Gone are the days when, to insulate the house from the outside, it was necessary to use improvised materials that were not only inconvenient to use, but also ineffectively performed their direct function, that is, they poorly protected the walls of the house from the outside from bitter frost and cold winds. In addition, from year to year, the owners of such housing had to patch up the leaky places with clay, manure, moss, etc., since in those days there was no siding and other facing materials that could protect the insulation from the harmful effects of the environment. Today everything is much simpler and the issue of house insulation is no longer as acute as before. Having a minimum set of simple and affordable tools plus instructions, you can easily and correctly insulate the house outside and with your own hands. As part of the article, we will consider in more detail such a popular insulation today as mineral wool, list all its advantages and disadvantages, and also provide detailed instructions on how to warm a house outside with mineral wool for siding on our own.

The main varieties of mineral wool

Stone wool is highly resistant to fire and does not deform for a long time

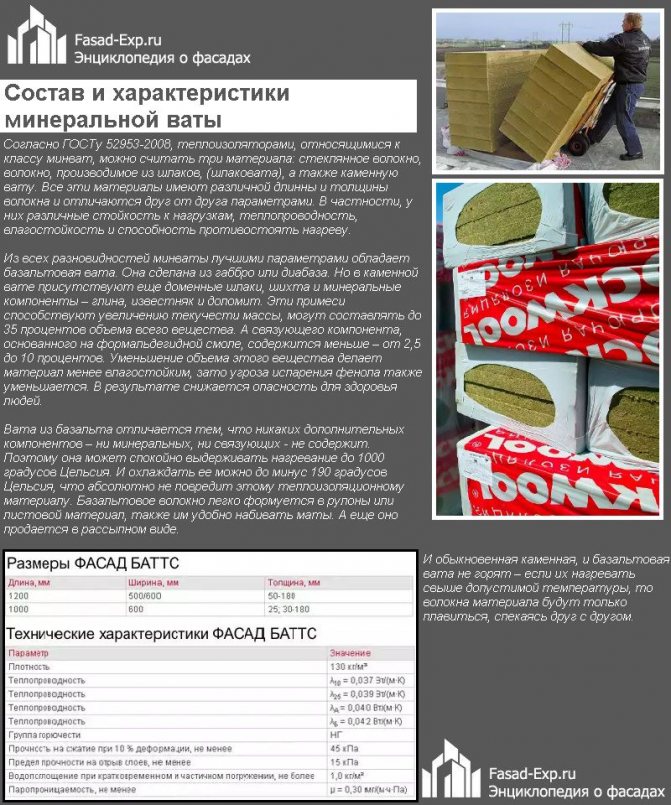

Depending on the constituent parts of the mineral wool, it can be divided into 3 main groups:

- The stone variety includes rocks with analogs of gabbro-basalt groups, due to which the material has low water absorption and, conversely, high resistance to fire. Consequently, stone wool is able to withstand the highest temperatures without deforming for a sufficiently long time. Available in rolls.

- The slag type of mineral wool is produced using waste after melting non-ferrous or ferrous metals. It has good quality indicators, but they are slightly weaker than the previous type.

- In the production of glass wool, glass, limestone and other materials are used, and therefore this type can withstand high temperatures. Perhaps the only drawback is the fragility of the material, in which small particles can get directly onto the skin.

Advantages and disadvantages

Pros:

- Low thermal conductivity.

- Resistance to temperature influences.

- Durability (up to 80 years old, with good density).

- Easily assembled and fills spaces in the frame thanks to its expanding properties.

- Protection of walls from direct infrared radiation.

- Excellent soundproofing.

- Inedible for rodents.

Minuses:

- High installation requirement.

- High material cost.

- Do not use acrylic plasters.

- High requirements for the implementation of technology.

Material advantages

It is best to insulate the outside siding of a house with mineral wool, because installation is quite simple, and the quality of thermal insulation is high. Thanks to this, you can save a lot on heating appliances and heating in general. So, the main advantages of this insulation:

Mineral wool is an environmentally friendly material that resists fungus and pests

- applies to any surface and plane;

- fire resistance and fire safety;

- environmental friendliness;

- resistance to fungus and pests;

- low shrinkage after mounting;

- high operational life;

- high thermal insulation performance;

- resistance to moisture;

- the ability to install directly on the wall or using the lathing.

Do-it-yourself insulation of a house outside with mineral wool for siding: advantages and disadvantages of insulation

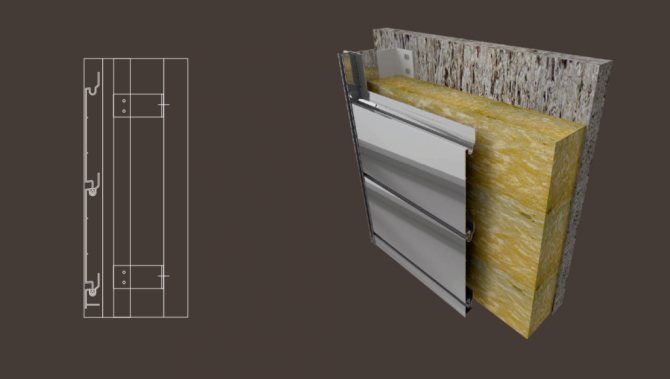

Basically, when insulating the walls of a house from the outside, experts recommend using mineral wool in the form of ready-made slabs, which have a standard width and length, as well as an optimal thickness of 50 and 100 mm, sufficient depending on climatic features and requirements. Since the mineral wool slab insulation has standard dimensions, it is very convenient to attach it to the wall by first preparing the supporting subsystem intended for further cladding with siding or other finishing materials for the facade.

You can, of course, use roll insulation for exterior wall decoration, but working with it is a little more difficult.

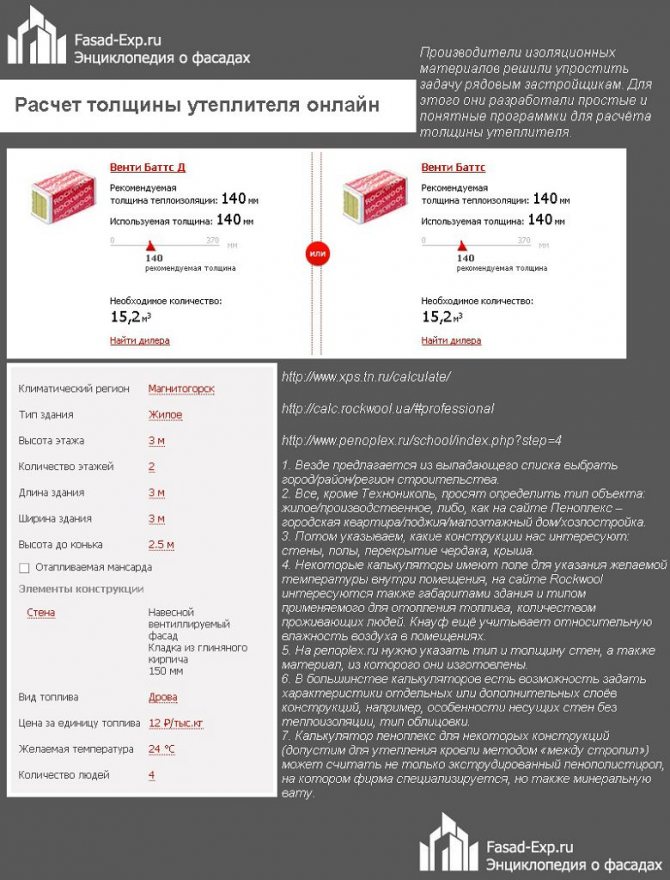

The thickness of the insulation for the walls of the house outside for siding should be chosen based on the climatic characteristics of a particular region, as well as taking into account the technical characteristics of the material from which the walls of a particular structure are erected. So, for example, in more windy or northern regions of the country, as well as when insulating brick buildings, it is better to use an insulation 100 mm thick, thereby guaranteeing high heat saving rates.

Advantages of insulation - mineral wool

- Fireproof. Mineral wool is not a combustible material, which means that it can be easily used as a heater, on almost any surface, including outside the building.

- Eco-friendly material. The materials and components included in the mineral wool are constantly tested and laboratory tested under various conditions. These tests allow manufacturers to claim the high environmental performance of mineral wool. Mineral wool insulation can be used to insulate living quarters both inside and outside without fear of harm to health.

- High degree of thermal insulation. Mineral wool is capable of providing a sufficiently high degree of thermal protection outside the house, for example, a plate of this insulation with a thickness of only 50 mm, in terms of thermal insulation characteristics, can be equal to a brick wall with a thickness of 900 mm !.

- Good vapor permeability. Another very important advantage of mineral wool insulation should be noted, namely the good vapor permeability of the material. As you know, excess moisture, accumulating under the facade cladding, can quickly render both the insulation itself and the walls of the house unusable. Mineral wool practically does not interfere with the free circulation of moisture vapor, so it can be safely used to insulate walls outside the house.

- Easy to handle. The material is easy enough to machine and in order to cut the insulation it is enough to have a simple knife at hand.

- Minwata is easy to install. It is worth noting that the installation of mineral wool slab insulation both outside and inside is easy and quick, since the slabs have standard and convenient sizes, so the installation can be done with your own hands, without resorting to the services of installers. Thus, you can significantly save money on installation work, especially with large volumes, and spend them, for example, on further measures for cladding the facade with siding.

- Minvata is an economical material... The cost of mineral wool quite allows it to be used as an insulation material in large areas, for example, when insulating the walls of a house from the outside without fear of significant financial costs. In addition, the insulation has a fairly high thermal efficiency, which will further significantly reduce the cost of heating the room by up to 50%. In any case, this is a good investment, which pays off quickly, considering also that the comfort in the house and the health of the residents are certainly more expensive than these investments.

What are the disadvantages of mineral wool

Remarkable is the fact that mineral fiber-based insulation has practically no significant drawbacks.Unless a small amount of dust can form when working with the material. To protect the respiratory tract when working with mineral wool, you must wear protective respirators.

It's important to know! It should be borne in mind that the composition of mineral wool contains formaldehyde resins, which at high temperatures evaporate a substance harmful to health, namely phenol. Conscientious manufacturers are able to control the volume of these substances in the material at the optimal level and do not allow their critical value. Therefore, in any case, it is better to purchase mineral wool only from reputable manufacturers.

Materials and tools used

Mineral wool is fixed with mushroom dowels

It's no secret that insulating a wooden house with your own hands under siding also implies the presence of some tools and materials:

- drawn up schematic drawing;

- mineral wool;

- construction brackets;

- straight suspension (universal);

- screws and dowels;

- building level;

- special glue;

- screwdriver and hammer drill;

- butyl tape;

- bars or metal profiles.

It is worth noting that the insulation of a wooden house for siding can be done using a metal profile or wooden slats. But the principle of mounting is practically the same. Therefore, tools and fixing materials are selected in accordance with the crate used. Butyl tape is glued between the joints of the membrane, which is installed on the mineral wool.

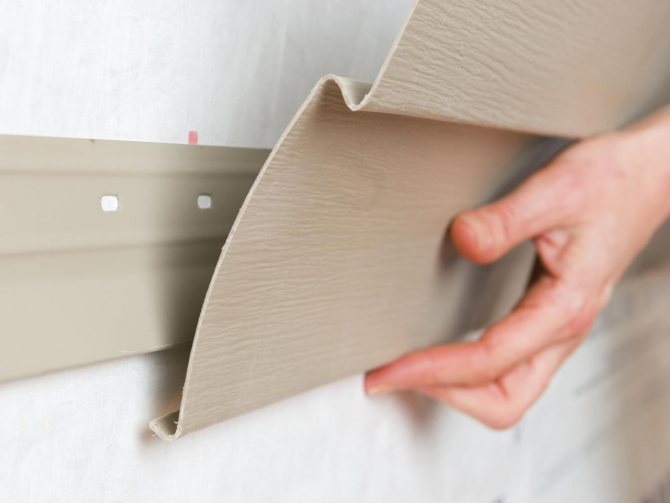

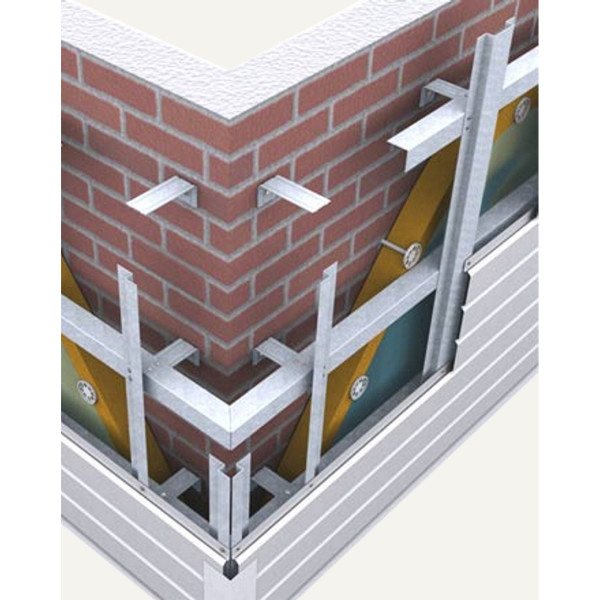

Siding installation

When the walls of the house are insulated with mineral wool, you can install siding panels. For this, a counter-lattice is formed with vertical axes when the siding is mounted horizontally and horizontal axes when it is installed vertically. The pitch of such a batten depends on the type of siding material - the heavier it is, the smaller the distance between the axes. Racks are installed in the corners of the house and around windows and doorways. For horizontal fastening of vinyl siding panels, a distance between the axes of 40 - 60 cm is recommended, for metal - from 20 to 40 cm. Additionally, it is necessary to strengthen the frame for siding with a more frequent arrangement of racks if frequent strong winds prevail in the region. The first is to fix the "starting" bar along the entire perimeter of the facade... From it, the following panels are joined in a row by a castle overlap. If necessary, in some places the siding is fixed on rivets or self-tapping screws. The joints of the panels are covered with decorative and docking strips. The evenness of the rows is checked by the level. Window and door openings and other junctions are avoided with particular care. The last row is also decorated with a finishing bar.

Advice from the "facade"

Decorative trims and fittings are often chosen in a contrasting color to the primary siding color for the facade finish.

The technology of wall insulation outside with mineral wool in accordance with simple rules for installing the frame and laying the slabs will provide warmth and comfort inside a residential building for a long time.

The order of work

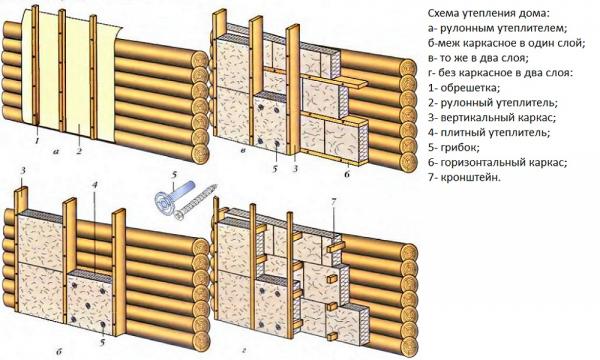

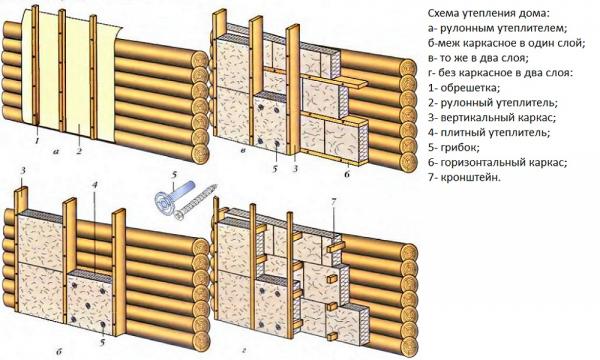

Most often, the insulation of the house from the outside, especially for siding, is carried out using a wooden structure. A double lathing is being erected to provide ventilation between the insulation, cladding and wood. First you need to draw up a diagram. Here are 4 options from which you can choose the right one.

Scheme of home insulation options

Next, you need to thoroughly clean the surface of a wooden house from dust and dirt. It is advisable to do this in dry weather. After that, it is imperative to prime the tree in order to avoid the formation of mold in the future. Now you need to mix the glue base and lubricate the surface of the mineral wool with it. Then the cotton wool is applied to the wall surface and glued.If you use rolled mineral wool for siding, then it is applied along the entire length. If the cotton wool is in the form of blocks, then gluing is done in a checkerboard pattern. It is imperative to strengthen the structure with dowels, since the glue is unable to withstand the mass of cotton wool.

It is advisable to use 2 layers of insulating material, between them a reinforcing mesh is installed for the strength of the structure. Glue is also applied to the mesh, after which it is, as it were, embedded in cotton wool.

Warming process

Wooden or log houses, as a rule, do not need insulation either outside or inside, since the wood itself is a fairly good heat insulator. It is justified to insulate a house from a solid log or bar in harsh climatic zones and if the thickness of the walls is insufficient to maintain a comfortable microclimate.

The same can be said about brick buildings. They are in dire need of outdoor insulation. With insufficient wall thickness in such buildings, it is cold in winter and hot in summer.

The most practical material for thermal insulation of walls is mineral wool. Most experts advise using vinyl siding as a finishing material.

Let us consider in more detail the process of insulating a house from the outside and creating a ventilated facade by finishing the building with siding.

Preparing the walls

The timber walls should be dried, moss and fungi should be removed. After cleaning and complete drying, the surface must be primed. Primers require both brick and wood walls. This process is necessary for better adhesion between the mineral wool and the surface to be insulated.

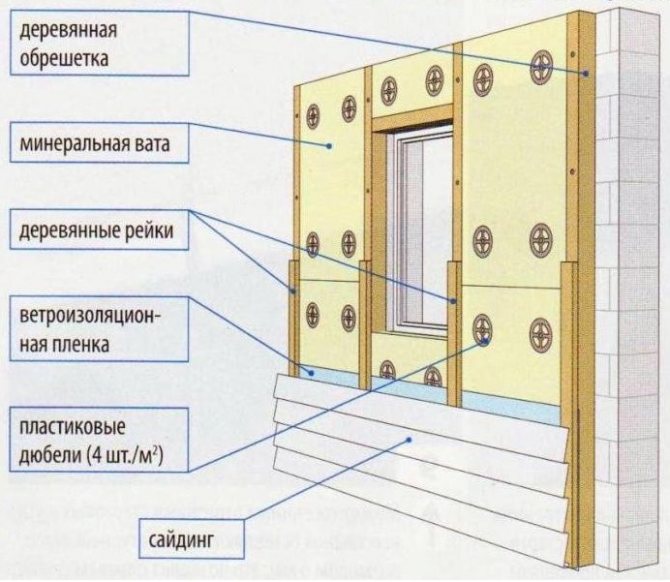

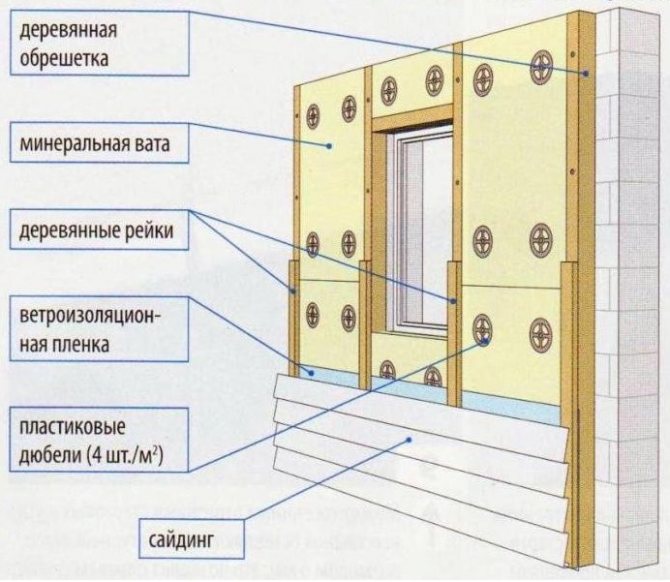

Lathing

After a thorough priming, we proceed to the filling of the horizontal lathing. For it, you can use a wooden beam 50 × 50 mm or a galvanized profile. The vertical rails are packed in 58 cm increments. It is recommended to carefully lath the wooden crate for attaching the siding and soak it with an antiseptic.

Insulation laying

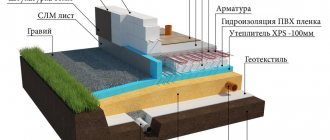

The heat insulator fits between the guide rails. You can fix the mineral wool on a brick or wooden wall using special plastic dowels-umbrellas. After fixing the thermal insulation layer, it should be protected from external moisture. This is an important process that prevents moisture from entering the insulation. It is necessary to fasten the hydro-barrier over the entire wall area using a construction stapler.

Now you can proceed to the final part of the insulation work - filling the vertical sheathing for attaching the siding. A 30 × 50 mm wooden lath can be used. A distance of 30 mm will be enough to ventilate the facade.

As for log buildings or houses made of solid wood trunks, the algorithm of the insulation process remains unchanged.

Important! Many "sofa experts" recommend laying a layer of vapor barrier directly on the wall to be insulated, so as not to let moisture from the street into the room. At the same time, such "specialists" almost never take into account the moisture emanating from the room. What happens in this case: the moisture at the exit from the wall will bump into a vapor barrier, between them the humidity will increase significantly, and when the temperature drops, it will condense on the wooden walls, which will lead to wetting and rotting of the wood, as well as the gradual spread of fungi, mold and other things in it troubles.

As you have seen, there is nothing difficult in wall insulation, it is only important to choose the right material and strictly adhere to the sequence of work.

Installation of lathing and siding

The question of how to install the crate should be given special attention, since the strength of the entire structure depends on it. It is preferable to install the slats in this order: if the siding is installed horizontally, then the slats are mounted vertically. In the case when it is necessary to install the siding vertically, the crate is laid horizontally.Please note that the pitch between the slats is determined by the distance between the holes for siding fasteners. Also, slats are mandatory installed in the corners, near openings, and so on.

Siding insulation scheme

It should be noted that the plane of the sheathing must be checked all the time with the building level, because the evenness of laying the siding depends on this. Wooden slats are mounted into the walls using dowels or galvanized nails (weaving). Please note that the lathing is also treated with a primer if it is made of wood.

The siding is installed directly on the elements of the sheathing using self-tapping screws or nails. In this case, it is necessary to make a ventilation opening of several centimeters between the insulation and the facing material. Thanks to this, the walls will breathe. The siding is laid directly from the bottom up.

Please note that this material is quite brittle, so a very sharp knife and saw should be used when cutting.

- How wall color stencils are created and used

- Installation and operation of moisture-resistant panels for bathtubs made of fiberboard, MDF and chipboard

- Advantage of Penetron waterproofing

Insulation bookmark

The main difficulty when insulating with mineral wool for siding is to correctly combine the size of the insulation plates and the step of the frame racks. In IAF systems, hydrophobized slabs with a density of 35-50 kg / m 3 are mainly used, and with two-layer insulation - 70-80 kg / m 3 for the inner layer. These materials have a standard width of 60 cm, which causes certain difficulties.

For wooden frames without an offset counter-lattice and metal IAF systems, such a step of the frame racks is suitable for cladding with vinyl and metal siding. For galvanized gypsum plasterboard profiles and wooden frames for cladding with wooden siding, the spacing of the posts should be reduced to 40 cm or less. To adjust the width of the insulation, there are two options: use slabs whose length is a multiple of 40 cm and cut them across, thereby irrationally increasing the number of joints, or reduce the spacing of the racks to 30 cm and cut the standard slabs lengthwise.

The density of the slabs allows them to be inserted, however, due to the considerable height of the heat protection belt, it is required to provide additional fastening in order to exclude shrinkage of the insulation under its own weight. To insulate stone walls for this purpose, disc-shaped dowels are used, which are placed with a density of 5-6 pcs / m 2. In the frame walls, the insulation is supported by thin (15–20 mm) spacers, which are fixed between the posts as the insulation is laid at the horizontal joints.