Types of structures

Heating circuit - elements used as a heating system by transferring heat energy into the air. The most popular systems are those that use boilers as a heating source, boilers with a connection to the water supply. The liquid, crossing the heating elements, reaches the set temperature, heading to the heating circuit.

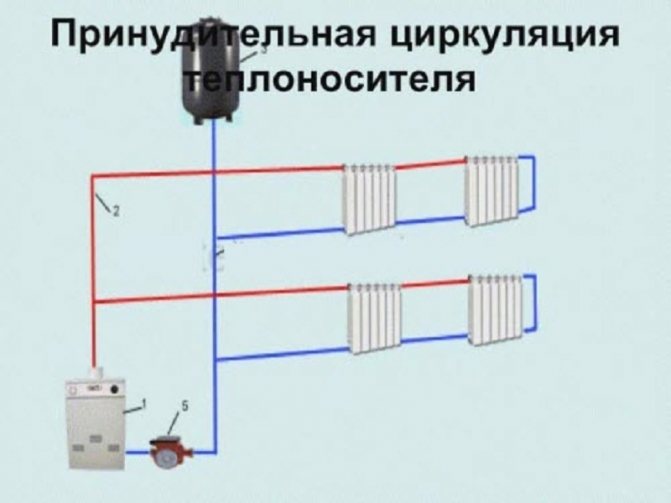

The movement of the coolant is provided by two methods:

- natural;

- forced.

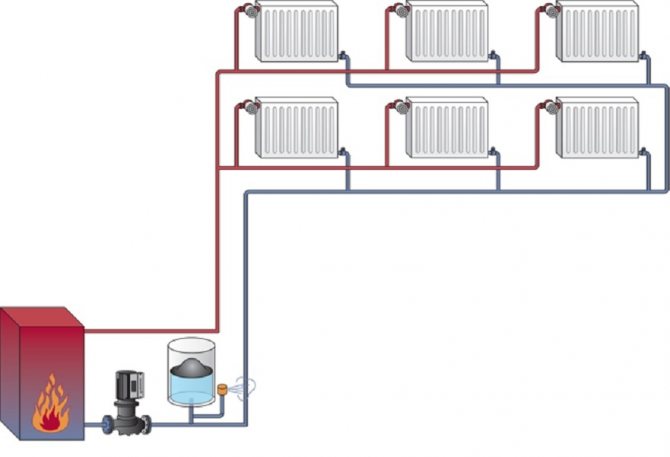

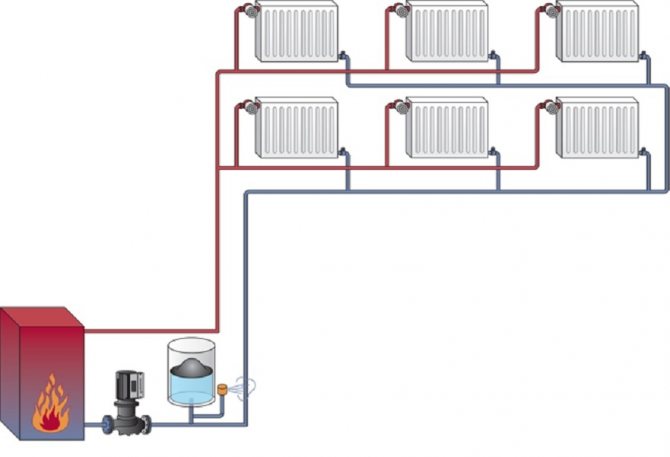

Forced circulation through pipes

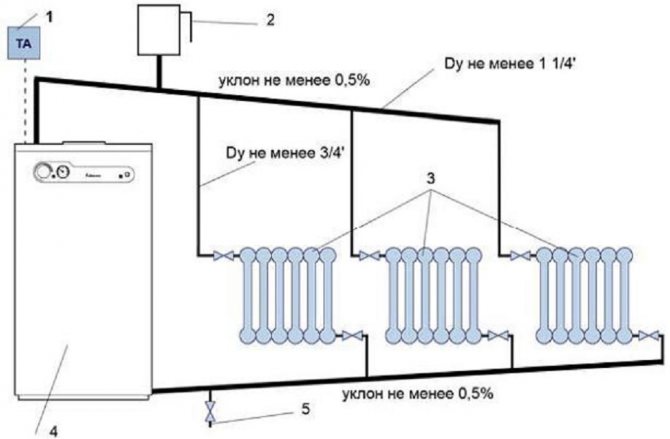

Systems with natural movement of the coolant are simple and reliable. Efficiency depends on the correct structure of the heating circuit. In the latter case, a pressure-generating pump is introduced. The coolant moves through the pipeline.

Heat sources for heating liquid - boiler, boiler equipment. The mechanism of work is based on the conversion of one type of energy into heat. Depending on the raw materials, heating source, boilers operate on gas, solid fuel, electricity, and fuel oil.

All types of boiler units can be used to heat a private house. Gas, solid fuel devices are popular.

Depending on the connection of heating devices in the heating circuit, a distinction is made between one-pipe and two-pipe systems. One-pipe system - when the batteries are connected in series, water, crossing each element, returns to the boiler.

One-pipe scheme

Minus - uneven heating of the room. Each subsequent radiator receives less heat energy.

In a two-pipe heating circuit, the batteries are connected in parallel with the riser. The negative side of the system is the complexity of the design, high material consumption. In multi-storey buildings, only a two-pipe heating system can be used.

Two-pipe scheme

UPS models

PN-1000 energy is a powerful backup power source. Thanks to the built-in stabilizer, the device provides a nominal output voltage when the mains voltage changes within 120-275 volts. The waveform in the form of a smooth sine wave is ideal for supplying reactive inductive loads, such as the electric motor of a heating system pump. The PN-1000 energy together with the Delta DTM 12100L 100A / h accumulator provides uninterrupted power supply for the 150W heating pump for 8 hours. The device has a built-in line noise filter, information display and RS-232 interface.

You can find this and other voltage stabilizers for the heating system from the Energia company on the website of the official representative of the Energiya.ru company.

The compact emergency power supply Teplokom 222/500 is intended for use in heating gas systems. This simple device with a single-phase relay-type regulator allows operation with a load not exceeding 230 W.

The universal stabilizer Skat ST 1515 provides a voltage of 220 V with network fluctuations from 145 to 260 V and a frequency value of 50 Hz ± 1%. If the voltage exceeds the specified parameters, the load will be disconnected automatically.

Summing up

Based on the operational requirements for electric motors of heating pumps, the UPS must provide the following parameters:

- The voltage form is a smooth sinusoid;

- Power reserve - not less than 20%;

- Automatic load disconnection;

- Minimum switching time to reserve.

In addition, the device must operate in a certain temperature range, have a device for indicating modes and physical quantities.

Read with this:

How to choose a three-phase voltage regulator?

Uninterruptible power supply for a gas boiler: types, features and selection criteria

Overview of voltage stabilizers for houses, apartments and cottages

Choosing a relay voltage stabilizer: design, advantages and disadvantages

Did you like the article? Share with your friends on social networks!

Heating without pump

Previously, the design of water heating systems was carried out without circulation pumps. The difficulty arose when buying, installing devices that cause forced circulation of water in the circuit. When foreign manufacturers appeared on the market, the situation changed dramatically. Circuits with forced circulation of a heat carrier are more often used.

Failures in the supply of electrical energy have not been eliminated everywhere.

As soon as the electricity is cut off, the water circulation stops. The room is cooling down. The batteries get cold. The heating system is not working efficiently. The water in the circuit freezes. It is required to start the source of thermal energy.

Advantages disadvantages

From a technical point of view, natural water circulation is effective in tall buildings. The reason is the properties of the fluid in transferring pressure from the surface to the circuit to the lower unit.

The advantage of gravitational water circulation is saving building materials. Expensive pumps, electrical supply to the circuit are not needed. Any man can design, install, operate the system. There is no need to pay for the services of the master. With proper construction, the system will heat the house for a long time, efficiently. Major repairs will not be required for more than 30 years.

The scheme of natural water circulation assumes a self-regulation process. The heating system is characterized by high thermal stability.

Disadvantages:

- high level of inertia;

- exposure of regulated pipe slopes during installation;

- the use of pipes of large cross-section;

- high probability of freezing due to poor water pressure;

- airing of heating devices.

Air bleed devices will be required to correct the air problem in the batteries. An expansion tank is installed in the system to control the water level in the boiler.

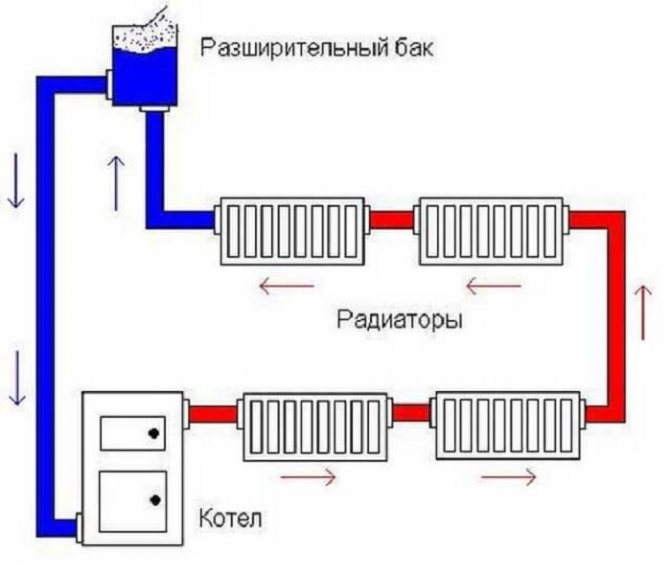

Natural circulation of the coolant in the pipes:

Operating principle

The law of physics: after heating, thermal energy increases in volume, losing its previous density. The unit in which heat is exchanged between the source and the carrier is a heat exchanger.

The heated liquid is lighter than the cooled one, the heat generator is placed at the bottom of the heating circuit. The slightly warmed up heat carrier moves upward. In its place, cold water descends through pipes. In the case of natural circulation in the system, three physical laws are considered: friction, expansion of bodies with increasing temperature, and the continuity of the jet.

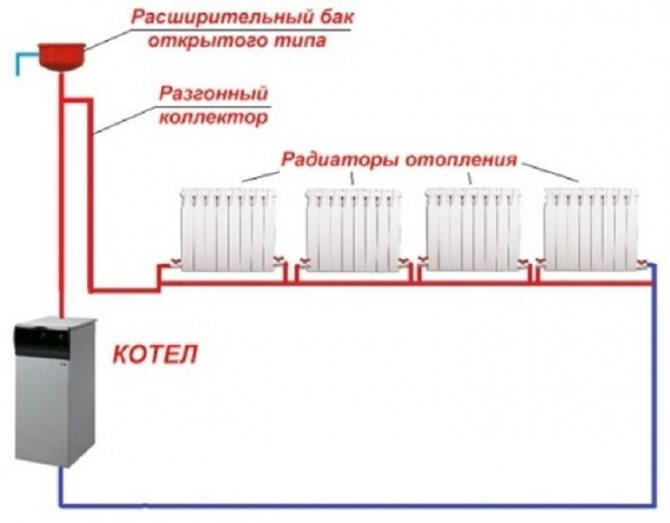

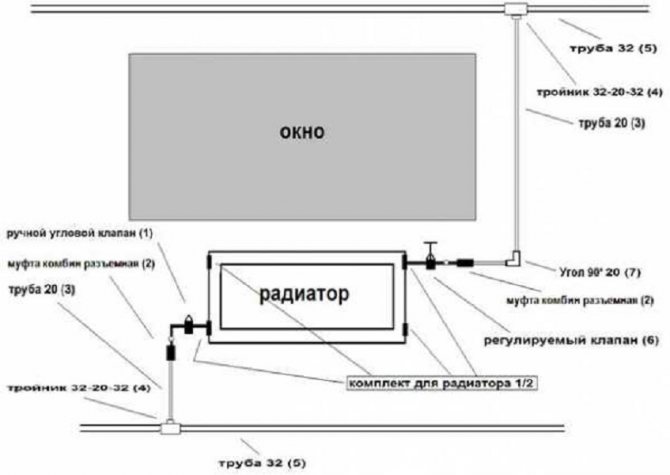

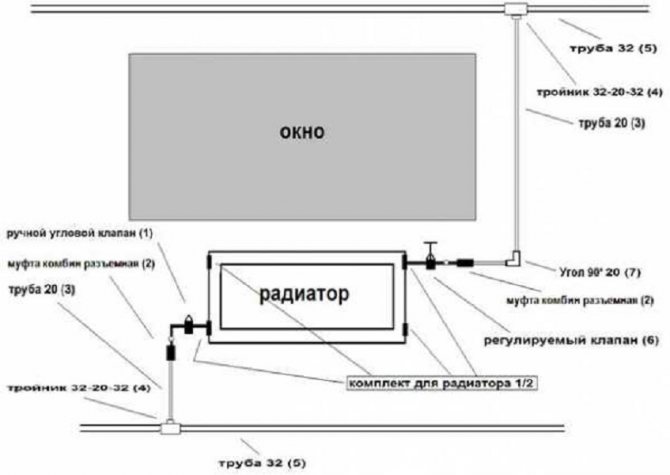

The structure of the water heating circuit with natural circulation of the coolant includes:

- Heat generator - boiler. Water is heated in the heat exchanger.

- Pipes. Form the direction of water movement. The pipeline is supplied to boiler equipment, radiators.

- Heating devices - radiators in different designs (differ in shape, material).

- Expansion tank. Protects at the stage of compensating for the increase in fluid volume due to thermal expansion. Installed at the top of the heating circuit.

The simplest scheme without a pump - the heated coolant moving through the pipes leaves the boiler, the chilled water flows back. Vicious circle.

Water circuit diagram without pump

Having flowed up the system, the water begins to be distributed to the radiators. Processes opposite to circulation in boiler equipment are observed. Displacing the cooled liquid, the coolant fills the radiator. Water gives off heat to the battery.Thermal energy enters the air, warming up the room. The liquid cools down and circulates towards the boiler. The process is cyclical.

Single-pipe heating

The difference between one-pipe schemes is efficiency. Systems are rarely used. The heated coolant, rising through the pipes, successively bypasses the batteries located on the second floor. Heading down the pipes, there are radiators located on the lower floor. Returns to the boiler.

The temperature of the upper floors of the house is higher than in the apartments on the ground floor. For sufficient circulation of liquid through the pipes, a high performance heating element is required. For private houses, the scheme is suitable in terms of efficiency, quality of heating the premises.

The system can be made more efficient by the additional introduction of a bypass line - bypass. A closing section is made from the pipe. The diameter of the material must not exceed the dimensions of the pipeline. The bypass connects the inlet, outlet of the radiator. It is connected to a T-piece at the top of the heating circuit, in front of the expansion vessel. Divides the circuit into two parts.

The correct mechanism for the operation of the heating circuit depends on the expansion tank. Dimensions - on the number of batteries. More than three quarters of the total volume should not be filled.

In a private house, it is better to make a vertical pipe connection. Installation of two risers is in progress: lifting, lowering. The installation of an expansion tank is not required if you make an automatic bleeding system for each battery, which accumulates at the top of the convector.

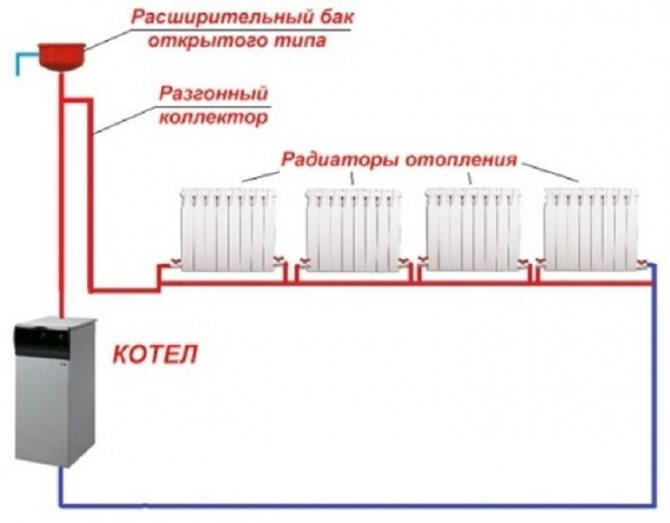

Two-pipe heating circuit

The two-pipe scheme eliminates the problem of uneven heat distribution. Two circuits are introduced at once. The first is responsible for the circulation of hot water from the source to the radiator. The second is for the outflow of the remaining liquid.

Methods for connecting pipes: with passing circulation, dead-end. The passing movement is characterized by the creation of battery taps of the same length. Uniform heating is maintained. The scheme did not gain popularity due to the high consumption of building materials (pipes).

Preference is given to a connecting scheme with cold, hot water circulation in different directions. Batteries closer to the heating device warm up faster.

The heating scheme is divided according to the type of pipe layout. Heated water is supplied from the basement, basement. The return line is located just below the feed unit.

Scheme with the upper piping of heating pipes

Why do you need a pump for a warm floor

Floor heating circulation pump

Laying the contour implies the presence of bends, which makes the natural flow of fluid impossible. Heating of the coolant does not exceed a temperature of 40 degrees. All this affects the efficiency of the system - any violation leads to the formation of air jams. A pump is needed to solve this problem, although some homeowners are trying to save money by equipping heating without forced circulation.

The underfloor heating pump creates sufficient pressure in the system, pumping water through the pipes. Natural circulation leads to heat loss.

System installation

When designing a water-type heating circuit without a pump, you need to correctly position the boiler, the lower radiator. The higher the battery in relation to the boiler equipment, the worse the outflow. Heating devices are best installed in the basement. The circulation rate of the coolant is affected by:

- section of pipes. With a decrease in the diameter of the pipeline, the resistance to the coolant increases;

- pipe material. It is better to use polyurethane products;

- number of bend points. With a decrease in the quantity, the efficiency of the heating circuit increases. Performance depends on the number of valves.

Installation work

To calculate the power of boiler equipment, you need to apply the recommendations of SNiP. For one square meter of the heated room, a heating element with a capacity of 0.1 kW is needed. When installing the heating unit, it is necessary to insulate the hot water riser, the room with the expansion tank.

Installation work: install the main riser. An expansion tank is mounted on top. Connect the wiring at the level of 1/3 of the room height from the floor. Pipes are diverted to radiators. One-pipe wiring involves connecting pipes to the boiler from the last radiator. Two-pipe - parallel connection of batteries, tie-in of branches into a common pipeline.

Steam use

The heat carrier can be water, steam. Steam generators are installed to convert water into steam, supplied through pipes.

Mechanism: hot air is lighter than chilled air. The heated steam quickly moves up the heating unit. Artificial heating is not required. When entering the batteries, the gas is cooled. It turns into a liquid state. Returns to the cauldron again.

Heating systems of a liquid type without a pump are popular. This applies to projects of private, country houses. It is important to make calculations. This will protect against freezing in the cold winter.