Home / Solid fuel boilers

Back to

Published: 24.05.2019

Reading time: 7 minutes

0

1062

In the absence of an opportunity to connect to the centralized gas supply system, the owners of private houses and summer cottages decide to install an automatic solid fuel boiler.

Firewood, coal, peat or sawdust (pellets) are used as fuel in such units. But since manual loading of the listed raw materials becomes difficult, many consumers prefer devices with the automation of such a process.

- 1 The principle of operation of automatic long-burning boilers

- 2 Difference from semi-automatic boilers

- 3 Internal structure

- 4 Types of automatic boilers

- 5 Requirements for the installation of an automatic solid fuel boiler

- 6 5 best boilers with automatic fuel supply

Content

- Automation for solid fuel heating boilers

- Automation processes

- Automation for a heating boiler (types and device)

- Manual boilers with automation

- Boilers with automatic solid fuel supply

- Solid fuel boilers for long burning

- Automation for anthracite boilers

And yet, the majority of the population is discouraged by the maintenance of solid fuel boilers, which must be done every 3-4 hours. Due to the fact that the fuel burns quickly, it is necessary to regularly throw coal or wood into the firebox. Ash pan cleaning is also a laborious process and not the most pleasant one. And the regulation of temperature is a whole problem: for this, the owner must correct the position of the damper, with the help of which the flow of air masses into the furnace is controlled.

Now, thanks to automation, all these processes can be performed less frequently or remotely, while saving money on electricity and gas.

Difference from semi-automatic boilers

Photo source: kijiji.ca

Unlike semi-automatic models, where only the rotation frequency of the fan blades is controlled, automatic units are also able to control the intensity of fuel loading. The raw material is supplied by means of a screw mechanism from a special warehouse. In appearance, the installation is similar to a meat grinder, but the role of meat is played by the fuel composition. It is used as:

- Coal (bituminous or brown).

- Pellets.

Automatic long-burning coal-fired boilers can operate for 3-4 days without reloading fuel. And if the owners are forced to leave the premises, it is enough to activate the defrost protection mode, in which the system will maintain the optimal temperature regime. A semi-automatic boiler requires direct human participation.

Automation for solid fuel heating boilers

The invention of automation, which makes the maintenance of the unit easier and more convenient, made it possible for solid fuel boilers to become competitive again. Moreover, such equipment can be installed on almost all models of boilers for heating.

Automation for solid fuel boilers can be installed in almost all models

Automation processes

- This function will be performed automatically.

- Automation simplifies the regulation of the temperature of the solid fuel heating system: the procedure is reduced to setting the CH and DHW indicators. Further, in the boiler, using special equipment (pump, fan, etc.)the regulation of the air supply is started, which does not require human intervention. When the solid fuel device cools down by more than 10 degrees, combustion intensifies, and if it is necessary to reduce the temperature, simply air is supplied in smaller portions. Thus, the automation will help save fuel and at the same time maintain a comfortable temperature in the room. It also allows you to leave the unit turned on for a minimum during your absence so that the room does not cool down.

- Another advantage of the automation is the security system, which, in the event of a malfunction of the boiler, turns off the device and notifies the residents of the malfunction with a sound signal. This allows you to quickly eliminate malfunctions that have arisen in the functioning of the unit.

- Since the automation makes a solid fuel boiler dependent on electricity, manufacturers have provided for cases of power outages. The device will be able to work autonomously even without power supply for a certain period of time.

- In modern models of automatic boilers, it is even possible to load fuel without human intervention. To do this, they are equipped with a special bunker designed for storing fuel, from which firewood or coal automatically goes into the furnace. The only drawback is that such a system requires the fuel to be of a certain type and size. The ash cleaning function can also be performed automatically.

- Automation allows you to control the heating system using a control panel, which will reduce your visits to the boiler room to a minimum.

What tools to buy in order to weld heating pipes like clockwork? If the choice fell on stainless steel pipes, then read about the installation here.

The most accurate calculation of the diameter of the heating pipe at the link: https://prootoplenie.com/otopitelnoe-oborudovanie/truby/diametr-trub.html

The main functions assigned to automation

Before installing a solid fuel boiler, you should carefully study the principle of its operation and control mechanisms. Studying the processes of the operating cycle of the heating device will allow you to understand how the devices and mechanisms that control the heating system work. What is automation for solid fuel boilers today, and what are its main functions.

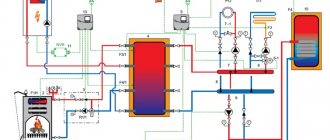

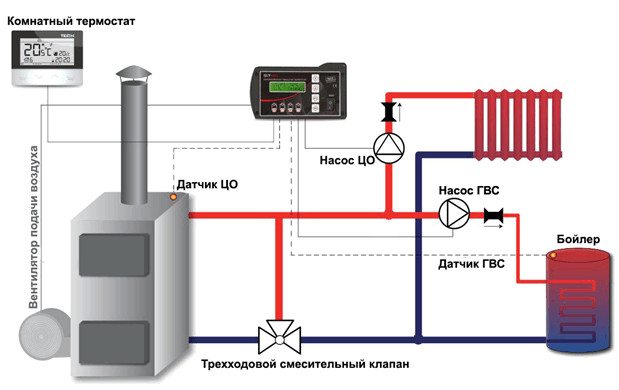

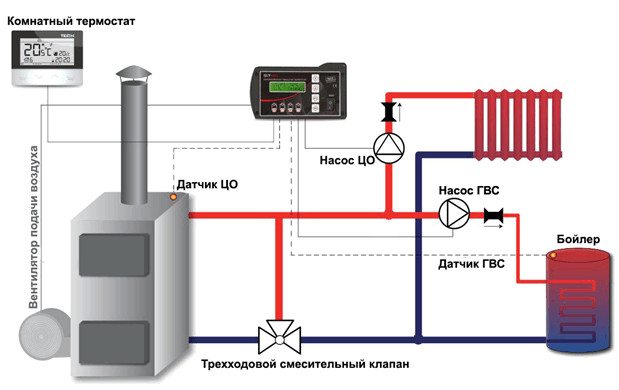

The following functional tasks are assigned to automation:

- ensuring optimal temperature conditions in the heating circuit;

- performing a controlling function for the operation of the pump and the three-way valve in the mixing circuit;

- ensuring control over the operation of the circulation pump on the main heating circuit;

- control of the temperature of water heating in the DHW system;

- provide switching on / off of the three-way valve;

- boiler equipment automation is a set of equipment together with a room thermostat.

The diagram shows the usual piping of an autonomous heating system with installed automation.

Automation of many processes during the operation of solid fuel heating devices allows to achieve significant savings in fuel resources and free the inhabitants of the house from the function of a stoker. Today, automation is a set of complex and energy-intensive devices, each of which solves a certain range of problems and issues.

An automatic boiler is a unit that is capable of operating completely and completely in an autonomous mode, starting with fuel loading and ending with heating temperature control.

For reference: All processes, starting with fuel filling, ignition and control over switching on and off, are done in automatic mode. Without your participation. The presence of sensors and controllers allows the system to react on its own to a changing situation.Based on the parameters you have set, the boiler operates in the set modes.

Automation for a heating boiler (types and device)

Manual boilers with automation

For the operation of a manual boiler, coal is placed on an already burnt layer. The intensity of heat transfer is regulated by manually opening / closing the damper.

This class of heating units has its advantages: such boilers are easy to manufacture and quite simple to operate, they are relatively inexpensive and can consume both different types of coal and firewood.

The disadvantages include low heat transfer at high fuel costs, the need to often add firewood / coal. At the simplest level, this type of boilers can be improved by the appearance of a thermostat that controls the degree of flap lift when the temperature changes. More sophisticated models are equipped with a fan and a thermometer, which are controlled by a simple regulator.

Manual boiler with automation

Boilers with automatic solid fuel supply

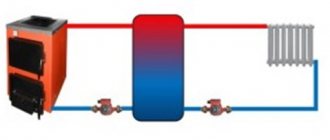

This type of automated boilers is represented by screw units, the mechanism of which consists of the location of the fuel - a bunker (pits or just a room where pellets or pea coal are stored), a screw (auger conveyor) that supplies fuel to the burner, a heat exchanger and a furnace. This type of boilers is represented by a huge number of diverse models.

How to efficiently and quickly make greenhouse heating with your own hands in your home? The best and most reliable double-circuit turbocharged gas boiler, we select here.

Take care of stoves, make stove heating in a private house with your own hands, instructions at the link:

A significant disadvantage of this type of product is the impossibility of operating such units based on the combustion of anthracite and the need to use long-flame coal. On the other hand, the plus of auger boilers is that pellets (pellets from wood chips and waste) can act as an alternative to coal. Today it is wood waste that is called one of the most economical, energy-saving and environmentally friendly fuels.

There are boilers with a pneumatic fuel supply system, which is based on a compressor for supplying air in pneumatic lines, resembling a vacuum cleaner in type. Interestingly, such a structure is capable of transferring fuel over distances of up to 1000 cm and up to 250 cm in height.

Boiler with automatic solid fuel supply

Solid fuel boilers for long burning

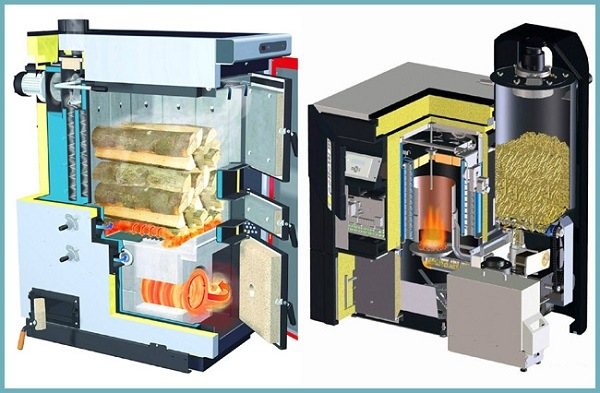

Boilers of this type have a great advantage due to the increased volume of the furnace. A feature of such devices is the installation of heat-resistant parts in the combustion chamber, which improve the quality of combustion of solid fuel. Conventionally, this type of heating device is divided into three subspecies:

- classic boilers with an increased volume of the furnace;

- upper combustion pyrolysis boilers;

- bottom combustion boilers.

On average, at one load, such units can work up to 26 hours. Leading manufacturers of solid fuel boilers have developed models that can function for up to 5 days without additional fuel supply, and the efficiency of such units reaches 90%. In pyrolysis boilers, wood gas burns, the release of which is the result of exposure to high temperatures. It is blown through the nozzles and burns with a colorless flame.

The advantages of pyrolysis boilers include a small amount of ash formed as a result of combustion and high efficiency. The disadvantages are the high price and the need to use only very well dried firewood.

Long burning solid fuel boiler

Automation for anthracite boilers

This type of aggregates is not widespread, since anthracite is found mainly in the territories of Russia, Ukraine, and China.The principle of operation of this equipment is based on obtaining heat when processing this type of coal.

The advantages of such boilers include the comparative cheapness of fuel and its wide distribution in our country.

Automated anthracite boiler

Features, pros and cons

The main functions of the automatic control unit include:

- Metered air supply for burning.

- Performance control heat generator.

- Indirect regulation of heat output depending on the temperature of the coolant.

- Direct power control regarding the temperature of the air in the house or weather conditions.

- Ensuring operability water heating installation in a safe mode.

- Automatic fuel supply.

- Ignition and extinguishing the furnace of the unit.

Positive aspects of using automation:

- The indicator has increased boiler operability.

- No need for constant monitoring over the combustion process.

- Economical fuel consumption.

- Maintaining a constant temperature in the heating system.

- Increased security during the operation of the unit.

- Increasing the interval between scheduled inspections.

- In the event of a failure of the parts, special sensors send a signal to the control unit, and the heating system automatically turns off (stops its work).

Disadvantages:

- High price. The presence of additional options for automation significantly affects the price of the device.

- Given the volatility of the control unit, there is a need to purchase an uninterruptible power supply, or you can use a mechanical draft regulator.

Principles of operation of boilers with automation elements

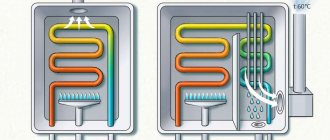

An important role in the operation of a solid fuel boiler is played by a firebox, which serves as a heat exchanger. It is here that the combustion of fuel takes place.

Around this structural element is a water jacket, which is heated by the hot walls of the fuel. Subsequently, this water enters the pipes and radiators. In this case, the liquid circulates by gravity without any special pumps.

The intensity of combustion of a solid fuel boiler can be adjusted manually, using a gate, or using mechanical dampers. If you want to increase the temperature in the room, then it is necessary to raise the damper, which will increase the air flow and speed up the combustion process.

Mechanical automation for gas boilers

This is a long-used and proven option that does not require an electrical connection. Mechanical control systems are used to equip atmospheric heating and hot water appliances. Their purpose is to maintain a stable temperature of the coolant and turn off the boiler in the event of a malfunction.

The design of such systems is simple. The heat exchanger is equipped with a temperature sensor with a temperature-sensitive core made of an iron-nickel alloy (Invar). The user sets the maximum heating temperature with a manual regulator and starts the boiler. When the set temperature is reached, the core lengthens and presses on a mechanical valve that cuts off the gas supply.

For the same purposes, a bimetallic plate can serve, which deforms when heated and cooled, causing the valve connected to it to turn off or on. Bimetallic thermosensitive elements are often used for traction control in smoke exhaust systems. They can work in conjunction with an electromagnetic relay, since a potential difference arises between the soldered plates of different metals when heated. Since it requires a sufficiently strong heating of the element, such sensors are suitable for monitoring the presence of a flame. When it goes out, they will ensure the shutdown of the fuel supply.

Mechanical automation for a gas boiler is good in that it does not depend on electricity.However, it also has disadvantages - low sensitivity and a rather large error in setting the temperature, reaching 1 - 2 ºС. Nevertheless, the popularity of devices with mechanical control remains high due to their complete autonomy and budgetary cost, available to a wide range of buyers.

Installation of automation for solid fuel boilers

Direct connection of the boiler to a closed system is very dangerous, therefore, CH systems equipped with such units must necessarily include open expansion tanks, where water would come into contact with oxygen. This allows H2O to expand when heated, filling this container.

During installation, the correct choice of the diameter of the pipes is of great importance, which must be installed in strict accordance with the instructions provided by the manufacturer.

Features of the installation of automation depend on the model of the solid fuel boiler

What are the types of automation

The capabilities of modern electronic devices included in the set of equipment for monitoring the operation of the heater are wide enough, allowing you to configure the devices in accordance with your own priorities and desires. In most cases, a set of modern complex heating devices includes:

- a computer that controls the heating device;

- fan or air turbine.

Today, it is possible to equip ordinary semi-automatic solid-fuel units of almost any kind with an automatic Comfort Eco-type control unit. A semi-automatic solid fuel boiler equipped with such a kit can already carry out most of the processes independently. The sensors regulate the heating temperature of the coolant, the state of traction. All information goes to the screen. A conventional pyrolysis boiler or a long-burning unit with automation becomes an order of magnitude more convenient and safer to use.

If everything is more or less clear with electronics, then the mechanical part should be dealt with in more detail. There is a classification of automation in terms of autonomy. In this case, it is customary to distinguish:

- automation, volatile - powered by electricity;

- automatics, non-volatile, which does not require connection to the mains.

In the first case, the operability of the main devices is feasible only when the devices are connected to the power supply. To increase the safety of such devices, the autonomous heating system is equipped with a UPS. The first option looks preferable, since network-powered automation has more functionality.

The second case is focused on greater autonomy. Such options are very convenient in situations where power outages are frequent, and the heating device is configured to work independently without unnecessary electronics.

Important! If your boiler is configured properly and operates autonomously, without additional means of monitoring and recording temperature, you need to visit the boiler room more often.