Home / Hammam

Back to

Published: 14.05.

0

1

- 1 Way of work and design

- 2 Features of the selection, installation and operation of fireplace stoves 2.1 Choosing the power of the stove

- 2.2 Steel or cast iron?

- 6.1 The easy way

- 7.1 Steel or cast iron?

- 8.1 The easy way

A bit of history

Where did this design come from, and why is its popularity unabated these days? The history of the appearance of a potbelly stove begins at the end of the 18th century. Essentially, it is a cheap alternative to expensive fireplaces and stoves. The device gained particular popularity during the October Revolution, when all the norms and foundations of life were turned upside down. It became problematic to heat residential and non-residential premises, so this simple unit quickly spread throughout the country. After all, everything solid that could burn was used here as a fuel. And this is firewood, coal, peat, furniture, wooden windows and doors.

The potbelly stoves received the second round of popularity during the Great Patriotic War. In many cities, centralized heating networks did not work, and the country saved energy by sending them to the front. The population had no choice but to use the old proven method - to install potbelly stoves in their own apartments.

This oven saved a large number of people from freezing. It worked flawlessly, however, it consumed a lot of fuel. And this is its big minus. But this is the simplest and cheapest device that you can make with your own hands, and it is used in an elementary way.

Currently, potbelly stoves have found their application in country houses, garages, bathhouses and other outbuildings. In modern apartments, they were practically not used, if only as a decorative element, creating the style of antiquity. But recently, the fashion for them has returned.

True, consumers began to impose more stringent requirements on stoves-stoves:

- Reduced fire hazard.

- Presentable appearance.

- Economical fuel consumption.

Let's take a look at these requirements separately and reveal the secrets of the new popularity.

Principle of operation

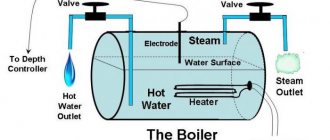

The device of this equipment includes a combustion chamber in which firewood and coal are laid. The heat exchanger is placed directly above it. As the combustion process progresses, energy is released, which heats the water circulating inside the plates or coil. After that, it moves into the pipeline going to consumers - radiators, underfloor heating. The cooled liquid is returned back to start a new cycle.

The movement of the coolant can be carried out by gravity or forcibly. In the first case, it is necessary to lay the piping at a slight slope, in the second, the installation of a circulation pump is required.

Fire safety requirements

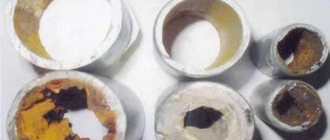

It is this selection criterion that is fundamental. Older stove designs are metal stoves made from segments of cast iron or sheet metal. Such units were not famous for a wide variety of forms. These were mainly cubic or cylindrical structures. The inner part is a firebox, where wood or coal was burned.

The fuel burned in the firebox and heated the device to very high temperatures.In fact, the stove was one incandescent element, from which any thing that got on its surface could catch fire. According to statistics, fires from operation occurred more often than from all other heating appliances in general.

If we talk about modern models, then they should be divided into two categories:

In the factory, where each technological stage is controlled for quality, it is possible to produce stoves that meet all fire safety standards and requirements. With homemade counterparts, things are worse. Nobody controls this production. Each master himself comes up with gadgets and devices that supposedly will protect the property of consumers from fire. That is, there is no guarantee.

Therefore, when the question arises which option to prefer, everyone decides for himself. It is important to prioritize here:

- The first is the high safety of operating a stove in an apartment.

- The second is the price equivalent. Of course, the homemade option is cheaper. But is it worth the risk of purchasing a low-quality device at a low price? After all, it can cost a hundred times more if a fire breaks out.

Design of modern bourgeois

This category is broader. We will not do the layout by model, just consider a couple of options that will show how extensive the variety of ovens on offer is.

For example, the Marina stove stove. This is a cast-iron-steel unit, which is faced with special heat-resistant ceramic tiles. The manufacturer today offers a fairly wide color palette. Here, sandy color, creamy, red, green, brown and so on. That is, each consumer will find for himself such an option that will perfectly fit into the design of a city apartment.

We add that the weight of the device is only 195 kg. This allows the unit to be placed directly on a concrete floor slab without an additional slab foundation or plinth. With a power of 9 kW, this heater will heat up a city apartment with a total area of up to 90 m², not to mention a separate room.

The design of the stove provides for the combustion of solid fuel by the pyrolysis method. This is when the wood does not burn, but smolders in the combustion chamber. In this case, the flue gases are removed to the second furnace, where they are enriched with oxygen and burned. In essence, a two-stage combustion is obtained. Therefore, the efficiency of this type of bourgeois reaches 90%. In a traditional design, it is 75%. So the difference is impressive.

There are also stove stoves made of cast iron in the model line. This is a real work of art. Such furnaces are a sectional structure, each part of which is molded according to artistically designed sketches. In this case, the variety of decorative design is limited only by the imagination of a person.

Such stoves are most often made to order, so they are not cheap. Their technical and operational characteristics are very high. The design is thought out to the smallest detail - from the body and the firebox to the chimney. By the way, in all modern potbelly stoves, the chimney can be installed both on top of the device and on the side.

Fuel economy

This is the last criterion for bourgeois, which are used in modern apartments. Above, it was already mentioned about the designs of long-term combustion. They are today the most popular option when it comes to installing a stove in an apartment.

What is the design feature of this model? The thing is that the firebox of the device is divided into two parts - lower and upper. The split border can be horizontal or angled. It all depends on what conditions for the combustion of flue gases we are trying to achieve. With an angular placement of the border, the combustion efficiency is slightly higher due to the higher gas concentration inside the narrowed part of the chamber.

Firewood or coal is usually smoldering in the lower firebox. Oxygen-enriched flue gases are burned in the upper one. Channels are specially installed for oxygen to enter the chamber. At the same time, there is one very important criterion that ensures full combustion of fuel in the first chamber. The fuel must be properly stacked, that is, with a minimum amount of gaps between its parts.

For example, if it is firewood, then they must be laid out horizontally in order or in the form of a cage. The distance from the walls of the stove should be minimal. If the stove has a cylindrical shape, then in addition to horizontally laid logs, it is necessary to lay firewood in a vertical direction. They must be placed in the gaps between the walls of the unit and the corners of the stacked firewood pyramid. In this state, a minimum amount of fresh air penetrates into the wood, but it is quite enough for the fuel to smolder.

The flue gases flow through the exhaust channels under the influence of physical laws upward into the second combustion chamber, where they burn, releasing additional heat.

Attention! One load of solid fuel is enough for a whole day. In traditional stove stoves, fuel fill is enough for only a couple of hours.

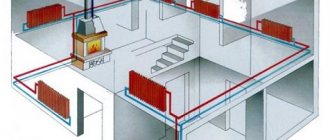

Pros and cons of heating with a water circuit

In winter, the stove must be heated continuously, laying firewood in manual mode

Brick stoves with a water circuit used to heat a private house have their advantages and disadvantages. They must be taken into account when choosing a similar device for a bath or living room. You need to choose the right model taking into account the specific parameters of the house. The best option would be a long-burning stove, capable of operating for 12-14 hours after one fuel fill.

The list of advantages of a furnace with a water circuit includes:

- economical fuel consumption in comparison with systems operating on other energy carriers;

- the ability to install a stove complete with other heating systems;

- the stove's ability to successfully fit into any interior design project.

Of the disadvantages of such units, they note the need to heat the stove in winter in a continuous heating mode. Otherwise, the rooms will not be warmed up to the optimum temperature.

Useful Tips

- Installing a potbelly stove in a city apartment is a serious matter. It is never placed close to a wall or other supporting structure other than the floor. A minimum distance of 5–7 cm must be observed.

- In front of the firebox, non-combustible material must be laid on the floor. This is a safety precaution in case coal falls out of the combustion chamber. Although modern potbelly stoves for a city apartment are a reliable device, experts still believe that "God protects those who are careful."

- Do-it-yourself installation of the unit is not so difficult if you figure it out. Any man can cope with this process without much difficulty. But is it worth the risk? Therefore, we recommend calling a specialist, and let all the responsibility fall on his head.

- Special attitude to the chimney. If your potbelly stove will run on gas, then you can use the coaxial option for removing carbon monoxide gases. If wood or coal will be used as fuel, then we recommend an ordinary vertical chimney. The coaxial version with solid fuel combustion products, where soot is present in large quantities, may not be able to cope.

- Modern potbelly stoves can operate on different types of fuel. Of course, it was initially assumed that they would operate on solid fuels. This has always been the case. But the availability of various types of energy sources made it possible to create units of various designs. So the choice has become much wider. Here it is important to correctly place those elements that contribute to the combustion of a particular type of fuel.For example, gas burners are installed on gas stoves. In electric models, special heating elements are mounted.

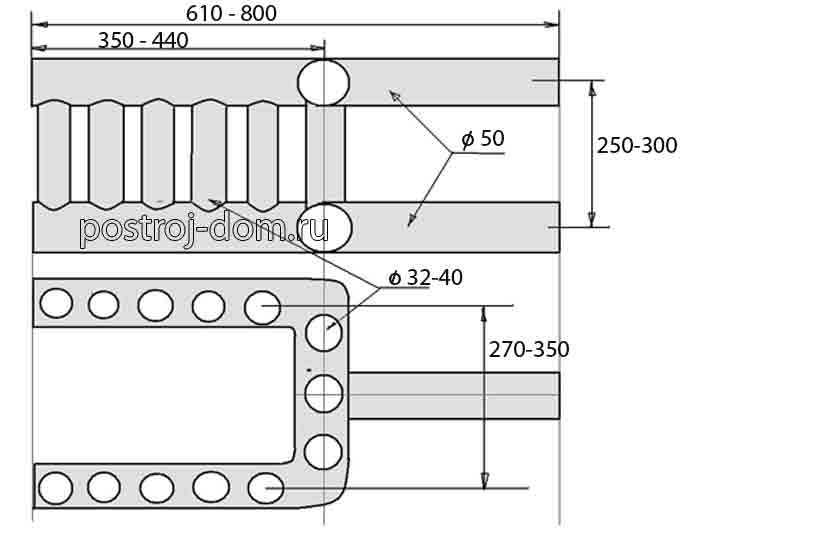

Heat exchanger manufacturing

The power of the heat exchanger depends on the materials from which it is made. If the part is cast iron, models of the MC-110-300 and MC-90-300 series will be the best choice. Due to their small size, they easily fit into the firebox, their heating area for each rib will be 0.14-0.16 m2. Taking these figures into account, you can calculate how many sections are needed to heat each circuit. For every 10 square meters of premises, 1 kW is needed, equal to approximately 0.1 m2 of the total heating of the heat exchanger.

We suggest that you familiarize yourself with Installing a gas burner in a sauna stove

For the manufacture of the simplest heat exchanger, sheet steel can be used. Such a heat exchanger can be easily cleaned of ash, but is not capable of heating large areas. Tubular models have higher efficiency and are suitable for large buildings.

In the photo of stoves with water heating, you can visually familiarize yourself with the various design options for heat exchangers.

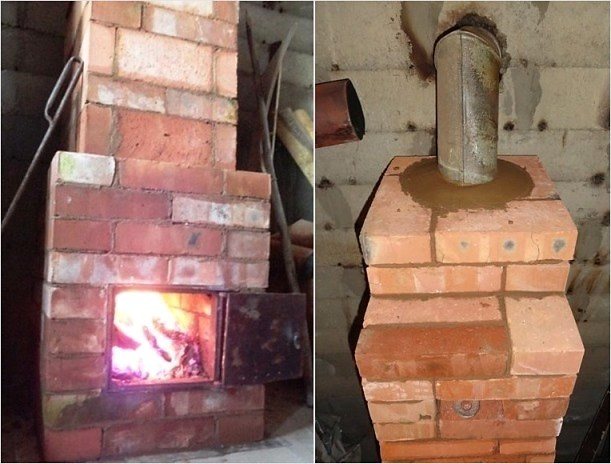

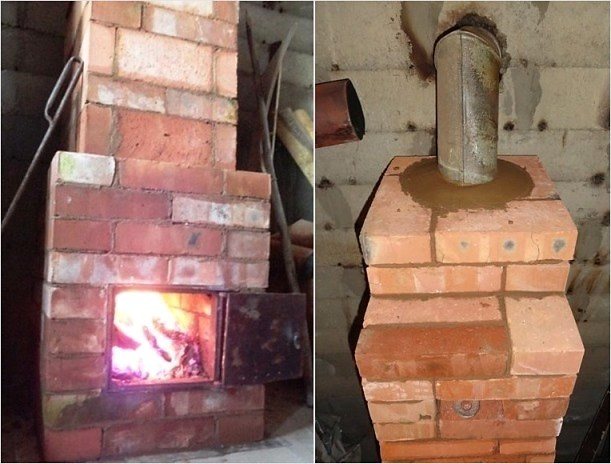

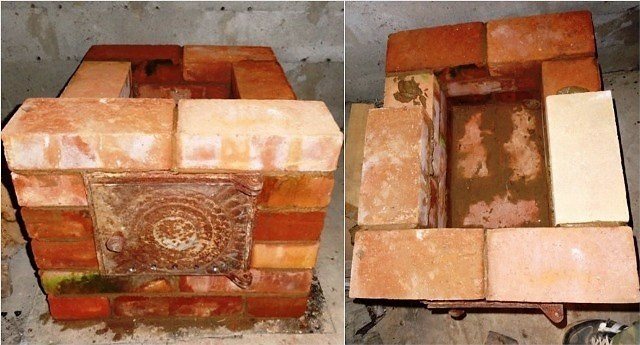

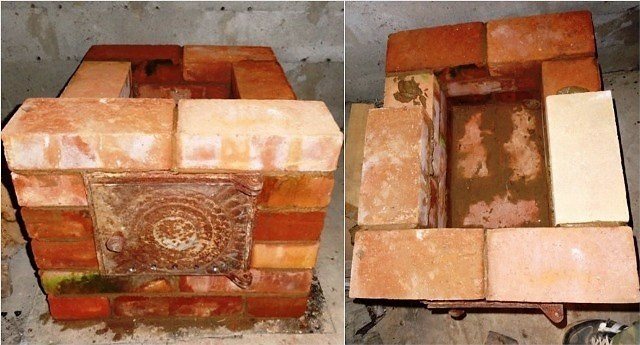

The easy way

Let's say you have a ready-made brick oven (heating, heating and cooking or ordinary fireplace).

We are required to do the wiring around the house and spend a minimum of money. The easiest way to build a boiler into a brick oven is to make and place an ordinary coil in the firebox. Typically, a heat exchanger oven is more efficient and economical. It is worth noting that any form of heat exchanger can be used.

There are three nuances to consider:

- Limit difference in height at the entrance and exit.

- Maximum surface area.

- The heat exchanger must not interfere with the combustion process and fuel supply.

It is desirable that the heat exchanger is made of heat resistant stainless steel. While this material will cost you significantly more than steel, which will rust over time, it alone will last much longer.

In those cases when the furnace is just being erected, it is possible to ensure that the water boiler in the brick furnace works as efficiently as possible.

To achieve this, you need to fulfill the following conditions:

- Combustion products must come out of the chimney at the highest possible temperature. The efficiency of such a furnace will be the higher, the greater the amount of heat transferred inside the furnace.

- Ideally, if the heat exchanger is installed outside the firebox. This approach is explained by the fact that the flame, being a volatile substance, easily gives up its heat and cools, as a result of which we have partial combustion of fuel, the efficiency of the furnace deteriorates. Although, it would seem, the highest temperature is present in the firebox.

- The scheme should be such that the water in the heat exchanger moves towards the heat flow. In other words, the cooled heat carrier must meet the coldest furnace gases, and the heated one must meet the gases with a higher temperature.

Thus, it will be possible to maintain a large constant temperature between the two sections, and more efficient heating can be achieved. Among other things, much less condensate will accumulate on the heat exchanger, which provokes rusting of ordinary steel.

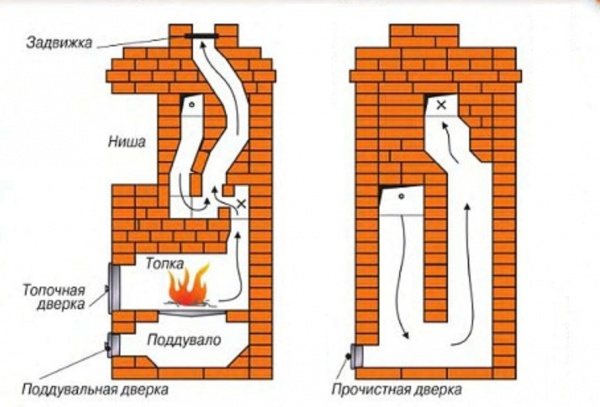

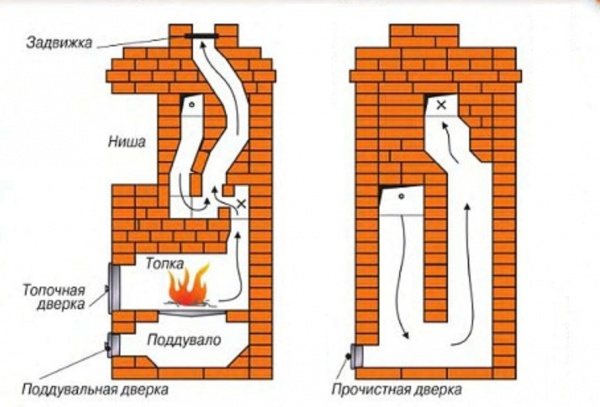

This method of arranging a stove with a water heating boiler is very simple - it involves the installation of a bell-type chimney with a heat exchanger placed inside, capable of holding a large amount of coolant. It is best to use a register welded together from several large-section pipes as a heat exchanger in this case.

Installing the boiler in the stove with our own hands according to this scheme, we get the following results:

- Furnace gases will stay in the bell longer - the hottest ones will accumulate in its upper part, and their escape outside the bell will occur after the combustion products have cooled down and go down.

- There are no obstacles to combustion in the firebox. Fuel combustion will be as efficient as possible.

- The natural movement of flows in the heat exchanger located in the bell is from bottom to top. The coldest exhaust gases come into contact with the coolant that has just entered the heat exchanger.

If all the conditions for connecting a boiler for a brick oven with water heating are fully met, a ready-made heating system, created by oneself, will be as effective as possible. However, which version of the heat exchanger is best suited for you is up to you.

Furnace types

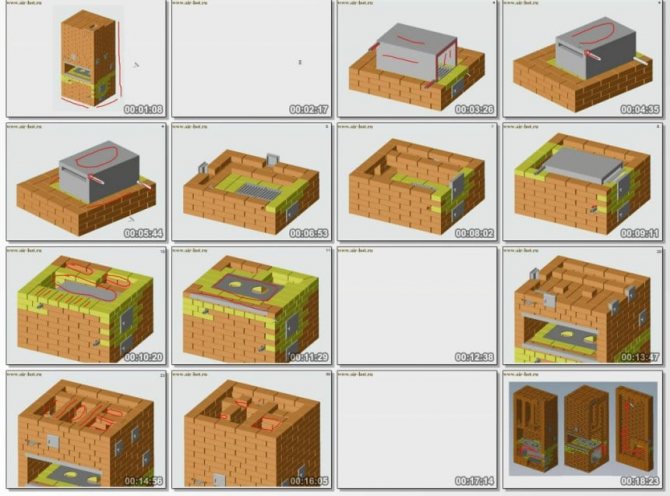

The history of the evolution of stove structures goes back many centuries. Unsurprisingly, folding a heat-efficient and reliable stove is an art form. But with proper preparation and diligence, you can do it yourself, here is a good video tutorial:

You can fold the oven using a variety of methods. At the same time, there are a number of parameters that determine the specifics of the future stove:

- Purpose.

- The temperature to which the walls should be heated.

- The time required to heat the walls and the amount of fuel required for this.

- Chimney design.

- Heat transfer level.

- Scheme of the movement of gases in the channels.

- The form.

- Exterior wall finishing material.

- Main material.

Based on all these parameters, you will fold the oven of your dreams. The main thing at the initial stage is to draw up a drawing, with detailed diagrams. The project needs to describe in detail all the features of the future design. But before that, you need to decide what kind of stove you need.

It is easiest to fold the heating stove. It performs the main function - it gives warmth to people and the home. Such structures do not carry any additional functionality, but they are reliable and easy to use, for which they have won many sympathies among summer residents.

Naturally, all heating stoves are classified according to heat transfer, the time required for kindling and the degree of heating of the walls. It is on these parameters that you need to rely first of all before folding the stove with your own hands.

If you expect to get a moderately heated stove, you can fold it into one brick. Such ovens heat up slowly and also cool down slowly. The average wall temperature is about 60 degrees.

Heating stoves cannot be called a refinement of architectural thought. But the massive design and uncomplicated shapes create a sense of monumentality. In addition, if you skillfully fold bricks in this stove, it can become an excellent decor element.

Moreover, do not forget about the exterior decoration. After you fold the stove, you can plaster it and put tiles on top. Firstly, it will protect the structure from destruction, and secondly, it will give it a beautiful and aesthetic appearance.

Typical representatives of the family of heating stoves include such designs as:

- "Dutch",

- OPT-3,

- Triangular oven,

- Stove Grum-Grigimailo,

- OTP-11

- Rectangular heating,

- T-shaped.

These ovens are rarely very popular. The fact is that in order to put them together it takes a lot of time and materials, and the functionality turns out to be poor as a result.

Very often, in country houses, the owners decide to lay down the heating and cooking stove. This construction has many advantages over a conventional stove. On it, without any problems and even comfortably, you can cook food using pine, birch or yew firewood.

The main element of such a stove is the hob, which is made of cast iron. The oven is not built in everywhere, since it takes a lot of skill to fold it. The most advanced designs have the following additional capabilities:

- a chamber for baking bread,

- stove bench,

- niche for drying firewood,

- boiler of water heating.

In fact, the number of additional functions depends solely on your capabilities and desires. In fact, a real multifunctional combine can be folded from a simple stove, which will become the main decoration of the kitchen. It's not even worth talking about savings. In addition, food made on such burners is always tastier.

Such ovens can keep warm for a long time. Not only that, they provide powerful traction. The main thing is to fold everything correctly so that the smoke goes directly into the chimney, and not inside the room. The most common designs:

As you can see, there is a huge variety of heating and cooking stoves, on which you can cook something tasty without problems and with the benefit of the family budget.

Constructions with heating shields are a cheap solution that includes all the functionality necessary for giving. To fold such a structure, you need a minimum of materials and physical labor. Enough 175 bricks for a full-fledged masonry.

Features of the selection, installation and operation of fireplaces

Such ovens are virtually universal; they are suitable for outbuildings and multi-storey country houses.

You can make a fireplace stove with water heating by simply installing a glass door. Such a stove will become not only an important functional element, but also a stylish part of the interior of the house.

But, working with such a furnace, a number of requirements must be observed:

- the operation of the furnace must be constantly monitored, firewood and (or) coal must be laid on time, the ash pan must be cleaned;

- it is advisable to use the oven only in winter. It is not worth using it for cooking in summer, since a lot of energy will go to the heating system, which is not needed in warm weather;

- you need to regularly check the condition of the chimneys;

- due to the high temperature, the heat exchanger may burn out over time; to replace it, partial disassembly of the furnace will be required.

In order for home heating to be effective and safe, when buying, installing and using industrial stoves with a fireplace effect, you need to take into account some of the nuances:

- selection of power;

- body and heat exchanger material;

- conditions for safe installation;

- rules for connecting to the heating system;

- requirements for the arrangement of the chimney;

- selection of firewood and other types of fuel;

- proper firebox, cleaning and do-it-yourself maintenance.

Choice of oven power

The most important parameter that must be taken into account before buying a particular model is the heat output of the heating unit. It is measured in kilowatts, and it is generally accepted that 1 kW of stove power can heat 10 m² of house area.

We offer you to familiarize yourself with a long burning sawdust stove

However, it should be borne in mind that the manufacturer tests the stove in conditions close to ideal, and when using insufficiently dried wood, its power may decrease by a third. Therefore, to use a stove with a heating circuit as the only source of heating, it is better to buy a model with a small power reserve.

Steel or cast iron?

Heating stoves-fireplaces are steel and cast iron. Steel furnaces are cheaper, lighter, but more susceptible to corrosion. Models made entirely of cast iron have increased durability, corrosion resistance, but at the same time they are much heavier, they are afraid of sudden changes in temperature, from which they can crack.

The best option is combined models, in which the body and slightly heating elements are made of steel, and the elements of the firebox, grates and doors that are exposed to strong overheating are made of forged cast iron. They are not afraid of prolonged exposure to high temperatures and are suitable for constant use, and with intermittent heating, the condensate formed in the pipes does not cause corrosion.

Due to their low weight, industrial models do not have special requirements for floor preparation, they do not need a separate foundation.The only requirement is the finishing of wooden floors with non-combustible materials: sheet metal, ceramic tiles or fire-resistant types of coating, which can be done with your own hands at a minimum cost.

Which brick is better to fold the stove from

It is necessary to distinguish between ordinary heat-resistant bricks from oven bricks. Firstly, the latter can withstand temperatures above 1000 degrees. Secondly, if it is rapidly cooled, no cracks form in the structure.

For the construction of stoves, four types of stove bricks are used:

- Quartz. This brick is the result of firing sand and clay.

- Carbonaceous - consists of graphite.

- Fireclay. Best for a fireplace. But one cannot discount its unique thermal insulation qualities. It is able to withstand temperatures up to 1600 degrees. At the same time, it does not crack and does not lose its qualities. The only negative is the yellowish tint.

- The main one is used when you need to fold the metallurgical furnace.

In reality, there are no strict rules regarding the choice of materials for masonry during construction. Nevertheless, there are some recommendations that are best followed, the main one of which concerns fireclay bricks. It should be placed in the hottest places, namely in the area of the firebox and chimney. For all other zones, the grade must be at least M-200.

What are the principles for determining the installation location

It is worth understanding that the question of where the stove should be located in the house is extremely important and responsible, therefore, it is worthwhile to approach the search for an answer with special care.

The principles for determining the location are as follows:

- Any stove should be as close to the central part of the house as possible so that the external chimney does not go far from the ridge.

- The correct location of the device will be in the event that other communications are not carried out under it, for example, water supply.

- When installing two ovens in one zone, it is still better to design for each foundation in order to protect yourself from the rapid destruction of products.

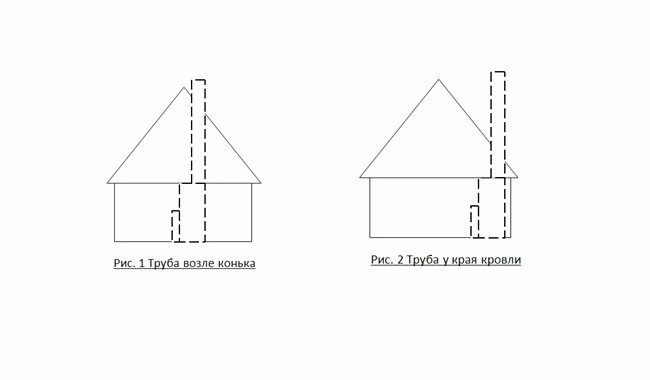

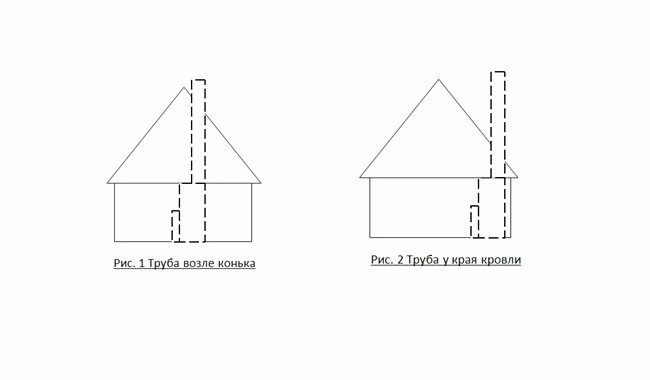

The location of the pipe relative to the ridge of the house

In addition, it is worthwhile to clearly understand that one structure must heat at least two rooms, otherwise its installation will not be advisable.

Good to know: Why iron ovens heat up a room rather than brick ovens

Do-it-yourself oven

Seat selection

To fold a good heating structure, you need to choose the right place. In doing so, the following standards should be taken into account:

- From the chimney to wooden structures, it must be more than 37 cm.

- The minimum distance of the pipe from the ridge is one and a half meters. The height above the ridge is half a meter.

- If it is 1.5-3 meters from the pipe to the ridge, it can be placed flush with it.

It is best to fold the stove in the middle of the house. This will ensure even heat distribution and ease of use.

Materials and tools

In addition to brick, you will also need a number of other materials to fold the stove. These include:

These are the main materials without taking into account the components, and you still need to take care of the vents, the blower, the firebox, and so on.

To fold a good stove, you need to knead the right solution. It is best to use special refractory clay, in extreme cases, you can also red. Grains of sand should be no more than 1 mm. The optimal ratio is achieved empirically. This is usually 1 to 1 or 1 to 2. Plus 25 percent water from the total clay.

Metal objects play the main role in the construction of the furnace. To fold a decent structure, you need doors and half doors, grates, cast iron dampers, latches and views. All these elements, if necessary, can be made by hand, but you will need to purchase iron sheets.

Of course, you won't be able to fold the stove without good tools, you will need:

- hammer-pick specially for the oven,

- Master OK,

- rule-ruler,

- wash brush,

- roulette,

- plumb line

- level.

With this simple toolkit, you can fold any oven.

Stove construction process

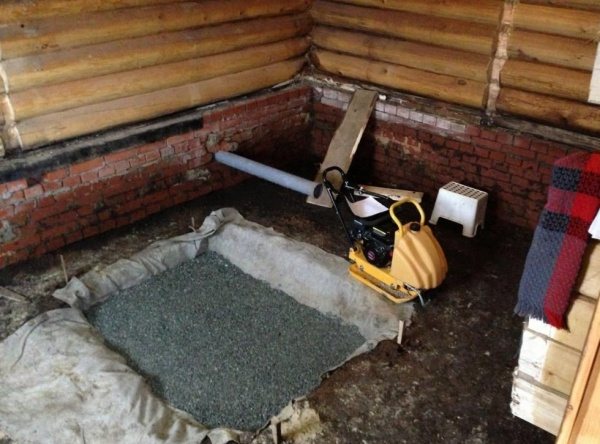

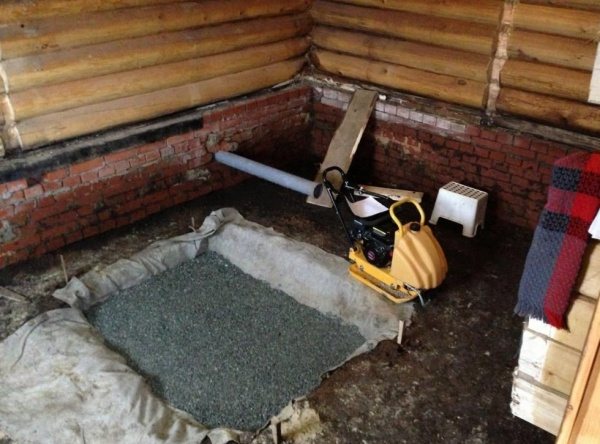

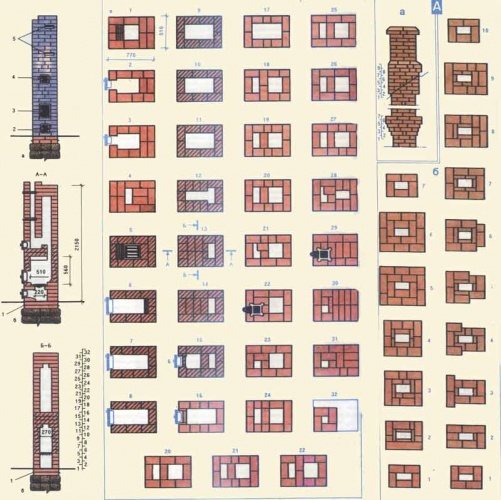

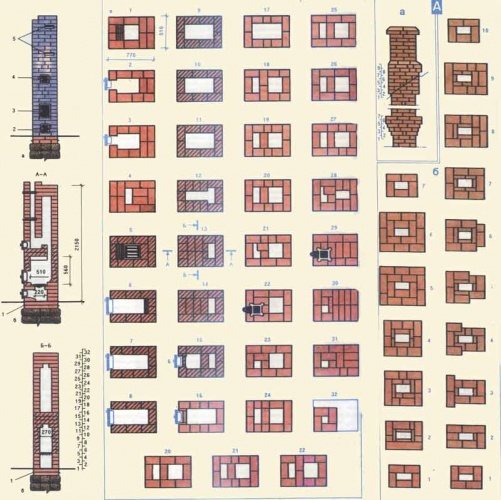

For the foundation, a pit is dug, backfill and a reinforced frame are made. The resulting structure is poured with concrete. Before folding the stove, make sure you have brick patterns in front of your eyes.

It is very important to keep order when working. Otherwise, you will not be able to fold a high-quality oven. The slightest deviation in the design will lead to the fact that one of the channels will be blocked. The result is more than disastrous. The smoke, instead of going out through the chimney, will go into the room.

The first row is laid along the cord. Each next masonry is checked using a level. The corners are controlled by body kits. After the laying is completed, the oven equipment is installed, for example, the burners. The pipe is led out at the very end. To learn more about how to fold the oven, see the video below:

In order to fold the stove in accordance with current standards, the distance from the inner wall of the chimney to the nearest structure must be at least 38 centimeters. When installing a cast iron plate, the gaps on the sides should be at least 5 millimeters.

Outcomes

Folding the stove is within the power of each person. The main thing is to choose the right look from the very beginning and draw up a project where you need to describe in detail the features of the future stove. In order not to bother creating unique drawings, you can take ready-made drawings.

The comfort of a country house built far from gas supply networks is unthinkable without a stove. In the cold season, it gives us pleasant warmth, ridding the air of dampness.

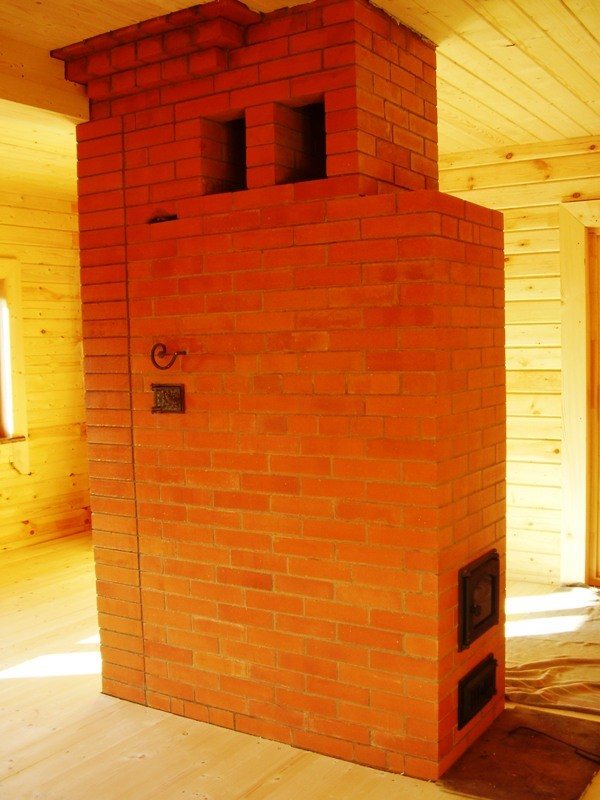

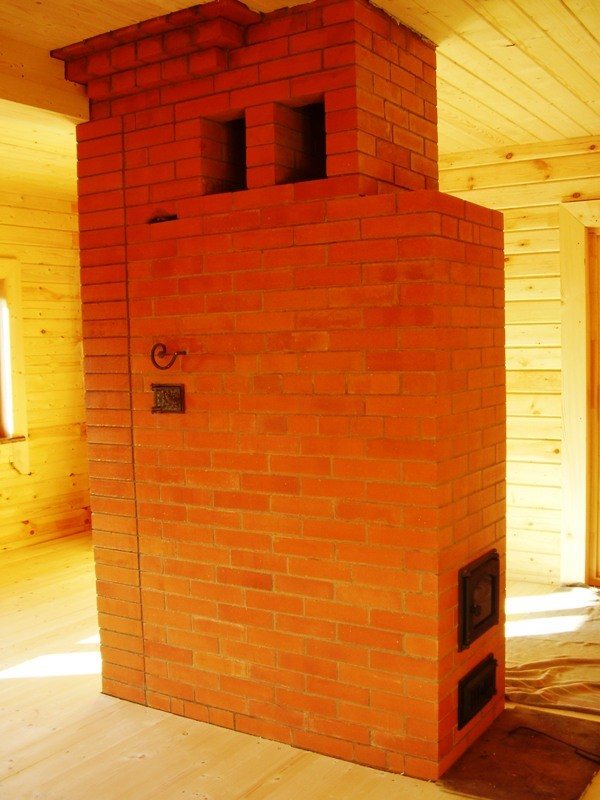

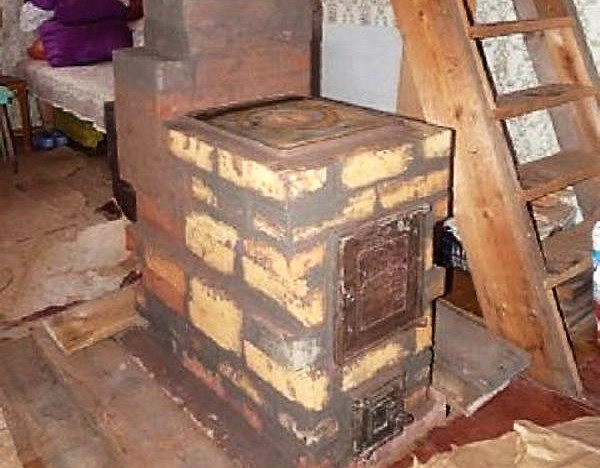

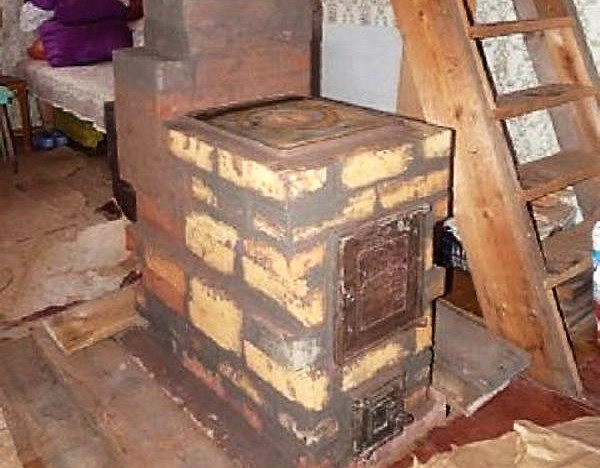

The market today offers customers all kinds of designs of metal "burzhuikas". Despite this, many summer residents prefer the classic version - a brick-built heating stove. Its advantages are obvious: due to its high weight, it accumulates a lot of heat and gives it away for a long time, warming up the room well.

The content of the article:

The service life of a brick structure significantly exceeds the service life of a metal one. The minimum cost of materials and ease of arrangement attract the attention of home craftsmen to a simple stove for giving.

Our article will help you test yourself as a stove-maker. In it, we will consider several options for simple wood-burning stoves and give practical recommendations for laying them.

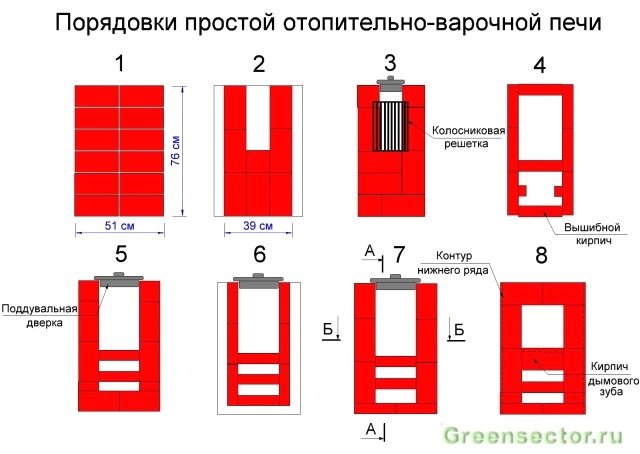

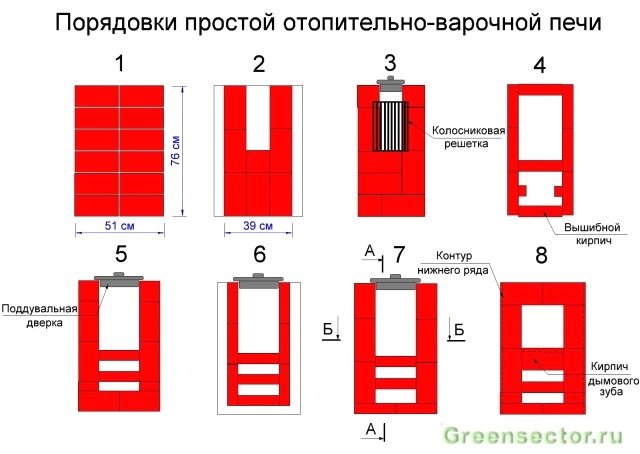

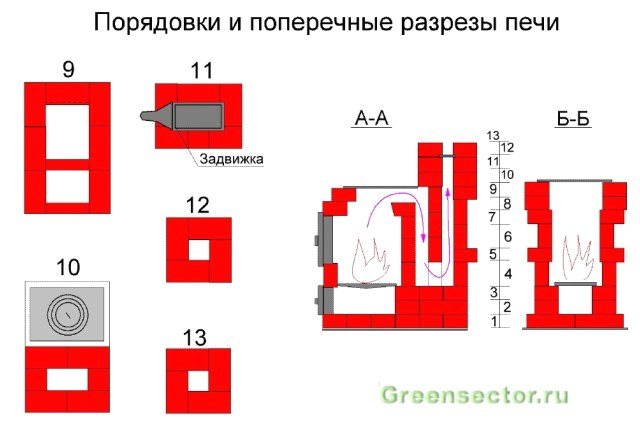

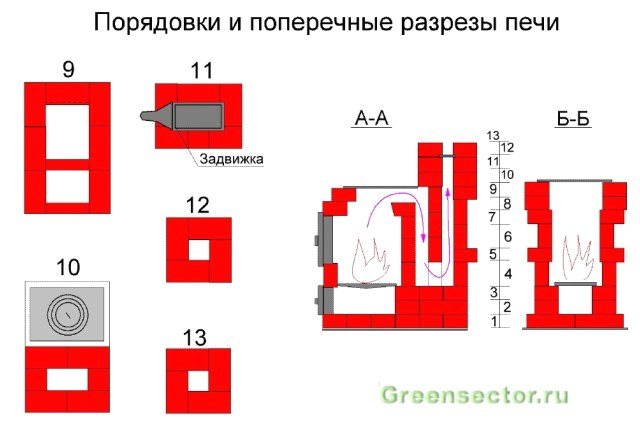

You will be convinced that there is nothing complicated in the drawings of these structures. Having learned to read "orders" - brick layout schemes, you can build a full-fledged heat generating device with your own hands.

How to fold the simplest brick oven?

First you need to decide what you want to get from the future stove. If you only need to heat the rooms, and you use bottled gas or electricity for cooking, then choose the option without a stove and oven. Anyone who loves soft, healing warmth chooses the option with a stove bench.

For regular cooking of large quantities of food and pet food, a simple oven with a hob will do just fine.

We'll look at three examples of ovens with a step-by-step guide to laying them:

- Simple straight-through;

- With a hob;

- Heating.

Let's say right away that one cannot expect high heat transfer from a simple design, devoid of gas revolutions. For this reason, such stoves are installed in garages and other small rooms with an area of no more than 16 m2.

We will consider this option so that beginners get their first simple lesson in practical masonry.

A powerful foundation is not needed for such a stove. Having poured large gravel with a layer of 15-20 cm, filling it with cement mortar and leveling the surface to a level, in a couple of days you can start laying.

The dimensions of the furnace in the plan: width 2 bricks (51 cm), depth 2.5 bricks (64 cm). Since there is no blower chamber in it, holes for air intake are drilled directly in the furnace door.

The orders of this design are simple. The main condition during work is to observe the dressing of the seams so that the upper brick covers the seam between the two lower ones.

Main characteristics

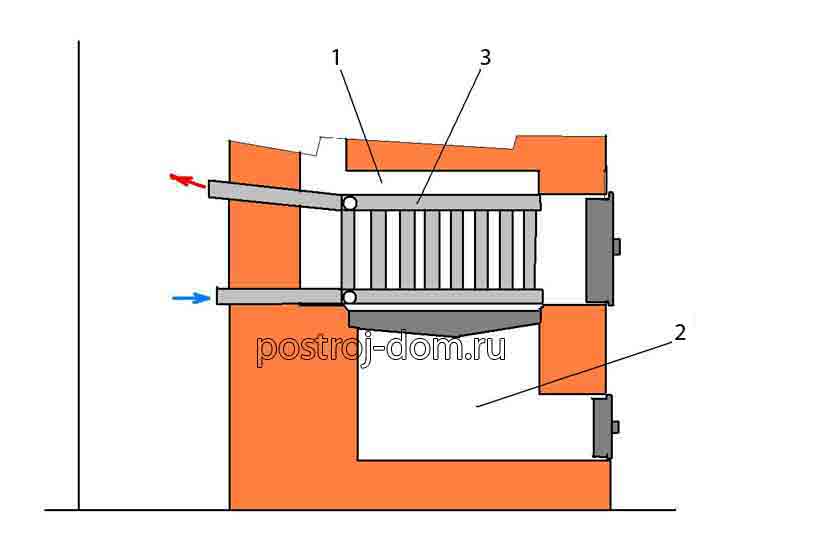

Depending on the type of heat exchanger, the device can be divided into two types

- Flat. Here, several plates are introduced into the brick body, in which water is heated. The advantages of such a unit are in the increased surface area from which radiation occurs, as well as in the ease of cleaning. On the other hand, these elements take a long time to reach the desired temperature. Flat plates block the access of an open flame to the masonry, so the walls of the stove itself do not radiate enough heat.

- Tubular. In this case, a coil is welded from steel pipes, preferably seamless ones. It is easier to mount it than the previous elements. The main thing is that it matches the size of the combustion chamber. Such a wood-burning boiler for heating has a larger heat exchange surface. The tubular design does not block the access of the flame to the outer walls, so the direct transfer of energy is unimpeded.

Oven with hob

In the simplest version, such a structure has small dimensions (width 2, and depth 3 bricks - 78x53 cm). Nevertheless, even in such a limited area, a single-burner stove can be placed.

Work gets done when you have everything you need at hand.

Therefore, buy the following materials and accessories in advance:

- Solid red brick - 107 pcs;

- Blowing door - 1 piece;

- Grizzly grate - 1 piece;

- One-burner cast-iron stove - 1 piece;

- Furnace door - 1 piece;

- Pipe gate valve - 1 pc.

Refractory bricks for a wood-burning stove are not needed. Buying it is a waste of money. But red should be chosen carefully, rejecting cracked and uneven.

Solution preparation

A masonry mixture is made by mixing four parts of clay with one part of water and adding eight parts of sifted sand to them. The normal consistency is determined simply: the mortar easily slides off the trowel without leaving streaks on it. When laying, it should not flow out of the seams.

The volume of the solution is determined based on the number of bricks. With an optimal seam thickness (3-5 mm), one bucket is enough for 50 pieces.

Having prepared the masonry mixture, you can start laying the base. Its width is made 10 cm more than the width of the oven. The height of the foundation is selected so that the bottom of the first row of bricks is at floor level.

If the underground is deep enough (50-60 cm), then there is no need to dig a hole under the foundation. It is enough to make a formwork on the ground with a plan size of 76 x (51 + 10cm). Two layers of roofing material are laid on its bottom to protect it from moisture. Having laid the concrete, he is given a week to gain strength, after which they start laying.

The dimensions of the oven we are considering with a hob are 3 x 1.5 bricks (76x39 cm).

Master's advice: lay out each new tier of brick without mortar (dry). After adjusting the bricks to size, you can start laying.

The first row is placed on a layer of clay mortar (4-5 mm). Aligning the base with a level, lay out the second, leaving room for the blower door.

Before installing the door, you need to screw a soft wire to it and lay its ends into the seams for better fixation.

To compensate for the thermal expansion of the metal, a gap is left between the door and the brick. Before installation, its frame is wrapped with a wet asbestos cord.

The masonry of the third row is carried out, overlapping the seams of the second. At this level, a grate is installed in the firebox.

The fourth row is placed on the edge, observing the dressing of the seams, and the walls of the combustion chamber are formed. Behind it there will be the first and only smoke circulation (see section А-А in the scheme №2). To clean its bottom, a so-called knockout brick is placed in the rear wall without mortar, periodically removed to remove ash.Inside the chimney, two supports are made of pieces of brick to support the internal partition.

The stones of the fifth row are placed flat, leaving room for the furnace door. At the rear of the stove, in order, we see the walls of two smoke channels. During work, their surface must be thoroughly cleaned with a wet cloth from the clay protruding from the seams. This is an essential prerequisite for good traction.

Helpful advice! Focusing on the order drawings, do not forget to look at the two cuts of the stove. They will help you better imagine its design and not make mistakes when laying out bricks.

Raising it into the masonry up to the eighth row, they block the fire door, laying a wire in the seams that fixes its frame. At the same level, a brick with a beveled end - a smoke tooth - is placed in the back of the fuel chamber. It improves heat output by preventing flue gases from escaping quickly into the chimney.

Having finished the ninth row, an asbestos cord is laid on it in a clay solution. It is necessary to seal the joints of the cast iron plate and brick. On the tenth row, the firebox is covered with a hob.

On the eleventh, a smoke valve is installed in the pipe. It is also compacted along the contour with an asbestos cord dipped in clay.

12 and 13 row - the formation of the pipe walls. After their completion, a light sheet metal pipe is placed on the furnace, which is brought out to the roof.

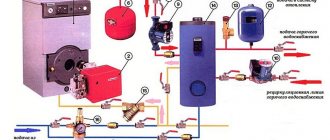

Connecting the stove to a hot water heating system

Without a doubt, the purchase, installation and piping of two separate units will cost you more than one combined heat generator. But, by implementing this option, you get full heating with two energy sources, effectively operating in automatic mode.

In our pair of heat sources, a wood (coal) boiler is the main one, and an electric one is an auxiliary unit. As the latter, you can use any of the three types of electric boilers on the market:

- traditional heating element with built-in circulation pump and control unit;

- electrode with a remote control panel;

- induction with a separate control panel.

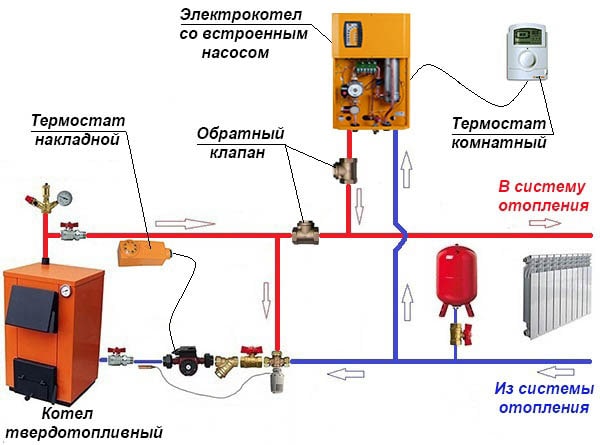

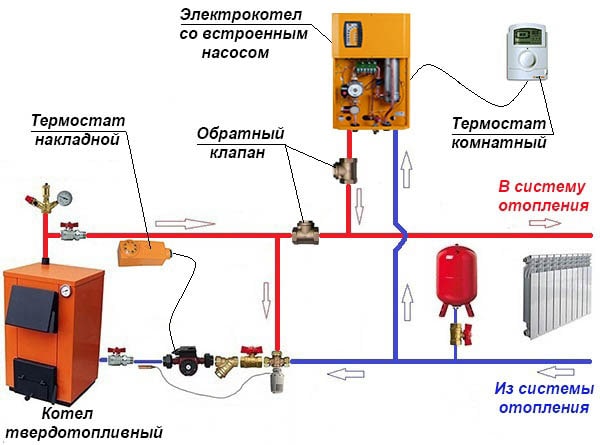

Connection diagram for 2 boilers - on electricity and wood. Thermostats provide automatic start of the electric boiler after stopping the wood-burning boiler and vice versa.

The system operation algorithm looks like this:

- The TT boiler is inactive and its circulation pump is off. The heating devices receive heat from the electric boiler, which is guided by the room thermostat, where you have set the desired temperature. To prevent the coolant from moving in a circle through a parallel ring, 2 check valves are involved in the circuit.

- You melted a solid fuel plant. For a while, it will begin to gain temperature, and the water will circulate in a small circle, guided by a three-way valve with a thermal head. The pump will turn on at the command of the overhead thermostat installed on the supply pipeline.

- When the coolant in the small ring heats up to 55 ° C, the temperature sensor of the thermal head, which is on the return line, will be triggered. The three-way valve will open slightly and the heat will go to the heating system.

- The electric boiler will turn off heating at the signal from the room thermostat and go into standby mode.

- After the solid fuel burns out, the water in the system, and behind it the air in the rooms, will begin to cool down. The overhead thermostat of the TT boiler will “see” that the coolant has cooled down and will stop the pump.

- When the temperature in the house drops to the value set by you, the room thermostat will re-activate the electric boiler.

The water circuit is lined with fireclay bricks so that it does not burn out ahead of time

To fully connect the device to the general system, you will need to purchase a coil for the water heating stove. It is installed inside the firebox. When choosing it, the thickness of the walls of the stove is taken into account, if we are talking about a device that runs on wood, the walls can be thinner.

Units fired with coal briquettes can have denser walls.This condition cannot be ignored, otherwise the boilers will quickly burn out, and they will have to be replaced before the expiration of the prescribed service life.