To whom in Russia floors are good

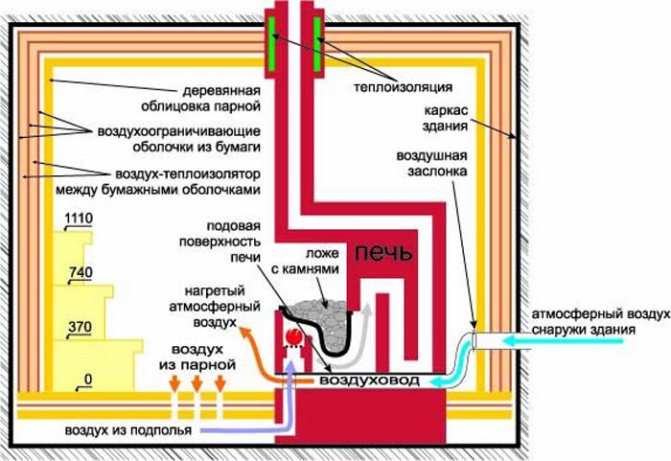

Warm bath floors were invented a long time ago, by the ancient Greeks, and were improved by the ancient Romans. However, retaining the Greek name for this invention - hypocaust.

From the point of view of convection and efficiency of the entire heating system, the hypocaust can be called the optimal design. However, this design also has disadvantages, and significant ones.

disadvantages

- First of all, the high cost and low maintainability. And the initial installation is a very troublesome process.

- The second drawback is the excessive tendency to dry out the air. In the bathhouse, with its high humidity, one could not be afraid of such a phenomenon. But if we are talking about a rest room and a dressing room, then ensuring optimal air humidity for a person becomes a real problem.

- The third drawback is the impossibility of vertical temperature zoning. If in an ordinary bath, if necessary, to cool down, it is enough to move lower (this rule is true, not only for a steam room), then in a room with a hypocaust you cannot count on this - the floor is hotter than at medium heights.

- Well, and the fourth serious minus is the wood's dislike for running out in humidity and heat. It seems to be warming up and drying, but in fact it turns out that the wood, baked on one side and moistened on the other, rots less, but dries up and warps.

From all that has been said, we conclude: warm floors in a bath are good not with wood, but in combination with other, less classic flooring materials, for example, tiles.

On the other hand, it is very tempting to feel a warm floor under your feet. But is there any point in all this trouble? Indeed, in a small bath, it is enough to splash on a wooden crate covering a concrete floor or tiles - comfort, and quite decent, is provided.

Advantages of underfloor heating in a bath

Has a heated floor in the bath and advantages, in addition to those mentioned. They manifest themselves only when it comes to large areas and when heating is installed in the bath, which allows it not to freeze in winter during long interruptions in operation.

Simply put, for bath complexes or large premises, you might think about how to make a warm floor in a bath. For small banks, this is simply an unnecessary waste of money and effort. Although the final decision is, of course, up to the developer.

System advantages and disadvantages

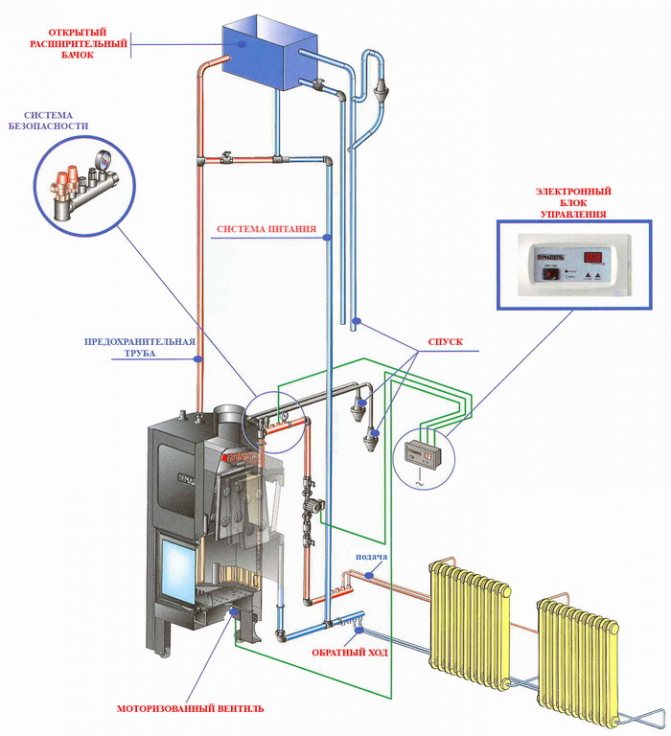

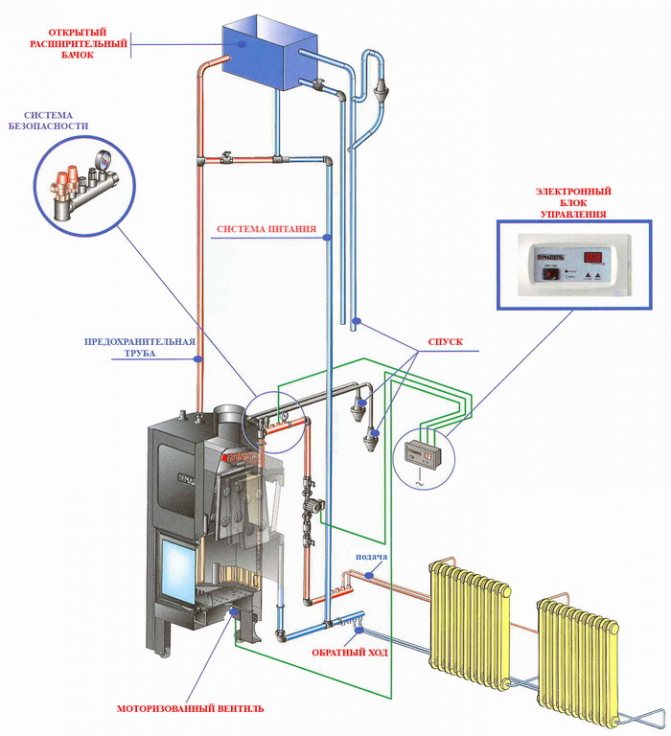

Diagram of a water heating system from a stove A heated water floor in a bath, powered by a stove, has the following advantages:

- No structural elements will generate electromagnetic radiation, like an electric floor heating.

- Such a system is considered environmentally friendly and harmless to humans.

- The ability to maintain a comfortable microclimate in the bath.

- Saving.

The disadvantages of the system include the following points:

- In winter, the water from the pipes will have to be drained so that the frozen liquid does not break them. Otherwise, the stove will have to be constantly heated. However, if you constantly heat the bath with wood, no savings will come of it. The only way out is to use antifreeze instead of water.

- The second disadvantage is that a lot of heat is spent on heating the storage tank, so the stove does not cope well with its main tasks - heating the steam room and washing room.

- With the simultaneous heating of the floors of several rooms of the bath, for example, a steam room, a rest room, a washing room and a shower, a large volume of heat carrier will be required, which will significantly increase the heating time.

- In such a bath, it will not be possible to install leaking floors.Otherwise, the insulation will get wet, and the system will become ineffective.

Varieties and features

Discarding the classic scheme of a hypocaust with a stove in the basement, we can say that there are two main types of underfloor heating - water and electric.

Water floors

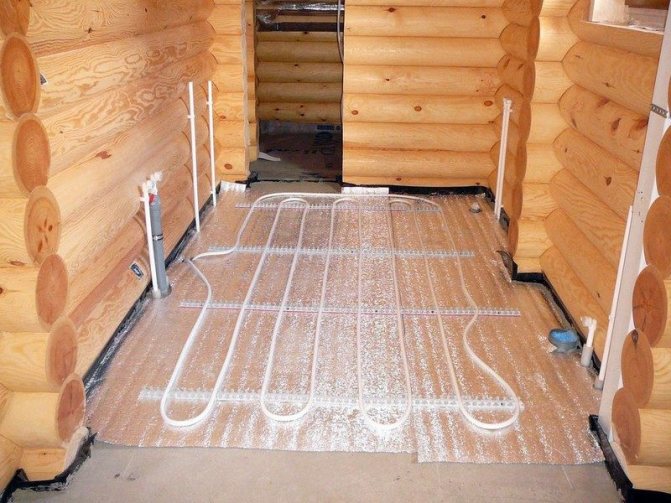

I would like to feel the warmth under my feet in the bath everywhere, including in the washing room and in the steam room - the solution would be a heated water floor in the bath. It is quite costly during installation and is practically not repaired - any repair, in fact, comes down to replacing the entire structure. But it has the lowest operating costs. And he is also not afraid of moisture, so he is good in a washing and steam room. So this is the most versatile option.

The heat carrier of a water-heated floor is most often water. Antifreeze or ethylene glycol is sometimes used. In any case, such a floor requires an autonomous heating boiler.

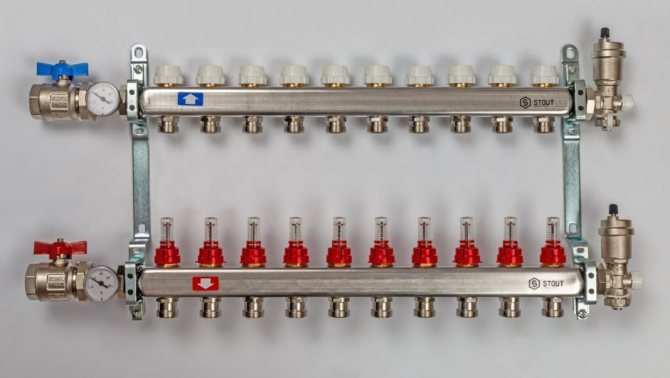

In this case, the boiler is needed directly in the bath. The idea of diverting the mains from the main cottage heater is usually bad and unprofitable. The system must not be allowed to freeze in winter. To adjust the entire underfloor heating system, you have to install a collector box - so the system turns out to be very cumbersome.

Some craftsmen recommend feeding the water floor system from the sauna stove. This cannot be done. Let me explain why.

- Firstly, you should not take away the heat needed to heat the stove.

- Secondly, the stoves are heated irregularly, and the water circuit just needs a clear periodicity - freezing is destructive for it. So there must be a separate boiler for the water floor.

Electric floor

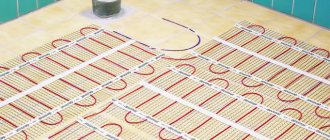

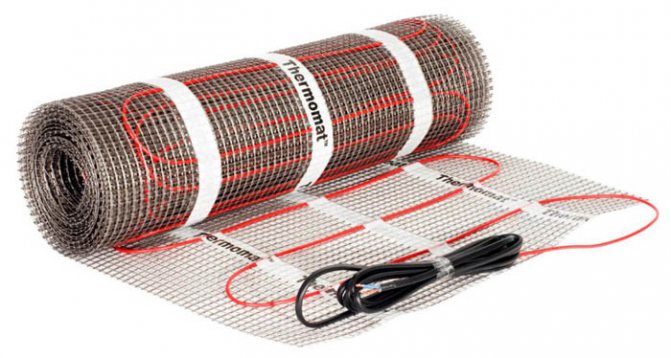

Lighter in weight and easier to install, it is worth recognizing the electric floor heating system. A warm floor in a bath with your own hands is the easiest way to do just this. Electric floors are of two main types. First, in the form of mats. The second, in the form of a heating wire, is laid, like water pipes, in zigzags.

Electric underfloor heating systems are simple. Roll mats are easy to repair and easy to install. However, they are completely unsuitable for washers and steam rooms. Even with all the precautions.

More precisely, at the time of using the steam room, these systems must be de-energized for safety reasons. And, taking into account the human factor, it is easier not to put them in humid rooms at all.

A significant disadvantage of electric floors is the high cost of operating costs and the need for increased electrical power. But they are very light and are not afraid of frost. It is worth mentioning the ease of adjustment and changing the heating mode.

Warm water floors from a wood stove in the house

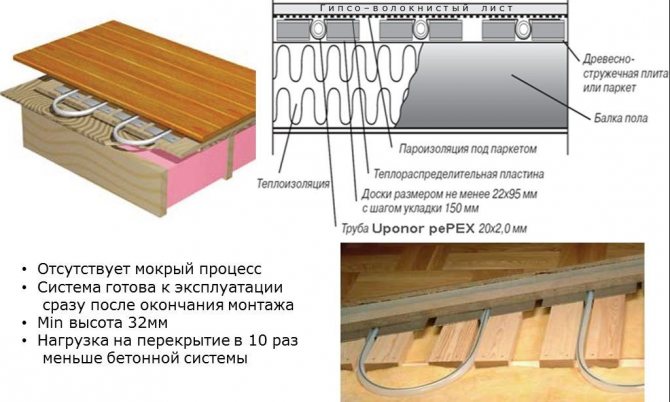

This heating scheme can be implemented for a private house. Condition - the power of the furnace must provide heating of the entire coolant for a long time. This requires a good indirect heating tank of at least 1000 liters. Oxygen barrier XLPE pipes. Their installation is done on a special substrate.

Features of the organization of the underfloor heating system from the stove in a private house:

- collector wiring is required;

- pressure stabilizer, if two or more collectors are installed;

- the maximum length of one circuit for a pipe of 16 mm is up to 70 m.

It is important to ensure uniform heating of water in all circuits. This requires manifolds with thermostats for each section of pipelines.

Underfloor heating base

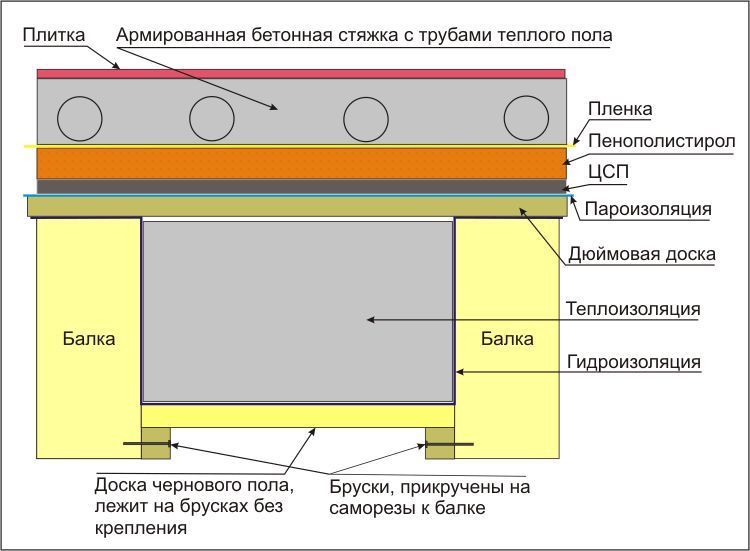

The best option for a base for a warm floor in a bath is a concrete floor. Wooden floors will also work. The main thing is not to forget to insulate it - there is no point in heating the subfloor.

It will not be possible to combine a warm floor and crevice water removal. Underfloor heating can be done only where there is drainage along the slope into the ladder. In the rest room and dressing room, of course, there is no such restriction.

The slope in the bath room is made with a screed. With a screed thickness of more than 3 cm, a reinforcing mesh is used.

If you are going to lay tiles on top of the heaters, then the concrete floor is definitely the best base - if only because of the rigidity of the structure.

When pouring the screed layer in which the heaters are located, a damper tape must be laid around the perimeter of the room - it plays the role of a compensator during linear expansion from temperature changes.

Floor insulation can be very diverse. Cork, expanded clay, foam glass. If you do not want to once again make the floor heavier and fill the heating element with concrete (screed), this is especially important for infrared heating elements, then you should use special foam polystyrene plates - they have channels for fixing elements of the heating system.

The distance between the turns of the floor elements must be maintained according to the manufacturer's recommendation, but not more than 40 cm. A larger distance will give uneven heating.

The location of the furniture in the room should be taken into account. There should be no heating elements under it. This is an unnecessary waste of heat and unnecessary damage to furniture.

It is good to lay something foil under the warm floors. And the dampness from the basement will not go, and as a heat reflector will do.

Electric floor

The two-core cable is easier to lay as there is no need to connect the other end to the thermostat

Externally, a cable for floor heating is very similar to an ordinary TV wire. But its functional purpose is completely different. The heating cable converts electrical energy into heat and transfers it to neighboring materials. The main indicator that characterizes different types of electrical floor heating systems is the specific heat generation. On sale you can find systems with an indicator from 150 to 400 W / m². But an electric heated floor in a bath should have a specific heat release of at least 250.

Attention: the electric cable for underfloor heating can be two- or single-core. A single-core cable has higher electromagnetic radiation, but is within the normal range. In addition, the two-wire cable is easier to lay, since the other end does not need to be connected to the thermostat.

If in the washing compartment the lower floors are wooden, then when laying the cable with your own hands, special attention should be paid to fire safety. All wooden structures are treated with fire retardants. Despite the fact that there will be no direct contact of the cable with the wooden elements, all connections and joints must be carefully insulated. In addition, before laying in a Russian wooden bath, it is necessary to check the integrity of the insulation layer of the heating cable.

After installing the electric mats and checking the operation, the screed or tiles can be laid

Work on the construction of floors with an electric heating system is carried out in the following order:

- After the preparatory work on waterproofing and insulation of the base of the floor, you can proceed to laying the heating elements.

- To make it easier to lay the cable with your own hands, manufacturers of warm electric floors sell them on special nets that come complete with special fasteners and guides. The guiding elements will help to maintain the specified distances between the cables during installation, and the fasteners will make it easier to fix the elements to the floor.

Important: the minimum distance from the cable to the walls is 50 mm. The maximum permissible distance between the cables is indicated in the instructions for the heating system. Any heating elements must be at least 100 mm apart.

- We lay the cable on the floor surface evenly, without kinks and tension. Do not forget to respect the required distances, otherwise it may lead to overheating and short circuits.

- After laying the cable, the system is connected and tested.

- Only after that, a reinforcing mesh is laid out on the floor surface and a screed is poured.

- After 28 days, the cement-sand screed is solid and ready for the installation of a facing, such as ceramic tiles.If you use dry factory mixes for pouring the screed, then the curing time is significantly reduced. In addition, such a screed can be additionally reinforced with fiberglass.

It is important to know: the cable can be laid with a snake or a snail. In the places where equipment and furniture are supposed to be located, it is not necessary to lay heating cables.

Video instructions for laying a warm electric floor:

More about water systems

Water systems are laid in a snail or wave. The first method is more difficult, but gives a more uniform heating.

Do not forget that the system of water-heated floors needs a circulation pump - it will not work by gravity. Before filling the system with a solution (covering it with a coating), be sure to pressurize the system (check it under pressure) - then it will be troublesome to open and eliminate the leak. Splices and fittings along the laying route are not allowed, they are only possible in manifold cabinets.

Electricity as it is

Electric underfloor heating is of several types. The heater can be in the form of a wire - two-core or single. A two-core is more convenient to install, it does not need to be ringed, it fits in one direction and a plug is simply placed at its end.

The single-core wire is laid with the expectation that both ends must be brought to the controller. Don't forget about the temperature sensor. Its installation is also required and it is made in the floor between the cable turns.

The system with a single-core wire is easy to install, but it has a significant drawback, it gives high electromagnetic radiation. When using a two-core wire, the electromagnetic radiation is much less due to the opposing magnetic fluxes.

For floors made in the form of rolls or mats, the electromagnetic radiation is significantly lower. But there are restrictions on their use.

The power of heat mats ranges from 150 to 450 W per square meter of surface. For bath floors, it is considered optimal to consider 250 W per square meter.

Floor options

Attention! The main feature of the sauna room is high humidity.

When installing an electrical heating system, special attention should be paid to waterproofing, and wooden components (subfloor, logs, coating) should be treated with a fire retardant.

There are two main designs of electric floors: cable (convection) and film (infrared).

Cable

The recommended power of cable floors for baths is 250 watts per square meter. Single-core and two-core cables are used.

The preferred option is a two-wire one, it is easier to install: it is not necessary to connect both ends, an end cap is mounted on the other end. But the electromagnetic radiation from a two-core wire is higher.

A convenient option for a cable-type floor is mats. The mat is a heat insulator plate in which the cable has already been laid. Installation is faster and easier.

Cons of cable floors:

- complex installation, a screed device is required;

- energy consumption is higher than that of film floors;

- if the cable is damaged at one point, the entire structure fails.

Pros: high reliability of the system, the ability to adjust the temperature regime, acceptability for all types of coatings.

Infrared

The film floor is a thermal film rolled into a roll, consisting of flexible carbon strips 0.3 mm thick. The strips are sealed in a protective polymer sheath.

Advantages of the film:

- can be used without a screed (although it is better to make a screed for mechanical reliability and better tightness);

- parallel connection of elements: if one fails, this will not affect the overall performance;

- there is no electromagnetic radiation, and infrared is considered harmless;

- high strength: can be placed under porcelain stoneware and clinker.