Principles of functioning of a mini-boiler room

Mini-boilers are special installations that represent a container with heating equipment. The basic unit is equipped with one or more boilers for water heating. They differ in their power and are combined into a common network. There is a pump in the container, the power of which allows to provide the required pressure for the heating system. Gas mini—boiler rooms can work in automatic mode. The equipment installed in the container controls the circulation and operation of the coolant.

The operation of a separate mini-boiler room is based on several principles. First of all, the temperature in the boilers reaches a certain value. Powerful circulation equipment sets the direction of the coolant. Automation allows you to achieve smooth operation. Gas boilers in rare cases require additional maintenance, this is their advantage over solid fuel plants. Mini boiler room price over time it pays off many times over, avoids the construction of a special extension. It will take only a few days to install such an installation and connect it to the building's heating system.

Problems of centralized heating systems

The cost of district heating is constantly increasing. Despite the fact that heat prices are getting higher, residents of individual houses do not receive hot water for weeks due to the poor condition of the heating system.

In centralized systems, utilities are subject to great wear and tear. They deteriorate faster because service companies are in no rush to fulfill their duties. Also, the most common problem is the shutdown of the hot water supply in the summer due to the maintenance of the city system, such work can be delayed for a rather long time, houses that have their own autonomous boiler house do not face such a problem. Maintenance of an autonomous roof-top boiler room is performed as needed and takes from one to several days, depending on the type of work. The combination of these factors leads to an increase in the popularity of block-modular boiler houses, the design of individual heating systems. This option is cost effective and relatively independent.

Benefits of using mini boiler rooms

The advantages of stand-alone units include their compact size. Small mini-boiler houses are in steady demand in the heating equipment market. The advantages of using gas mini-boiler rooms include:

- efficiency and economy;

- affordable cost;

- ease of installation;

- operational reliability;

- high efficiency;

- the ability to work automatically without third-party intervention;

- automatic shutdown when an emergency occurs.

All mini-boiler houses are divided according to the type of fuel used. They can be gas, solid and liquid elements, electricity. Gas mini-boiler rooms are considered the most economical and environmentally friendly option. They are also suitable for urban applications. Many residential buildings contain installations of this type.

Use of roof-top boiler rooms for apartment buildings

Autonomous heating with an autonomous boiler room allows you to get guaranteed heat and pay only for yourself. Even some state institutions give preference to a complete re-equipment of boiler houses and their replacement with block-modular structures.Such equipment is more effective in different geographic areas. Modern multi-storey buildings are also equipped with heating systems for apartments. Convenient design of roof-top boiler rooms allows you to independently adjust the parameters of the heating system and maintain the desired microclimate.

Features of installation and packaging

As a rule, the installation of a gas mini-boiler room is carried out outside the structure, which needs heating. The construction of an additional extension is not required. Pipelines are brought into the room through the walls. The mini-boiler room is controlled using a special control panel. It is installed inside the building and is directly connected to the boiler using a cable.

Mini-boiler houses are characterized by an open-type firebox, a circulation pump and a gas burner. The installations can be additionally equipped with a fire alarm, an emergency alert system, and a separate chimney.

Today buy mini boiler room Is to save yourself from a lot of problems. Such an installation runs on mains gas or LPG. All units are equipped with circulating pumps. Gas mini-boiler rooms are installed in a special metal box with special heaters. The walls of this box are made of steel sheets, which are interspersed with mineral wool insulation boards. The boiler condition is monitored by the operator remotely. In case of an emergency, a signal is sent to the control panel, and the unit automatically stops working.

On request, a diagram, certificate, permit, passport are provided. You can buy a gas mini-boiler room using the feedback form, or call tel. 8 (8452) 40-05-31,76-10-17

Requirements for a room with a gas boiler in accordance with SNiP

For the installation of a gas boiler and equipment in a separate room, the following room is selected or prepared.

- If the boiler capacity is ≤ 60,000 W, then H-ceilings of 2.2 meters are sufficient. With high-power equipment, ceilings of 2.5 meters or more are already needed.

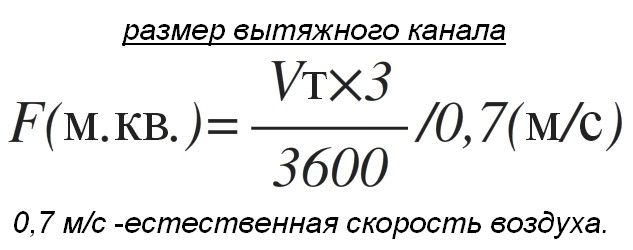

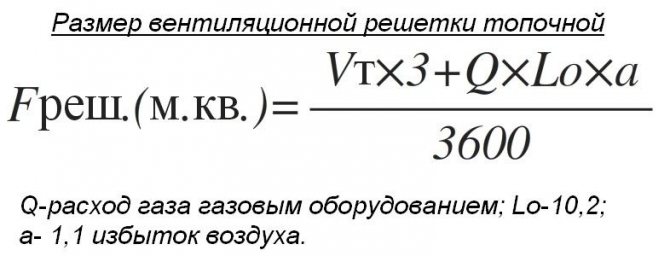

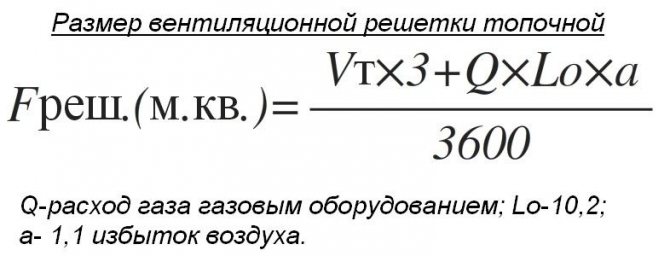

- The room should be equipped with ventilation with three times air exchange per hour. The ventilation channel calculation is calculated using a special formula:

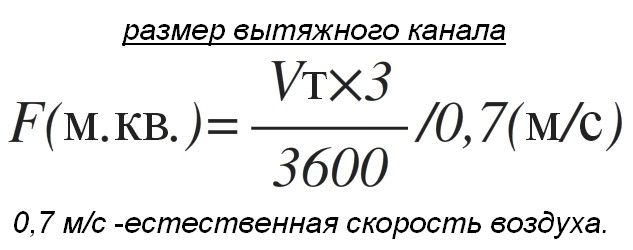

- Louvered grilles are installed in rooms with a gas boiler and a stove. They are responsible for the flow of air into the room and are calculated using the following formula:

- The room must have a window with access to the street. The glazing area of the window must be at least 8⁄10 square meters, but with the calculation of 3⁄100 per 1 cubic meter of the room.

- The total volume of the room for the installation of one gas boiler must be ≥ 7.5 cubic meters. For the installation of two gas boilers ≥ 15 cubic meters;

When installing gas boilers with a capacity of 60,000 watts, as well as in the following rooms:

- Basement rooms;

- Freestanding furnaces;

- Furnaces on the first floor, isolated from other rooms.

A contamination signaling device must be installed.

- The chimney of a room with a gas boiler is equipped according to the boiler's data sheet.

Boiler documents

Let's say you have equipped a furnace in compliance with all requirements. Buying a boiler? It is too early. First of all, check if the old papers are not lost on gas, and take them out into the light of day:

- Gas supply contract, if the boiler is heating. Sub-consumers can only install hot water boilers.

- All documents for the gas meter. Any boiler cannot be installed without a meter. If it is not there yet, there is nothing to be done, you need to set and arrange, but this is another topic.

Now you can buy a boiler. But, having bought, it is too early to install:

- In the BTI, you need to make changes to the registration certificate at home. For privatized apartments - through the organization operating the building. The new plan should include a closet under the boiler, and clearly marked: "Furnace" or "Boiler room".

- Submit an application to the gas service for the project and technical specifications.As part of the required documents and a technical passport for the boiler, so it must already be purchased.

- Install the boiler (see next section), except for the gas system. This can be done while the gas workers are preparing the project, if the premises are approved.

- Call a specialist to make the gas piping.

- Submit an application to gas workers for commissioning.

- Wait for the arrival of the gas service engineer, he will check everything, draw up a conclusion on suitability and give permission to open the gas shut-off valve to the boiler.

Note: gas workers are not allowed to give permission to individuals to work on gas equipment. Therefore, to connect the gas to the boiler, you will have to call a specialist or then "resolve the issue" with the inspector during commissioning. As a rule, the former is cheaper.

Rules for installing a wall-mounted and floor-standing boiler

- A room with boiler equipment will need a lot of light. One cubic meter of room accounts for 0.03 m² window opening (the box and the details of the window package are not taken into account). A free opening window is required.

- The height of the ceilings in the furnace starts from 2m.

- The presence of a supply and exhaust ventilation system. The air in the boiler room is renewed three times in an hour... This condition must be observed, otherwise there is a risk of gas contamination of the room.

- Boiler room from the rest of the house will trim refractory partitions, from forty-five minute time limit, that is, during this time, the overlap material will contain the flame.

There is no clear boundary between the rules for installing a boiler room in a cottage and in a city dwelling. All requirements are the same. The difficulty may lie in the fact that in a private house it is necessary to allocate an entire hall for a water heating system, and in an apartment it is not always possible to combine a room with a furnace.

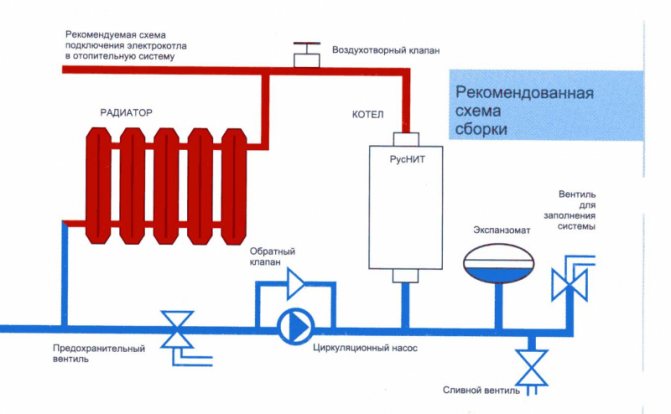

Parts and equipment

Boiler installation requirements depend on the type of unit. Wall-mounted water heaters are characterized by lower power ratings, they are smaller in size. The requirements for them are more democratic than in relation to the floor ones.

Requirements for floor-standing units:

- In the door of the furnace, a window with a window or a through hole is required for additional air intake. It is better if there is a ventilation system where air is removed through an opening in the ceiling.

- The need for a sealed chimney. A powerful gas-fired water heater requires a special chimney, built according to the pipe-in-pipe principle.

- The access to the heating unit must be free, without piling up extraneous things.

- Plumbing and sewerage are required.

- Only concealed wiring is allowed, a detached switchboard is equipped.

- The floor-standing boiler is heavy, therefore there are certain requirements for the floor.on which it is located. Only non-flammable and durable coatings are allowed - stone, paving stones, ceramic tiles or concrete.

- The minimum front door width is 0.8 m.

Of course, smaller numbers are allowed by SNiP, but taking into account all the requirements, it is better to select a room for the furnace with an area of 4 m2, where ceilings are not lower than two and a half meters with walls finished with facing materials.

Gas boiler installed in a residential building, be sure to ground... The most common and recommended by builders is the point option (with one electrode). It is recommended to install a universal module ZZ-000-015.

Attention! In the furnace do not store any foreign objects, the more flammable. The exhaust and air intake are bred to different ends of the room.

The boiler is equipped with a gas meter, which is also installed accredited specialists of Gorgaz.

Gas outlet

It is not necessary to build a bulky brick or asbestos-cement pipe under the chimney.Best fit stainless steel or furanflex, protective sleeve or ceramic.

Photo 2. Wall-mounted gas boiler with a stainless steel gas outlet connected to it.

Location relative to the chimney

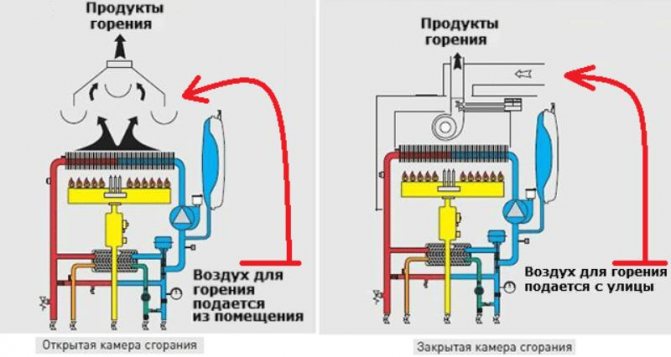

The choice of a chimney device depends on what type of chamber the boiler is equipped with - open or closed... The location of the chimney is also determined in advance. Projects of new buildings are initially focused on internal chimneys. If gas heating is arranged in an old building, an external chimney is made.

Diameter and length of the gas outlet

Gas outlet section - 5.5 cm2 per 1 kW of powerdeclared in the passport. In modern buildings, it can be led out into one chimney maximum two boilers or water heaterslocated at different levels of the building, and the distance between the incoming gas flows not less than half a meter... If a both heating units stand on the same floor, in the chimney make a cut to a half-meter height - this distance is strictly observed. The final indicator of the cross-section depends on the total operation of the two heaters.

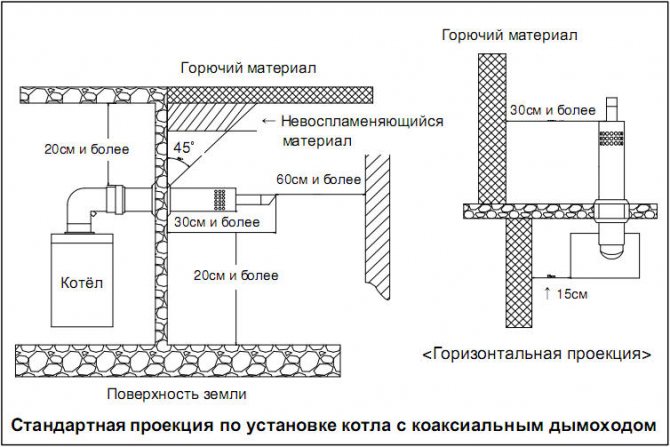

Flue gas outlet - strictly vertical. Maximum permissible pipe slope does not exceed thirty degrees, and the deviation to the side - maximum per meter... The section of the inclined channel is equal to or less than the section of the vertical pipe.

The cross-sectional area of the chimney is equal to or greater than the cross-sectional area of the exhaust channel. The horizontal part of the chimney is tilted towards the boiler 2 cm for each meter of the channel.

A revision is installed on horizontal segments. At the bottom of the vertical pipe is installed tee with plugequipped with a condensation hole.

Number of knees

The degree of "tortuosity" of the pipe depends on the category of the chimney. In the outside, the most straight pipe is drawn through the wall, from the outside it goes up - to the desired height.

The pipe takes the base from the boiler, passes through the floor layers and rises above the roof. The pipe along the way forms two forty-five degree knees.

Roof flue gas outlet location

Flue pipe above the ridge minimum 50 cm and away from him 150 cm... When deleted in 150-300 m the top of the pipe is not below the ridge itself. The minimum pipe height on a flat roof is 100 cm.

Important! Trumpet above one hundred and eighty centimeters requires additional strengthening!

Power

It is obvious that the boiler output must be sufficient. But it should not be excessive, especially if the heat exchanger is cast iron. Drops of condensate from the flue will crack the hot cast iron. There is another dangerous effect: the dew point temperature of the exhaust gases is about 56 degrees Celsius. If the water temperature in the heating return is lower, acid condensation may form in the combustion chamber.

With a properly selected boiler power, the temperature in the combustion chamber will be 80-90 degrees. The permissible difference in power is large enough, but if a 60 kW boiler is installed in a medium-sized private house, then acid rain from the inside will quickly disable it.

The required boiler power for a particular room is determined by a heat engineering calculation. It is easier for residents of high-rise buildings: the data is in the DEZ, the technical inventory bureau or the owner. In any case, you can use the approximate data by calculating an intermediate value for yourself. The maximum power values are given for cases with a minimum outside temperature of -25 / -40 degrees:

- One room apartment on the middle floors - 8/14 kW.

- Corner apartment 60 sq.m. total area on the top floor of the block Khrushchev - 20/28 kW.

- Private house 100 sq. M common - 24/38 kW.

Chimney and ventilation for a gas boiler in a private house

It is imperative to comply with regulations when installing ventilation. Violation of the installation rules can lead to a fire or explosive situation.

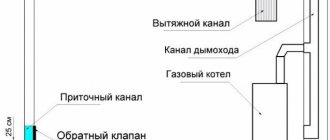

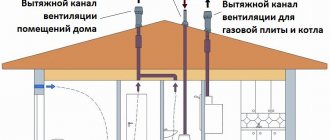

- Ventilation and chimney must pass through ducts isolated from each other.

- It is necessary to install forced ventilation in the boiler room.

- It is necessary that the air circulates constantly, therefore, the ventilation should not be closed.

- The size of the ventilation window must be at least 1/30 of the boiler room area.

- No more than three turns in the chimney pipe are allowed.

- It is better to install the boiler as close as possible to the chimney.

- If the chimney passes through the wall, then there must be two hatches. Main and revision. In this case, the revision must be placed below the main one by at least 25 cm.

- At a distance of 50 cm from the boiler, the flue pipe must be made of carbon steel or stainless steel. This is due to the high temperature of the flue gases in the vicinity of the boiler.

It is also important to bring the chimney to the roof according to the correct scheme. Traction power and boiler efficiency depend on this. For this, a special scheme is used:

- On a flat roof, raise the pipe at least 0.5 meters from the roof or parapet.

- If the exit on the roof slope is closer than 1.5 meters from the ridge, then the chimney should be brought out 0.5 meters higher than the ridge.

- If the pipe comes out on a pitched roof from 1.5-3.0 meters further than the ridge, then the pipe must be raised with your own hands to a height not less than the highest point of the ridge.

- When the pipe comes out more than three meters from the ridge, you need to measure the height of the pipe with a line at an angle of 10 degrees from the top.

Choosing a boiler for a private house

It is especially important that it is correctly calculated required power of the gas boiler... If you choose a boiler that is too small, then it will not be enough for full heating and there will be an uncomfortable temperature in the house. But you should not choose too powerful a boiler. As a result, fuel is used inefficiently and the service life of the equipment is reduced. The choice should be made with a certain margin of power, since constant work at the limit of possibilities has a bad effect on the duration of operation.

For the correct choice, you should use a simple formula.

It is necessary to divide the area of the heated room by 10. Then, multiply by the regional coefficient. It directly depends on the temperature conditions of the region where the house is located.

- For temperate latitudes 1.0-1.2

- For northern latitudes 1.5-2.0

- For southern regions 0.7-1.0

These calculations give an approximate climatic power requirement. For a more detailed and accurate selection, you should also take into account the volume of the heated house and the quality of insulation.

Special requirements for attached boiler rooms

There are not very many of them. Three new requirements are added to the paragraphs above:

- The extension should be located on a solid section of the wall; the distance to the nearest windows or doors should be at least 1 meter.

- It must be made of non-combustible material with a fire resistance limit of at least 0.75 hours (concrete, brick, cinder block).

- The walls of the extension must not be connected to the walls of the main building. This means that the foundation must be made separate, disconnected and not three walls must be built, but all four.

The extension is made of non-combustible building material

What to keep in mind. If you are going to arrange a boiler room in a private house, and there is no room of a suitable volume or the height of the ceilings is slightly lower than the requirements, they may go to a meeting and demand, in return, to mutilate the glazing area. If you are planning to build a house, then all the requirements must be met, otherwise the project will never be approved for you. They also take a tough approach to the construction of attached boiler houses: everything must comply with the standards and nothing else.