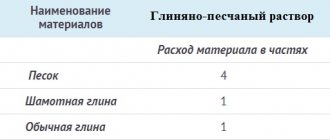

Kiln clay

Clay is an irreplaceable material in the preparation of masonry mortar. It owes its demand to unique properties, which consist in the magical transformation of clay into stone after being treated with fire. During the firing process, it acquires the strength inherent in brick, gives excellent adhesion to the structure and withstands the highest temperatures. However, in order to achieve its maximum qualities, it is necessary to prepare a mortar for laying the oven with an optimal ratio of ingredients.

The autonomy and special rustic flavor of wood heating of country cottages compete with gas boilers. You can fold the oven for your home yourself with the right choice of materials. To avoid the appearance of cracks in the housing, brick and masonry mortar should react equally to mechanical and thermal loads, exposure to flue gases. The cement mixture deforms when heated and is not suitable for the construction of heat-resistant structures.

Masonry mortars for the main parts of the oven

1. The furnace part made of refractory bricks (marked with Ш) can withstand heating above 1000 C. The masonry is fastened with a heat-resistant mixture, the main component of which is fireclay clay.

2. The heat storage chamber is heated up to 600 C, the effect of flue gases and acid condensate. For the walls use ceramic bricks (solid "stove" M 150) and clay mortar.

3. The chimney is under its own and wind load. The outer pipe is laid out of ordinary bricks on a lime mixture.

4. In case of deformation, the foundation requires disassembly of the furnace. Therefore, a strong cement-lime composition and solid brick with good bearing capacity are chosen for the base.

Traditionally, clay mortar is used for laying stoves, since it can withstand temperatures up to 1400 C, has a maximum density, that is, it completely does not let smoke and waste into the room. The microporosity of the material allows the walls of the furnace to absorb moisture vapor and "breathe". When heated, clay joints do not expand or crack when cooled. It is possible to disassemble the structure in case of repair work without deformation and waste.

Tricky energy-saving meter Pays off in 2 months!

Clay is a common mineral on Earth. Outcrops are visible almost everywhere. Despite this, not every clay is suitable for oven work.

The complex of basic qualities is determined by fat content. Clay is oily, medium-fat and lean.

- Oily ˗ plastic, but when dry it cracks and gives strong shrinkage. This leads to deformation and destruction of the structure.

- Medium fat clay is the best option. She has good adhesive properties, strong, heat-resistant, hygroscopic. When dry, it gives a moderate sediment, does not crack.

- Skinny clay has low adhesive properties. It is dry, cracks quickly, the masonry crumbles.

Finding good clay is a great success. Good seams occur at a depth of 5 meters. The surface ones are heavily contaminated with humus, they have a high content of sand impurities. It is loamy, skinny soil. She's not good for the job.

There is a clay formation under the loam layer. The thicker the layer, the better. The lower layers are the fattest clay, but it is also not clean. It is better to take from the middle layers with the lowest content of organic matter and impurities.

Optimal mix composition

The consistency of the mortar for laying ovens should be creamy, thick and viscous. To prepare the composition, oily clay is supplemented with 2 parts of sand.The proportions for clay raw materials of normal consistency and sand are 1: 1. The quality of the mass must be checked by fixing 2 bricks for a sample. After 5 minutes, the structure is lifted from the top. A high-quality bundle will withstand 2-3 lifts. The lack of adhesion indicates a poor-quality composition.

The stoves recommend supplementing the raw materials with table salt in the proportions: 150 g of salt to 10 kg of clay mass. The cement will improve the binding qualities of the material, which is added at the rate of 1 kg of cement (grade M400) per 10 kg of clay.

The laying of the sections of the chimney located above the roof is performed with lime-sand mortars due to the resistance of the material to moisture. Proportions of composition: 3 parts of sand, 1 part of lime dough or quicklime, 3 volumes of water.

Furnace mixtures are made using pure river sand. Sifted quartz white sand is optimal. Feldspar material with a yellowish tinge is suitable for all elements of the furnace except the firebox. Natural sand has a higher bonding power than artificial sand. Before preparing the composition, the material is cleaned of impurities using a sieve, then washed with water.

The clay oven mortar is made from quality raw materials. Clay is a micro-grained mineral supplemented with silicic and aluminum oxides. The material is distinguished by its bonding ability, plasticity, strength, and hygroscopicity. The sum of the characteristics is determined by a single value - the fat content of the composition.

For masonry ovens, an average saturation of raw materials is required. Excessively greasy composition cracks when dry. Raw materials unsaturated with minerals will not work either.

Types of clay solutions for stoves and fireplaces

When laying the stove, depending on the temperature regime of the zone being built, several types of mortar are used:

- 1200-1300 С - clay-fireclay and cement-fireclay;

- 1100 С - clay-sand mixture;

- 450-500 С - lime-sand;

- 220-250 С - cement-lime;

- range of atmospheric temperatures (furnace foundation) - cement-sand mixture.

Of the listed masonry mortars, clay or chamotte made from it are included in three mixtures: clay-sand, clay-chamotte and cement-chamotte).

Consider these important components of masonry kiln mixes.

Checking the quality of the solution

The first test is carried out before preparing the clay for the brickwork of the oven. In order for the solution to come out of high quality, it is necessary to accurately identify the fat content of the clay. It will depend on this, what additional components are required.

How greasy oven clay is revealed as follows:

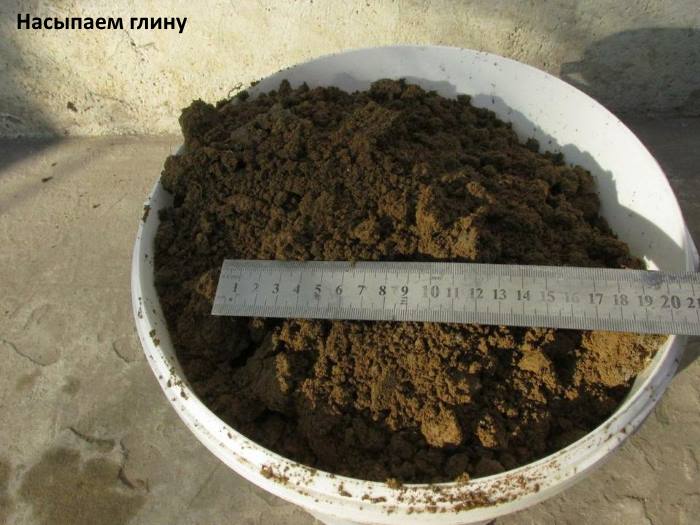

- A small amount of clay - about 1 kg - is thoroughly cleaned using one of the methods described and soaked for several days.

- The resulting mass is divided into five identical parts. Nothing is added to the first, the second is mixed with 25 percent sifted sand, the third with 50 percent, the fourth with 75 percent and the fifth with 100 percent.

- Each of the parts is kneaded separately. If necessary, add a little water until a pasty texture is achieved. You can determine the readiness of the solution with your hands. If it does not stick, the mixture is considered ready.

- The resulting material is checked for ductility. Each of the five particles is rolled into a small ball and flattened into a cake. All the resulting samples are marked with labels, which indicate the proportions of sand, and sent to dry. It will take 2-3 days for the fragments to dry.

- The resulting samples are tested. The cake should not be cracked or shattered when compressed. If you drop it on the floor, it should remain intact. Based on the results of such testing, the correct proportion of sand and clay components is revealed.

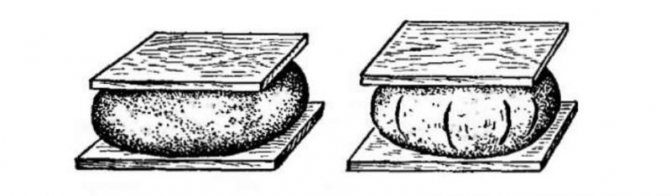

You can test for fat content and plasticity in another way. Roll into balls about 3 cm in diameter, placing each ball between two carefully rounded boards.Gently, smoothly press on the upper one, check the condition of the ball. If it cracks immediately, the composition lacks fat content. If cracks occur at half compression, the mixture is too greasy. With the correct proportion of the components, most of the specimen will flatten but not collapse.

Correctly formulated mortar does not crack immediately after application

Additionally, kiln clay is tested before use. Better to redo the mortar than waste time building a stove that will crumble. To check, the composition is scooped up by hand and rubbed with fingers. A good quality binder should be slippery and oily. Experienced stove-makers detect the readiness of the composition by ear when mixing.

Correctly made mixture "whispers" - makes a kind of rustling sound, and lags behind the shovel. You can also dip the trowel into the mixture, pull it out, and then turn it over. If a thick layer sticks, the composition is too oily, it must be diluted with sand. If the layer of solution falls off, there is an excess of sand, you need to add pure clay.

The main indicator is fat content. Distinguish between oily and skinny clay. The first, when dried, significantly decreases in volume and cracks, and the second crumbles.

Clay can be oily and skinny

Immediately, we note that there is no strictly defined ratio of sand and clay to obtain a good solution. The proportions are determined experimentally, by selection depending on the fat content of the breed.

You can determine the fat content of clay rock in the following way. Roll up the rope of clay, assuming a thickness of 10-15 mm and a length of 15-20 cm. Wrap them in a wooden form with a diameter of 50 mm. If the clay is oily, then the tourniquet is stretched gradually, without cracking. Normal provides a smooth stretch of the rope and breaks, reaching a thickness of 15–20% of the original diameter.

Clay components of mortars for brick heaters

Fireclay refractory kaolin clay is best suited for masonry ovens

The clay composition differs depending on the added components:

- clay-sandy;

- clay-cement;

- clay-limestone.

Stove makers tend to choose the first option. Fractional proportions depend on which clay to use for the oven. If it is oily, the ratio of sand will be 2: 1, if it is medium fat - 1: 1. Also, with good quality clay, you can do without additives.

The strength, reliability and pleasant appearance of stoves and fireplaces largely depend on the quality of the masonry mortar with which they are laid. If some component is not enough or too much, the seams will crack. As a result, smoke from the stove will begin to pass into the room, and fuel costs will increase, since due to excess air supply, it burns faster. Or you can not waste time calculating the proportions, but buy a ready-made composition.

We offer you to familiarize yourself with: The project of a bathhouse with a flat roof. Bath roof - basic recommendations for the selection of the type and building instructions (90 photos)

Masonry mixture for fireplaces and stoves consists of a binder, aggregate and water. If there is only one knitting element in it, then it is considered simple, if two, then complex. The main characteristics are strength and ductility. At the same time, according to plasticity, they are divided into 3 types: skinny, normal, fat.

Clay is a sedimentary rock of fine-grained structure, the forming substance of which is kaolinite, consisting of a mixture of silicon oxides (47%), aluminum (39%) with water (14%). The name kaolin comes from the Chinese area of Kaolin, where such white clay was first discovered. In the presence of iron ions of various valences in kaolin clay, the color of this material can be different - yellow, red, brown, blue, green, but this has little effect on the physical properties.

Clay pit and a clay sample of plastic consistency

Chamotte is a powder obtained by crushing pieces of clay that have sintered during high-temperature firing and have lost molecularly bound water. The size of the chamotte crumb fractions after crushing or grinding is from 0.2 to 2.5 mm. Sifting chamotte powder allows you to separate fractions by size, after which finely ground powder is often called chamotte clay, and coarse - chamotte sand, but the chemical composition and properties of these materials are identical - high heat resistance and low water absorption.

Fireclay filler of industrial production and packaging

The degree of clay sintering depends on the value (or) and duration of high-temperature exposure, which determines the division of chamotte into:

- low-burned - firing temperature 600-900 C, water absorption up to 25%;

- high-burned - for ordinary firing at 1300 C and water absorption is less than 5%, for special-quality ones - at 1500 C with water absorption of less than 2%.

Instructions for use

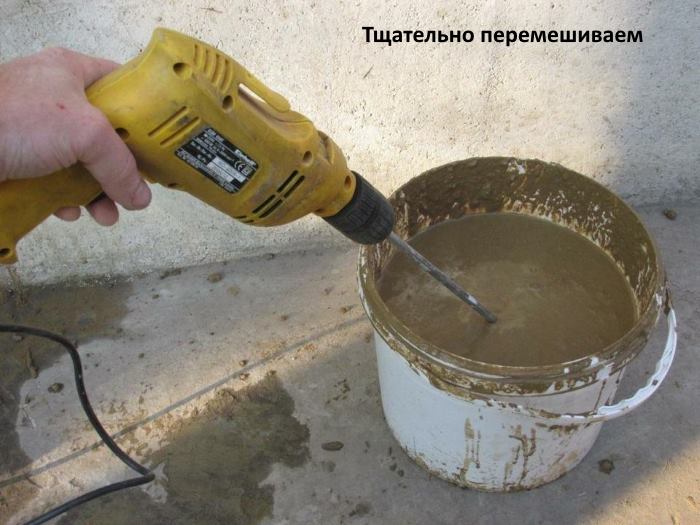

Ready solutions should be poured with the volume of water specified by the manufacturer and mixed with a mixer or use a drill attachment. Mixing with tools is mandatory as it is difficult to do it by hand, which requires more water to be added to the composition. This, in turn, contributes to a change in the characteristics of the mixture.

Dry ingredients are poured into warm water, thoroughly mixed, after which the composition should be left to "rest" for an hour. In consistency, you should get a mixture that resembles thick sour cream. If it breaks, then add water. If, when raking the composition with a trowel, a trace of it remains on the surface, then there is too much liquid - when raking the solution with a trowel to the side, it should keep its shape well and not tear.

When using ready-made mortars, you can additionally not soak the bricks, since dry mixtures are characterized by a water-retaining capacity, which makes it possible to shorten the installation time of the furnace and reduce the drying time of the masonry.

Methods for removing impurities

The kiln solution requires clean sand. To separate it from impurities, it must first be sieved and then washed. For sifting, a fine-mesh sieve with a mesh size of 1.5 mm is used. Next, the sand is washed like this: a sacking with a sagging is pulled onto the holder (a kind of net should be obtained), into which the sand mixture is placed.

The clay is stirred with water and left to soak

To remove impurities from the clay, it is washed. Crushed, placed in the upper part of an oblong container (for example, an old trough or bath). Place the container at an inclination of 4–8 °. Water is poured into the lower part so that it is at the top and does not touch the clay. Clay is washed with a small spatula or iron scoop.

The sand is sieved through a fine mesh sieve

If you bought a packaged dry clay, you need to soak it. The process of saturating clay with water is quite simple. For work, a wide and deep container is taken, dry clay is poured to a level of 10–20 cm, leveled and water is added. The amount of water - so that everything is completely covered. After a day, it is thoroughly mixed with a shovel, if necessary, liquid is added and again left for the same period. When everything turns into a paste, we can assume that the clay is ready. This is repeated several times until all the required amount is soaked.

The first step is to remove impurities from the natural clay stored for oven laying. There are different ways to do this.

Dry punching

You can wipe the clay through a sieve dry or soaked

The most primitive way. Use your hands to select everything that is superfluous - grass, pebbles, debris, grind large lumps. After that, the plastic material must be rubbed through a metal sieve with cells of about 3 mm.

The method can be made slightly less laborious by drying the clay.To do this, clay lumps are laid out on a wooden canvas and dried in the sun. In winter, this is done in the cold, laying it under a canopy so that it does not get covered with snow. With a small amount of material, they are placed indoors, on a heated stove or on a heating radiator. The speed of drying depends on the size of the lumps: the smaller they are, the sooner they dry.

Pour the dried clay into a box with thick walls and grind with a tamper. After grinding, clay dust is sieved through a sieve with fine meshes to remove various inclusions from it: pebbles, chips, and other debris.

"Dry punching" is a rather laborious task, therefore it is more expedient to soak the clay after manual cleaning for 2-3 days.

- Place the material in a large basin in layers of 12-15 cm, wetting abundantly.

- Pour in water at an approximate ratio of one to four to the clay.

- When the mass is soft, mix with a concrete mixer or other means.

- Wipe through the wire mesh 2–2.5 mm.

The bottom layer - sand and stones - is not suitable for bonding bricks

There is also an older method of torturing:

- Several holes are drilled vertically in a wooden container with a small distance between them.

- Each of them, before filling the tub with a liquid clay mass, is muffled with a wooden stopper.

- Grains of sand and a variety of small stones precipitate first due to their greater weight.

- Subsequently, after settling, clay particles settle to the bottom.

- The upper layer of water gradually becomes lighter, but you need to wait until the liquid becomes transparent. As soon as the border of the clarified moisture drops slightly below the first hole from the top, remove the plug. The settled water flows out of the container.

- After the appearance of the next level of settled liquid, take out the next plug.

This process is repeated until all clarified water is completely drained. To speed up the precipitation after loading the solution into the tub, you will need to add bitter Epsom salts - about one pinch per bucket. If there is no wooden barrel at hand, it can be successfully replaced by a metal container suitable in height and volume. The principle of operation is the same with one difference - first, short lengths of pipes are soldered into the holes, plugs are installed in them.

When all the settled liquid is drained, the liquid clay is transferred to a wide box and left in the sun to evaporate excess moisture. After the dried material ceases to be fluid, stir it periodically with a shovel. As soon as the mass becomes similar in texture to thick dough and stops sticking to the palms, it is covered with polyethylene or oilcloth and stored until the start of the oven work.

DIY oven solution

Before starting the preparation of the solution, the clay is soaked for a day in a small amount of water. After that, water is added, with the help of a small stick with a shovel-like end, the clay is mixed with water until the consistency of sour cream. A trowel can be used to check that there is sufficient water. The trowel should not leave gaps; an even plastic trace (furrow) should remain behind the tool. The finished mixture is sieved through a large mesh sieve. After that, add sand to the solution and mix thoroughly.

The drill mixer ensures uniform mixing. Thanks to this, there will be no cavities with "clay milk" in the solution.

Using a drill mixer will greatly simplify the mixing process. Drills are both specialized and in the form of a simple attachment for a drill or hammer drill, which operate at low speeds. The finished solution should not stick to your fingers, and water (sludge) should not flow on its surface. For the masonry of the firebox, a one to one proportion of clay and sand is often used. Chamotte powder is added to the mixture.

Clay solution and technology for its preparation

For the construction of the foundation and the chimney, it is recommended to use a composition based on lime and cement.

A special dough made by mixing quicklime and water in a 3: 1 ratio. Sifted sand is added to the finished dough through a fine mesh sieve in a ratio of 3: 1 - for 3 volumes of sand 1 volume of dough. The finished mass is diluted with water until a thick mass is obtained.

A lime-based mixture for laying a kiln turns out to be quite plastic and durable.

The fat content of the lime composition is determined by the amount of sand. For an excessively fat mixture, 5 volumes of the sand component are required, for a normal one - no more than 3 volumes.

Strength and water resistance can be increased by adding cement. To prepare such a composition, it is necessary to use components in the following proportions (parts):

- Cement - 1;

- Sand - 10;

- Lime dough - 2.

The preparation of the solution has the following sequence of actions: the cement and sand components are combined in a separate container. The finished lime-based dough is diluted with purified water until a thick consistency is obtained. Bulk components are introduced into the diluted dough and mixed. To increase the viscosity, the composition is diluted with water.

The main characteristic parameter of this material is fat content, which combines the degree of plasticity, strength, water resistance, as well as adhesion before and after curing.

In nature, there are three types of clay - lean, medium fat and oily, there are no clear boundaries between them.

The belonging of a material to one of the types is determined by simple mechanical manipulations, the most accurate of which is performed as follows.

About half a kilogram of clay is mixed with water until a homogeneous pasty consistency is obtained, after which a ball with a diameter of about 5 cm is formed from the resulting mass.

The ball is placed between two pieces of glass, which are slowly squeezed, observing the formation of cracks in the clay:

- the destruction of the ball at the beginning of squeezing indicates a low fat content - thin clay;

- the appearance of thin cracks after reducing the diameter of the sample by 1/3 of the initial value indicates that the clay is of normal fat content;

- if cracks appeared only when the ball was squeezed to half the diameter, a mass of high fat content.

We suggest that you familiarize yourself with: How to overlay a stove in a bath, a diagram of a brick lining of a stove in a bath (13 photos)

Determination of the fat content of clay by squeezing: on the left - fat, on the right - normal.

The main factor affecting the fat content of clay is the percentage by weight of sand in it:

- 15 to 30% are skinny;

- from 5 to 15% - medium fat;

- up to 5% - fatty.

When performing furnace work, different solutions are prepared and for different purposes:

- installation of the foundation;

- oven masonry;

- plastering and facing work.

For these purposes, solutions are used:

- clay;

- lime-clay;

- sand-cement;

- lime.

The stoves are placed on a clay mortar, adding a little salt or cement for strength. Many people use only clay with water, no additives. To facilitate the mixing of the solution, some stove-makers make wooden flooring from boards with low sides. The wide working area of mixing allows for better preparation of the solution.

The stoves are placed on a clay-sand mortar

First you need to determine how much material you need. The calculation is as follows: when laying 50 pieces of bricks flat with a seam thickness of 3-5 mm, about 20 liters of masonry mixture will be required (increase by 15-20% if we are building a Russian stove).

Clay mortar is used for the main structure of the kiln, it can also be used for cladding. Consists of clay, water. Aggregate is sometimes added: sawdust, shavings, construction sand. The clay mixture is prepared in the following proportion: 1 part of filler is added to 2 parts of clay.More often than others, clay-sand mortar is used for laying the furnace.

The components are mixed into a homogeneous mass until a creamy state. The masonry mass should come off the shovel well and leave no marks. Also, separable water should not appear on the surface - if this happens, you need to add sand. To give greater strength, salt is added to the solution: 100–250 grams per bucket of solution. Less commonly, cement is used - 750 grams per bucket.

How to prepare a mortar for laying stoves is demonstrated in the video. At the same time, you will see the consistency to which you need to soak the clay.

Sand-cement mortar is used to level the surface irregularities and lining the furnace (tile, mosaic, stone). Cement mortar for the kiln is used for sealing joints, when laying the foundation. It is prepared as follows: the required amount of building sand and cement is measured, mixed well, poured with water to the desired consistency - such a state when it is sufficiently mobile and squeezed out of the seam without much pressure. The proportions of materials depend on the brand of cement composition, most often 1: 2.

Lime is used as a mortar for plastering ovens, for laying foundations and pipes. Cooking it is fundamentally different. First, lime is slaked and kept in a special pit for about a week. After that, a solution is prepared with sand. The C ratio depends on the fat content of the lime (usually 1: 2 or 1: 3).

For plastering the furnace, lime-clay mortars are used with the addition of asbestos to give greater strength. The proportions of the solutions are as follows:

- clay-lime dough-sand-asbestos 1: 1: 2: 0.1;

- clay-sand-cement-asbestos in the same ratio;

- gypsum-sand-lime dough-asbestos 1: 1: 2: 0.2.

The cooking technology consists in combining all dry components and adding clay, gypsum or milk of lime diluted with water. Then the components are mixed until smooth.

There is a refractory (chamotte) mortar for laying the core of furnaces. For its preparation, chamotte and refractory clay are mixed in a 1: 1 ratio, then water (one fourth of the clay mass) is added and mixed well.

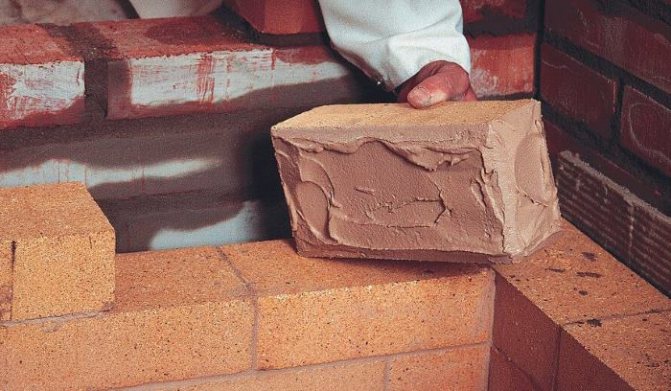

This is what a good solution looks like on fireclay brick

It is necessary to monitor the quality of the solution. After all, only a sufficiently plastic composition is able to ensure good adhesion of the oven masonry and the tightness of the seams.

Clay is one of the best options for laying a brick oven. But you should not use it for chimneys and foundations, as it collapses due to high humidity. For manufacturing, you will need fine sand (up to 1 mm) and good quality clay. The sand must first be sieved through a sieve to remove debris and small stones.

The maximum temperature that the clay mortar can withstand is 1000 ° C. Moreover, its volume during heating changes in the same way as a brick. Therefore, the masonry remains intact and strong. Compared to others, the consumption of the clay mixture is higher. So, for laying hundreds of bricks, you will need 2 buckets of clay and one and a half sand. Consumption can be reduced if the composition is passed through a sieve, and the seams are made thinner and use a building material that is even without chips.

It is recommended to pre-soak the clay in two days, then it will become more plastic. To make the composition as thick as sour cream in consistency, the clay is passed through a sieve, in the same way the sand. After mixing with the desired ratio of components, it is sieved again. Then it will turn out to be as homogeneous and high quality as possible.

Guide: how to check quality

To find out the quality of clay and whether it is suitable for laying fireplaces and stoves, you should make several solutions with different proportions, or rather, 5 mixtures consisting of the following components:

- clay without any additives;

- the same ratio of clay and sand;

- clay and 10% fine sand, as well as 25 and 75% sand.

Each of the five compositions is thoroughly mixed dry, and then water is poured. It is added until the mixture looks like a thick dough that sticks to your hands. To check for quality, the same amount of test is taken from each. The resulting portions are formed into balls with a diameter not exceeding 5 cm.

But you can use a faster way to check for quality. The ball fits between two boards slightly larger than itself. After that, the top board is pressed on it until cracks appear. If they appeared immediately, then it has weak plasticity, which means that the ratio of the components is chosen incorrectly.

Such a composition cannot be used for a brick oven. If cracks began to appear in the ball only after compression by 30%, then the proportions of the components were selected correctly. It is considered the best option for laying fireplaces and stoves. If cracks appeared only after the ball was flattened by half, then it has too high plasticity.

Truly working legal way to save money. Everyone needs to know this!

There is another method of quality control. For this, tourniquets are made and wound on a stick 5 cm thick. If no cracks appear on it, this indicates high plasticity, the tourniquet is cracked and torn - low plasticity. If rare cracks are visible, and it remains intact, a solution of good plasticity with the correct ratio of all components.

For the construction of the foundation of the furnace and the construction of a chimney above the roof, formulations with lime are used. You will need water, sand and lime dough. To increase the strength, cement is added to it, and gypsum is added to reduce the setting time, but it is usually poured only for plastering work.

The quality depends entirely on the lime dough. An amount of water is poured into powdered or lumpy lime so that it cannot boil. The dough preparation process takes almost half a month. During this time, it should be covered with a little water. The ready-made lime must be stored for a month before using it to mix the solution.

Masonry mortar preparation. Determination of fat content

The process of preparing the masonry mortar itself is simple. Earthen milk, sifted sand are taken in the required proportions, thoroughly stirred with a mixer until smooth. The difficulty lies in determining the proportions, since even within the same deposit, clays can have a significant spread in fat content. Actually, the whole subtlety consists in the correct determination of the fat content of the solution.

Furnace literature describes methods of sculpting sausages, wrapping them around a stick, tensile and break tests, rolling balls and squeezing them between two planks ... Actually, they are all obscure and incomprehensible for a beginner. Therefore, it is better to apply something else.

Pechnik Mikhailov S.P. in his book proposed an original method for determining the fat content of a mixture. With small additions, it can be safely recommended for both beginners and experienced craftsmen.

First of all, they take some kind of standard container. For example, a tin can. It will work as a single measure of volume. Using this container, several samples are made with different contents of clay and sand. The ratio is 1: 1, 1: 2, 1: 3, 1: 4, 1: 5, 1: 6. Mix well each test batch. And watch how she behaves. You can make samples on all six, but here it is just to mix them up and get confused. Therefore, the mixture is first assessed by its behavior on the trowel and tactile sensations.

First, they watch how each of the parties sticks to the trowel. Just stir the mixture with a trowel and remove it. Almost all of the thin mortar comes off the trowel, practically without lingering on the trowel. Normal solution adheres evenly. The fatty solution lays down in separate lumps.

Additionally, check by touch, rubbing the solution between the thumb and forefinger. A normal solution feels like solid grains, evenly slippery, like soapy. If the solution looks more like an abrasive, it is skinny. If there are pronounced slippery areas without signs of abrasive, it is oily.

Having selected the closest to normal out of six test batches, they finally make a conclusion on the suitability. A small ball is molded from each selected batch - somewhere like a lump of snow for playing snowballs. And this lump is thrown onto something iron. It doesn't matter which one. On a sheet of iron, the wall of a bucket, a peeled bayonet of a shovel. Something metallic and more or less smooth. They are thrown with such an effort so that, upon impact, a cake with a thickness of five millimeters is obtained. And a leaf with such a cake is left to dry in the shade.

Without trying to force the process. It should dry out to a leathery state or a little stronger.

If the cake is cracked or easily peels off the metal, without even falling apart, it is a greasy solution in a single piece. It is required to add sand.

If the sample on the metal looks more like street dirt and is easily cleaned off with separate grains, like sand, the solution is skinny. The addition of clay will not hurt.

A normal solution adheres firmly to the metal, it is difficult to clean off. As soon as a similar result is obtained, they find out from which batch the sample was taken. Consequently, this proportion turned out to be optimal. And now the oven solution is prepared in exactly this ratio.

In terms of density, the masonry mortar should be like thick sour cream. Although there may be variations - as it is convenient for anyone.

Clay components of mortars for brick heaters

One or another type of clay oven mixture purchased in a store is prepared according to the instructions on the package, there are no questions here.

If it is decided to use a home-made mortar for laying the stove, then the main conditions on which the quality of the mixture preparation depends are two - the correct preparation of the components and the observance of the proportions of the components.

Using the example of a clay-sand mortar, we will consider the preliminary operations and mixing rules.

Using the data in this table as a basis, you can achieve high quality masonry mortar by slightly adjusting the proportions with reference to the parameters of the components used.

The natural clay prepared for the stove must be cleaned of foreign impurities - everything foreign (plant remains, stones, debris) is manually removed, and large lumps are broken. Then the mass is rubbed through a metal mesh with a mesh size of approximately 3 mm.

We suggest that you familiarize yourself with: Mortar for laying a brick oven: proportions and how to prepare

Such "dry punching" is a laborious procedure, therefore it is more rational to pre-soak the manually cleaned clay for 2-3 days in a tin trough - lay in layers of 12-15 cm, wetting them abundantly, then cover the entire bookmark with water (approximate ratio: 1 part of water per 4 parts clay). After 2 days, mix thoroughly with your feet or with a mixer and rub through a sieve with a mesh of 2-2.5 mm.

Ways to soak clay

Sand is prepared during soaking. Fireclay sand does not require preparation, except that it is sieved if purchased in bulk. And river sand must be sifted through a sieve with a mesh of 1-1.5 mm, then rinsed with running water in a container until the turbidity disappears and laid out on a clean inclined plane in order to remove moisture residues as much as possible.

There is no strict ratio of the volumes of these components, since any clay initially contains some amount of sand. Therefore, the proportion can be from 1: 2 to 1: 5, ideally the clay should only fill the voids in the solution between the grains of sand.

In order to have an approximate idea of the volumetric ratio of the components, the bucket is filled 1/3 part with a clay suspension when it is ready, and then sand is poured along the edge.The materials are thoroughly mixed in any container to the desired consistency with the addition of the required amount of water. The readiness of the mixture for laying the furnace is checked as follows - it should be held on the trowel after turning its plane by 1800 and slide off it when it is in a vertical position.

Testing the readiness of clay-sand mortar

If the mixture falls from inverted to 180

base, then you need to add clay to it. If the solution does not slide off the vertical plane, add sand. After correction, the check is repeated.

By testing the solution in this way, an approximate volumetric ratio of the components is obtained.

Clay-sand mortar is used in furnace zones with temperatures up to 1000 0C. Full or partial replacement of river sand with chamotte sand allows you to use the mixture for laying a furnace with an operating temperature of up to 1800 0С, including in places of direct contact with a flame.

Variants of the classic style of stone ovens

Functions of the solution in the structure, its properties

Traditionally, there are several ways to build household stoves. If we discard those rarely used today (for example, adobe or adobe bricks), then in the dry residue we have one familiar massive furnace made of red ceramic bricks, erected on a clay-sand mortar.

Masonry mortar holds all structural elements in place, seals it. Actually, a correctly calculated and erected stove should not fall apart even if, for some reason, all the solution from the seams disappears. So the solution in the structure plays the role of a sealant and some stabilizer that holds all the elements in a single order. Therefore, the mortar must firmly adhere to the brick and have a certain degree of strength. This is achieved by selecting the composition of the solution for fat content.

The second important property of masonry mortar is fire resistance. It should not burn out or release any foreign substances when heated. In this case, it is required to withstand a temperature approximately the same as the brick itself.

Another important point. When heated, any material expands. Some are subject to thermal deformations to a greater extent, some to a lesser extent. But absolutely everything is expanding. Simply put, CTE (coefficient of thermal expansion) is characteristic of all materials, but each has its own parameter.

The furnace operates in a wide temperature range, therefore, the CTE value and its difference for different materials are important to take into account. And, sometimes, somehow compensate. In brickwork, the CTE difference cannot be compensated for. Consequently, the CTE of the binder of the masonry mortar and the brick itself must coincide. Which can be solved quite simply. The main component of the solution is clay - exactly the same clay is used to form a brick. After firing, the clay is sintered and changes its properties. But the CTE remains the same.

Fireclay bricks are laid with a mortar based on refractory clay, and red brick - based on red. In the first case, chamotte, a ground shard of baked clay, serves as a weaker. In the second - ordinary sand

It is not a problem to purchase ready-made masonry refractory mortars. Moreover, the volume of fireclay masonry in household stoves is small. But with the preparation of a clay-sand mixture (when designating a mixture, it is customary to indicate the binder first, and the weaker second), problems may arise. Now there are ready-made works on the basis of red clay on sale. But most stove-makers still prefer to prepare the solution on their own.

Proportions and mixing of the solution

You can not add sand to clay of medium fat content - it has the correct proportions of the components 1: 1

In addition to cleaning before mixing, the clay for laying the stove must be prepared. The material is laid out in a box or barrel upholstered with metal, filled with water so that the liquid covers it entirely.If there are large lumps, they need to be broken into smaller pieces in advance. Everything is mixed well and left for a couple of days.

The clay composition should be of a pasty consistency, without impurities. If, after 48 hours, small lumps are found in the mass, it must be mixed again, broken all seals and kept for another day.

After preparation, you can start preparing the solution. If clay is mixed with sand, the latter is poured into a prepared container, then plastic material is laid out, and a sand layer is again poured over it. A shovel is used to mix the components. If moisture appears at the top, add a little sand. Topping up with water is required in an overly dry composition. The solution can be considered ready if it slowly slides off the shovel and becomes uniform.

If the base is medium fat, you do not need to add the sand component. Step-by-step instructions for breeding clay without sand for the stove with your own hands:

- The material is laid out on a wooden platform in layers, each layer is moistened.

- Upon reaching a height of 30–35 cm, the mass is mixed. For this purpose, you need to spank the upper layer with the back of the shovel.

- The kneading continues until a homogeneous substance is formed.

You can check whether the masonry clay for the stove has been prepared correctly as follows: apply a thin layer on the red brick, put another block on top and leave it for an hour or two. If, when lifting the upper brick, the lower one does not fall off, you can use the composition for the construction of the stove. Clay sets for a long time, you can immediately mix the required amount of binder. It will take about 20 liters to lay out a 50-brick stove for a bath, and to build a Russian stove 15-20 percent more.

Failure to comply with the proportions of the components of the solution lead to cracking of the structure

How to dilute clay for oven putty:

- The dry base is ground and soaked.

- Sand with lime or cement is introduced. Proportions of medium-fat clay with sand and lime 1: 2: 1. When including cement powder, it is necessary to proceed from the amount of the sand component in a ratio of 1: 3.

- To make the plaster layer stronger, you can add asbestos, fiberglass, hemp or straw in a 1: 2: 0.1 ratio (clay / sand / additives).

When additional ingredients are included in the clay solution, they are first mixed with each other, and only then with the previously soaked clay.

The plasticity and fat content of the masonry mortar are regulated by the addition of sand. You can determine the proportions as follows:

- Take a little clay and distribute it into 5 equal parts, of which we put sand in 4 portions in the amount of 1/4, 1/2, 1 and 1.5, and leave one without sand. After adding water, we knead each separately. The resulting blanks must be plastic and not stick to your hands. Flat pancakes are formed from them and dried. The quality of the mass is determined in this way: if the workpiece crumbles, then there is more sand than necessary, and the presence of cracks indicates its lack. It is optimal if the sample remains without cracks and is homogeneous.

Good mortar does not crack after drying

- You can do it easier: moisten a spatula in water and lower it into a clay solution - if the batch does not stick and the trowel gets almost clean, then the solution is suitable for masonry. In case of sticking, add sand, the clay is oily.

- Leave the clay solution alone. If after some time he pushes water to the surface - the clay is thin, you need to add more of it to the batch.

- Dilute a bucket of clay with water until it becomes sour cream. Dip a wooden stick into it and determine the thickness of the adhered layer: if 1 mm and insignificant plasticity, you need to add clay, if the layer is thick and too plastic, gradually add sand (1 liter per bucket). It is necessary to achieve normal fat content, that is, the adhesion of a layer of 2 mm and individual clots.

Having determined experimentally the necessary proportion of the ratio of sand and clay in the future solution, we proceed to the preparation of the basic materials.

Solution for other cases

A little cement can be added to the solution. Approximately a trowel for a bucket. It is better to lay out the fireboxes nevertheless on clean clay and sand. These are the recommendations of the Finnish stove manuals. And, it should be noted, a very useful advice - the results are good.

When you need to cover up cracks in the masonry or for some other repair, it is good to add ordinary table salt to the solution. Somewhere a pound per bucket. The solution then turns out to be stronger, more reliably adheres to the surface of the brick.

Many, when installing the cast-iron flooring of kitchen stoves, do not use a pure solution, but add a little sheet of asbestos, previously soaked in water, to it. They tear up sheet asbestos into small pieces (you don't need much) and soak the pieces in water. In just a few minutes, the scraps disperse into separate fibers, capable of reinforcing a fire-resistant masonry mortar. Therefore, the asbestos slurry obtained in this way is kneaded with sand and clay, and then used when installing cast iron plates. The same composition is also suitable as the first layer (spray) when plastering ovens. Subsequent covering layers are already applied without asbestos.

Main components

Used for furnace foundations that are not exposed to heat. Cement and sand are taken in a proportion depending on the brand of binder: M400 - 1: 4; M500 - 1: 5. The dry ingredients are sieved and mixed with water. The viscosity is checked by the degree of adhesion to a wooden oar or a shovel handle. It hardens quickly, therefore, the batch must be prepared immediately before work.

The composition of complex solutions depends on the place of their application. To protect the foundation and the street part of the chimney from moisture, you can make a cement-lime mixture, for the main body of the furnace - a cement-clay mixture. They will increase the strength and water resistance of the masonry.

The preparation of a multicomponent mortar is reduced to mixing one part of cement, three portions of lime dough and 5 to 15 sand. Kneading is done with a shovel or mixer. First, a conventional lime mortar is prepared, then cement is added and water is added. In another way, dry ingredients are mixed and poured into the diluted dough. It must be used within 45 minutes, otherwise it will lose its plasticity.

https://www.youtube.com/watch?v=78fqp8T0NoM

It is not difficult to make a high-quality mortar for stove masonry yourself if:

Tags: bath, clay, stove

«Previous post

The difficulty of self-preparation of the mixture

The advantage of preparing masonry material from ready-made compounds is ease of operation. You will need a capacious container, a mixer or an electric drill with a nozzle. A manual kneading method is also possible, but it requires physical effort. It is advisable to avoid adding too much water as it will this will reduce the performance of the composition.

The solution must be prepared in parts as work is done. The mixture is not allowed to freeze, because repeated mixing will disrupt the structure of the raw material.

The manufacturer's recommendations for the proportions of water and dry material must be followed. The volume of the liquid is also affected by the temperature in the room. Less water is required in cooler weather.

To prepare the composition, the dry mixture is poured into warm water. The mass is thoroughly mixed, the raw material should turn out to be creamy.The solution is allowed to brew for 1 hour, then thoroughly mixed again.

Ready-made styling compositions have a high water-holding capacity. When laying, additional moistening of the blocks is not required, which speeds up the work process and shortens the drying time.

The elasticity of the mortar allows making thin seams (2-4 mm). The walls acquire an aesthetic appearance and do not form cracks. When applying heat-resistant raw materials indoors, it is required to maintain a temperature of at least 10 ° C and not higher than 35 ° C. The mixture is spread on blocks with a layer of 10-12 mm.

During the independent laying of the firebox, foundation part, chimney, external wall panels and facing work, it is necessary to mix different types of compounds. The underground part is laid using a standard cement mixture. For walls that are exposed to high temperature conditions, a clay composition with the addition of plasticizers is required.

It is important to determine the required fat content of the clay - the main component of the composition. Material should be tested; compression cracks indicate excessive sand. Seams made of unsaturated clay crumble over time, the structure deforms. Too greasy material leads to shrinkage.

We offer you to familiarize yourself with: Technology of filling walls for painting

Adding cement to the compound will increase the strength of the joints. But it should be borne in mind that the substance will enhance the adhesion of the mixture, therefore, it is required to dilute the solution in small proportions.

It may take several days to prepare different types of mixtures on your own. The clay must be soaked in advance; some of the components need to be carefully sieved.