The operation of a pellet boiler is based on pellets - a special type of solid fuel, which is obtained as a result of processing peat, agricultural waste and sawdust. Many people liked such a boiler due to the use of raw materials on a budget. It can be used to heat rooms without running water. There is a pellet burner inside the pellet boiler. The fuel must be independently moved from the loading area to the working area. In this article we will talk about the best boiler models and find out in more detail their principle of work with the rules of correct installation.

Principle of operation

The main principle of operation of a pellet boiler is the implementation of a metered supply of fuel to the combustion chamber. How much the user loads the pellets, so much heat he will receive. They are fed into the combustion chamber in certain portions, which makes the boiler different from other competitors. Then they go to the burner mechanism. It can be flare, retort and flow. For example, in forced-feed boilers, the fuel is supplied by a screw. The serving size directly depends on the required temperature. A fan located at the burner supplies air, the amount of which is calculated by the controller. The heat from the combustion of the pellets is removed by a heat exchanger.

Disadvantages of pellet boilers

Speaking about the advantages of this type of solid fuel boilers, it is worth mentioning their disadvantages.

- despite the fact that pellets are made from wood waste, the unit of heat generated will cost more when compared with wood-fired boiler equipment;

- storage of pellets is required in a dry room, since under the influence of moisture they begin to swell and fall apart, which causes the augers to clog

- to work offline in remote suburban areas you will need to purchase a generator and additional equipment, what can make purchasing a pellet boiler an expensive pleasure;

- pellet consumption per month can be about 1 ton... Knowing the price of pellets in your region, it is not difficult to calculate how much it will cost you to heat a country house in winter. As practice shows, your costs will be comparable to the use of electric boilers and exceed the costs if you use natural gas as fuel.

TOP 7 best pellet heating boilers

We analyzed a large number of models, as a result of which the following boilers became the basis of the rating:

- Heiztechnik Q BIO DUO 35;

- Kiturami KRP 20A;

- ACV ECO Comfort 25;

- ZOTA Pellet 15S;

- Pelletron 40 KT;

- Ferroli SFL 3;

- Stropuva S20P.

We propose to dwell in more detail on the description of all the above models. This will help you find out their main advantages and disadvantages, which will play a leading role during the purchase.

Heiztechnik Q BIO DUO 35

The first in our rating is the Italian-made boiler. The design has a double-type firebox, due to which the amount of warm air that affects the heat exchanger increases several times. In addition to pellets and a burner, there is also a steel grate, the main function of which is to store firewood.

| Dimensions (edit) | 159x70x71 cm |

| Construction weight | 556 kg |

| Power indicator | 35 kWt |

| Tank capacity | 300 l |

Price: from 150,000 to 200,000 rubles.

pros

- microprocessor-type control;

- there are two ways to supply fuel: manual and automatic;

- the bunker holds a large amount of fuel (300 l);

- The efficiency from burnt wood is 88%;

- high power (35 kW);

- the profile shape of the wheels is easy to clean;

- the maximum heating area varies from 120 to 350 m².

Minuses

- large weight and dimensions (556 kg, 159x70x71 cm).

In connection with the move to the private sector, we decided to buy a heating boiler. Given the poor communication in the village and frequent power outages, especially in winter, it was decided to take a closer look at the pellet boiler. It is quite large and cumbersome, so it is perfect for a stationary installation. Has a high heating capacity. We do not fill the tank completely, but it is still hot in the house. It works quite economically and does not require large expenses. It is also unpretentious in care and requires compliance with minimum sanitary standards. It copes well with the task and is fully consistent with its value.

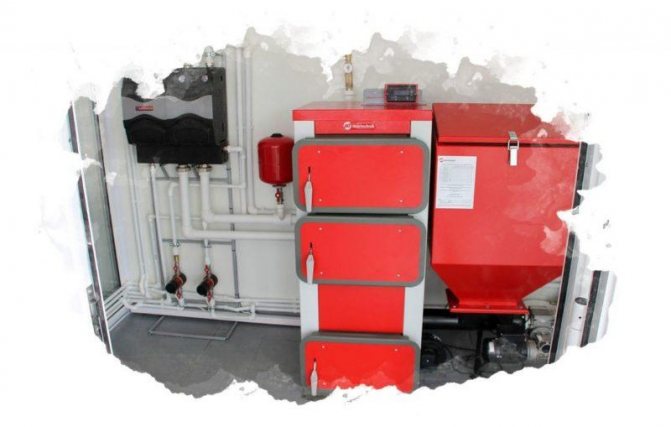

pellet heating boiler Heiztechnik Q BIO DUO 35

Kiturami KRP 20A

The next boiler is being sold to shops on behalf of a South Korean manufacturer. Due to its high power rating, it copes well with heating large premises (300 m²). Heats water to temperatures ranging from 50 to 85 degrees. There is overheating protection, which consists in triggering a thermal valve and supplying cold water to the system.

Pellet boiler (to take or not?)

Ganjik81 wrote: Now pellet boilers have become very popular, so I started thinking because I am building a new house, there is no gas nearby. A friend advised a pellet boiler, like it is economical and very easy to maintain. At the expense of economical, I would argue that I found the cheapest boiler for 163,000 tons. If anyone has experience, please share. I'll be very thankful. Since it's time to do the heating.

Ganjik81, Here is my annual experience of using the Teplodar Kupper Pro-22 boiler. The Teplodar boiler came with a crookedly welded pipe for heating elements, it was not possible to screw them in. The device of the burner turned out to be pathetic, but one could put up with it if it worked normally. There are cases of fire in the supplying plastic sleeve, the supply of pellets is not automatically regulated during operation, as well as the fan speed. The control board often fails, as it is fixed in the bunker body and during the first installation and unscrewing it, you 99% have every chance of damaging it (not a warranty case). The board is overheating from the boiler on which it stands, there is no fan. Temperature sensors constantly fail as a consumable. There is simply no logic, algorithm, smart settings in this block. In the installed pellet burner, after a month of use, after a detailed examination, it became clear that my grate not only narrowed, but also lengthened by 18 mm and sagged like a snot, blocking the normal passage of air and blowing ash from the far part of the brazier, where it was constantly accumulating in a small hill. After reducing its size, welding the plates around the edges so that the pellets did not fall into the pallet through the slots, giving geometry, he was sent to an undeserved rest as a spare. He made a grate from cast iron, took a 6 mm thick valve as a basis, cooked 3 mm electrodes on cast iron. I put it in 60 seconds. the auger poured a normal amount of pellets, closing the light guides (there was no longer a pocket for them, like in a billiard pocket), ignition took place in 3 minutes. 45sec. I think it should ideally be made of cast iron or metal at least 6 mm., I have 2.5. You don't need to reinvent the wheel, so you have saved. Teplodar could not answer objectively, directly and honestly, they say, in new models, the grate will be finalized, and kroilovo always leads to a hitalov. Low efficiency, low quality of the metal used, low quality of the radio components used in the control unit, it is unreasonably expensive to replace the unit. I do not recommend this model, I read on the Teplodar forum people groan and complain about the disgusting build quality, the price of replacing the block reaches 36,000 rubles. On the official section, the negative is removed, the developer's zero reaction.For this boiler, I ordered myself a smart control unit for 12,000 rubles, instead of the killed and wretched APG-25, my friends recommended it, this is really smart electronics.

Installation rules

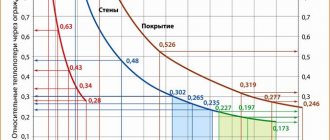

Before installation, it is necessary to calculate the heat loss and select the required performance, taking into account the area of the room. Install the equipment in a garage or basement. Safety flooring should be made of non-combustible durable material. The installation site must be equipped with a concrete elevation of 10-15 cm. The temperature in the boiler room should be +10 degrees with moderate humidity. Ventilation should be done in accordance with the indicated power in the equipment passport. Installation is carried out in accordance with the design documentation and safety requirements. Installation should be done by qualified personnel.

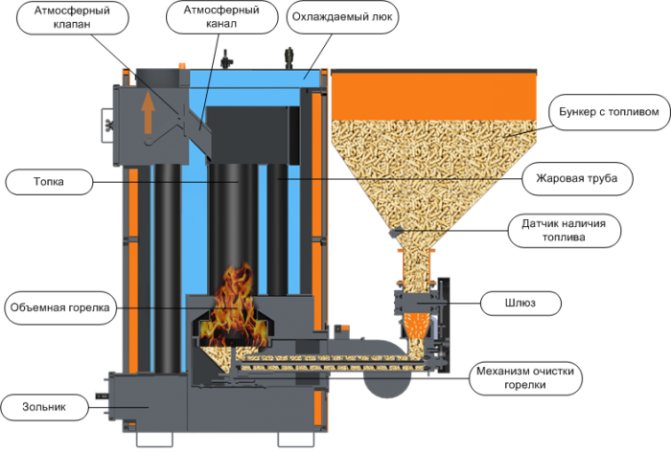

The device and principle of operation of pellet boilers

Pellet boilers Is an efficient equipment designed for heating private houses and buildings for various purposes.

The operation of such equipment is based on the combustion of fuel pellets with their automatic supply to the burner and forced air blowing.

The pellet boiler is made of sheet steel or cast iron and consists of a body, burner, furnace, heat exchanger, feeder and fuel tank.

The pellets loaded into the bunker are gradually fed into the combustion chamber by means of an auger transmission, where they are burned.

Thanks to the standard pellet shape, it was possible to organize a fully automatic fuel supply process.

Advantages of pellet heating

+ low cost of heat

+ high thermal performance due to the high calorific value of the pressed fuel and its complete combustion (there is no need to buy equipment with a large power reserve)

+ high performance characteristics (cost of pellets, efficiency, reliability) comparability in efficiency with a medium-class gas boiler of a professional series

+ high degree of automation

+ easy maintenance (in most cases it comes down to periodic ash removal)

+ no problems with the supply of pellets (growing market of suppliers in the Krasnodar Territory and beyond) + the ability to buy fuel in stages and at any time of the year

+ safety, does not require approval from regulatory authorities

+ no requirements for the boiler installation room

+ low ash content of wood pellets

+ low fire hazard of pellets

+ delivery and storage of pellets is much easier than any other type of fuel, and they are immediately ready for use

+ pellets are compact fuel suitable for long-term storage.

Minuses

– Equipment cost (which is offset by simple operation and reliability)

– The need to organize the delivery and storage of pellets (for a private house of 150 m2, it is enough to purchase and place pellets for 4 m2 once and they will be enough for the entire heating season)

We have accumulated extensive experience in working with pellet boilers and opted for Roteks products.

Selection Tips

A few tips from experienced buyers and connoisseurs will help you make the right purchase and not regret it after a while:

- If you want to save money on your purchase, then choose a non-volatile boiler with a simple circuit.

- If you want to save on fuel, then you should buy an expensive boiler with sophisticated automation.

- It is best to choose a large hopper to avoid adding fuel frequently.

- Choose a high efficiency model.

- The most convenient to use are models with autonomous operation and fuel supply. They calculate the pellet portions themselves in accordance with the set temperature.

Equipment features

Pellet boilers differ in power and design features. Manufacturers offer models that work:

- only on wood pellets;

- on pellets, while briquettes and firewood can be used as a backup fuel;

- on pellets, which can be replaced with wood or briquettes due to the presence of several combustion chambers.

How does the boiler work and work?

Each such device has a burner, hopper and auger mechanism. The principle of operation is as follows: the pellets, once in the bunker, are sent through the screw mechanism to the furnace with a burner.

Here they burn, emitting heat, which heats the coolant. Thanks to the special design of the combustion chamber, the efficiency of premium models can reach 96%.

The presence of an automatic control system allows you to regulate the rate of fuel supply and maintain any given temperature of the coolant.

The volume of the hopper has a direct influence on the frequency of loading the pellets used for heating. Depending on the design features of the model, ash removal from a special ash box can be carried out weekly and once a month.

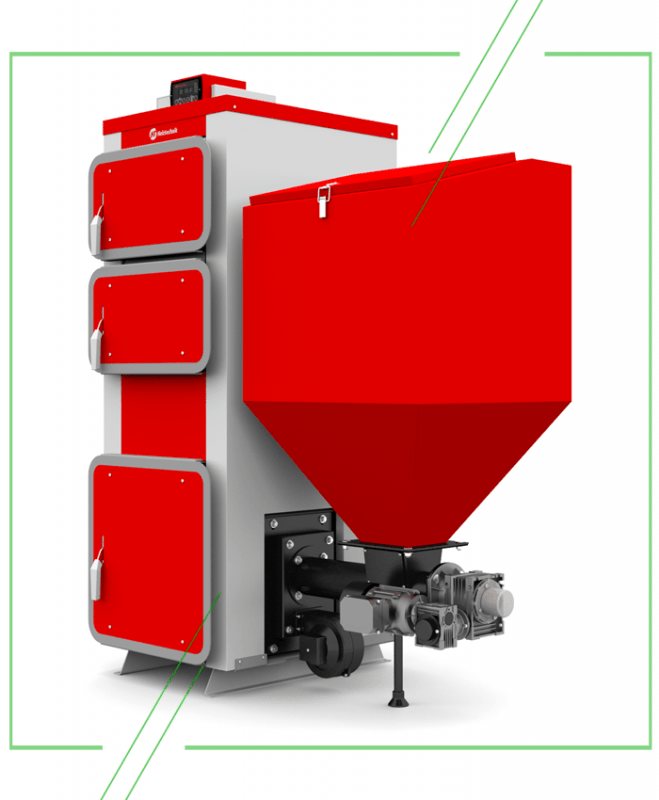

FEATURES

- Hopper left or right (factory setting only).

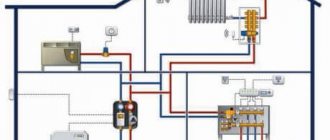

- Traditional wiring diagram.

- Attention! When piping the boiler, 1 meter of straight water at the outlet of the boiler and 1 meter of return water at the inlet of the boiler are carried out with a metal pipe.

- Auger fuel supply.

- Standard chimney.

- High efficiency when working with coal and pellets.

- Low flue gas temperature.

- High reliability and build quality.

- Frontal cleaning of the heat exchanger.

- Unpretentiousness to fuel.

- The possibility of using firewood and coal.

- Service life 15-20 years.

- Warranty 24 months.

Steel pellet boilers TERMODINAMIK series "EKY / S" (Basic equipment)

| Model | Power, kWt) | Price, rubles |

| EKY / S 25 | 25 | 134 900 |

| EKY / S 40 | 40 | 188 100 |

| EKY / S 60 | 60 | 225 150 |

| EKY / S 80 | 80 | 264 100 |

| EKY / S 100 | 100 | 295 450 |

| EKY / S 125 | 125 | 343 900 |

| EKY / S 150 | 150 | 384 750 |

| EKY / S 175 | 175 | 424 650 |

| EKY / S 200 | 200 | 465 500 |

| EKY / S 250 | 250 | 570 000 |

BASIC EQUIPMENT

- Operational fuel bunker.

- Screw feeder with electric motor.

- Air charging system with electric fan.

- Digital control panel.

- Service tool.

- Ash removal box.

- Circulation pump (for models EKY / S 17-25-40-60).

- Turbolizers.

- Wiring closet.

- Fire protection hydraulic valve.

BURNER

- The unique shape of the burner takes into account the peculiarities of burning pellets, coal, cake, shells, etc., which allows using different types of fuel at different times without modifying or replacing the burner.

CIRCULATION PUMP (for models EKY / S 17-25-40-60)

- Has three speed levels. The pump is a wet rotary type and runs silently. The special, closed rotor shaft made of deep-drawn stainless steel prevents clogging. An energy-efficient three-speed motor ensures that the pump matches the system perfectly and eliminates hydraulic noise.

Heating pellet boilers series EKY / S 17, 25, 40, 60, 80, 100, 125, 150, 175, 200, 250 kW

Boilers of this series are designed to burn any dry, crushed, solid fuel of organic origin with dimensions up to 25 mm (pellets, coal, cake, nut shells, sunflower husks) in automatic mode. Suitable for working on wood and coal, in the mode of manual loading of fuel into the furnace.

All boilers have three-way fire-tube, horizontally located, heat exchangers made of high-quality steel, at least 4 mm thick.

Thanks to the design of the heat exchanger, the temperature of the flue gases does not exceed 120 degrees Celsius. The boiler efficiency reaches 85%.

Automatic fuel feeding function ensures high efficiency and easy operation.

Reviews of heat pumps in premises without permanent residence

Ust-Kamenogorsk, complex

Initially, the area of the complex was 500 square meters, heating costs on average 43 kW / h. Then the area of the building was increased and 2 floors were added. As it turned out, it was impossible to connect to the central heating system, they began to look for alternatives.

For 1200 sq.m.made geothermal heating with four heat pumps with Danfoss compressors with a total heat output of 100 kW. Now the average consumption is 22 kWh. Of course, this is largely due to the competent wall insulation and the use of convectors on the ground floor, but the heat pump has given huge savings. If we calculate taking into account the increased area, the costs decreased by 4.5-5 times.

Commercial and economic complex heated by heat pumps with a capacity of 100 kW

Kremenchuk, Ukraine

There was a two-story building, which was heated with solid fuel according to the boiler-radiator scheme. We decided to connect to a gas pipeline that passed nearby. But many problems immediately arose and as a result the cost of the solution exceeded 40 thousand dollars.

We decided to install a ground-water heat pump for 14.6 kW of thermal power. Now it works successfully, the efficiency is somewhere around 360-400%. Installation and launch cost 13 thousand green. Compared to gas (at a similar facility), we pay five percent less. Now we are planning to install a heat accumulator in order to be heated at the night rate.