Gas heating systems are by far the most popular type of heating equipment used in private houses. They can be used not only as the only source of thermal energy, but also in a single connection with heaters operating on different types of fuel. In this case, not only correct installation plays a very important role, but also the connection diagram of a double-circuit gas boiler to all communications and its interaction with all other equipment.

- 2 Differences between gas boilers of the heating system

- 3 Where can I connect the boiler to the heating system

- 4 Diagram of connecting the boiler to the heating system

- 5 Connecting the boiler to the gas pipeline and water supply

- 6 Conclusion

Connecting a gas boiler to the heating system

Any owner of a city apartment or private house dreams of autonomous gas heating. Today, only such a device is capable of providing a comfortable temperature in an apartment at minimal cost. Connecting a double-circuit gas boiler is a very important matter, for which you should issue a permit... It must be installed only if finances allow you to purchase a gas double-circuit boiler with a boiler and a full set of automation. According to TU, such housing must have conditions for the installation of this structure.

If there is not a lot of finance, and the appearance of hot water in the apartment is not expected, then it is best to buy a simple single-level gas boiler. Such an installation costs much more than a water heater, however, given how much it will cost to install a gas meter, with existing tariffs such a structure will easily pay off in 1.5 years, or even earlier.

To connect the boiler to the heating system, you will need the following items:

- scheme;

- water purification filter;

- water heater;

- boiler - single-circuit or double-circuit;

- cold and hot water taps.

Differences between gas boilers of the heating system

Such heating structures are easily installed independently using schemes. Connecting other gas boilers will require special skills. It should be noted that many specialized firms are ready to take on work related to the preparation of premises and execution of all required documents.

A typical boiler is quite simple: a gas burner and a heat exchanger. Gas, water are connected to it and the exhaust is discharged into the chimney. They start using it only after completing all the documents.

A double-circuit heating boiler with a water heater and automation is multifunctional and simple. It is just as easy to install as usual. Automation is used in this way: a system with a microprocessor and a double thermostat monitors the temperature outside and in the apartment, and, according to the established program, reduces heating to a minimum if people are not at home. Gas is consumed by such an installation 50% less than with manual or automatic regulation. Savings are very significant in harsh weather.

Such a home boiler room has one serious drawback - if the power supply is interrupted, then the automation turns off, and the double-circuit unit switches to the mode of minimum heating of the room. Therefore, for a double-circuit heating boiler, additional costs are required for a guaranteed power supply.

Where can the boiler be connected to the heating system

There are the following requirements to connect a gas boiler:

- It must be installed in a boiler room, which is a separate room with a minimum area of 4 m2 and a ceiling height of at least 2.55 m.

- The boiler room must be equipped with one window. The minimum door width should be 0.8 m.

- The boiler room must be finished with non-combustible materials, while a raised floor and a brick oven are strictly prohibited.

- Air must enter this room through a non-closable through air duct.

For wall-mounted hot water and other boilers the following rules apply:

- The boiler exhaust must necessarily go into a separate chimney without using ventilation ducts. This is explained by the fact that hazardous combustion products can get into the adjacent room.

- The horizontal part of the flue must be at least 3 m long and have at least three turning nodes.

- The flue must have a vertical outlet, while it must be raised above the highest point of the gable on a flat roof by at least 1 m.

- Due to the fact that after cooling of the combustion products, hazardous substances are formed, the chimney must therefore be made of chemically heat-resistant materials.

When installing a wall-mounted hot water boiler in the kitchen you must adhere to the following rules:

- There must be free space under the unit.

- The height of the suspension structure in accordance with the cut of the highest branch pipe cannot be lower than the top of the washing spout.

- The floor under the unit must be covered with a non-combustible durable metal sheet.

- The combustion room should not contain any cavities in which an explosive gas mixture can accumulate.

A gas boiler it is not recommended to install in the following cases:

- If you plan to install it in an apartment building or an old Khrushchev, in which there is no main gas duct.

- If there is a false ceiling in the kitchen, which is not planned to be dismantled. A capital mezzanine will also not work.

In all other cases, you can install and connect gas boilers in your own apartment. Any structure is installed in a private house. If the extension for the boiler room is made outside, the relevant authorities will find fault less.

For a small private house, it is best to install a wall-mounted boiler, because you will not need to install a concrete or brick pallet under it. Automation of gas boilers does not consume too much electricity.

How are two boilers arranged in a heating system?

The creation of a heating circuit, in which two boilers in the heating system operate either one at a time or together, is associated with the desire to provide redundancy or reduce heating costs. The joint operation of boilers in an integrated system has a number of connection features that should be considered.

Possible options - two boilers in one heating system:

- gas and electricity;

- solid fuels and electricity;

- solid fuel and gas.

Joint work of gas and electric boilers

Combining a gas boiler with an electric boiler in one circuit, as a result of which a heating system with two boilers is created, can be implemented quite simply. Both serial and parallel connection is possible. In this case, a parallel connection is preferable, because it is possible to leave one boiler running while the other is completely stopped, switched off or replaced. Such a system can be completely closed, and ethylene glycol for heating systems or ordinary water can be used as a heat carrier.

Joint operation of a gas and solid fuel boiler

This is the most difficult option for technical implementation. In a solid fuel boiler, it is extremely difficult to control the heating of the coolant. Typically, such boilers operate in open systems, and the excess pressure in the circuit during overheating is compensated in the expansion vessel.Therefore, it is impossible to directly connect a solid fuel boiler to a closed circuit.

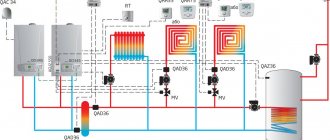

For the joint operation of a gas and solid fuel boiler, a multi-circuit heating system has been developed, which is two independent circuits.

The gas boiler circuit operates on a radiator and a common heat exchanger with a solid fuel boiler and an open expansion tank. For the room in which both boilers are installed, it is necessary to fulfill the requirements for both gas and solid fuel boilers

Joint work of solid fuel and electric boilers

For such a heating system, the principle of operation depends on the type of electric boiler. If it is intended for open heating systems, then it can be easily connected to an existing open circuit. If the electric boiler is intended only for closed systems, then the best option would be to work together on a common heat exchanger.

Dual fuel heating boilers

To increase the reliability of heating and to avoid interruptions in the operation of the heating system, dual-fuel heating boilers operating on different types of fuel are used. Combined boilers are manufactured only in floor-standing design due to the rather large weight of the unit. A universal unit can have one or two combustion chambers and one heat exchanger (boiler).

The most popular scheme is the use of gas and wood to heat the coolant. It should be borne in mind that solid fuel boilers can only work in open heating systems. To realize the advantages of a closed system, an additional circuit for the heating system is sometimes installed in the tank of a universal boiler.

There are several types of dual-fuel combined boilers:

- gas + liquid fuel;

- gas + solid fuel;

- solid fuel + electricity.

Solid fuel boiler and electricity

One of the popular combination boilers is a solid fuel boiler with an installed electric heater. This unit allows you to stabilize the room temperature. Thanks to the use of heating elements, such a combined boiler has acquired a lot of positive qualities. Let's consider how the heating system works in this combination.

When fuel is ignited in the boiler and when the boiler is connected to the electrical network, heating elements immediately start working, which heat the water. As soon as solid fuel ignites, the coolant quickly heats up and reaches the temperature of the thermostat, which turns off the electric heaters.

The combi boiler operates on solid fuels only. After the fuel burns out, the water begins to cool down in the heating circuit. As soon as its temperature reaches the threshold for the thermostat, it will turn on the heating elements again to heat the water. This cyclical process will help maintain a uniform indoor temperature.

To optimize the heating circuits, heat accumulators in heating systems were invented, which represent a large volume of capacity from 1.5 to 2.0 m3. During the operation of the boiler, a large volume of water is heated from the pipes of the circuit passing through the storage tank, and after the boiler stops operating, the heated water slowly releases thermal energy into the heating system.

Heat accumulators allow you to maintain a comfortable temperature for a long time.

In order to avoid critical situations in winter, reduce heating costs and ensure its reliability, many owners prefer either installing a system with two boilers on different fuels, or installing a universal dual-fuel boiler. These heating options have certain advantages and disadvantages, but they fully provide their main task - stable and comfortable heating.

spetsotoplenie.ru

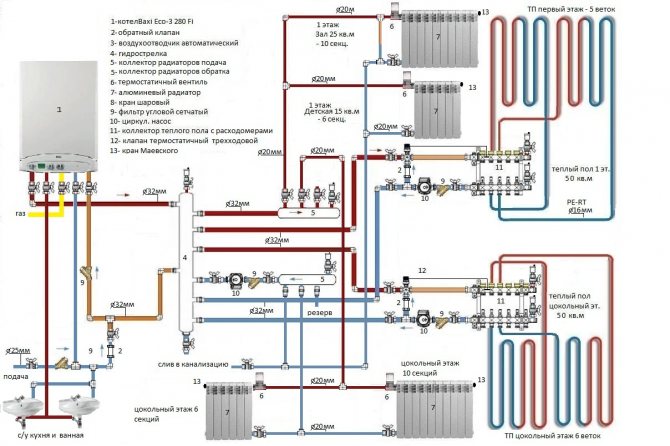

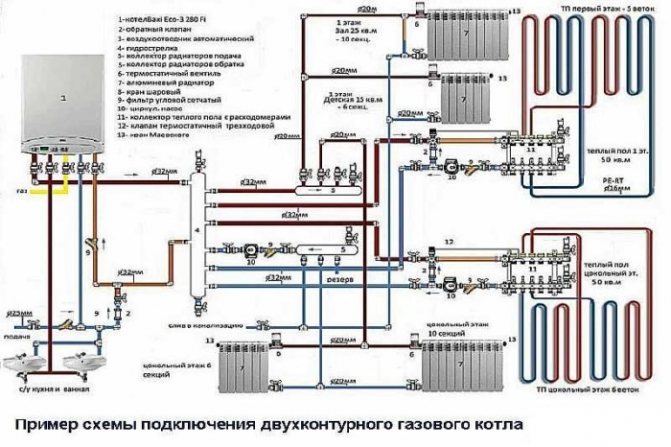

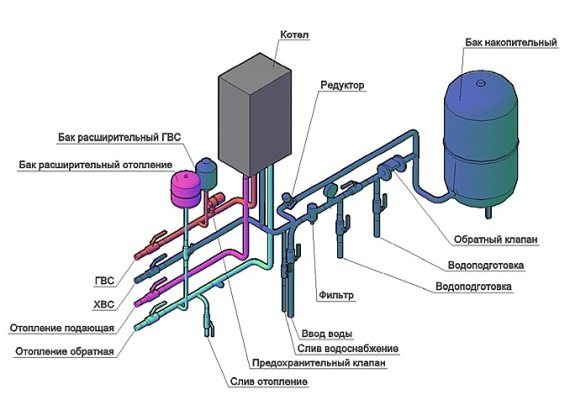

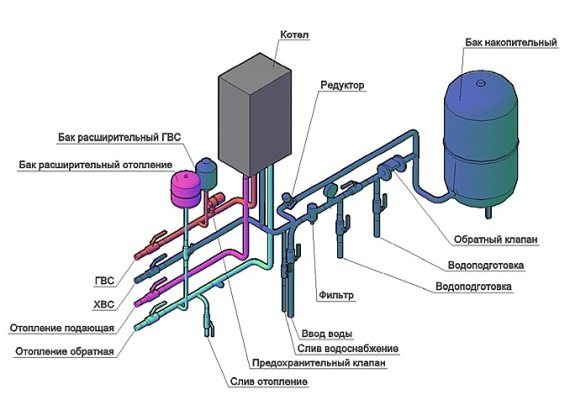

Diagram of connecting the boiler to the heating system

The heating boiler connection diagram does not allow its body to touch tightly to any of the walls. They begin to make the piping of the boiler, that is, three systems are connected: electrical, gas and hydraulic. Gas piping should only be carried out by a gas specialist and should be performed last, after all systems have been connected.

The hydraulic and electrical connections can be made by yourself. In this case, follow the instructions supplied with the boiler. A typical strapping scheme helps in this. For any boiler, the following conditions must be met:

- in the heat exchanger, water and hot gases must necessarily go in a counterflow, because with any automation it can explode;

- it is very important not to confuse the cold and hot water pipes.

After completing the hydraulic piping the entire system should be carefully examined again.

If antifreeze has been used for the heating system, then it must be drained and the system flushed with water several times. Antifreeze admixture in the water can cause an explosion.

It is advisable to use coarse filters. They must be located at the bottom of the system. A dangerous situation can arise when dirt accumulates between the thin fins of the heat exchanger. At the beginning and at the end of the heating season, the sediment must be drained through the "mud trucks", their condition must be checked and the entire system must be flushed.

If the structure has a built-in expansion tank and a de-airing system, then it is better to remove the old tank. At the same time, they tightly shut off the old tap, before checking its condition. A dangerous situation can arise due to air leaks.

Connection diagram of a solid fuel and gas boiler in one system

A good option are combined wood-gas heating boilers or two boilers, one of which runs on solid fuel and the other on gas.

Any of these two options makes it possible to receive heat in the event that there is no firewood left in the firebox, and there is still gas in the cylinder. It is better to combine two different boilers because the network will work constantly, even if one of the devices breaks down. If the gas-wood device breaks down, the system stops working and the room will be cold.

Difficulties of using two boilers in one system

The main difficulty lies in the fact that gas boilers for a private house must operate in a closed system, and an open system is the safest for solid fuel devices. The open-type piping is in demand because the boiler can heat water to 110 ° C or more, raising the pressure above the permissible limits.

It can be lowered by lowering the combustion intensity. But the effect will be visible when the coals are completely burnt out. Even with low burning, they are very hot and continue to heat the water, raising the pressure.

In such a situation, you need to relieve pressure. An open-type expansion tank copes with this task. When its volume is not enough, water is discharged into the sewer through a pipe installed between the tank and the sewer. Such a tank allows air to enter the coolant. This is bad for the internal elements of a gas boiler, pipes and radiators of the heating system. Solutions to the problem:

- Combination of a closed and open heating system by using a heat accumulator.

- Organization of a closed system for a wood or pellet boiler using a special safety group. In this case, the two units are connected in parallel and operate both in pairs and separately.

Strapping with heat accumulator

The idea of using a heat accumulator lies in the following nuances:

- A gas boiler, receiving gas from a cylinder, and heating devices form one closed system. It includes a heat accumulator.

- Gas-generating boilers for wood, coal or pellets are also connected to a heat accumulator.But the water heated by them gives off heat to the heat accumulator, and then it is transferred to the coolant, which circulates through a closed system.

To make such a harness with your own hands, you need to have:

- Open expansion tank.

- The hose that will be located between the tank and the sewer.

- Shut-off valves (13 pcs).

- Circulation pump (2 pcs).

- Three-way valve.

- Filter for water purification.

- Steel or polypropylene pipes.

The circuit can operate in four modes:

- From a wood-burning boiler with the transfer of degrees through a heat accumulator.

- From the same boiler bypassing the heat accumulator (the gas device will be turned off).

- From a gas boiler that can receive gas from a cylinder.

- From both boilers.

Organization of an open system with a heat accumulator

- Do-it-yourself installation on two fittings of a wood-burning boiler of shut-off valves.

- Expansion tank connection. It must be placed so that it is above all the trim elements. The pressure under which a solid fuel boiler supplies water often exceeds the pressure under which the coolant is supplied from a gas boiler connected to a cylinder. To equalize these values, you need to correctly adjust the open expansion tank.

- Installation of taps on the pipes of the heat accumulator.

- Connection of the heat accumulator and the boiler with two pipes.

- Connection of two pipes to pipes located between the heat accumulator and the boiler. They are cut in near the taps, which are located near the battery fittings, or at a short distance from the valves. Cut-off valves are mounted on these tubes. Thanks to these pipes, it will be possible to use a solid fuel boiler bypassing the heat accumulator.

- Jumper insert. It connects the supply and return pipes located between the wood-burning boiler for the house and the heat accumulator. This jumper is attached to the supply line by welding or using fittings, and to the return line using a three-way valve. A small circle is formed along which the coolant will circulate until it heats up to 60 ° C. After that, the water will move in a large circle through the heat accumulator.

- Filter and pump connection. They are installed on the return line in the place between the three-way valve and the pipe of the boiler heat exchanger. To do this, a U-shaped tube is connected in parallel to the line, in the middle of which there is a pump with a filter. There should be taps before and after these elements. This solution allows you to make a bypass through which the coolant will move in the event of a power outage.

Closed system with heat storage

It is not necessary to connect a device similar to an expansion tank, because the gas boiler connected to the network or cylinder already contains a diaphragm expansion tank and also a safety valve.

To make this circuit correct, you need:

- Connect a tap and a pipe to the supply connection of the gas device that will fit the heating radiators.

- Place a circulation pump on this pipe in front of the heating devices.

- Connect heating devices with your own hands.

- Remove the pipe from them, which will go to the boiler. At its end, at a short distance from the gas unit, which is powered by a gas cylinder, a shut-off valve must be installed.

- Connect two pipes to the supply and return lines, which will fit the heat accumulator. The first one must be connected in front of the circulation pump, the second one - immediately after the radiators. Shut-off valves are installed on both pipes. Two pipes are connected to these pipes, which were cut into an open system before entering and after exiting the heat accumulator.

Closed system with two boilers

This scheme provides for the parallel connection of two boilers. Particular attention is paid to the safety group. Instead of an open expansion tank, a closed diaphragm tank is installed in a special room.

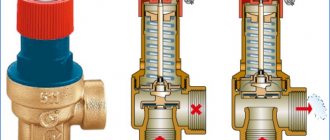

The security group consists of:

- Air bleed valve.

- Safety valve to reduce pressure.

- Pressure gauge.

The strapping is done according to the following scheme:

- Cut-off valves are installed at the outputs of the heat exchangers of both boilers.

- A security group is installed on the supply line, which departs from the solid fuel device. The distance between it and the valve can be small.

- Connect the supply pipes of both boilers. At the same time, before connecting to a line that departs from a solid fuel boiler for a house, a jumper is cut in (to organize a small circle). The tie-in point can be located at a distance of 1-2 m from the boiler. A reverse petal valve is placed at a short distance from the jumper. If the wood-burning boiler stops working, the coolant under the pressure created by the gas unit operating from the cylinder will not be able to move along the supply line towards the solid fuel device.

- The supply line is connected to heating radiators located in different rooms and at different distances from each other.

- The return line is mounted. It should be located between the radiators and boilers. In one place it is divided into two pipes. One of them will be suitable for a gas boiler. A return spring valve is placed on it in front of the unit. Another pipe must fit the solid fuel boiler. The aforementioned jumper is connected to it. A three-way valve is used for connection.

- Before branching the return line, it is worth installing a diaphragm tank and a circulation pump.

A similar scheme is used when universal double-circuit combined heating boilers with wood-gas are mounted. Such units can operate on gas from a cylinder. The piping does not use pipes that fit the gas boiler and check valves.

poluchi-teplo.ru

Connecting the boiler to the gas pipeline and water supply

Such a diagram for connecting a gas boiler is completely no different from a diagram for connecting equipment to a heating system, there is only the difference in the diameter of pipes and valves... Shut-off valves must have detachable connections. Hot water is connected on the right side, cold water on the left.

Much attention must be paid to the scheme for connecting the boiler to the gas pipeline. This is due to the fact that if the device is connected to the gas incorrectly, an explosion may occur.

There is a branch pipe in the center of the boiler and work begins with its connection to a branch of the gas pipeline with a valve installed. Protect the heater against small debris. A special valve is installed on the valve used to stop the gas supply. Then, using paint and tow, they begin to seal all threaded connections. The use of other means is strictly prohibited.

It is not recommended to turn on the device immediately after installation. All connections must be carefully checked to ensure that all steps are followed correctly.

Connecting a wall-mounted double-circuit model

First of all, the device is hung on the wall. To do this, markings are carried out on the surface and brackets are mounted, which will serve as a support. It is best to organize an additional air flow indoors, for which a window is required. Even if the model has a fan, this requirement should not be neglected.

Gas units have the same position of the nozzles for connecting to the heating system, so any model has similar actions. On the underside of the device there is a pipe (strictly in the middle), which is responsible for connecting to the gas pipeline. On the sides of it there are two water connections. At the edges there are places for connecting heating communications - on the right is a return pipe, on the left is hot water supply to radiators.

First, coarse water filters are installed on the return pipe so that no debris gets into the boiler from the system.This element is simply screwed onto the pipe, while the arrow should look towards the heat generator. Next, they connect to the heating circuit, for which it is necessary to mount shut-off valves on the return and supply pipes. These elements are necessary in order to make it possible to disconnect the device from the system so as to leave the pipes untouched. It will be best if you use "American" cranes, where there are detachable connections.

To connect the boiler to the water supply, almost identical steps are performed. Only here pipes and taps of other diameters are used. The pipe with cold water is supplied from the left side, and with hot liquid from the right. Hoses are also equipped with filters and American.

In order not to get confused, you can familiarize yourself with the following diagram:

As for the connection to the gas main, it is better to entrust this matter to professionals. Of course, at first glance it may seem that such work is not very difficult. But in fact, if a certain branch pipe is not tightened at least a little bit, then gas will start to start up, and this is already a consequence. If, nevertheless, it was decided to carry out everything independently, then you will need to perform the following steps:

- the gas nozzle is located in the center of the boiler, which has branches with installed taps - work begins with them;

- a special filter is put on the branch pipe - for this it is imperative to use tow and paint in order to ensure proper sealing of the joint (FUM tape or any sealing thread is prohibited);

- after the filter, it is convenient to use a flexible connection - a corrugated stainless steel hose (but not rubber material), which is connected by means of ordinary union nuts and paronite gaskets;

- every joint is now checked to avoid potential gas leaks.

It is best to entrust the launch of the equipment to professionals, because if something goes wrong, the specialists will immediately notice it and will be able to fix the problem on the spot.