At home, by definition, it should be warm. It can be provided in a variety of ways. However, the zealous owner strives to do this as efficiently and economically as possible. These options include installing a wall-mounted gas boiler. And this is quite justified, since gas heating is very profitable, and the equipment is quite simple to operate and install.

If you also started thinking about purchasing a wall-mounted heating boiler, then be sure to read our material. In it, we will try to tell as much as possible about the principles of operation of such equipment and the types of wall devices. And also we will consider all the nuances of connecting such a system.

The principle of operation of a wall-mounted gas boiler

The installation and connection of the heater depends on its type. Therefore, you need to understand exactly how the device works and which of its varieties you have to deal with.

Any wall-mounted gas boiler is a compact device, the maximum power of which is limited to 42 kW.

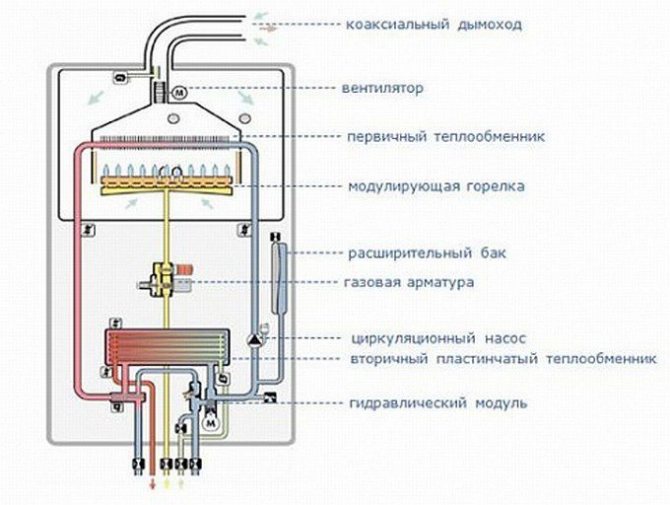

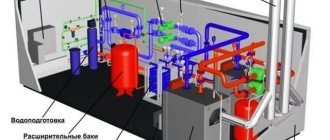

The main elements of the system include:

- Gas burner... It supplies gas to the chamber where the combustion process takes place. The injectors distribute the fuel as evenly as possible. Modern modulating burners can maintain a set temperature and regulate the strength of the flame.

- Heat exchanger, along which the coolant moves. The best efficiency for a copper device. There can be two such elements in condensing boilers.

- Expansion tank... Designed to compensate for excess water resulting from heating.

- Circulation pump... Powerful models can have two of these elements.

- Boiler automation or a system of devices whose task is to maintain a given temperature in a heated room. May include electrical or non-volatile appliances.

- Controlling and regulating devices boiler operation.

- Fan... Used only in turbocharged models.

- Security system... Stops the boiler in case of dangerous situations.

Modern models are additionally equipped with self-diagnostic systems that are able to determine about 90% of boiler faults. The display shows the number of the diagnosed breakdown, which is promptly corrected by the master from the service.

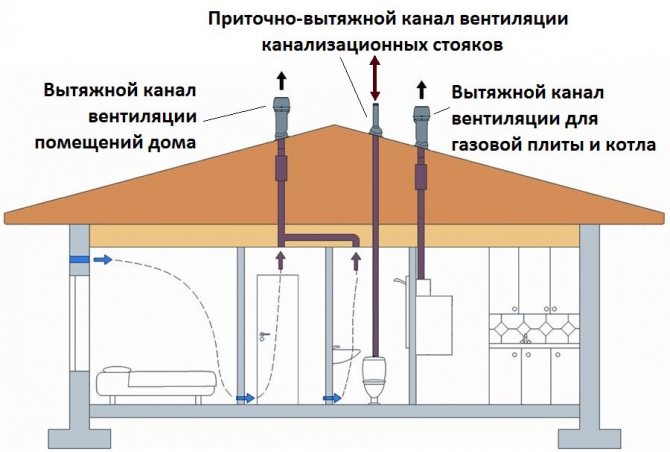

Ventilation

You should not neglect the arrangement of a high-quality ventilation system. It is on this that the safety of operation of gas appliances and their efficiency depend. According to technical features, any boiler requires air for high-quality combustion of gas in the chamber. Therefore, it is worth studying the gas consumption rates for the selected boiler and creating appropriate conditions for it for high-quality work. When operating a gas boiler, there is always a risk that it may go out during operation. To prevent this from happening, it is necessary to install gas sensors and automated heating systems. Many boilers are already equipped with these systems, and the home owner only needs to ensure the possibility of high-quality ventilation of the room in the event of an emergency shutdown of the automation. There are cases where a small amount of gas can still get into the room.

Varieties of wall devices

According to their functional purpose, gas heating units are divided into two groups:

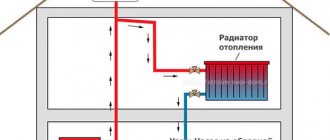

- Single-circuit. Designed for heating only. They are connected to the heating circuit and heat the coolant.In this case, the organization of hot water supply is carried out by installing an electric or gas water heater of any type.

- Double-circuit. They heat the room and provide hot water. An additional circuit for heating water is built into the boiler. The technological feature of the device is the impossibility of simultaneously heating water and heating the room.

The priority action of double-circuit units is to heat the water, the heating operation stops at this time. Considering that water can be heated quickly, the boiler is quite efficient in heating the building.

According to the method of fuel combustion, all devices are divided into the following two groups.

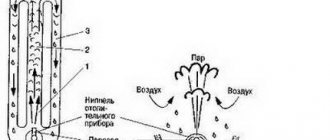

Group # 1 - devices with an open combustion chamber

Such devices are also called natural draft heaters. They take the oxygen necessary for combustion from the room in which the device is located.

To remove combustion products, they need a traditional chimney. Thus, a prerequisite for the installation of such a boiler is the arrangement of good ventilation.

If the heater is installed in a dwelling, high-performance fresh air ventilation must be installed here.

The best option for installing a heater with an open firebox is the presence of a separate room, the so-called furnace, where it is placed.

Systems with natural ventilation are quite popular due to their low cost and energy independence.

Group # 2 - devices with a closed combustion chamber

Turbocharged devices are equipped with a closed combustion chamber. They take the air, without which the combustion process is impossible, from the street. For this, the devices are equipped with coaxial type chimneys.

Such a chimney is made in the form of a structure of two pipes, one of which is embedded in the other. The combustion products are discharged outside through the inner pipe.

At the same time, street air flows in the opposite direction through the gap between the two pipes. It is clear that boilers with a closed-type firebox do not in any way affect the composition of the air inside the room, which makes it possible to equip them even in living rooms.

Is self-installation possible?

With your own hands, you can install a wall-mounted gas boiler of the simplest modifications. Such as, for example, single-circuit devices with an open combustion chamber.

To install them, you will need to connect the heating system, supply gas and organize a chimney. However, some boiler manufacturers in the technical documentation for their products indicate that the installation should be carried out only by specialists.

In this case, self-assembly of even the simplest models is prohibited. Thus, if you plan to install the equipment yourself, you should make sure that the manufacturer allows it before purchasing it.

Verification of the correct installation and connection of the device to the gas main should only be carried out by a specialist with a special permit.

In addition, the gas service representative must also issue a permit to operate the installed equipment. Without this, the owner of a self-installed and running device will face serious fines.

Thus, without the invitation of specialists, you can only connect the device to the heating system and to the water supply. Moreover, it is advisable to do this only if you have a certain experience.

Where to start installation?

First of all, you need to prepare the documentation that you need to install... You should start by initializing the gasification of the room. It can only be started if a gas pipeline is connected to it.

Then the owner submits an application to the relevant services, in which he indicates the volume of gas consumption he needs per month or year.In case of a satisfactory answer to the application, the gas pipeline suitable for the room must be equipped with a meter.

The owner receives permits and technical conditions in his hands, on the basis of which a project for connecting the equipment should be developed.

The latter includes a scheme for laying gas pipes from the heater to the point of insertion into the main line and all the conditions for installing equipment. The developed project must be approved by the gas service.

Together with the project, the owner of the premises where the boiler will be installed provides a certificate of conformity and a technical passport of the purchased equipment, an expert service conclusion on its compliance with all safe requirements and instructions for use.

Only after the project is approved, you can start installing the heater. In this case, all points of the project documentation should be clearly followed.

Gas heating remains the best option for organizing heat supply for apartments and houses. To install the equipment, you need to know the current standards, issue a permit in the appropriate service. Of particular difficulty is the installation of a wall-mounted gas boiler in a wooden house with your own hands. The requirements for such buildings are much stricter than for reinforced concrete or brick buildings.

Gas heating at home: possible variations

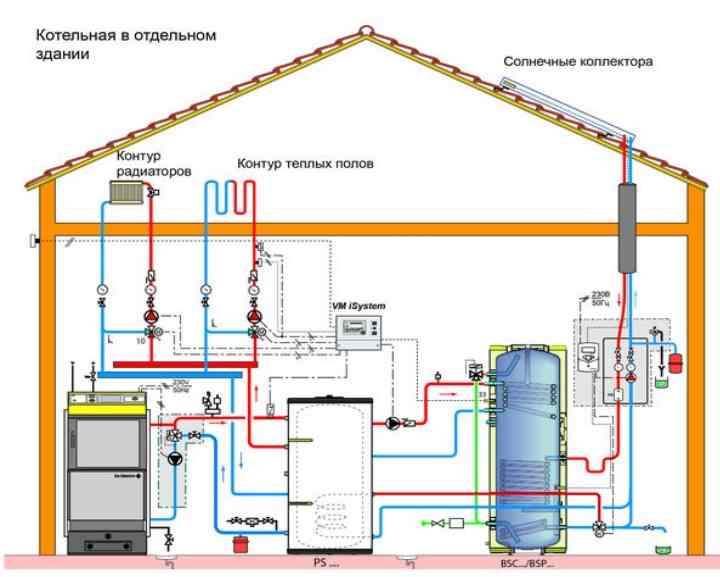

When installing the heating system in a wooden room, only 2 options can be implemented.

Option 1: Classic gas boiler

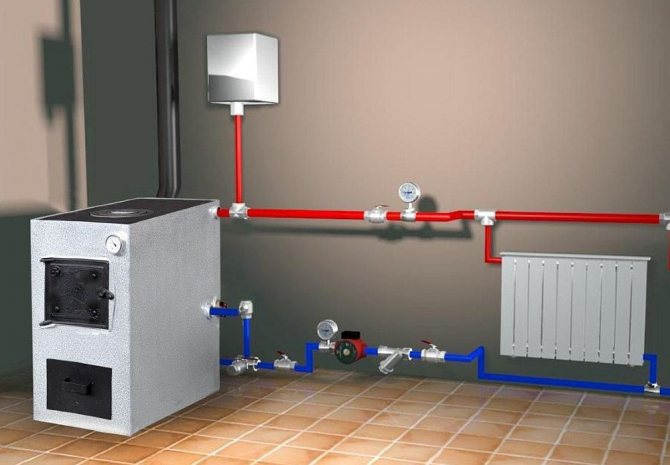

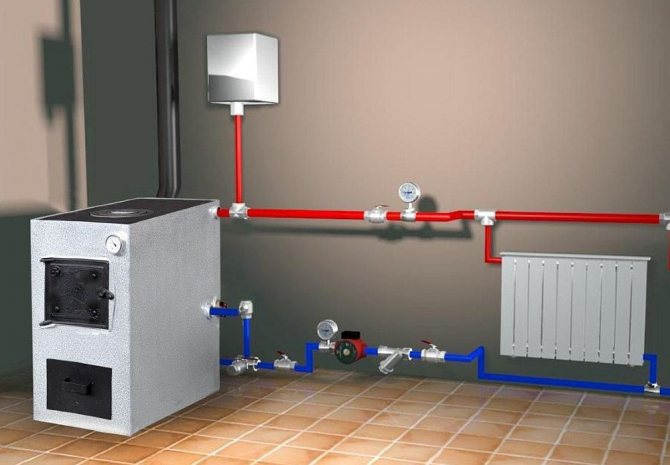

Such equipment will heat the coolant by burning gas. Gas will "go" through the pipeline and "transfer" heat to heating devices (radiators), which, in fact, will heat the interior of the house. If a gas pipeline is connected to the house, then you will install the above system as quickly and easily as possible.

The main thing is to bring the gas pipeline into the boiler room, which is ventilated as well as possible. This solution has a positive side, because it will increase security. The worst option in this case is the distribution of the gas pipeline throughout the internal living area.

Important! Only experts - professionals who clearly know their business and are familiar with all its most important subtleties - should design and draw up pipeline diagrams for gas equipment.

An example of a parapet gas boiler:

As a rule, convection boilers are the most popular among summer residents. But, the most economical ones are condensation ones, because their operation does not require too high a return pipe temperature (and, as you know, it does not allow heat to be stored in the room for as long as possible).

And the most optimal, "working" heating scheme should be based on the purchased boiler. That is, it can be barrack or one-pipe. The second option is good because there will be one thick pipe in the house, from which parallel branches will go to the radiator batteries.

Helpful advice! If you are used to saving money, then choose a boiler for your home, which is equipped with an electric ignition. Moreover, such heating is much easier to start (but, you will spend money on replacing batteries).

Electronic fired boilers do not use fire flames, which in the end further increases fire safety. If you live where there are constant changes in the power grid, then you should buy an uninterruptible power supply for your boiler.

This is what electric ignition looks like (igniter)

Option 2: Gas convector

This option will suit you in the event that a gas main is not laid near the house, and you systematically bring gas cylinders to the dacha. Moreover, the convector in this case is just an ideal option.

There is no need to divert pipes from convector-type equipment around the perimeter of the room, because the convector itself is mounted under the window, and the gas cylinder is taken out further into a separate room.

The air in such a system passes by opening the window to the street, where the combustion products of the heating system are then also discharged.

The most important feature of this option is that the heat will be only in that part of the house (room) where the convector is installed. Therefore, if the house is multi-apartment, then several convectors will be needed. But, the main advantage of such a solution is the minimum cost of equipment.

The convector looks like this:

Stages of gas heating installation

To install a gas boiler, you must perform the following sequential work:

- Heating equipment is installed in the boiler room (which is as well ventilated as possible). It is worth “moving away” from the walls by 20-30 cm in order to provide free air access to the entire boiler;

- The walls near the boiler are plastered and treated with a material that is resistant to fire and high temperatures;

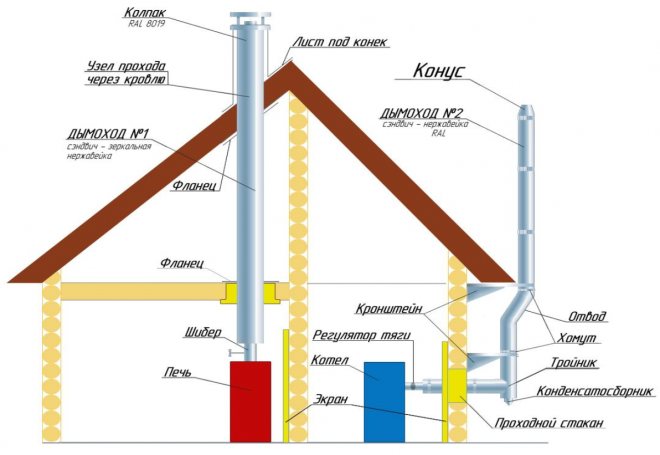

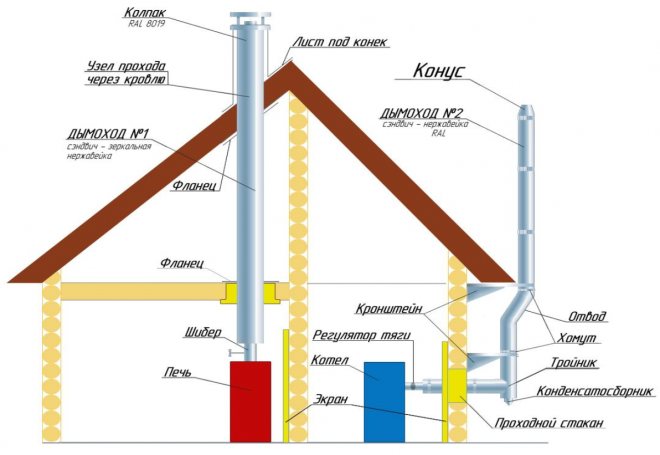

- The chimney is being installed and connected (more on this later);

- All its constituent elements are connected to the boiler: pump, pipes, collector, measuring and adjusting devices;

- At the penultimate stage, pipes are laid out, with their further connection to radiators;

- The batteries are installed last, and the performance of the entire system is checked.

After the completion of all commissioning works, the foreman performs pressure testing of the heating system.

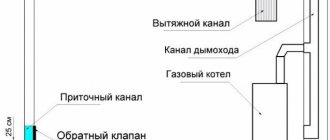

Chimney arrangement

For any boiler with an internal combustion system, a chimney is required. This is a requirement of safety rules. What this device looks like:

If a boiler with an open combustion chamber is installed in the room, then the chimney must be thick, vertical. If the heating equipment has a closed type of firebox, then a large chimney is not needed.

For the latter type of boiler, you only need to use a pipe with a cross section of up to 100 mm. And cover the inlet for it with materials that are resistant to high temperatures and fire. The air in such a system will come from the outside, so there is no need to ventilate the house.

Due to the fact that the house is made of solid timber, it is unrealistic to make smoke channels inside the walls. Therefore, some "sandwiches" are used - pipes made of metal with an additional insulated layer. They are displayed outside, parallel to the walls. But, this option has some peculiarities. If you live where there are very severe frosts in winter, then such insulation will not be enough.

Sandwich pipe example

As a result, the inside of the pipe will quickly cool down, and the air will gradually begin to descend. This will lead to reverse thrust and the gas equipment will automatically shut down as in an emergency. Therefore, if you nevertheless decide to use "sandwiches", then they should be mounted in that part of the house in which the maximum heating of the air can be ensured. In this case, the “street” part of the chimney should be as short as possible.

A built-in (or attached) chimney is ideal for a timber house. If you use just such a solution, it is important to remember that when installing it, all walls along which the pipe will run must be plastered.

An example of a good size and location

Helpful advice! The best option for a wooden house is a wall-mounted chimney and a boiler mounted in the kitchen.

A few words about fire safety

As we have already said, the issue of fire safety is extremely acute when it comes to a gas boiler in a wooden house. So, in order not to fear for your life in the future, you need to clearly follow all the established rules.

First of all, it must be remembered that the installation of a gas boiler in a private house should be carried out on a surface that does not burn and does not deteriorate under the influence of high temperatures.

The most optimal solution in this case is a galvanized steel sheet based on an asbestos substrate. At the same time, it is necessary that the stand on all edges protrudes 25 cm more than the dimensions of the boiler.

The boiler must be installed in a place that is at least half a meter away from other gas or electrical equipment. It is not worth laying an electric cable or any other communications over the gas boiler, because after a while the insulation will melt and the line will become unusable.

The chimney for our equipment must have a pipe with a diameter similar to the section of the pipe. In total, the number of its bends should not exceed three. Moreover, it is necessary to use exclusively round pipes - square and rectangular passages are prohibited.

Usually all combustion products from the boiler come out cooled, but you still have to additionally “reinforce” the walls with asbestos insulation. The same manipulations must be carried out with all coaxial pipes coming from the convector.

The smoking area should not be less than 4 square meters. In this room, there must be a strong and reliable door with a width of 90 cm and more, as well as a window.

Conclusion

Now you know how to install a gas boiler in a wooden house, and you are also familiar with all the main subtleties of this process, and are aware of fire safety techniques.

All of the above will definitely help you when arranging a heating system in your country house. Finally, as usual, we have prepared a useful thematic video for you:

Similar publications

- To read

How to install a gas boiler in a wooden house

- To read

How to install a plastic window in a wooden house

- To read

How to insulate the floor in a wooden house

- To read

Installation of hidden wiring in a wooden house

- To read

Bathroom in a wooden house

- To read

Requirements for the premises

The first task is to select the installation site. Basic norms are set out in SNiP on February 31, 2001. Installation in living quarters, bathroom or toilet is prohibited. Installation in a basement room is possible, but not in a basement. Also cannot be mounted in the attic. For powerful equipment over 36 kW, you need to equip a separate boiler room.

It is necessary to take into account the basic requirements - a gas boiler in a wooden house with a capacity of up to 60 kW can be installed in a room with the following parameters:

- The minimum volume is 15 m3. For each kilowatt of energy above the norm, you need to add 1 m?.

- Ceiling height - from 2.5 m and above.

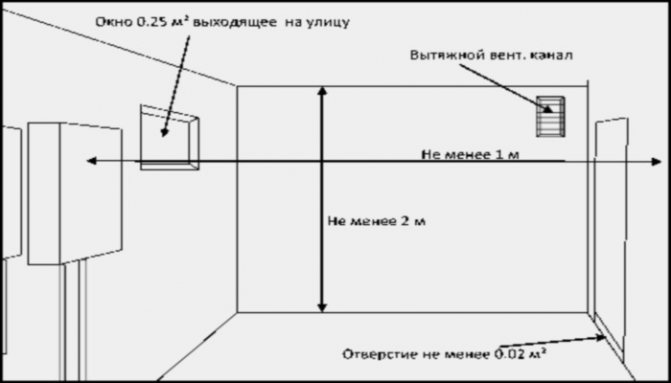

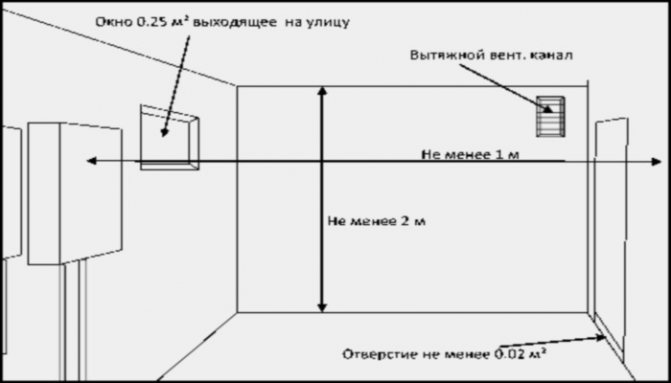

- The presence of forced and natural ventilation.

- Artificial lighting should be complemented by natural lighting.

The installation site is isolated from the living quarters by a door, if the installation is carried out in a separate boiler room, there must be an exit directly to the street.

Installation of a wall-mounted gas boiler in a wooden house in a separate boiler room is carried out according to the following rules:

- standard requirements for the volume and height of ceilings - 15 m? and 2.5 m;

- interior wall decoration with fire-resistant material with a fire resistance limit of 0.75 hours;

- normal room lighting - artificial and natural;

- the presence of ventilation systems.

In addition to the door to the street, there may be an additional doorway to the house. It is important that tightness is ensured - combustion products must not enter the building. Ventilation parameters depend on the type of combustion chamber - closed or atmospheric. For the second, the value of air exchange should not be less than 3 volumes of the boiler room per hour. Combustion air consumption is additionally taken into account. This parameter is indicated in the boiler passport. The distance from the heating equipment to the ventilation hole is at least 2 meters. The glazing area depends on the volume of the boiler room. At 1 m? requires 0.03 m? light opening. It is important - this is an indicator of the net inflow of light, excluding the width of the frames and imposts.

Projects of houses with a boiler room

Number of projects 1286

- 5 rooms

- 2 bathrooms

Dublin House Project

- To favorites

- 207² Total area

from 2 043 300 rub.

Construction time individually

- 10 rooms

- 4 bathrooms

House project DOK-309 / Sherbon

- To favorites

- 309² Total area

- 14 x 11m Building area

from 5 562 000 rub.

Construction time individually

- 4 rooms

- 1 bathroom

House project "Ignatievo"

- To favorites

- 148² Total area

from 1 400 000 rub.

Construction time individually

- 5 rooms

- 2 bathrooms

House Project 5-195

- To favorites

- 195² Total area

from 2 632 500 rub.

Construction time individually

- 5 rooms

- 3 bathrooms

Hals House Project

- To favorites

- 242.3² Total area

from 3 271 050 rub.

Construction time 132 days

- 4 rooms

- 2 bathrooms

Hercules House Project

- To favorites

- 125.23² Total area

- 11 x 9m Building area

from 4 110 833 rub.

Construction time individually

- 4 rooms

- 3 bathrooms

House project MS-202

- To favorites

- 133.9² Total area

- 12 x 9m Building area

from 4 832 789 p.

Construction time individually

- 5 rooms

- 2 bathrooms

Adriatic House Project

- To favorites

- 184.4² Total area

- 14 x 9m Building area

from RUB 2,190,000

Construction time individually

- 8 rooms

- 5 bathrooms

House project MS-474

- To favorites

- 474.1² Total area

- 13 x 26m Building area

from 11 998 823 rub.

Construction time individually

- 7 rooms

- 3 bathrooms

House project MS-339

- To favorites

- 329² Total area

- 13 x 11m Building area

from 6 604 420 rub.

Construction time individually

- 3 rooms

- 1 bathroom

House Project MPL-0020-R0057-0144

- To favorites

- 105² Total area

- 12 x 10m Building area

from RUB 1,587,000

Construction time individually

- 3 rooms

- 2 bathrooms

Ladoga House Project

- To favorites

- 155.5² Total area

- 13 x 16m Building area

from 2,390,000 rub.

Construction time individually

- 3 rooms

- 4 bathrooms

Rocky House Project

- To favorites

- 250² Total area

from 2 626 300 rub.

Construction time individually

- 6 rooms

- 2 bathrooms

Balkhash House project

- To favorites

- 170.4² Total area

- 11 x 10m Building area

from 1 850 600 rub.

Construction time individually

- 6 rooms

- 3 bathrooms

House project DOK-238 / Rhine

- To favorites

- 238.4² Total area

- 14 x 12m Building area

from 4 291 200 rub.

Construction time individually

- 4 rooms

- 2 bathrooms

House project DOK-231 / Mont Blanc

- To favorites

- 231.7² Total area

- 13 x 11m Building area

from 4 170 600 rub.

Construction time individually

- 6 rooms

- 2 bathrooms

Project Frame house 023

- To favorites

- 152² Total area

from 2 052 000 rub.

Construction time individually

- 7 rooms

- 2 bathrooms

Amber House Project

- To favorites

- 327² Total area

from 2 893 000 rub.

Construction time individually

- 5 rooms

- 2 bathrooms

House project 40-209

- To favorites

- 209² Total area

from 2 821 500 rub.

Construction time individually

- 5 rooms

- 2 bathrooms

House project Karelia

- To favorites

- 141² Total area

- 11 x 8m Building area

from 4 842 351 rub.

Construction time individually

See all projects

A boiler room in a private house is becoming commonplace today. But its arrangement should be carried out only in accordance with regulatory requirements. An appropriate project of the premises is being developed according to the established standards so that the boiler room meets the existing standards. Consider questions regarding the arrangement of a boiler room. You will learn what documents are required and how to properly design the premises.

An example of a boiler room for a large house with additional equipment Source remont-kotlov77.ru

Permits documentation

Unlike installing a solid fuel boiler in a wooden house, gas equipment requires a permit. To do this, you need to contact the local organization responsible for gas supply - Oblgaz or Gorgaz. The connection to the gas main should only be carried out by certified specialists, but the installation of boiler equipment can be done independently.

Stages of obtaining a permit:

- Obtaining a technical specification. It indicates the requirements for connecting to the gas main. It is necessary to provide a plan of the house with its characteristics.

- Drawing up a gasification project. This work is carried out by specialized organizations licensed.

- On the basis of the project, a permit is issued to install a parapet boiler in a wooden house. The same applies to wall-mounted or floor-standing models.

- After installation, gas service representatives must check the building and the pipeline for compliance with the technical conditions and the agreed design. They also connect the equipment to the pipeline.

To optimize time and financial costs, it is recommended to use the services of subsidiaries of Gorgaz. Their representatives know the nuances of design and the latest changes in the requirements for premises and equipment.

Electric heating of a wooden house

It is not always possible to install a solid fuel boiler or connect to a gas main. In this case, electric heating of a wooden house is chosen. To do this, you can install water heating with an electric boiler or consider a more economical option - film heating.

Film heating of a wooden house

In this case, you do not need to install heating batteries for a wooden house. In film heating, objects are heated, not air. Conductive carbon strips are applied to the polymer surface.

With the passage of an electric current, radiation with a wavelength of 10-15 microns is generated. When it hits the surface of objects, the temperature rises.

The main advantages of electric film heating of a wooden house are:

- Economical energy consumption... This is due to the rated power of the PLEN up to 200 W / m²;

- Low inertia... Unlike gas heating in a wooden house, the temperature rises quickly. However, after the first installation, the system must first stabilize;

- Small area occupied by PLEN. This is important for the electric heat supply of country wooden houses or cottages;

- Does not affect the humidity in the house... To maintain an optimal indoor climate, this option for heating a wooden building is considered the most optimal.

However, for PLEN it is necessary to ensure an uninterrupted supply of electricity. In the event of a power outage, it will not work. Therefore, PLEN is often made as an alternative system along with water heating of a wooden house.

For normal operation of film heating, the total area of film coverage should be 70% or more relative to the area of the ceiling or floor.

Installation diagrams

After preparing the premises and issuing permits, you can proceed with the installation of the boiler. The equipment installation site is finished with refractory materials. For wall models, it is imperative to use reliable fasteners.

How to hang a gas boiler on a wooden wall, and what standards must be observed? To do this, you need to familiarize yourself with the general rules:

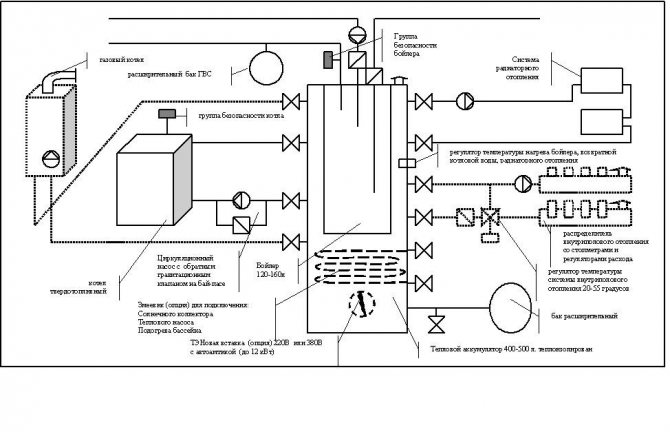

- Drawing up a diagram. The location of the nozzles for connecting to the pipeline, the location of the gas pipeline are taken into account. Before installing a gas boiler in a wooden house, the diagram indicates the location of auxiliary equipment - indirect heating tanks for hot water supply, a circulation pump, an expansion tank and a protection group.

- The minimum permissible distance to the surface of the wall on which the equipment is installed is 4.5 cm. To the side slabs this value is at least 20 cm. The distance to the floor is from 30 cm, to the ceiling is 45 cm.

- The opening in the floor or wall for the chimney is protected by a special fireproof sleeve. Its function is to prevent direct contact of the tree with the heated surface of the chimney.

- The use of plastic pipes for heating. To protect the line surface from overheating, it is recommended to install a steel pipe up to 0.5 m long at the hot water outlet from the boiler.

In practice, the same installation of a wood-fired boiler in a wooden house will be easier. But in the future, the cost of heating and maintenance will be higher than for gas heating.

Heating a frame house with electricity

Electric heating of a frame house is used in regions with different climates. It is very comfortable, relatively inexpensive to install and easy to operate. The high cost of electricity can be reduced by installing a new generation of economical heaters.

Different equipment is used for electric heating:

- warm floor;

- convectors;

- oil radiators;

- fan heaters;

- infrared heaters;

- air conditioner and others.

Convector heaters

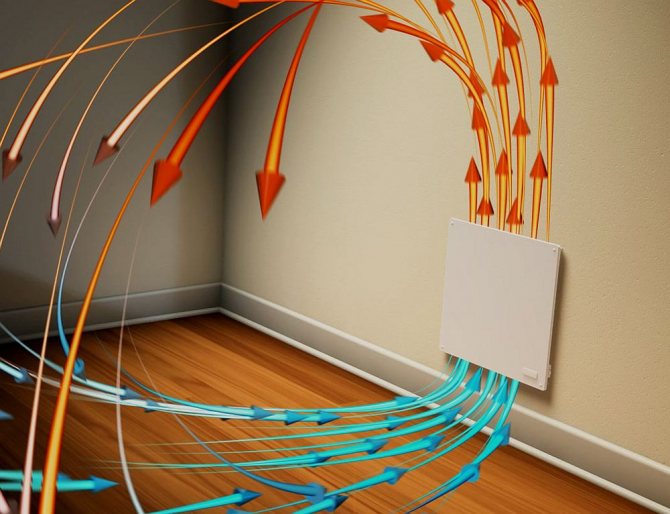

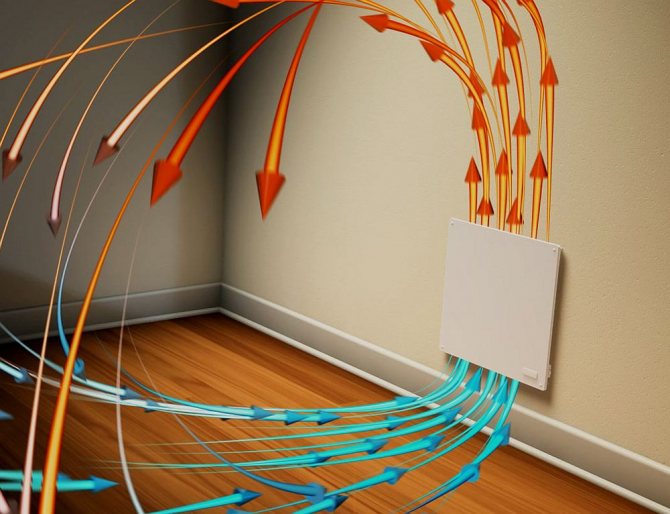

The convector is the most popular device for electric heating of a frame house. Its principle of operation is to heat the air. Cold air enters the convector from below, heats up and leaves it, rushing up. Then the air begins to circulate through the room, rising up in accordance with the laws of physics, and cold air descends downward.

The simplicity of this system lies in the fact that the air moves in a natural way, simultaneously heating the room. This makes it possible to heat even large rooms in terms of area and volume without any problems. It's believed that Heating efficiency using convectors reaches 90%.

But this heating method also has a significant disadvantage - electricity costs are very high, that is, the option cannot be called economical. But today you can find on sale newer convectors in which the temperature is regulated, the heat transfer is increased, which makes it possible to reduce heating costs. The advantage of these devices is that you can install them yourself.

Heating by fan heaters

Fan heaters are similar in principle to convectors, but unlike them, they have a forced air circulation system. Due to this, heat exchange in the air masses is carried out faster, and the house heats up in a much shorter period of time.

But when the fan heater is in operation, there is a lot of noise, and the cost of such heating will be high. Due to these shortcomings, fan heaters are not in high demand among owners of frame houses. This option is only suitable for quickly warming up the room in an emergency, and not for permanent use.

Oil radiators

Oil radiators have a similar operating principle as convectors - they heat the air only near themselves... With their help, it is impossible to heat a large area due to the lack of air circulation. Therefore, if there is a radiator in the room, it is only warm near it, and in other places of the room it is cool.

Although this is an economical option for partial heating of a frame house, it cannot be used for all rooms. Modern radiators are equipped with more advanced batteries, in which the heating level can be adjusted. These batteries contain oil, which retains heat from the electric coil and gradually releases it to the air. However, it is currently impossible to achieve accurate air temperature control.

Useful: Correct arrangement of a bathroom in a frame house

Infrared heaters

Another modern heating device that is used in heating frame houses is an infrared emitter powered by electricity. The advantage is that it heats objects, not air.

Almost instantly heated walls, furniture, tiles, floors in the area of operation also begin to give off their heat to the building. Thanks to infrared heaters, you can get the right temperature in your home quickly and without dry air, which is very convenient.

Warm floors in a frame house

Warm floors are made both in a finished house and at the construction stage. It is now a very popular heating option, for good reason.

- Firstly, warm floors can be arrange by zones (for example, in the kitchen, bathroom, in the open part of the bedroom, on the balcony, in the sitting area in the living room).

- Secondly, this is a very economical option for heating a house in spring and autumn, in which the most ideal circulation of warm air in the room is observed.

Due to the fact that the basis of the frame house is a tree that retains heat well, and the walls are well insulated, only warm floors can be used to heat residential buildings in the southern regions.

Air conditioning as a heating method

Another electrical appliance with which you can heat a frame building is an air conditioner. In the off-season, it is able not only to cool the air temperature, but also to make it higher. This is a way to quickly heat up a room without wasting energy.

Unlike the fan, the new air conditioners are almost silent, but the old ones are quite loud. The disadvantage of air conditioners is that they cannot be used at negative temperatures. But in the off-season, this is a good way to create a comfortable temperature in the house.

Wall backing material

The main requirement in the decoration of walls, floors and ceilings is fire protection. For this, a special substrate is used for a gas boiler in a wooden house. It should not support the combustion process, protect the walls from temperature effects.

Recommended backing material:

- Basalt wool. On a rigid base (metal sheet), a layer with a thickness of 50 mm or more is installed. The density of the cotton wool is maximum.

- Basalt refractory sheets. In the event of an open flame, they will protect the wooden surface of the walls from thermal effects.

It is forbidden to use polymeric materials - polypropylene, foam. For floor models, special attention is paid to preparing the floor surface. It is leveled, fire-resistant material is mounted. In this case, basalt wool is not recommended, as it will be compressed by the mass of the boiler. The way out is to install basalt sheets.

Is it possible to put a gas boiler in a wooden house

Room requirements for installing a gas boiler in a wooden house include the following:

- The boiler room is located on the basement floor or in one of the rooms. In a wooden house, it is forbidden to install a gas boiler in the basement, except for a specially equipped, free-standing room.

- The room must comply with the requirements described in the PPB and sanitary standards.

- It is prohibited to place heating equipment in living rooms. Installation in the kitchen-living room is not allowed, installation in the bathroom and toilet is conditionally prohibited.

- Personal protective equipment and fire extinguishing equipment, as well as smoke detectors and fire alarms, are required.

Before commissioning, the heating system is checked for operability, as well as the presence of all the necessary safety nodes. The Gaznadzor inspector will make sure that the requirements for the installation of boiler equipment are met.

Separately, an audit is carried out for the availability of all documents required for commissioning the boiler. The minimum package of documents includes:

- The results of the research of the electrical laboratory, which checks the parameters of the installed grounding.

- Permission from Rostekhnadzor.

- House gas supply project.

How to hang a gas heating boiler in a wooden house

The technical conditions for installing a gas boiler in a frame or log house are significantly different.

In the first case, we are talking about a hollow material, therefore, special fastening rails are used for fixing. With a large weight of boiler equipment, it is recommended to install a gas boiler in a frame house on through studs fixed outside the building.

The hinge of the boiler in a frame house significantly increases the load on the wall. There are restrictions on the weight of the equipment. If you plan to install a model with a built-in buffer tank, preference should be given to floor-standing boilers.

The methods of fixing the boiler to the wooden wall of a log or log house are distinguished by the ease of fixing. For installation, special wood screws are used, which ensure reliable fastening.

When installing attachments, you will need to comply with PPB standards and maintain minimum distances to door and window openings.

What substrate to use on a wooden wall

If the boiler room is lined with wood, fire protection is provided. A substrate on a wooden wall for a gas boiler is performed in several ways:

- A layer of basalt insulation is hung on the wall, after which it is sheathed with a steel sheet.

- Special basalt fire retardant sheets are used. The advantage of this solution is the minimum thickness of the protective layer, while ensuring maximum fire protection.

Installation of a wall-mounted boiler in a wooden house without preliminary production of a protective layer is prohibited!

- Author: Maria Sukhorukikh

Rate the article:

- 5

- 4

- 3

- 2

- 1

(0 votes, average: 0 out of 5)

Share with your friends!

Stove heating

Modern stove heating is suitable for frame houses with seasonal and year-round use. Ideal for kakrasniks compact steel furnacesthat do not need a strong foundation.

Solid fuel boiler for heating a frame house

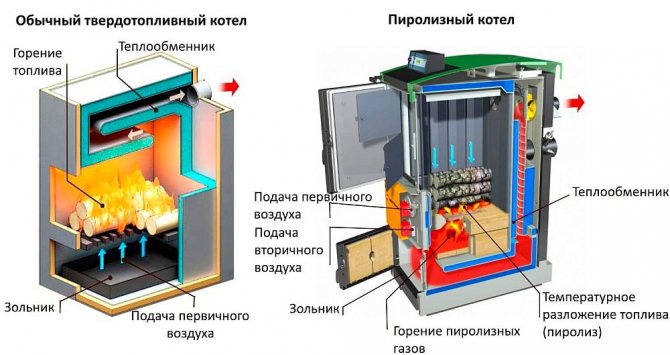

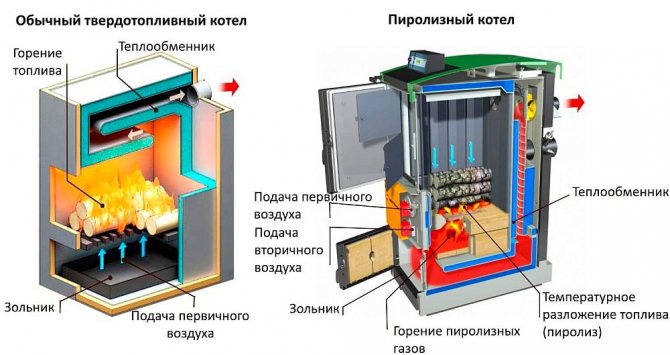

There are several types of solid fuel boilers that can be used for furnace heating of a frame house:

- natural combustion boilers;

- automatic solid fuel boilers;

- pyrolysis boilers, the principle of which is based on long-term fuel combustion;

- solid fuel boilers, which, during operation, supply secondary air to the furnace;

- long burning furnaces in the upper layer.

If earlier solid fuel boilers were primitive, now they are more complex than gas and electric ones. Modern installations extract maximum efficiency from firewood, leaving a little ash as a result. There are boilers for which you need forced air supply... Then they need to additionally install a smoke exhauster and various devices for controlling the device and monitoring.

When choosing a solid fuel boiler, you need to pay special attention to what kind of firewood should be for its operation. For example, pyrolysis boilers use firewood that is over 10 cm thick and has a moisture content of less than 20 percent. To achieve such humidity, it is necessary to store firewood for two years in a specially equipped dry room, where there is intensive air circulation, or to purchase already prepared firewood.

The boiler must be fully loaded - if the furnace is partially filled, all systems will not work properly. You can put a combined solid fuel boiler, in which, in addition to wood heating, gas can also be used - this is very convenient and practical.

Useful: Sewerage in a frame house

Solid fuel boilers have the following advantages:

- small expenses for the operation of the system;

- environmental friendliness, minimal harm to the environment;

- the ability to use anywhere in the world where there are no communications.

Practical for small houses heating and cooking ovenscombining a boiler and a cooker with or without an oven.

Heating fireplace

Usually a fireplace is installed in order to create a certain cozy atmosphere, but it can also be a full-fledged source of heat and energy in the house. It will not be enough to heat a large building. If we are talking about a small dacha, which is rarely visited, you can get by with one fireplace. Also, a fireplace can serve as a source of additional thermal energy in the presence of a full-fledged heating system.

According to the type of firebox, modern fireplaces can be divided into two groups:

- short burning;

- long burning.

So, in short-term furnaces, thermal energy is released very quickly, but firewood burns out in 5-8 hours.And in long furnaces, firewood burns for more than 8 hours, but at the same time the room heats up slowly. You can change the intensity of the blowing air, the power of the fireplace and other characteristics. You can calculate the required power of the fireplace to heat the room as follows: for every 10 sq. m requires 1 kW of heating power.