Experts consider autonomous heating systems with gas boilers to be the most economical due to cheap fuel and maintainability. Modern units are efficient, do not require constant attention, maintain a comfortable temperature and are protected from all sorts of problems. But the range of heating equipment is quite rich and choosing the best one is rather difficult, isn't it?

We will help you understand this issue - in this article we analyzed the gas equipment market, identified the best models based on user reviews and expert opinions, and now we offer you to choose the most efficient and safe non-volatile gas boiler for heating a private house.

The rating includes products of manufacturers Lemax, TERMOMAX, ATON, Protherm, and 7 out of 10 TOP places were taken by boilers of the Russian brand Lemax.

What is a non-volatile gas boiler?

Nonvolatile gas boilers operate only with mechanical assemblies and parts. They do not need to use electricity, which greatly increases their capabilities.

In the conditions of Russia, where in winter the temperature drops much below zero, it is important to ensure the continuity of the heating systems... At the same time, most of the power grids are overloaded, and in some villages there is no connection at all.

This makes non-volatile boilers a popular and preferred unit. All the main units of the unit are controlled only by mechanical methods, but this does not impair the quality of heating the house.

Non-volatile boilers are devoid of many parts, which simplifies the design and makes the operation more stable and reliable. Most users do not consider the lack of remote control and other additional functions to be a significant drawback.

Everyone understands that many add-ons make the device more vulnerable and unreliable.

NOTE!

The design of non-volatile boilers arose much earlier than more modern dependent units. The long period of existence has allowed manufacturers to work out assembly technologies and achieve high performance indicators.

Ventilation system and chimney

Since electric boilers for individual heating are independent of electrical energy, a chimney is required for the normal functioning of the system. It is this element that can provide good and natural air draft.

It is worth noting that chimneys are quite expensive, however, their installation must be carried out in accordance with all standards.

The ventilation system in relation to non-volatile boilers is also a critical issue. And the need to install ventilation or hoods is due to the fact that the chimney may not be able to cope with the removal of all combustion products in a natural way.

Coaxial flue gas boiler

What is the difference from the usual?

The difference between a non-volatile boiler is the absence of all units that need power. There is no built-in circulation pump, turbofan.

Control is carried out using mechanical devices - valves, mechanical sensors, regulators... This makes the design very simple and reliable, but all processes take place naturally.

For example, smoke removal is carried out using a stove draft in the chimney. Air is taken directly from the room. These features make the mode of operation dependent on the mass of external factors..

For example, chimney draft varies with weather, wind direction and strength. Drafts can disrupt flames. In addition, the room needs good ventilation, since the boiler actively burns out oxygen.

Many users solve these problems by installing external devices - a circulation pump and a turbo nozzle to enhance and stabilize traction.... This makes the operating mode more intense and even.

Pros and cons

The advantages of non-volatile boilers include:

- there is no dependence on the availability and quality of power supply;

- simplicity of design, absence of minor details;

- guaranteed continuity of the heating process at home;

- the cost of the boiler and repair work is much lower than that of volatile models;

- maintenance and cleaning can be done by yourself.

Disadvantages are considered to be:

- the protection system is limited to a few sensors;

- there is no possibility to carry out remote control;

- the operation of the boiler depends on external factors that cannot be controlled.

IMPORTANT!

Despite some disadvantages, non-volatile boilers are a practical and reliable solution. In some settlements, they have no competitors due to power outages.

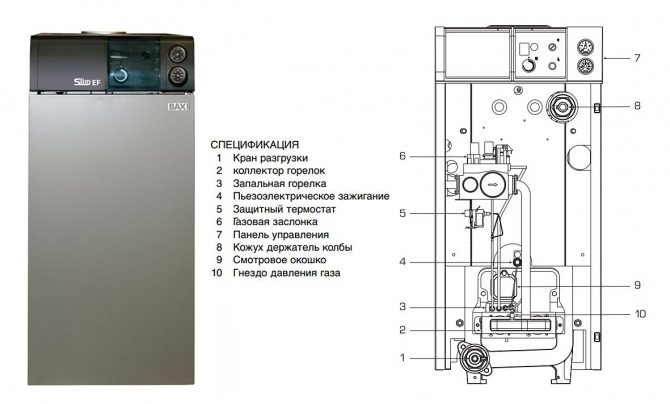

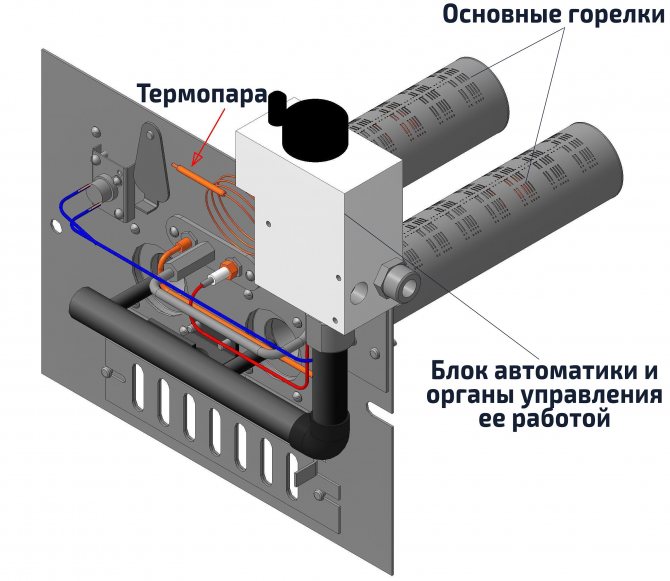

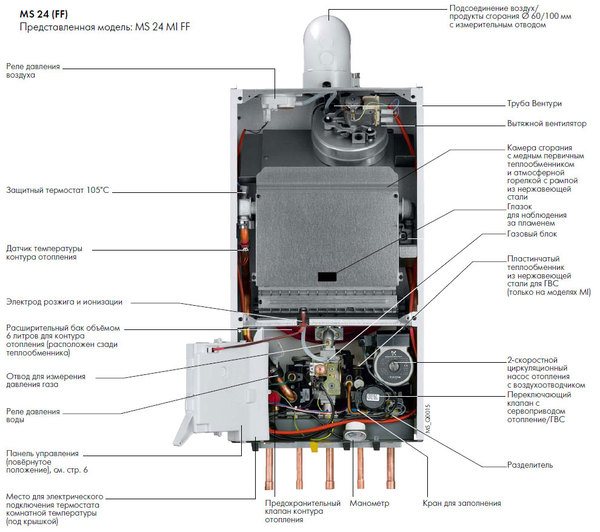

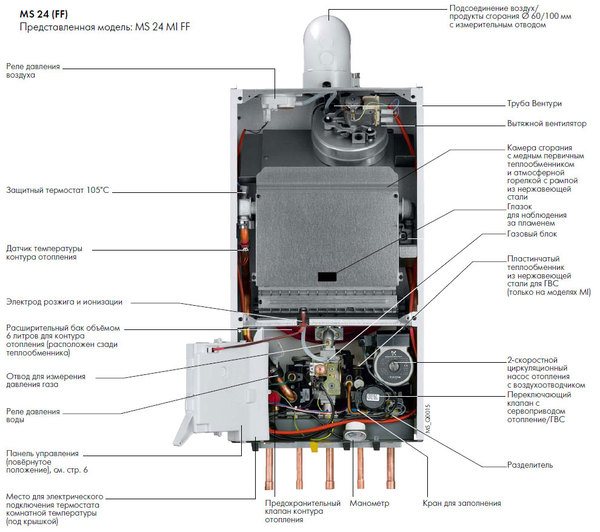

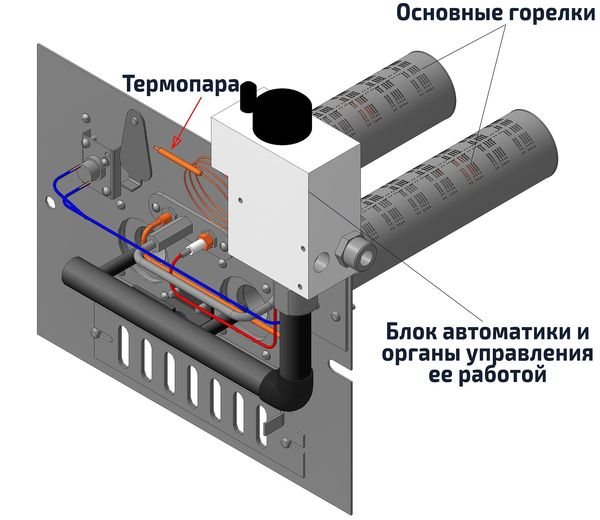

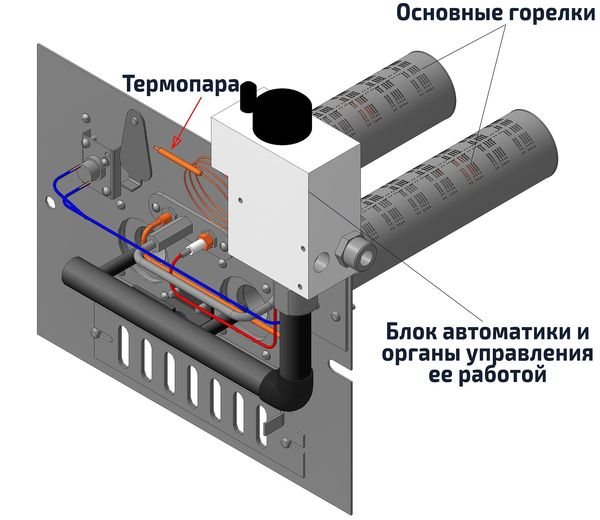

Device

The main elements of non-volatile units are the primary (main) heat exchanger and gas burner. They provide the main function of the boiler.

In addition, the structure includes:

- three-way valve, in which the temperature of the coolant is brought to the set value;

- gas equipment providing control and fuel supply;

- secondary heat exchanger (only for dual-circuit models);

- temperature and pressure sensors.

The list of units is small, but this is the main advantage of non-volatile boilers. The fewer parts, the higher the strength and resistance to loads of the structure as a whole.

How to choose the right model?

- First you need to decide on purpose of purchase... If the boiler is purchased for personal home use, then you should not buy expensive large devices. For heating an apartment or a small private house, a medium-price product is suitable, with a power of 10-15 kW.

- Then it is necessary estimate the budget, which will include purchase, delivery, installation. The last point often does not take part in the calculations, but in vain, because when purchasing an expensive boiler, you need to connect it correctly, otherwise a breakdown is inevitable.

- pay attention to reviews on the internetto find out how easy the chosen boiler is to operate and how difficult it is to find spare parts.

- Consult contact your equipment supplier for this matter. Almost all modern firms offer services of departure of the master to the installation site. The specialist will assess the area and furnishings and offer several options for the buyer.

Views

There are not so many varieties of non-volatile boilers as there are more modern dependent models. For example, there are no turbocharged units (with mechanical air supply).

There are the following varieties:

- single-circuit. Provide only heating of the heating agent for the heating circuit;

- double-circuit. They perform two functions - heating the coolant and preparing hot water.

By installation method:

- wall. They are installed in a hinged way on load-bearing walls or strong vertical surfaces;

- floor. installed on the floor or on a non-combustible stand. Most non-volatile units are made in floor-standing design;

- parapet. These are units that have the characteristics of several groups of gas boilers. They have a lot of features that make them practical and user-friendly.

NOTE!

As a rule, non-volatile boilers have a floor-standing single-circuit design. This is the simplest and most reliable option.This approach allows you to guarantee an uninterrupted supply of coolant to the heating system in difficult conditions.

Additional recommendations

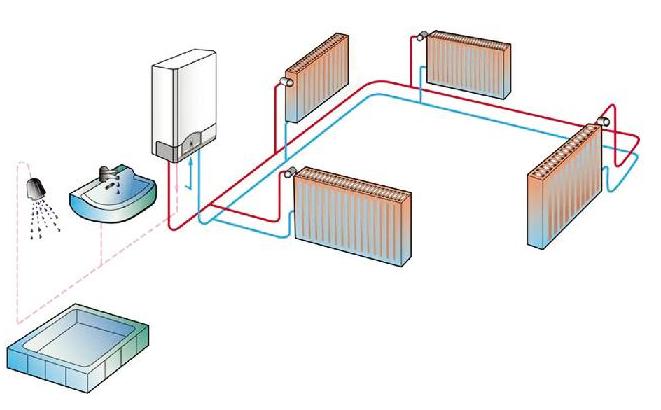

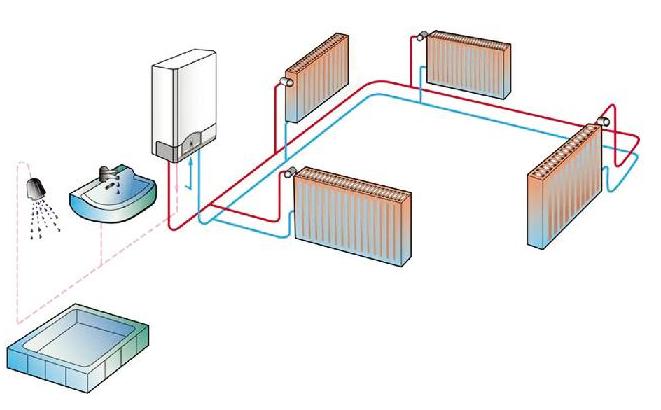

For normal operation of heating, which does not have forced circulation of the coolant, it is necessary to use pipelines with a larger diameter than in the case when a pump is used in the system. This is done in order to reduce the resistance to the natural movement of the coolant, although it leads to some increase in the cost of work.

It is also necessary to take into account the installation of the expansion tank, which also affects the cost. Some people still use built-in circulation pumps, but only where the power supply is periodically working.

Expansion tank.

It should be borne in mind that after connecting the pump, a bypass must be installed. This scheme also provides for the installation of three shut-off valves that allow switching the heating agent to natural circulation.

Principle of operation

The operation of a non-volatile boiler is based on flow heating of the coolant in the flame of a gas burner. The liquid enters the boiler, goes through the heating stage and enters the three-way valve.

There, a colder "return" is mixed in a certain ratio. This allows you to give the coolant the temperature set by the mode. EIf the boiler is double-circuit, then a secondary heat exchanger is installed between the main heat exchanger and the three-way valve to prepare hot water supply.

Smoke is removed by natural draft, therefore, a connection to a communal chimney of sufficient length is required.

Liquid circulation also occurs naturally, which requires compliance with the regulatory slope when installing the system.

Number of contours

As usual, a single-circuit autonomous heating boiler is intended only to heat the premises. Double-circuit boilers also supply hot water. Note that water heating in this case can be carried out in two ways - storage and flow.

The flow-through method assumes that the water will be heated by the flow-through method. Most often, this method is found in wall models. If the accumulative method is chosen, then a special boiler is provided for this, where the water is heated. This is most often the prerogative of floor-standing non-volatile boilers.

How to choose gas heating boilers?

Double-circuit wall-mounted boiler

Rating of TOP-5 non-volatile gas boilers

Consider the features of some models of non-volatile units:

Lemax Premium-12.5

Non-volatile floor-standing boiler of domestic production. The power of the unit is 12.5 kW, so the area of the room should not exceed 125 sq. m.

The model is equipped with a steel heat exchanger, overheating protection and a gas supply controller.

Basic performance characteristics:

- Efficiency - 90%;

- maximum heating water temperature - 90 °;

- pressure in the heating circuit (max) - up to 3 bar;

- natural gas consumption - 1.5 m3 / hour;

- dimensions (W-H-D) - 416x744x491 mm;

- weight - 55 kg.

Lemax gives a long-term guarantee for its boilers - the user receives technical support for 3 years.

Lemax Premium-20

Another floor-standing non-volatile gas boiler manufactured in Taganrog.

Its power is 20 kW, which is optimal for most private two-storey houses. The maximum area for this unit is 200 sq. m.

Boiler parameters:

- Efficiency - 90%;

- maximum heating water temperature - 90 °;

- pressure in the heating circuit (max) - up to 3 bar;

- natural gas consumption - 2.4 m3 / hour;

- dimensions (W-H-D) - 556x961x470 mm;

- weight - 78 kg.

The single-circuit design is intended for heating the coolant, but if necessary, an external indirect heating boiler can be connected.

Lemax Patriot-12.5

Non-volatile parapet model from Taganrog. A boiler with specific capabilities.

Non-volatile unit, but a closed combustion chamber. Boiler power 12.5 kW, suitable for heating 125 sq. m.

Main technical characteristics:

- Efficiency - 87%;

- maximum heating water temperature - 80 °;

- pressure in the heating circuit (max) - up to 2 bar;

- natural gas consumption - 0.75 m3 / hour;

- dimensions (W-H-D) - 595x740x360 mm;

- weight - 50 kg.

The main advantage of parapet boilers is their low fuel consumption - almost half as compared to conventional models.

Siberia 11

Products of Rostov manufacturers of heating equipment. BUTthe units are available in single and double-circuit versions, which expands the choice.

The power is 11.6 kW, allowing you to heat a house with an area of up to 125 sq. m.

Main settings:

- Efficiency - 90%;

- maximum heating water temperature - 90 °;

- pressure in the heating circuit (max) - up to Bar;

- natural gas consumption - 1.18 m3 / hour;

- dimensions (W-H-D) - 280x850x560 mm;

- weight - 56 kg.

Rostov units are positively assessed by specialists and ordinary users.

MORA-TOP SA 40 G

Czech gas non-volatile boiler with a capacity of 35 kW is designed for use in rooms up to 350 sq. m. The massive structure is equipped with a cast iron heat exchanger.

Parameters:

- Efficiency - 92%;

- maximum heating water temperature - 85 °;

- pressure in the heating circuit (max) - up to Bar;

- natural gas consumption - 3.9 m3 / hour;

- dimensions (W-H-D) - 630x845x525 mm;

- weight - 151 kg.

The cast iron heat exchanger has a sectional design of 5 sections... There are pressure and temperature sensors.

What documents will the developer need to install the boiler

Despite the seeming simplicity, it is hardly possible to perform installation without the involvement of specialized organizations. Moreover, a number of documents must be prepared prior to installation.

You will need:

- Natural gas supply agreement for an individual developer.

- Connection specifications.

- Equipment installation project agreed with the gas service.

After the installation organization finishes its work, the object is handed over to a gas service engineer. The correctness of the connection is checked, the compliance of the equipment with the project and standards Upon successful delivery, the consumer receives permission to use the system.