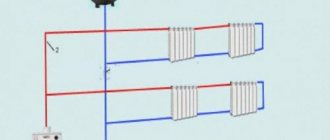

Gravity heating systems fully function only in one-story private houses with an area of up to 100 sq. m. If it is necessary to heat an apartment building or a spacious mansion, then you cannot do without a forced circulation system. The best solution is the selection of a circulation pump and installation of the unit in the heating circuit.

We propose to figure out what tasks the pump performs in the heating system, how the device works and works. We described the features of the operation of different types of pumps and outlined the main criteria for a competent choice. The information provided will help you choose the right circulation pump model and not be disappointed in the purchase.

Pump design and operation

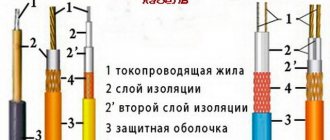

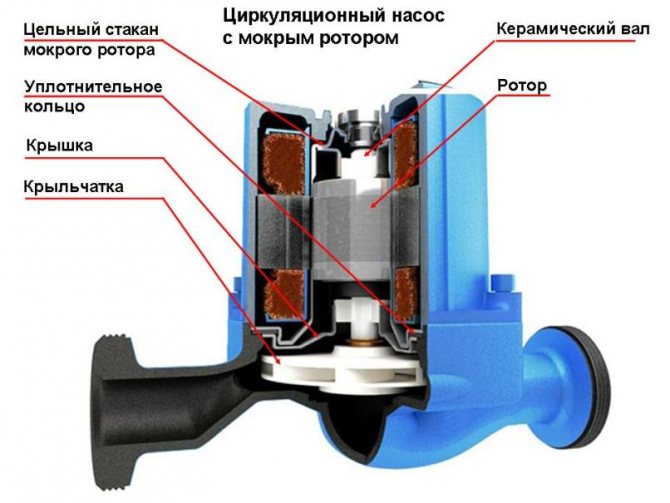

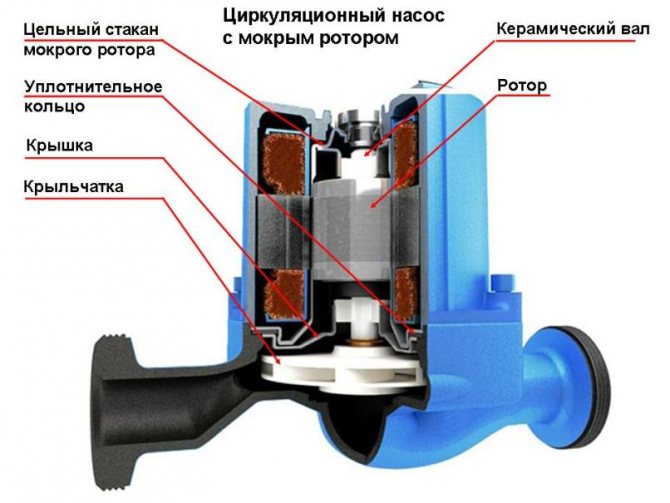

The design of the circulating pump resembles a drainage unit. The pump consists of a robust stainless steel / cast iron / aluminum housing and an electrical section that includes a stator winding with an integrated ceramic / steel rotor.

Installation of a pumping device for forced circulation significantly increases the efficiency of hot water supply and autonomous heating systems

The impeller is fixed on the shaft of the rotating part of the electric motor.

The impeller consists of two parallel discs connected by radially curved blades. On one of them there is a hole for the flow of the heat-transfer fluid, on the other there is a small hole for fixing the impeller on the shaft of the electric motor.

The body parts of the circulation pumps are made of steel and durable alloys. Under the walls of the casing, a hidden rotor with a fixed impeller

The electric motor itself is equipped with a special control board and terminals for connecting wires. For circulation pumps without electronics, a capacitor is installed instead of a board, and a speed switch is located on the terminal box.

When electricity is supplied, a wheel with blades rotates, creating a vacuum in the pipe and pumping the coolant. The rotor creates a movement of the working fluid in the direction from the inlet to the outlet valve.

The pump constantly draws water from one side and pushes it into the heating system on the other. Centrifugal force facilitates the transport of fluid along the entire line.

The created head overcomes the resistance in different parts of the circuit and ensures the circulation of the coolant.

Judging by the intensity of sales, the most popular in the domestic market are devices from the following manufacturers:

Image gallery

Photo from

Circulation device from Grundfos

Line of equipment with the Wilo logo

Heating devices from DAB

Circulation pump of the Jileks company

When choosing a circulation unit, first of all, you should pay attention to the following factors:

• required pump performance; • what pressure of water is required for the successful functioning of the heating or water supply system; • the selected pump unit must have a minimum energy consumption; • the pump should be very easy to maintain; • the guarantee of uninterrupted operation established by the manufacturer must have a sufficiently long period. By adhering to these selection criteria, you are guaranteed to choose the circulation pump you need. And for greater persuasiveness in choosing an aggregate of this type, the video will be on the page:

Thus, in this article, we talked about all types of circulation pumps, as well as how to choose the right one.

Types and advantages of circulation pumps

According to their design features, pumps for forced circulation are divided into pumping units with a wet rotor and high-performance devices with a dry rotor.

Image gallery

Photo from

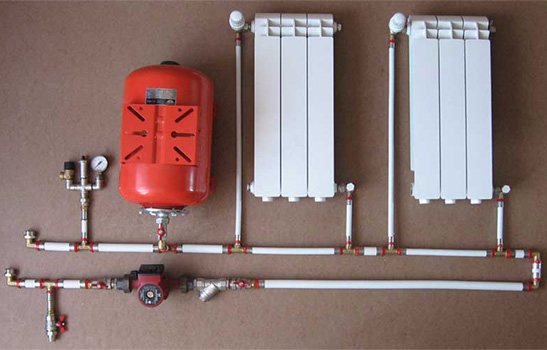

Closed heating system assembly option

Vacuum expansion tank - expansomat

Devices for air extraction

Overpressure relief valve

Wet pumps... The rotor and impeller of such pumps are in direct contact with the working fluid, which simultaneously performs two important functions: the role of lubrication and cooling of the device. The rotor and stator in such pumps are separated by a special vessel responsible for the tightness of the elements of the electric motor under voltage.

Wet circulation pumps are equipped with a step speed regulator. This allows you to choose the optimal operating mode, and therefore control the power consumption.

The rotor of the electric motor and the impeller in the pumps are in the pumped water, which moistens the supporting elements and constantly cools the motor (+)

Glandless rotor units are modular in design. Individual modules are selected depending on the required head and capacity. The prefabricated design greatly simplifies pump repair, since a failed module can be easily and quickly replaced with a new one.

Circulation pumps of this type are used in small heating systems. They function almost silently, and therefore are excellent for installation in residential premises.

The electric motor of pumps with a wet rotor does not need additional cooling, as it is constantly in contact with water. The pump contains a small number of working parts, which minimizes the need for frequent maintenance.

The main advantages of using "wet" type pumps:

- low level of generated noise;

- small overall dimensions and low weight;

- minimal electricity consumption;

- easy parameter setting, maintenance and repair;

- long service life.

Wet rotor units also have disadvantages. They are very sensitive to the quality of the working fluid. The presence of finely dispersed abrasive particles in the water leads to accelerated wear of the hydraulic part of the pump.

Image gallery

Photo from

Location of circulation pumps in the heating circuit

Installing the device on the supply pipe

Placement relative to the expansion tank

Mandatory use of a security group

In addition, the efficiency of such circulation pumps does not exceed 55%. However, this indicator is quite enough for pipelines of short length, and therefore pumps that are in direct contact with water are often used in individual heat supply systems.

For trouble-free operation of the "wet" type units, it is necessary that the pump is installed correctly. The main requirement is a strictly horizontal spatial orientation of the shaft. Only with this configuration is it possible to provide full lubrication of the bearings with liquid.

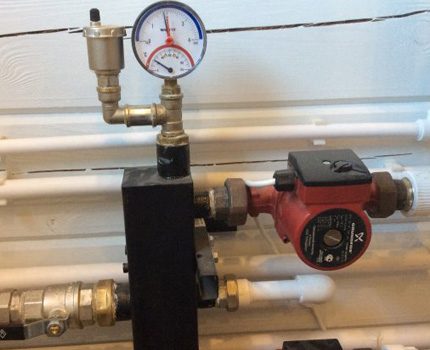

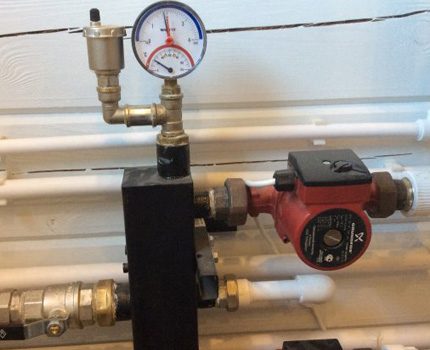

Competent installation of the circulation pump is the key to stable operation of the heating system throughout the entire period of operation

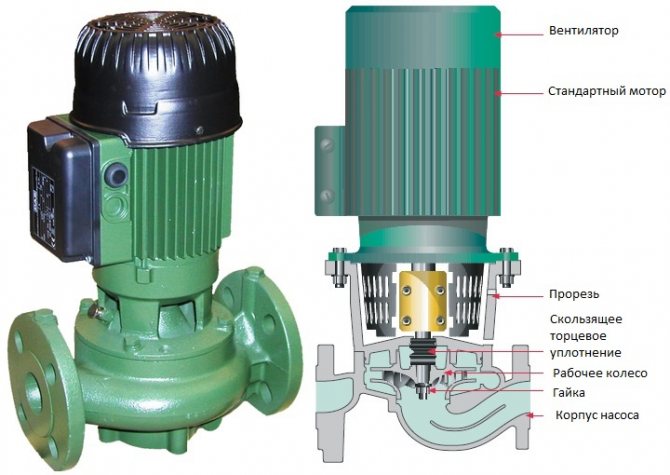

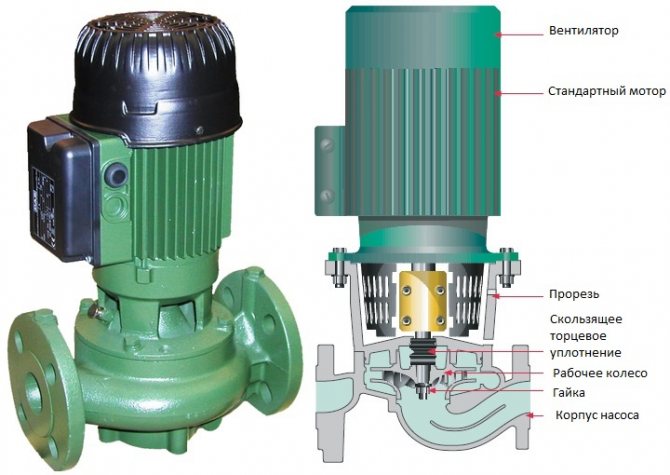

Dry rotor pumps are successfully used for pumping large volumes of coolant in large installations. The rotor assembly of such devices does not come into contact with water.

The body part of dry-type circulation pumps is made of durable cast iron or galvanized steel.The surface is coated with special protective compounds to prevent corrosive phenomena.

Dry rotor units are suitable for collective use in multi-storey residential buildings, entertainment centers and offices, and industrial facilities.

The design of the "dry" type pumps provides increased power. Such pump models are capable of creating high pressure in heating circuits (+)

There is a special sliding seal (2 protective rings) between the electric motor and the pumping part of the pump, which isolates the basic functional elements from liquid ingress.

These rings are highly polished and in close contact with each other. One of them (dynamic) is mounted on a rotating shaft. The static wheel is firmly fixed in the pump body.

A thin water film reliably seals the joint of the protective rings due to the differences in pressure in the circuit and the external environment.

For the manufacture of O-rings, coal obtained by the oil agglomeration method is used. Some pump versions for extreme applications have metal / ceramic backing rings.

The efficiency of devices with a dry rotor reaches 85%. This is an excellent performance compared to wet pumps. However, "dry" units make a lot of noise due to the cooling fan, and therefore they are installed in separate rooms with good sound insulation.

Circulating pumps of "dry" type are of 3 types:

- monoblock;

- console;

- "In-line".

Monoblock pumps belong to the category of low-pressure units. The electric motor and pump in such devices are mounted in one unit. They are easy to operate and maintain. Suitable for use in public utilities and apartment buildings.

Cantilever pumping devices are assembled on a single basis, with the pump and motor axes on the same line. The suction pipe is located on the outer part of the volute, the discharge pipe is located on the opposite side of the casing.

If cantilever units are installed in manufacturing plants, as well as in urban water supply systems, then In-line pumps are installed directly on the pipeline

In-line pumps mounted directly on the pipeline. The suction inlet and pressure outlet are located on the same line, and an automatic mechanism for compensating the depletion of O-rings is provided.

Advantages of using dry rotor circulation pumps:

- high performance;

- energy efficiency;

- low requirements for the quality of the energy carrier - the pumped liquid may contain neutral impurities;

- simple repair and replacement of spare parts.

In addition, today, manufacturers of heating equipment offer potential buyers double pump models. Such devices are used for power redundancy and additional safety net in emergency situations.

Twin pump motors can be operated together or separately. In the event of a breakdown of one pump, the second device continues to work normally, ensuring the smooth functioning of the boiler.

Reliable and trouble-free operation of the heat supply system will be ensured by twin circulation pumps, in which two impellers are connected in parallel

With proper operation, the service life of the circulation pump is at least 10 years.

How to choose the right pumping equipment?

The efficiency of the pump depends on the basic parameters - performance and pressure. The capacity shows the amount of heat transfer fluid that the unit must pump over per unit of time.This parameter is determined from the conditions of maximum workload.

Head is a quantity that expresses the energy of a fluid flow used as a heat carrier. Takes into account the hydraulic resistance of the entire system.

Image gallery

Photo from

Heating with five circulation pumps

Selection of equipment along the length of the pipeline

The relationship between the power of radiators and the pump

Selection of the pump according to the boiler power

You should also pay attention to the maximum temperature. Since the pump will pump heated water, it must withstand indicators up to 110 ° C.

It is very important to select a suitable circulating pump capacity. A low-power device will not cope with pumping the coolant fluid in the required volume. Pump parameters are selected based on the calculations performed.

If you install a more powerful unit, an unpleasant noise will appear in the pipeline. Also, in this case, the functional elements of the boiler equipment will wear out much faster than stated by the manufacturer.

The power of the circulation pump must be sufficient to cope with the hydraulic resistance in a closed circuit

Experts recommend choosing a circulation pump even at the design stage of a heat supply system. If the piping length does not exceed 80 m, it is sufficient to install one pump. With a greater length, it is advisable to mount several pumping devices at once.

When buying, you should pay attention to the materials from which the functional elements of the pump are made. Most parts directly / indirectly come into contact with a heated working fluid, and therefore are subject to rapid wear.

Therefore, it is advisable to give preference to circulation pumps with ceramic bearings and a rotor assembly.

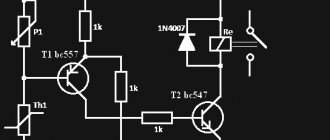

Electronics plays an important role. In order to regulate the temperature indicators inside the premises, thermostatic valves are installed in the heating circuits. As the temperature rises, they overlap, the pressure increases in the pipes.

As a result of these processes, an unpleasant noise appears. To get rid of it, it is necessary to turn the circulation pump to a lower speed, and it is inconvenient to do it manually.

Pumps with built-in electronics will help you to quickly and efficiently cope with this task. Such units smoothly regulate the pressure drops in the pipeline depending on the change in the amount of liquid.

The main advantages of modern pumps are efficiency and durability, compact overall dimensions, low noise level, automatic operation, convenient control panel

It is worth noting the additional functionality of the pumps, namely:

- smooth adjustment;

- speed control;

- automatic mode of operation;

- built-in informative display.

The simplest models of circulating pumps are without the ability to regulate the rate of fluid transport. Modern multifunctional pumps are two / three-speed units with infinitely variable control. They are distinguished by high precision of settings.

Equipment operating in automatic mode is equipped with a control panel. The settings of such devices are extensive and depend only on the modification of the devices.

This can be automatic speed control depending on changes in the temperature indicators of the air inside the room, an electronic off / on timer, automatic start of the pump at a minimum flow rate.

The presence of a digital display makes it possible to receive all the necessary information about the operation of the pumping device: the temperature of the heating fluid, resistance in a closed loop, performance, errors, etc.

What structural elements it consists of.

To understand how a circulation pump works, first of all, you need to know how a unit of this type works.As a rule, pumping mechanisms of circulation type consist of the following structural elements: • the body of the unit, which can be made of such metals as cast iron, steel, brass, aluminum or bronze; • a rotor built into the pump casing, which can be either metal or ceramic; • impeller or impeller, which is fixed on the rotor shaft; • an electric motor that drives, in fact, the pumping mechanism. It is also important that, depending on the pump model, its electric motor can be either single-phase or three-phase.