from 18 to 160 mm. The material can be put on entirely on a metal structure or cut lengthwise and then glued together. The latter option is used if the pipes are not insulated during the construction of the pipeline, but in the process of its modernization.

- Rolls. Can be foil or not. Foil insulation is most in demand. Such material can be used to insulate floors and other complex, hard-to-reach systems.

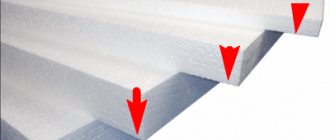

- Thermal insulation pipe Energoflex can also be produced in the form of sheets. The material is a flexible thermal insulator plate that is used to ensure the operation of fittings or pipeline sections with large pipe sections.

Roll

Tubular

Sheet

Thermal insulation material Energoflex is also produced in the form of self-adhesive tape and plates.

Material specifications:

- excellent quality of organic thermal insulation - indicators fluctuate around 0.038-0.039 W / m * s;

- wide scope and large size range;

- the permissible temperature regime ranges from -60 to +90 degrees Celsius;

- with correct installation and observance of operating rules, the duration of use is at least 25 years;

- resistance to chemicals of any nature - high pressure polyethylene does not react with oils, saline solutions, acids and alkalis;

- excellent water-repellent properties - the porous structure absorbs no more than 3.5% of the moisture volume.

When choosing a heat-insulating material, it is important to take into account that Energoflex products are susceptible to direct sunlight.

What is energy flex insulation?

Energoflex is a new generation insulation. It is specially designed for laying sewage systems, hot water supply, heating and is designed to protect them from temperature extremes and freezing.

Its basis is foamed polyethylene. In the process of manufacturing this material, a propane-butane mixture is fed into it under pressure.

EThis allows you to get a high-quality heat insulator with a porous structure at the output.

The peculiarity of the energy flex is that these cells are closed and air is conserved in them, which, as you know, is the best heat accumulator.

Energoflex is sold in special packages that are convenient for transportation.

Properties

Energoflex for pipes has such technical characteristics that when pipes are insulated with this material, a dense structure is formed that well protects pipes from moisture and temperature changes.

Important indicators are:

- Heat carrier temperature.

- Thermal conductivity.

- Water vapor permeability.

- Flammability of the material.

- Density.

Energoflex for pipes has such technical characteristics that it can be used in the temperature range from -40 ° C to +95 ° C, if the density is 25-40 kg / 1 sq. M.

There are ready-made solutions for energy flex thermal insulation. Thanks to this, the acquisition of a suitable option is carried out very quickly.

Energoflex: technical characteristics

- Resistant to mechanical damage and deformation;

- Temperature range of use from -40 * С to + 95 * С;

- Flammability group G2 (moderately flammable);

- Water vapor diffusion resistance - more than 3000;

- Lightweight and flexible for maximum ease of installation;

- Has an increased resistance to heat transfer, which entails lower costs for the device and operation of pipelines;

- Resistant to aggressive environments;

- Absolutely not hygroscopic;

- Has increased durability;

- Long lasting, not subject to decay. Service life 20-25 years;

- Effectively reduces structure-borne noise;

- It is an environmentally friendly material. When working with him does not require personal protective equipment.

Insulation materials

51 votes

+

Voice for!

—

Against!

Energy saving technologies have become a guiding star of the 21st century. People learn not just to waste the planet's natural resources uncontrollably, but to use them wisely. Various heaters and insulation schemes are used both in industry and at the household level. Thermal insulation of equipment and various units is a technological necessity. Insulation of pipelines is laid to maintain the temperature of the coolant - be it superheated steam or coolants.

Content

- Types of pipeline insulation materials

- ROLS ISOMARKET products video

- ENERGOFLEX is a Russian product

- Technical characteristics of thermal insulation ENERGOFLEX Pipe insulation

- Roll and board insulation

Types of pipeline insulation materials

Insulation material is used to maintain the required coolant temperature. It is used for thermal insulation:

- air ducts of ventilation systems;

- freezer pipes;

- sewer pipes;

- hot and cold water supply pipelines;

- central heating pipelines.

Various materials are used for thermal insulation of pipelines: stone wool, polyurethane foam, expanded polystyrene, foam insulation, foamed polyethylene. Due to the ease of installation and affordability, the latter, in turn, occupies up to 90% of the market in domestic use.

ROLS ISOMARKET products

ROLS ISOMARKET produces thermal insulation under several brands: Energoflex® (ENERGOFLEX), Energofloor® (Energoflor), Energopack® (Energopak).The company's plant is equipped with equipment from KraussMaffei Berstorff GmbH - one of the leading manufacturers of extrusion technology for polymers.

Thermal insulation is available in the form of flexible tubes, mats and cloths.

The material has great elasticity, high resistance to aggressive environments. Provides additional protection of metal pipes from corrosion, protects pipelines during installation and operation.

The company produces more than one hundred standard sizes of insulating pipes and about two dozen standard sizes of sheet and roll material. A system of branded accessories has also been developed for easy installation.

ENERGOFLEX is a Russian product

In September 2000, the first Russian plant for the production of technological insulation from foamed polyethylene was launched. Production is a joint project of STROYCOM and LIT Information Technology Plant. The company's products have received the necessary quality certificates from the State Construction Committee of Russia and international ISO quality certificates. The brands produced have excellent performance properties that are not inferior to foreign counterparts, meet the requirements of fire and hygienic safety. Thermal insulation material is produced from high pressure polyethylene (LDPE). The structure of the material has a closed cellular structure, which makes the material an excellent heat insulator. The material has low thermal conductivity and good resistance to moisture penetration, effectively reduces structure-borne noise, does not rot. When working with him, there is no need to use personal protective equipment. It is widely used for insulation of heating, ventilation systems, water supply and air conditioning systems. It is a prime example of good quality at a reasonable price.

Technical characteristics of thermal insulation ENERGOFLEX

The technical characteristics of the thermal insulation depend on the type of insulation material. Let's consider each in detail.

Pipe insulation

ENERGOFLEX pipe insulation is available in three colors: gray, red and blue, for easy identification of pipelines during installation. Thermal conductivity of lambda insulation at an ambient temperature of + 20 ° C is 0.036 W / m ° C. Thermal insulation has a wide range of operating temperatures of the coolant from -40 ° C to + 100 ° C. Fire characteristics meet GOST 30244-94 “Building materials. Flammability Test Methods ”Refers to the G1 flammable materials group.

ENERGOFLEX is an environmentally friendly and safe material, does not contain chlorofluorocarbons and freon. The density of the material is 25kg / m3 ± 5kg.

Roll and board insulation

Roll insulating material is produced with a thickness of 3-20mm. Thermal conductivity l - 0.036-0.038 W / m ° C. The density of the material is 20 ÷ 30kg. The adhesion of the adhesive layer to the metal surface is at least 300g / cm2. Refers to the flammability group G1. The operating temperature of thermal insulation is -40 + 80 ° С.

The modulus of elasticity under a load of up to 2 kPa is 0.39 MPa, under a load of 5 kPa - 0.77 MPa. The tensile strength in the longitudinal direction is 0.2 MPa, in the transverse direction - 0.1 MPa.

The relative compression under a load of up to 2 kPa is - 0.09 MPa, with a load of 5 kPa –0.2 MPa.

The water absorption of the material by volume is no more than 2%. ENERGOFLEX is also a good sound insulator. The percentage of noise absorption at frequencies of 200-1250 Hz. is 25-55%, at frequencies 1600-3600Hz - 30-60%.

Preparation of installation of thermal insulation ENERGOFLEX

Thermal insulation is designed for outdoor and indoor use at ambient temperatures from -40 ° C to + 70 ° C and relative humidity up to 100%. The manufacturer does not recommend using thermal insulation in direct sunlight. When working with insulation, use only high-quality materials, accessories, fixtures and tools.

The surface of the insulation must be solid, rough, without depressions, dents and holes. If there is dirt on the thermal insulation, it must be removed with a cleaner before installation.

The surface of the piping must be free of contamination, oil stains and rust. Clean contaminated surfaces with ENERGOFLEX cleaner or other cleaning agent. When installing thermal insulation on air ducts of ventilation and air conditioning systems, they must first be coated with an anti-corrosion coating. When installing thermal insulation in two or more layers, the installation must be done with a seam offset.

Heat insulation of pipelines and equipment should be carried out in a disconnected state. You can continue to operate the system no earlier than 24 hours after installation.

When insulating pipes outdoors, it is necessary to choose insulation with a covering material in accordance with SNiP 2.04.14-88.

During installation, it is forbidden to stretch the thermal insulation in the longitudinal or transverse direction. It is recommended to compress it slightly.

Tools and fixtures

For the installation of thermal insulation, special tools and devices will be required.

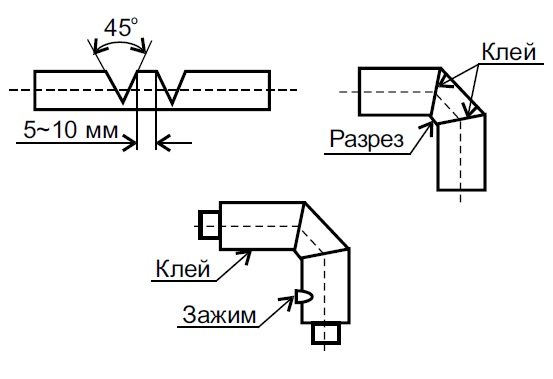

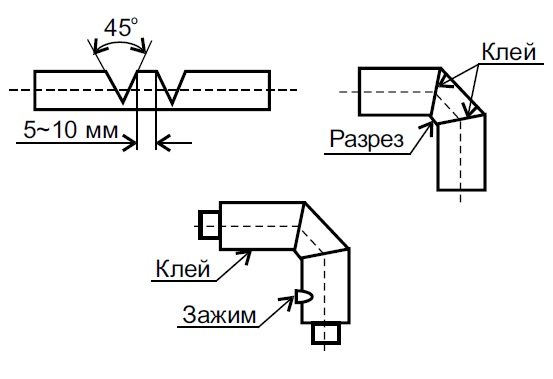

- miter box ENERGOFLEX - for setting the angles of rotation of pipes and for cutting out corner wedges;

- long blade knife (~ 300mm) - for cutting roll material and large diameter pipes;

- short knife (~ 70mm) - for small diameter pipes;

- brush - for applying adhesive;

- ring punches - for making holes in the insulation;

- building ruler;

- roulette;

- smooth spatula - for applying glue;

- pen or pencil.

Bonding insulation ENERGOFLEX

Before applying ENERGOFLEX adhesive, it must be thoroughly mixed. It is recommended to use glue in a container of 0.5 liters. The adhesive is applied in a thin layer to both glued surfaces. Connect the surfaces five minutes after applying the glue. If the glue on the surface is dry, it is reapplied. The use of glue is recommended at an ambient temperature not lower than + 17 ° С, optimally - + 20 ° С. If the glue has thickened, it can be diluted with ENERGOFLEX thinner.

Installation of thermal insulation ENERGOFLEX

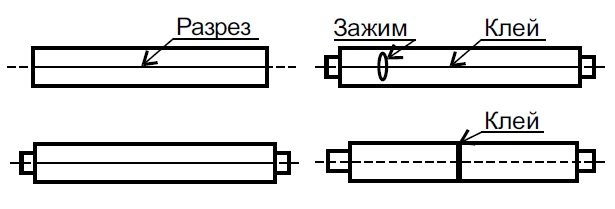

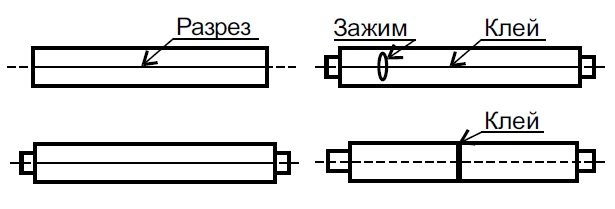

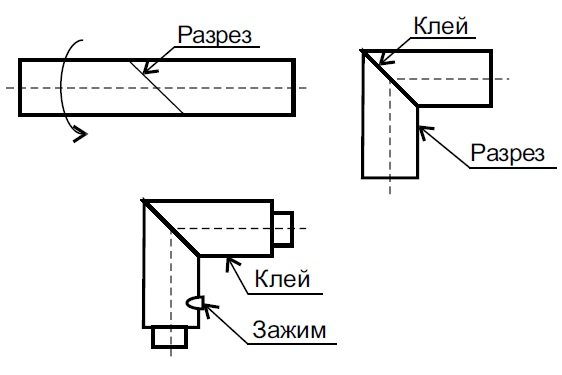

When installing pipes for thermal insulation, various methods of work are used.

Tension method. Recommended for use with pipes that have not yet been installed. ENERGOFLEX is put on the pipes, the ends of the insulation are glued together.

If the pipes need to be welded, the thermal insulation should be displaced from the welding point by 250-300mm and welded. Glue the ends of the insulation.

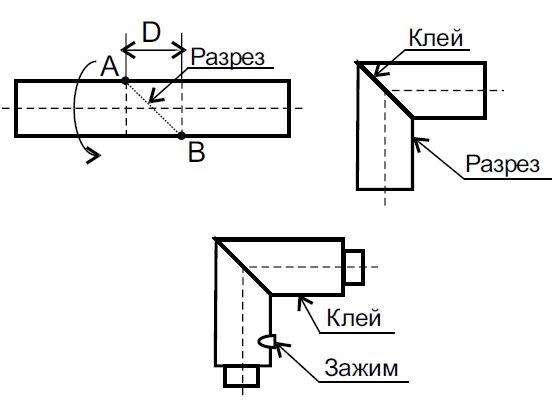

Slitting method. Thermal insulation is installed on already installed piping systems. The thermal insulation tube must be cut with a short-blade knife along the axis, mounted on the pipeline. Glue the cut and additionally secure it with a clamp, glue the ends of the tubes together.

Installation of rolls. Thermal insulation of pipes with a diameter of over 160 mm is carried out with roll material. This installation method is also used for the installation of several layers of thermal insulation. To do this, measure out the required circumference, cut off the required length and width section from the roll, and carry out installation.

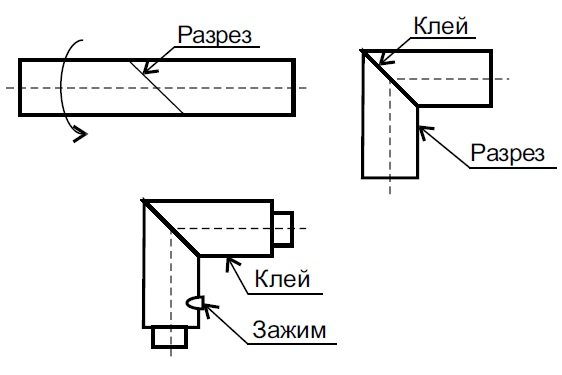

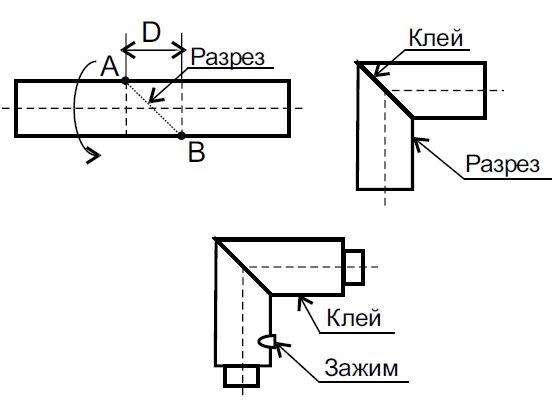

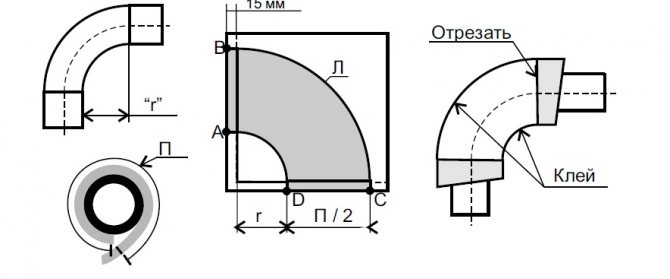

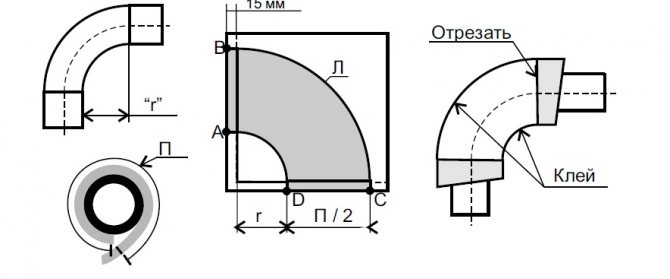

Wedge cut method. This method must be used on pipelines with a diameter of up to 90 mm. In the insulation tube, using a miter box, wedges are cut from the inside at an angle of 22 ° or 45 °, depending on the angle of rotation. The distance between adjacent wedges is 5-10 mm. All cuts are glued and held together with a clamp.

Bevel cutting. The method is used to obtain right angles of rotation. Subsequent operations are similar to the previous methods.

Diameter marking.

For bends of pipes with a diameter of 90 mm and above, it is recommended to use roll insulation.

To do this, cut out two half-sectors ABCD, which are glued along the line L, the thermal insulation is installed on the pipe and the inner corner is glued. The remainder is cut perpendicular to the pipe.

From the whole variety of insulating materials for pipelines, you can easily choose the one that you need in this particular case. The use of thermal insulation will save money, maintain the required temperature of the coolant or prevent liquids in the pipeline from freezing, and prevent the appearance of condensation.

How is energy flex insulation applied?

This material is resistant to aggressive media such as cement, lime, concrete. This makes it possible to use a wide range of energoflex in construction and installation works.

Long-burning boilers must be chosen based on several rules. Which ones, you can find out in this article. Want your home to retain heat better? See our article on how to properly insulate walls.

Find out what to consider before purchasing an electric heating boiler.

It is designed to protect equipment from condensation, which guarantees the prevention of corrosion. When laying the heat insulator, it is not recommended to stretch it; the seams should be glued with special self-adhesive tapes. There is a special glue for sealing the joints. It is fixed to the pipes with the help of Energoflex plastic clamps.

Energoflex can be of various diameters and thicknesses.

Energoflex super

Energoflex Super is available in several versions. Release form: sheets 10, 13 and 20 mm thick. and tubes 1 and 2 m long. with a technological notch. The material is highly resistant to chemical attack.

You can find out about the properties of induction heating boilers in this article: https://prootoplenie.com/otopitelnoe-oborudovanie/kotlu/indukcionnyjj-kotel-otopleniya.html See how it is recommended to carry out floor insulation in a frame house.

Do you think that insulating a balcony is an expensive process? In order not to think in vain, find out how much it costs to insulate the balcony.

Sheet is designed for insulating pipes of large diameter, it is an effective steam and moisture insulator. Meets all standards of sanitary and environmental safety. Sheets Energoflex Super is recommended to be used as the second and subsequent layers when installing multilayer thermal insulation.

Tubes of 1 m. Length can be from 15 to 42 mm in diameter. with a wall thickness of 9 mm. Each tube has a sticker on which a barcode is applied and the size of the material is indicated.

They are intended for retail stores, have increased thermal insulation properties, are easy to install due to their flexibility and technological notch.

The Energoflex tube 2 m long is intended for heat and sound insulation of internal engineering systems. They are distinguished by increased strength, moisture resistance, protect against condensation, corrosion, freezing.

Energoflex Super Protect is equipped with an additional coating that significantly increases its technical characteristics

What is this material

Thermal insulation "Energoflex" for pipes has been produced since September 2000. This is the first Russian technical heat insulator, the characteristics of which are in no way inferior to foreign counterparts. The material is available in several types, which allows you to choose the best option for a particular case.

"Energoflex" is a flexible, moisture-proof, technical heat insulator. It is made of polyethylene by extrusion of LDPE and foaming with butane-propane. Its production technology excludes the use of freon. The material has a structure with closed microcells filled with air, which provides high thermal insulation properties.

Thermal insulation is the main function that Energoflex performs for pipes. The technical characteristics of the material provide excellent frost protection. It also protects against overheating. In addition, this material is a good sound insulator, retains and absorbs unnecessary noise.

Energoflex Super Protect

Designed to protect pipes in heating and hot water systems, which are laid in enclosing structures, floors and walls. Release form: 10 meter tubes with polymer coating in blue and red, laid in bays.

Feature of the material: it has no technical notch. Guaranteed service life of 25 years. Flammability class G1 (slightly flammable).

The polymer coating increases the strength of the heat insulator by 50% and acts as a compensator during thermal expansion of pipes.

Modification types "Energoflex"

- Type 1 - The manufacturer offers two main modifications of Energoflex, including Energoflex Super and Energoflex Black Star, in various variations. The most widespread is thermal insulation for energoflex pipes, which is used in heating and hot water supply networks, in ventilation equipment, air conditioning units, etc. In addition, the manufacturer has developed a universal glue Energoflex, which ensures reliable fixation of the insulation on round and rectangular products.

- Type 2 - In the range of products of the Energoflex Super modification there is an energy flex for pipes 1 and 2 meters long in a wide range of diameters (15 - 42 mm) and thicknesses, sheet and roll insulation, Energoflex Super Protect thermal insulation, Energoflex Super Al, Energoflex Super TP. The Black Star modification is represented by Energoflex Black Star and Energoflex Black Star Split thermal insulation, made in the form of tubes of different lengths and diameters, as well as Energoflex Black Star Duct roll material. Tubes made using energy flex super insulation are made with a technological cut along their entire length, which greatly simplifies their installation on existing communications.

- Type 3 - Energoflex Super Protect sheet roll insulation is successfully used to insulate many structures, including pipe products with an increased diameter, various containers and valves. Thermal insulation Energoflex Super Protect is distinguished by the presence of an outer polymer coating with high mechanical resistance. The elastic layer of polyethylene foam serves as a heater and a compensator for thermal expansion of the piping. This material is mainly used to insulate the piping of heating and water supply networks, which are laid inside walls and floors.

- Type 4 Energoflex Super Al has a protective layer of aluminum foil, which allows it to be used for thermal insulation of conventional systems, as a vapor barrier, as well as for the protection of structures where it is necessary to reduce the loss of radiant heat energy. It is recommended to use roll material, plates and mats of Energoflex Super TP modification as an insulator in conjunction with underfloor heating systems. The mechanical strength and chemical resistance of thermal insulation is achieved due to the polymer film, the uniform distribution of thermal energy is provided by a layer of aluminum foil.

- Type 5 Flexible tube energoflex Black Star is designed for thermal insulation of copper pipelines used in air conditioners. Unlike tubes of the Energoflex Super modification, these products do not have a technological notch, but their design allows easy fitting on the copper tube. Energoflex Black Star Split tubing is also used in air conditioning units, but features a durable protective layer of UV resistant polymers. The unique material design allows it to be used outdoors.

- Type 6 Thermal insulation Energoflex Black Star Duct is made in the form of polyethylene foam insulation on a self-adhesive basis. This material is primarily used for duct insulation in air conditioning and ventilation systems. Its use allows to provide not only reliable thermal protection, but also significantly reduces noise effects and vibration of structures. The material has no restrictions on its use, being harmless to humans.

The material is popular with builders, industrialists, manufacturing workers and plumbers. Acceptable in terms of cost and technical characteristics.

Energoflex Black Star

Specially designed for the insulation of copper pipes in air conditioning systems... It has excellent vapor and waterproofing properties. Provides protection against condensation and corrosion.

They have a smooth inner surface, thanks to which there is no need to use talcum powder when putting on the tubes.

Special sizes have been developed for all types of copper pipes in air conditioning systems. Ideal for insulating cold surfaces.

Energoflex Black Star Split is specially designed for the insulation of air conditioning units

energoflex

Thermal insulation Energoflex

SantechTorg Company offers thermal insulation Energoflex from foamed polyethylene is a new generation of thermal insulation which, thanks to a large assortment and high quality of products in the domestic market, energyflex thermal insulation has become a leader in the thermal insulation market.

Thermal insulation Energoflex is designed for thermal insulation of heating systems, hot and cold water supply, air-conditioning and air-conditioning systems, sanitary systems, enclosing structures in industrial and engineering systems.

In the city of Naberezhnye Chelny SantekhTorg company is the only official distributor of energy-flex insulation and has become a leading supplier of thermal insulation in the Republic of Tatarstan. We have been selling energy-flex thermal insulation for many years and have a large stock of energy-flex thermal insulation.

Benefits of thermal insulation Energoflex:

- thermal insulation Energoflex has all the necessary hygienic certificates, meets Russian and European standards.

- low thermal conductivity energy flex insulation is ideal for thermal and noise insulation of internal engineering systems.

- thermal insulation Energoflex combines the best price and quality.

- thermal insulation energoflex has its own line of original accessories, which makes it possible to install energyflex thermal insulation in the most efficient way and in the shortest possible time.

- thermal insulation energoflex reduces heat loss to a minimum, which means it saves you money.

- thermal insulation energoflex is resistant to aggressive media and durable.

The line of thermal insulation energoflex is constantly expanding and improving, thanks to in-depth analysis of market needs.

At SantechTorg will always help you choose energy flex insulation according to all technical standards and the most suitable for you.

Range of thermal insulation energoflex:

Assotiment thermal insulation Energoflex has 107 standard sizes of tubes, 24 standard sizes of rolls and a system of branded accessories for installation. Energopack ™ covering materials provide reliable protection of thermal insulation: they are resistant to aggressive environments, have increased strength, durability, moisture resistance and make it possible to widely use Energopack thermal insulation in engineering systems and communications. Thermal insulation Energoflex is the first product of the Russian market of foamed polyethylene and its leader in assortment, quality and service.

1. Tubes Energoflex Super 2 meters long.

Energoflex Super closed-cell polyethylene foam tubes are ideal for heat and sound insulation of internal engineering systems. The material of the products is resistant to aggressive environments, has increased strength, moisture resistance and durability. Flexible heat-insulating tubes are easy to install, effectively reduce heat losses and structure-borne noise, protect the equipment surface from condensation and corrosion, and prevent the coolant from freezing for a specified time. Environmentally friendly material, safe to use, does not require personal protective equipment.When used inside buildings, there is no need to use a vapor barrier and cover layer. Flammability group G1. The flexibility of the product and the technological notch along the entire length of the tube makes installation simple and convenient.

Technical characteristics of tubes Energoflex Super 2 meters long:

Maximum operating temperature - -40 - + 95 ° С Water vapor diffusion resistance factor, µ> = 3000. Thermal conductivity coefficient, W / (m ° С):

at 0 ° C - 0.035;

at 10 ° С - 0.037

at 50 ° C - 0.045.

2.Rolls Energoflex Super

Sheet heat-insulating material with a closed cellular structure Energoflex Super is an effective solution for insulating large-diameter pipes, fittings and vessels for various purposes. Possesses all the advantages of Energoflex polyethylene foam materials - low thermal conductivity, high moisture and vapor resistance, flexibility and surface strength - Energoflex Super rolls are distinguished by high energy efficiency, manufacturability of installation, durability, sanitary and environmental safety. It is recommended to use sheet material Energoflex as the second and subsequent layers in the design of multilayer structures for thermal insulation of pipelines. Sheet material Energoflex is a versatile material for insulating large-diameter pipes, fittings and tanks.

Technical characteristics of Rolls Energoflex Super: Operating temperature range, ° С - from -40C to + 95C. Water vapor diffusion resistance factor, µ> = 3000. Thermal conductivity coefficient, W / (m ° С):

at 0 ° C - 0.035;

at 10 ° C - 0.037;

at 50 ° C - 0.045.

3. Tubes Energoflex Super 1 meter long.

Energoflex Super tubes, 1 meter long, are specially designed for retail stores. They are produced with an inner diameter of 15 to 42 mm, a wall thickness of 9 mm, in a special cardboard box - a transformer, which in the "open" state is a mini-stand with full information about the product and its application. Each tube has a barcode and size sticker. The material is convenient for sales in hardware stores. The flexibility of the product and the technological notch along the entire length of the tube makes installation simple and convenient.

Energoflex Super tubes, 1 meter long, are ideal for narrow and hard-to-reach rooms.

Technical characteristics of tubes Energoflex Super 1 meter long:

Operating temperature range, ° С - from -40C to + 95C. Water vapor diffusion resistance factor, µ> = 3000. Thermal conductivity coefficient, W / (m ° С):

at 0 ° C - 0.035;

at 10 ° C - 0.037;

at 50 ° C - 0.045.

4.Energoflex Super Protect

Energoflex Super Protect is specially designed for laying heating and water supply pipes in floor and wall structures. It is highly resistant to mechanical damage and aggressive building materials. The polymer coating increases the strength of the pipes by 50%, thereby making the energy flex insulation a reliable protection for the pipes, and the elastic layer of polyethylene foam helps to compensate for the thermal expansion of the pipes. The advanced technology of the simultaneous extrusion of the polyethylene foam tube and the plastic film ensures reliable welding of the thermal insulation and coating.

A protective sheath of red or blue color of energy flex insulation, resistant to concrete, cement and mechanical damage.

Technical characteristics of Energoflex Super Protect: Maximum operating temperature - -40 - + 95 ° С Water vapor diffusion resistance factor, µ> = 3000. Thermal conductivity coefficient, W / (m ° С):

at 0 ° C - 0.035;

at 10 ° C - 0.037;

at 50 ° C - 0.045.

5.Rolls Energoflex Super Al

Energoflex Super Al: multi-profile thermal insulation based on foamed polyethylene Energoflex Super with a reflective layer of aluminum foil can be used both for insulating utility networks and as reflective insulation of enclosing structures, structures, where it provides effective protection against losses of radiant thermal energy.Thanks to the use of polished aluminum foil, the surface reflection coefficient of energy flex thermal insulation is at least 90%. Also, the material is an excellent vapor barrier. When designing thermal protection of enclosing structures, it is necessary to provide for the installation of reflective insulation on the inner surface of the structure, with the foil inside, providing the necessary air gap between the foil and the finish. The use of aluminum foil eliminates the formation of static electricity and the settling of dust on the surface of the energy-flex insulation material.

Technical characteristics of rolls Energoflex Super Al:

Operating temperature range, ° С - from -40C to + 95C. Water vapor diffusion resistance factor, µ> = 3000. Thermal conductivity coefficient, W / (m ° С):

at 0 ° C - 0.035;

at 10 ° C - 0.037;

at 50 ° C - 0.045.

Rolls Energoflex Super TP:

Energoflex Super TP is a convenient solution for thermal insulation of heated floors in residential premises of multi-storey buildings. Foamed polyethylene Energoflex Super is covered with aluminum foil, protected by a chemically resistant polymer film. Polyethylene foam reduces heat loss, foil evenly distributes heat from heating elements over the entire floor area, protecting the screed and floor covering from local overheating. The small thickness of Super TP energy-flex rolls allows to reduce the overall thickness of the underfloor heating system, saving space in living quarters. It is recommended to use Energoflex Super TP rolls in underfloor heating systems designed to create comfort in living quarters, in addition to the main heating systems. A ready-made thermal insulation system for a warm floor can significantly reduce installation time.

Technical characteristics of Energoflex Super TP rolls:

Maximum operating temperature + 70 ° С Thermal conductivity coefficient, U, W / (mK) <= 0.036. Water absorption by volume in 24 hours - no more than 2%. Relative compression: - under a load of 2 kPa - 0.09 MPa - under a load of 5 kPa - 0.20 MPa. Resistance to delamination of aluminum foil and polyethylene foam, not less than 100 N / m.

Energofloor Tacker slabs and mats

Energofloor® Tacker boards and mats are a ready-to-use thermal insulation system for underfloor heating. The system is specially designed for the most common technology for attaching pipes to the thermal insulation layer using harpoon brackets. It consists of expanded polystyrene covered with a durable polymer fabric. Thanks to the use of 25 mm thick expanded polystyrene, Energofloor® Tacker has a high thermal resistance. The test results showed that the material provides effective protection against impact noise and meets the highest sound insulation requirements in residential buildings in accordance with SNiP 23-03-2003 "Noise Protection".

Specifications of Energofloor Tacker Slabs and Mats:

Maximum operating temperature + 70 ° С Thermal conductivity coefficient, U, W / (mK) <= 0.037. Printing step - 5 cm. Water absorption by volume in 24 hours - no more than 2%. Compressive strength at 10% linear deformation, not less than 0.16 MPa. Flexural strength, not less than 0.25 MPa. The density of the base (expanded polystyrene) is 25.1-35 kg / m³.

Pipe thermal insulation Energoflex Black Star:

Thermal pipe insulation Energoflex Black Star: flexible polyethylene foam insulation pipes specially designed for thermal insulation of copper pipes in air conditioning systems. Possessing a closed-cell structure, the material has a high resistance to steam and moisture penetration, which is especially important when insulating cold surfaces. Tubes Energoflex Black Star reliably protect against condensation, are technologically advanced during installation, resistant to aggressive building materials and mechanical stress, durable and safe. The specially selected dimensions and smooth inner surface of the heat-insulating tubes make them easy to put on copper pipes without the use of talcum powder.

Technical characteristics of pipe thermal insulation Energoflex Black Star: Maximum operating temperature from -40 to + 95 ° С Water vapor diffusion resistance factor, µ> = 3000. Thermal conductivity coefficient, W / (m ° С):

at 0 ° C - 0.038;

at 10 ° C - 0.040;

at 50 ° C - 0.048.

Energoflex Black Star Duct:

Energoflex Black Star Duct: specialized self-adhesive material for heat and sound insulation of air ducts of ventilation and air conditioning systems. It is made of expanded polyethylene, has a closed-cell structure. It reliably protects against condensation and heat losses, is an effective noise-absorbing and vibration-damping material. Easy to install, harmless to health and the environment.

Technical characteristics of Energoflex Black Star Duct:

Operating temperature range, ° С from -40 to + 80 ° С Thermal conductivity coefficient, l <0.038 W / m * K at 0 ° С Vapor diffusion resistance, m ≥3000 Flammability group Black Star Dact Al G1 - thickness 3-10 mm, G2 - thickness 15 - 20 mm Flammability group Black Star Dact G1 - thickness 3 - 10 mm, G2 - thickness 15 - 20 mm Sound absorption in the frequency range 31.5 - 8000 Hz, dB up to 6.5 Adhesion of the adhesive layer to the metal surface, not less, g / cm 300 Environmental safety does not contain chlorofluorocarbons Service life, years 20 - 25

Energoflex Black Star Split

It is used for thermal protection of pipes of air conditioning systems located in the open air.

It is produced in the form of two-meter silver tubes with a polymer coating applied to them, securely welded to the surface of the heat-insulating layer.

Differs in high resistance to aggressive environmental influences, ultraviolet light, water vapor.

Belongs to the group of low-combustible materials (G1). The warranty period is 16 years.

Types of thermal insulation materials

Varieties of heaters for pipes Energoflex

There is a wide variety of pipeline insulation materials. Each type has individual characteristics that must be considered when choosing. For pipeline insulation the following are used:

- liquid products;

- polyurethane foam;

- expanded polystyrene;

- basalt wool;

- fiberglass materials;

- foam material.

Liquid insulation is in great demand due to the following characteristics:

- Due to its liquid consistency, the building material can be applied to hard-to-reach and uneven places, hidden areas.

- Installation, in comparison with the installation of other types of thermal insulation, takes less time and does not require special training.

- The more layers of thermal insulation are applied to the surface of the pipeline, the better the heat will be retained.

The composition is applied using a spray gun or a special brush.

Fiberglass insulation is also in high demand. The peculiarity of the material is low weight, the structure does not rot. Therefore, pipelines passing on the street are insulated with mineral wool. Installation is carried out as follows: the pipes are cleaned and degreased, then wrapped with an insulator and securely fixed with knitting wire. To enhance protection against harmful environmental influences, they are additionally insulated with foil or roofing material.

Basalt wool is an insulating material that is made in the form of plates and cylinders. It does not allow moisture to pass through, has increased strength and fire safety. Installation is easy, no special skills required.

Energoflex Black Star Dact and Black Star Dact Al

It is a roll-up self-adhesive material of black color, designed for heat and sound insulation of pipes in HVAC equipment and air exhaust systems.

Differs in increased elasticity and resistance to mechanical damage, high vapor barrier properties. It is an effective noise isolator and vibration compensator.

The Duct AL marking indicates that one side of the insulation is covered with polished aluminum foil.The form of release is a roll 1.2 m wide, resembling a plastic bag.

Energoflex TP will help you quickly and effectively insulate warm floors and make them even more comfortable

Energoflex Super TP

Designed for thermal insulation of heated floors. Feature of the material: covered with a film, highly resistant to chemical attack, has one-sided foil. Resistant to aggressive environments, prevents overheating of concrete.

Additional materials required for the installation of heat insulators:

Plastic clip. Designed for joining longitudinal seams (technological cuts) after the insulation is put on the pipes. Gray laminated self-adhesive tape. Size 48/50 mm. Red and blue reinforced self-adhesive tapes. Size 48 // 25 mm. Self-adhesive aluminum tape. Size 50/50 mm.

The materials of the same manufacturing company are best suited for energy flex.

Insulation energoflex: tips for use

The first and most important condition for a high-quality and safe installation is the production of work only on non-working equipment and non-functioning pipelines.

Their operation is allowed to start no earlier than 24 hours after the completion of the Energoflex thermal insulation installation.

It is installed on a welded pipeline only after the pipe section has cooled.

All work is carried out at a temperature not lower than 5 * C. At a lower level, self-adhesive materials are not able to provide a high-quality seal.

Glue is used to connect the joints. It is applied in an even layer on both surfaces to be glued and cured for 3-5 minutes.

Outcome

The Energoflex trademark is a development of the young and ambitious Russian company ROLS ISOMARKET. She is one of the few who work according to international standards and the only one that manufactures products not according to industry specifications, but according to the company's own strict standard. This ensures the reference quality of the materials produced.

The company is constantly looking for solutions to improve them. This allows you to be sure that products of the Enegoflex brand are beneficial from any point of view: cost, durability, ease and speed of installation, reliability of thermal insulation and other properties.